An Efficient Supply Chain Should Be Preferred When

Global supply chains are under unprecedented pressure, forcing businesses to re-evaluate their strategies. Efficiency is no longer just a cost-saving measure; it's a critical survival tool.

This article examines the specific scenarios where prioritizing an efficient supply chain is not just beneficial, but absolutely essential for business continuity and competitive advantage in today's volatile market.

Demand Surges and Volatility

When demand spikes unexpectedly, an efficient supply chain is the only way to capitalize on the opportunity. A responsive system ensures products reach consumers quickly, preventing stockouts and maximizing revenue.

According to a recent report by McKinsey, companies with agile supply chains see a 10% increase in market share during periods of high demand.

Without efficiency, companies risk losing customers to competitors who can deliver.

Highly Perishable Goods

For industries dealing with perishable goods, such as food and pharmaceuticals, efficiency is paramount. Delays can lead to spoilage, rendering products unusable and causing significant financial losses.

The cold chain, in particular, requires meticulous planning and execution to maintain temperature integrity throughout the supply chain.

Inefficiencies can compromise product quality and safety, leading to potential health risks and reputational damage.

Just-in-Time (JIT) Manufacturing

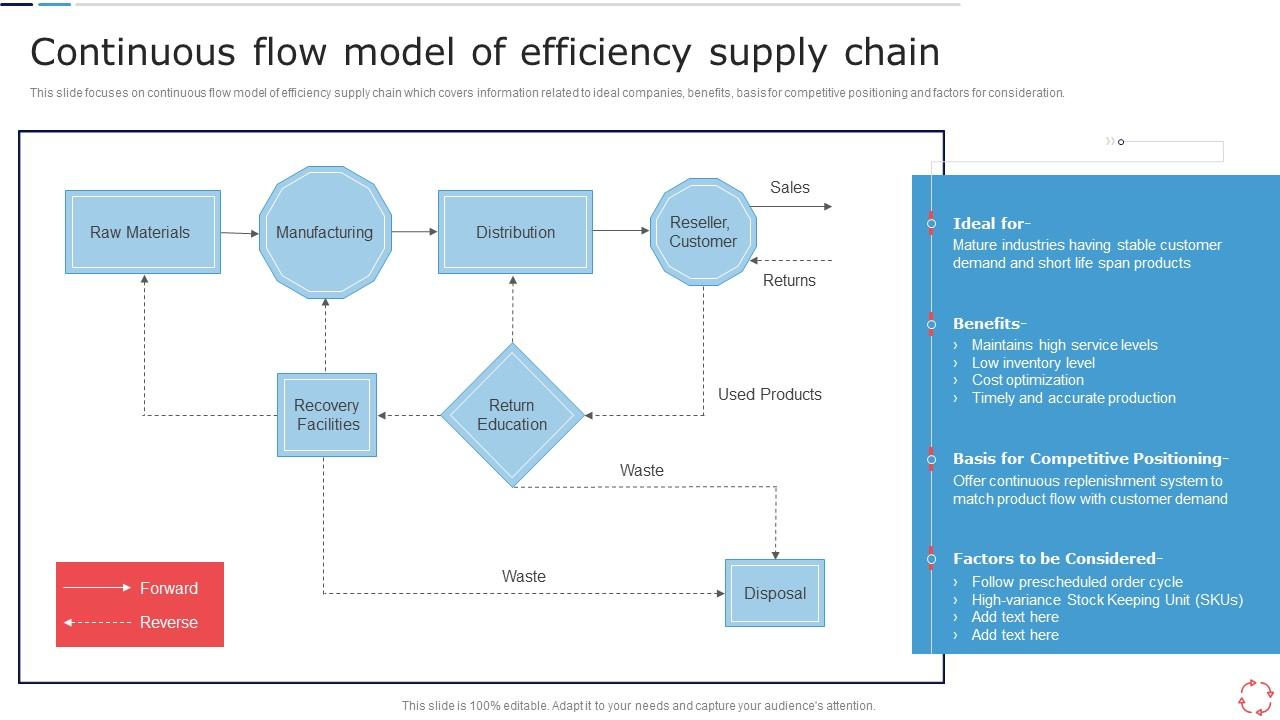

Companies employing Just-in-Time (JIT) manufacturing rely heavily on efficient supply chains. This lean production strategy minimizes inventory holding costs by receiving materials only when needed.

Any disruption or delay in the supply chain can halt production lines, leading to costly downtime and missed deadlines.

JIT requires seamless coordination and real-time visibility to ensure a continuous flow of materials.

