Bioethanol Yeast And Enzyme Strains For Sscf Commericially Availible

Imagine a field of golden corn, not just feeding us, but powering our cars, reducing our carbon footprint, and revitalizing rural economies. This vision, once a distant dream, is edging closer to reality, thanks to groundbreaking advancements in bioethanol production.

At the heart of this revolution lies the development and commercial availability of highly efficient bioethanol yeast and enzyme strains specifically designed for Simultaneous Saccharification and Co-fermentation (SSCF). These advancements promise to significantly lower the cost of bioethanol production, making it a more competitive and sustainable alternative to fossil fuels.

The Promise of Bioethanol: A Sustainable Fuel Source

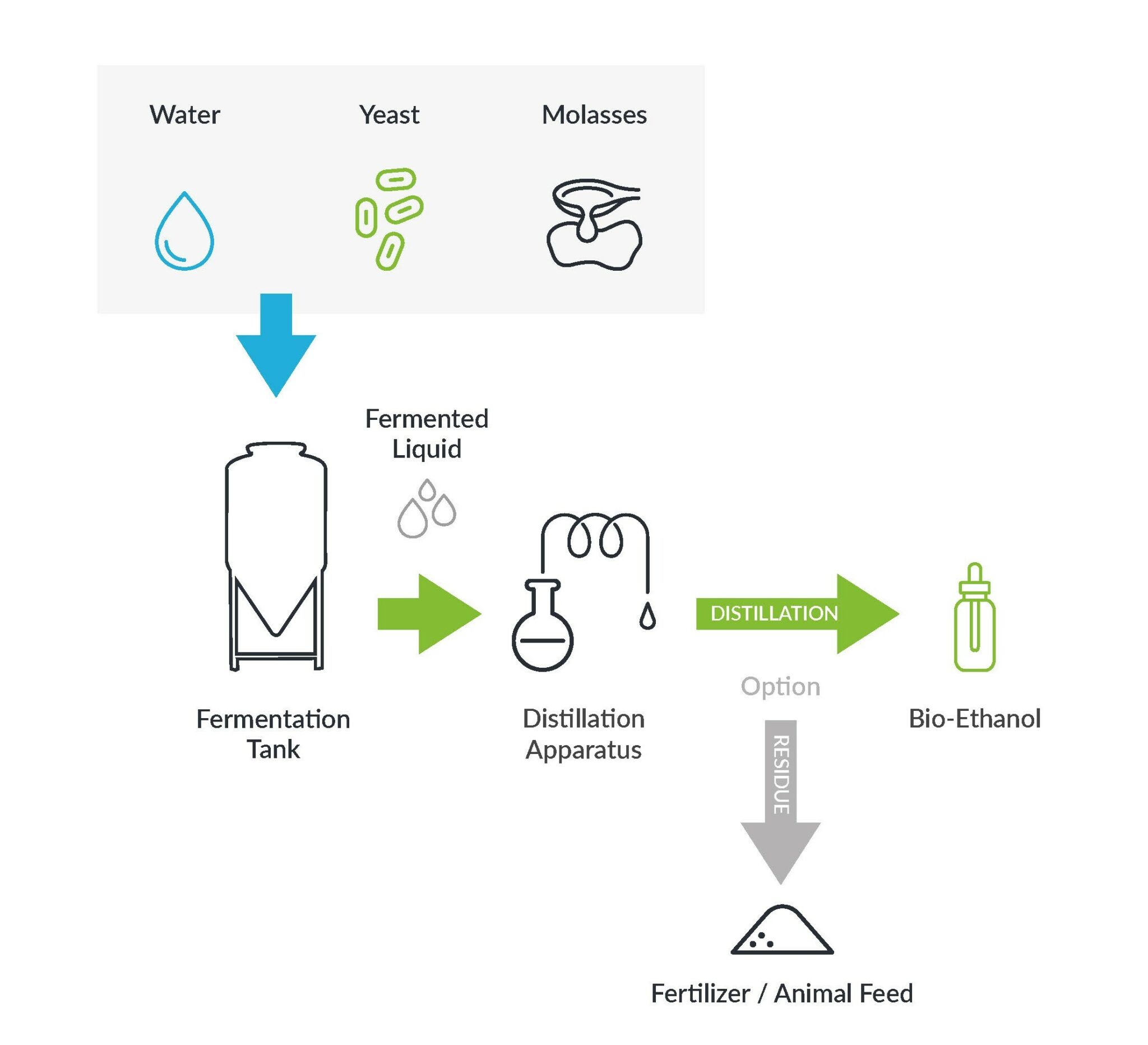

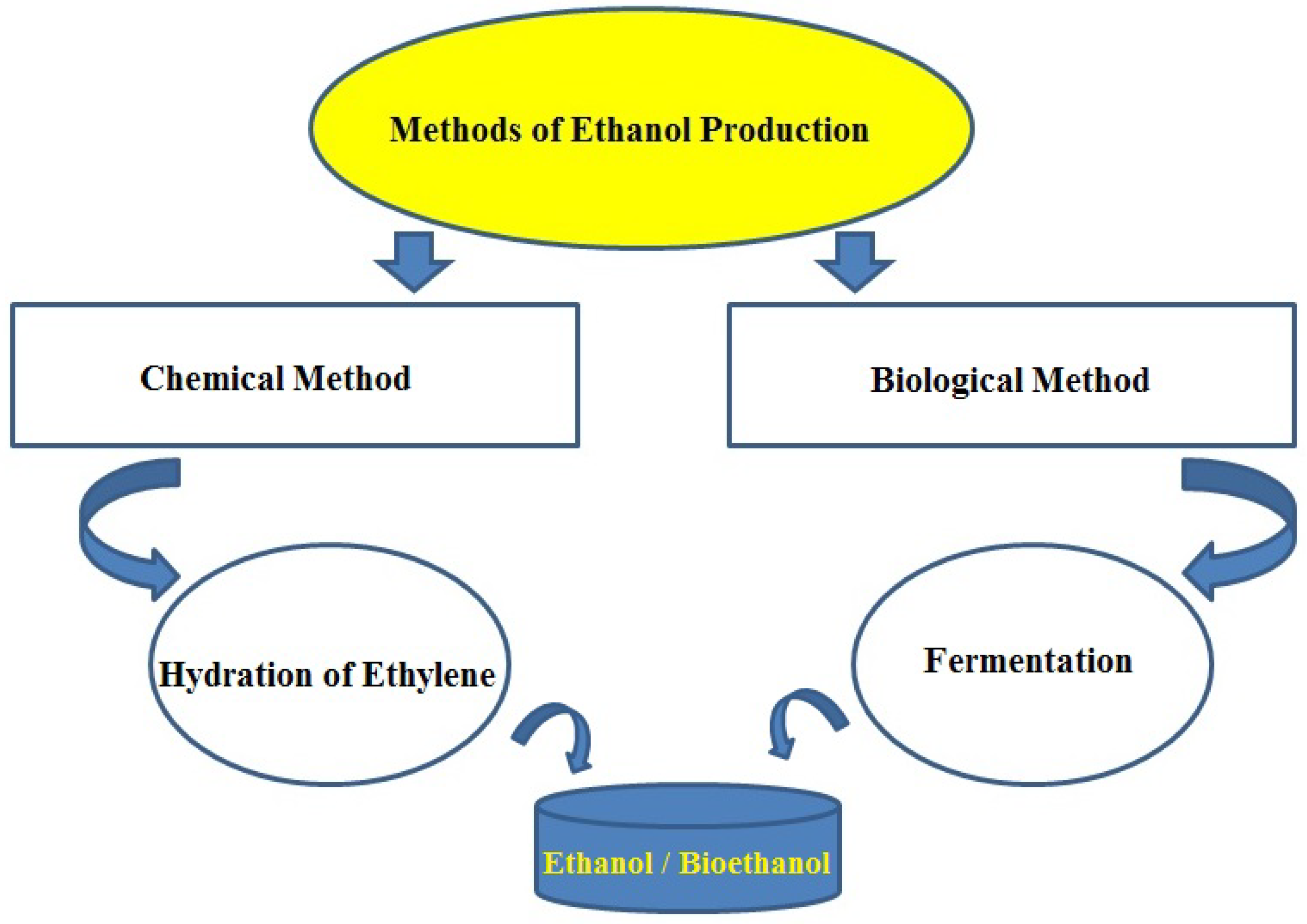

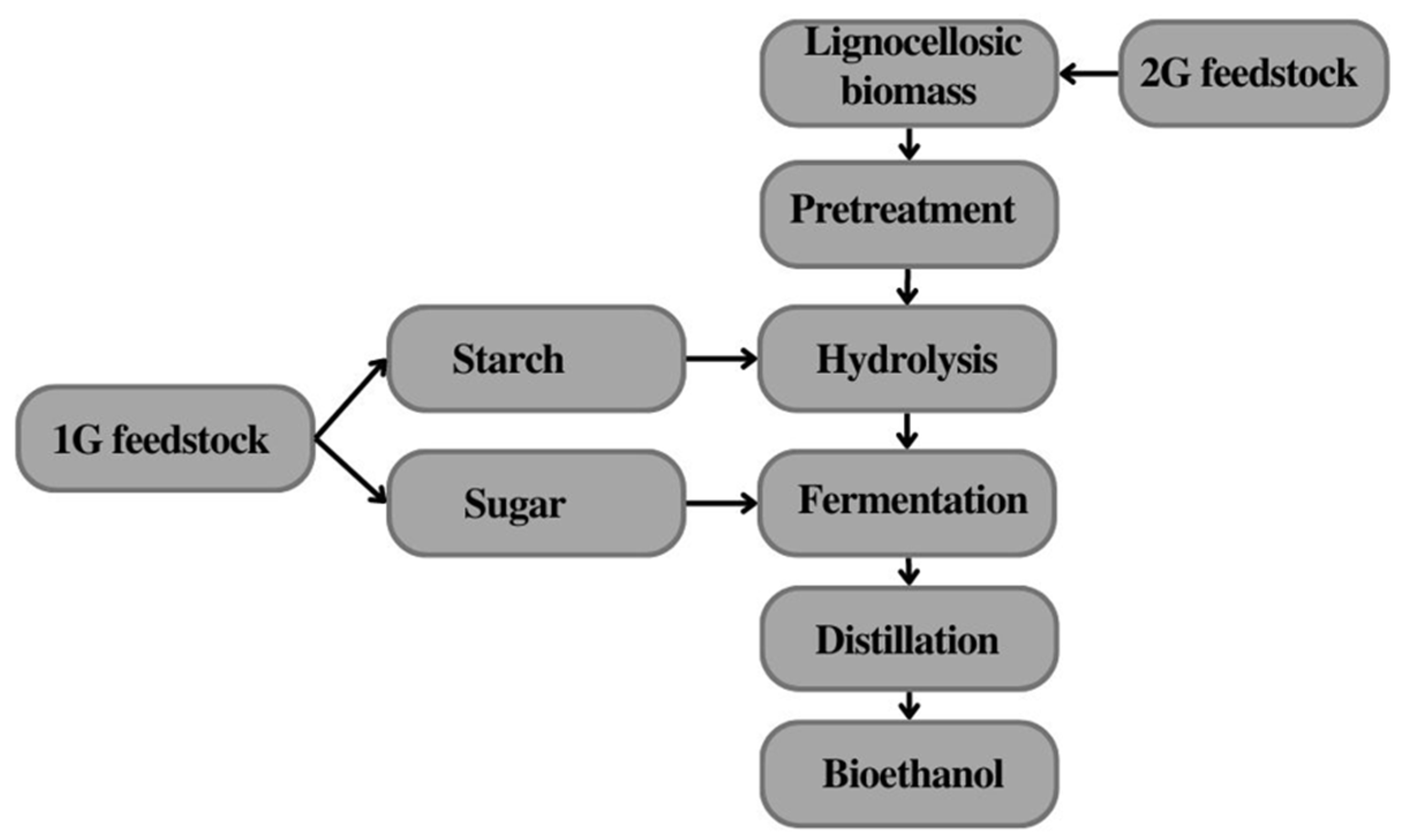

Bioethanol, an alcohol produced by fermenting sugars derived from plant biomass, has long been touted as a promising alternative to gasoline. Its allure stems from its potential to reduce greenhouse gas emissions, decrease reliance on foreign oil, and boost agricultural economies.

