Agricultural Food Grade Rubber Conveyor Belt Market

The agricultural food grade rubber conveyor belt market is facing a critical surge in demand, pushing manufacturers to rapidly scale production and innovate to meet evolving safety and efficiency standards.

This market is experiencing unprecedented growth driven by increased global food production, stringent regulations, and a heightened focus on minimizing contamination risks in food processing.

Market Overview: Demand Exceeds Supply

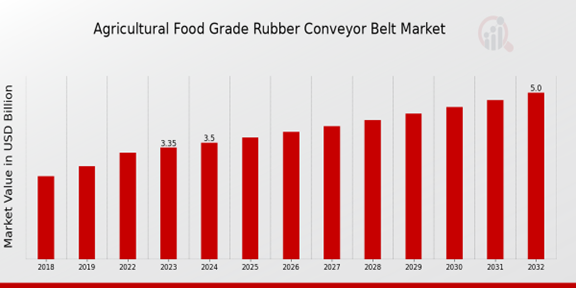

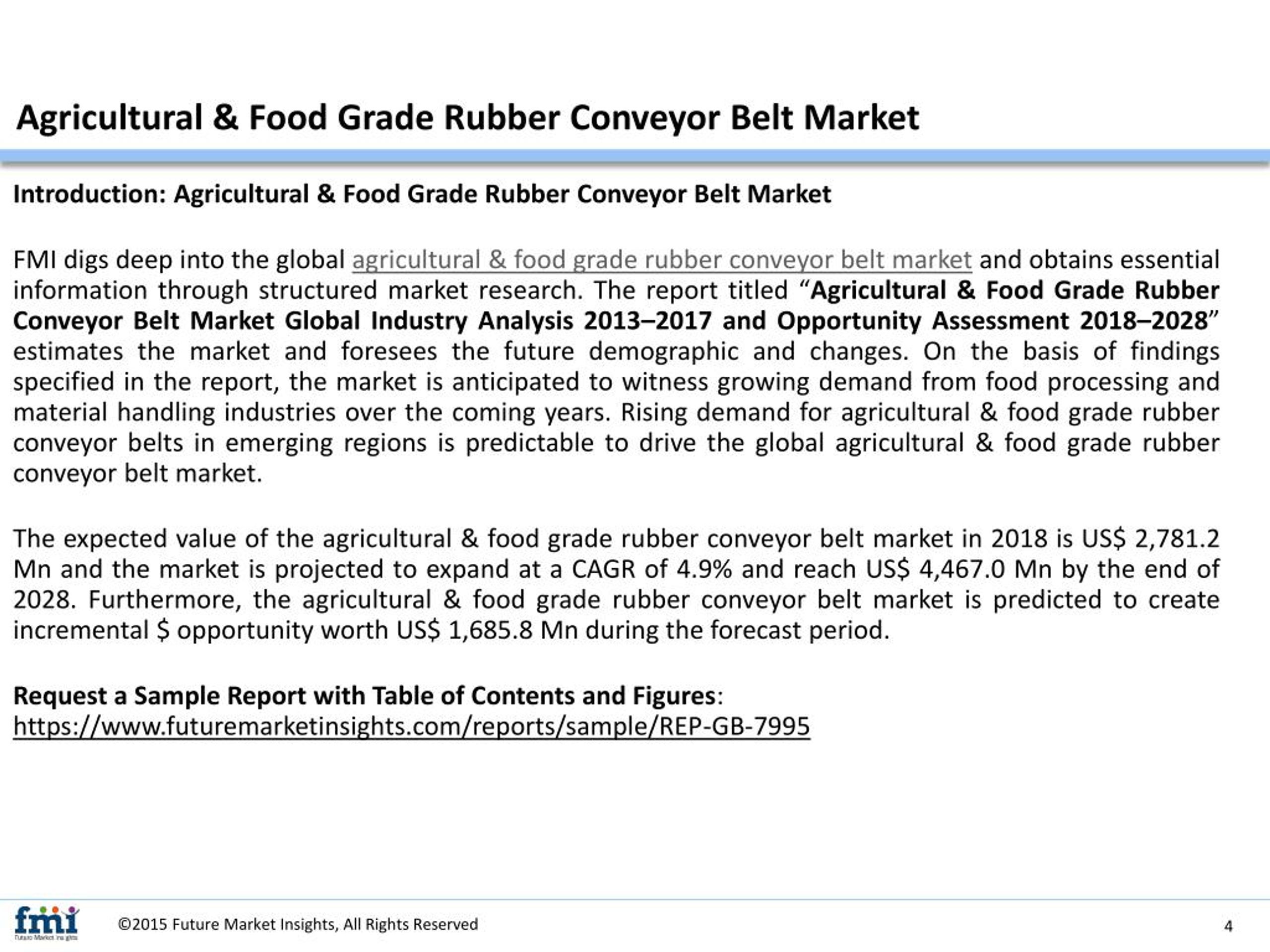

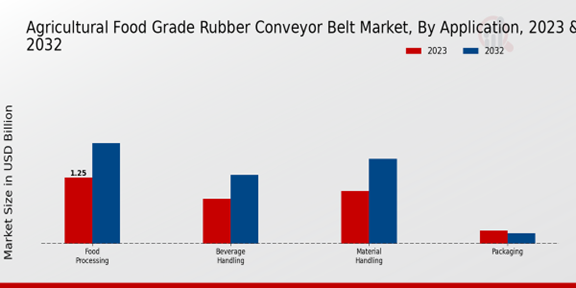

The agricultural food grade rubber conveyor belt market is currently valued at approximately $2.5 billion globally and is projected to reach $3.8 billion by 2028, exhibiting a compound annual growth rate (CAGR) of over 7%, according to a recent report by Market Insights Global.