Competitive Markets with Price Sensitivity

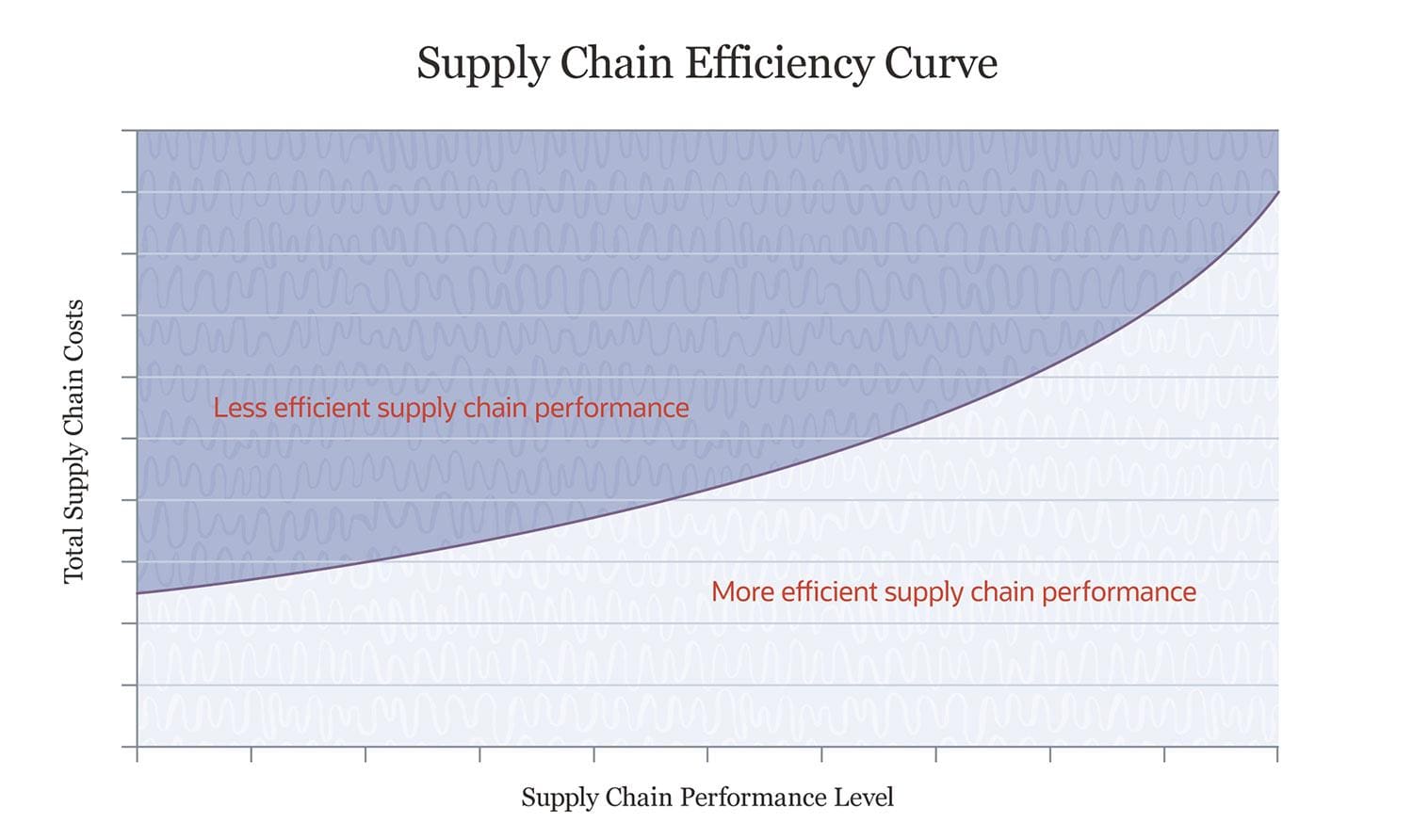

In highly competitive markets, even small price advantages can significantly impact sales. An efficient supply chain reduces costs across the board, allowing companies to offer competitive pricing.

Streamlined logistics, optimized inventory management, and reduced waste contribute to lower overall costs, boosting profitability.

Businesses operating in this environment need to constantly look to improve efficiency to stay ahead of their competitors.

Geopolitical Instability and Supply Chain Disruptions

Recent geopolitical events have highlighted the importance of resilient and efficient supply chains. Trade wars, political unrest, and natural disasters can disrupt supply routes, leading to shortages and price increases.

Companies need to diversify their sourcing, build redundancy into their supply chains, and invest in risk management strategies to mitigate the impact of disruptions.

Efficiency in adapting to new suppliers and routes is key to ensuring business continuity during these times.

E-commerce and Last-Mile Delivery

The rise of e-commerce has placed immense pressure on last-mile delivery. Customers expect fast, reliable, and affordable delivery options.

An efficient last-mile delivery network is crucial for meeting these expectations and maintaining customer satisfaction. Route optimization, efficient warehousing, and real-time tracking are essential components.

According to Statista, same-day delivery is expected to grow by 25% annually over the next five years, further emphasizing the need for efficient logistics.

Customized or Made-to-Order Products

When offering customized or made-to-order products, an efficient supply chain is essential for meeting specific customer requirements and delivering on time. Accurate demand forecasting, flexible manufacturing processes, and efficient logistics are crucial.

Delays or errors in the supply chain can lead to dissatisfied customers and damage the company's reputation. For example, Tesla's manufacturing processes have frequently been under scrutiny for these aspects.

Efficiency can become a competitive advantage in attracting and retaining customers in markets with a high demand for customization.

Conclusion and Next Steps

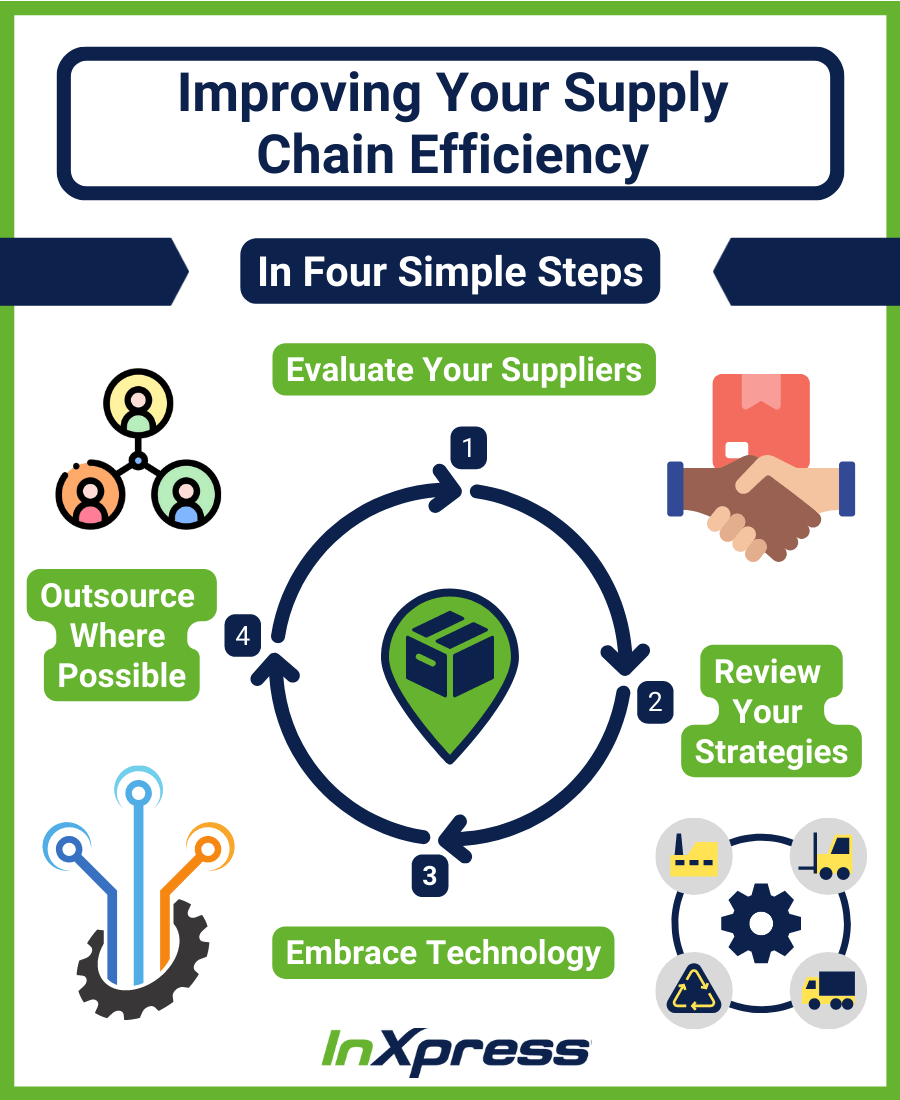

Prioritizing supply chain efficiency is no longer optional, but a necessity for survival and success in today's dynamic and unpredictable business environment. Companies must continuously assess their supply chains and identify areas for improvement.

Investment in technology, collaboration with suppliers, and a focus on data-driven decision-making are crucial steps toward building a more efficient and resilient supply chain.

Ongoing monitoring and adaptation will be required to navigate future challenges and maintain a competitive edge. The World Economic Forum is organizing a summit in Q4 to discuss strategies for developing resilient supply chains.