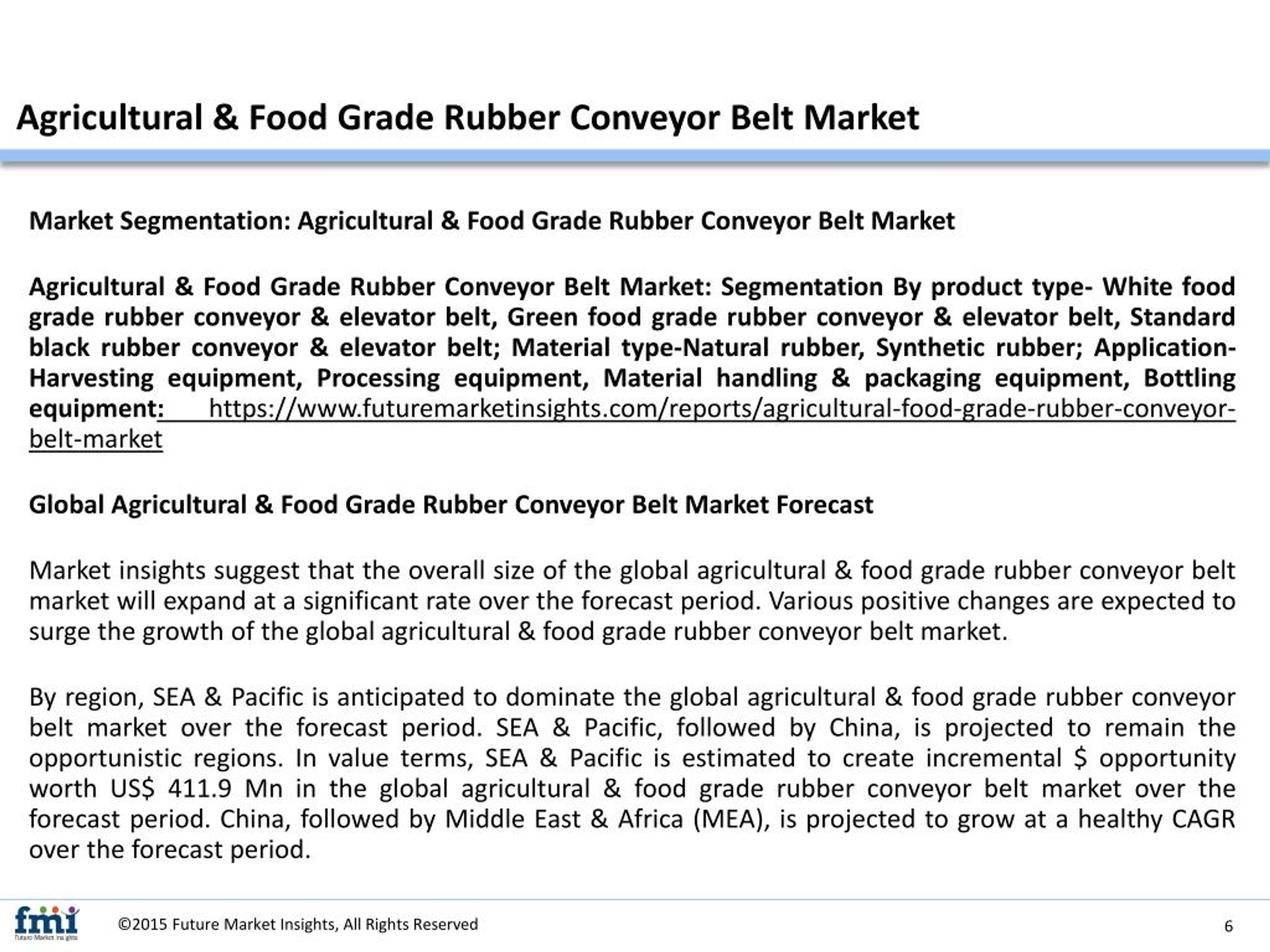

North America and Europe currently hold the largest market share, but Asia-Pacific is expected to be the fastest-growing region due to expanding agricultural activities and increasing investments in food processing infrastructure.

Key Market Drivers

The primary driver behind this surge is the escalating global demand for food. Increased populations and evolving dietary habits are placing immense pressure on agricultural production and processing capabilities.

Stringent food safety regulations, such as the Food Safety Modernization Act (FSMA) in the United States and similar regulations in Europe, are compelling food processors to adopt food grade conveyor belts that minimize the risk of contamination.

The increasing adoption of automation in agriculture and food processing further fuels the demand for high-quality, durable, and reliable conveyor belt systems.

Competitive Landscape

The market is characterized by a mix of established multinational corporations and regional players. Key players include Habasit, Ammeraal Beltech, Intralox, and Continental AG, among others.

These companies are focusing on developing innovative conveyor belt solutions that offer improved hygiene, durability, and efficiency. This includes belts with antimicrobial properties and advanced materials that resist wear and tear.

Mergers and acquisitions are also becoming more prevalent as companies seek to expand their market reach and product portfolios.

Material and Product Innovations

The dominant material used in agricultural food grade conveyor belts is nitrile rubber (NBR), known for its excellent oil resistance and durability. Silicone rubber is also gaining traction due to its high temperature resistance and inertness.

Recent innovations include the development of antimicrobial conveyor belts that inhibit the growth of bacteria and other microorganisms. This helps to further reduce the risk of contamination in food processing environments.

Manufacturers are also focusing on developing energy-efficient conveyor belts that reduce energy consumption and operating costs. Lightweight materials and optimized belt designs are key components of these innovations.

Challenges and Opportunities

The market faces several challenges, including fluctuating raw material prices and increasing competition. Supply chain disruptions, exacerbated by recent global events, have also impacted the availability of raw materials and finished products.

Despite these challenges, significant opportunities exist for companies that can offer innovative and cost-effective conveyor belt solutions. The growing demand for processed foods and the increasing adoption of automation in agriculture are expected to drive market growth in the coming years.

Companies are also focusing on developing sustainable conveyor belt solutions that minimize environmental impact. This includes using recycled materials and developing biodegradable conveyor belts.

Regional Analysis

North America is a major market for agricultural food grade conveyor belts, driven by its large agricultural sector and stringent food safety regulations. The United States is the largest market in the region, followed by Canada.

Europe is another key market, with Germany, France, and the United Kingdom being the largest consumers of food grade conveyor belts. The region's strong focus on food safety and sustainability is driving demand for innovative conveyor belt solutions.

Asia-Pacific is the fastest-growing region, with China and India being the largest markets. The region's expanding agricultural sector and increasing investments in food processing infrastructure are fueling market growth.

Impact of Regulations

Compliance with food safety regulations is a critical factor in the agricultural food grade conveyor belt market. Regulations such as the FSMA in the United States and the European Food Safety Authority (EFSA) guidelines in Europe are driving demand for food grade conveyor belts that meet strict hygiene standards.

These regulations require food processors to implement Hazard Analysis and Critical Control Points (HACCP) systems to identify and control potential food safety hazards. The use of food grade conveyor belts is a key component of these systems.

Manufacturers are increasingly focusing on developing conveyor belts that are easy to clean and sanitize, reducing the risk of contamination.

Conclusion: Urgent Action Required

The agricultural food grade rubber conveyor belt market is experiencing rapid growth and faces immediate pressure to meet escalating demand. Manufacturers must prioritize innovation, optimize production processes, and navigate supply chain challenges to capitalize on this expanding market.

Ongoing monitoring of regulatory changes and technological advancements is crucial for maintaining a competitive edge. Businesses must adapt quickly to ensure food safety and operational efficiency.