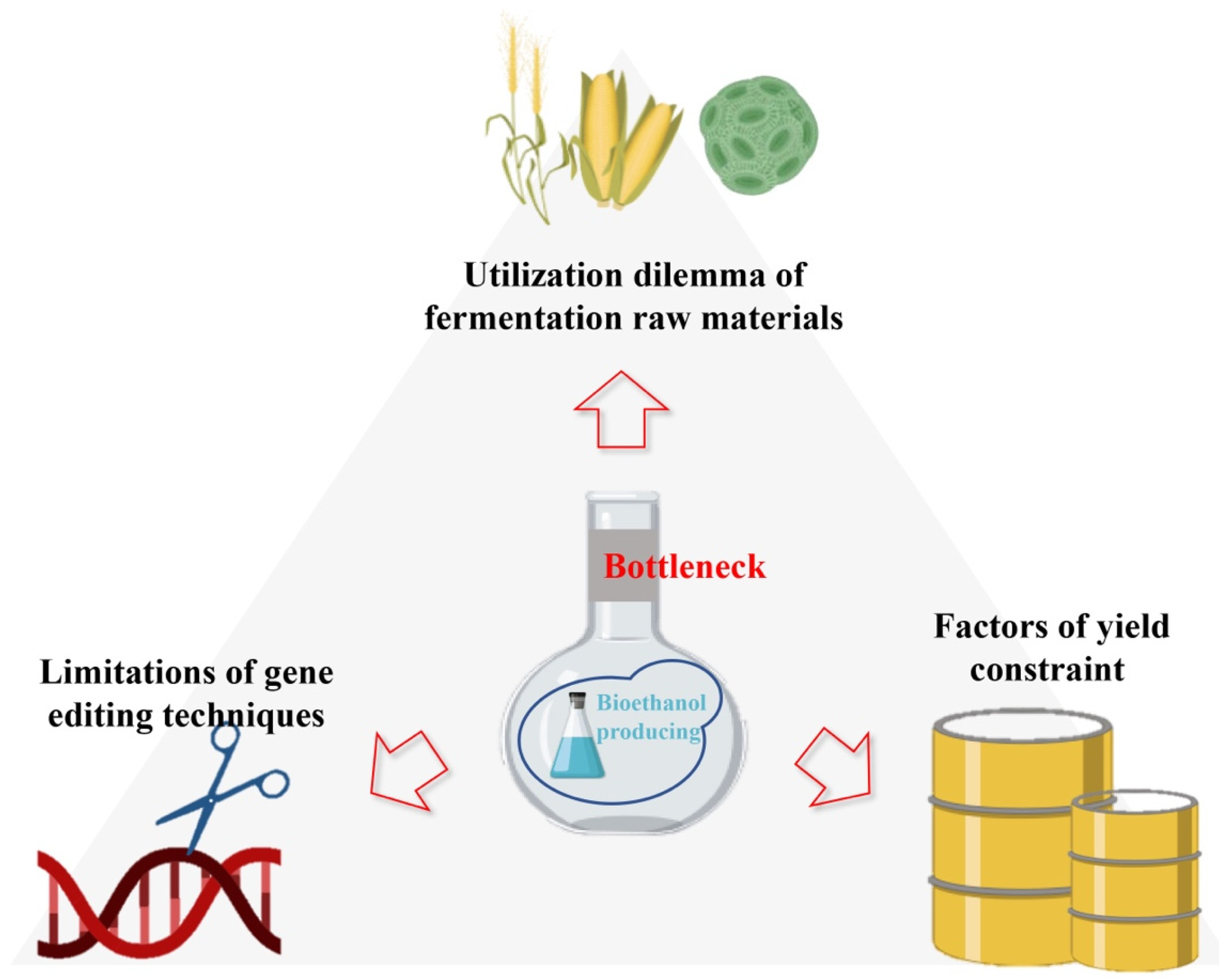

Traditional methods of bioethanol production, however, have faced significant challenges, including high production costs and the need for energy-intensive processes. One of the most promising methods is SSCF.

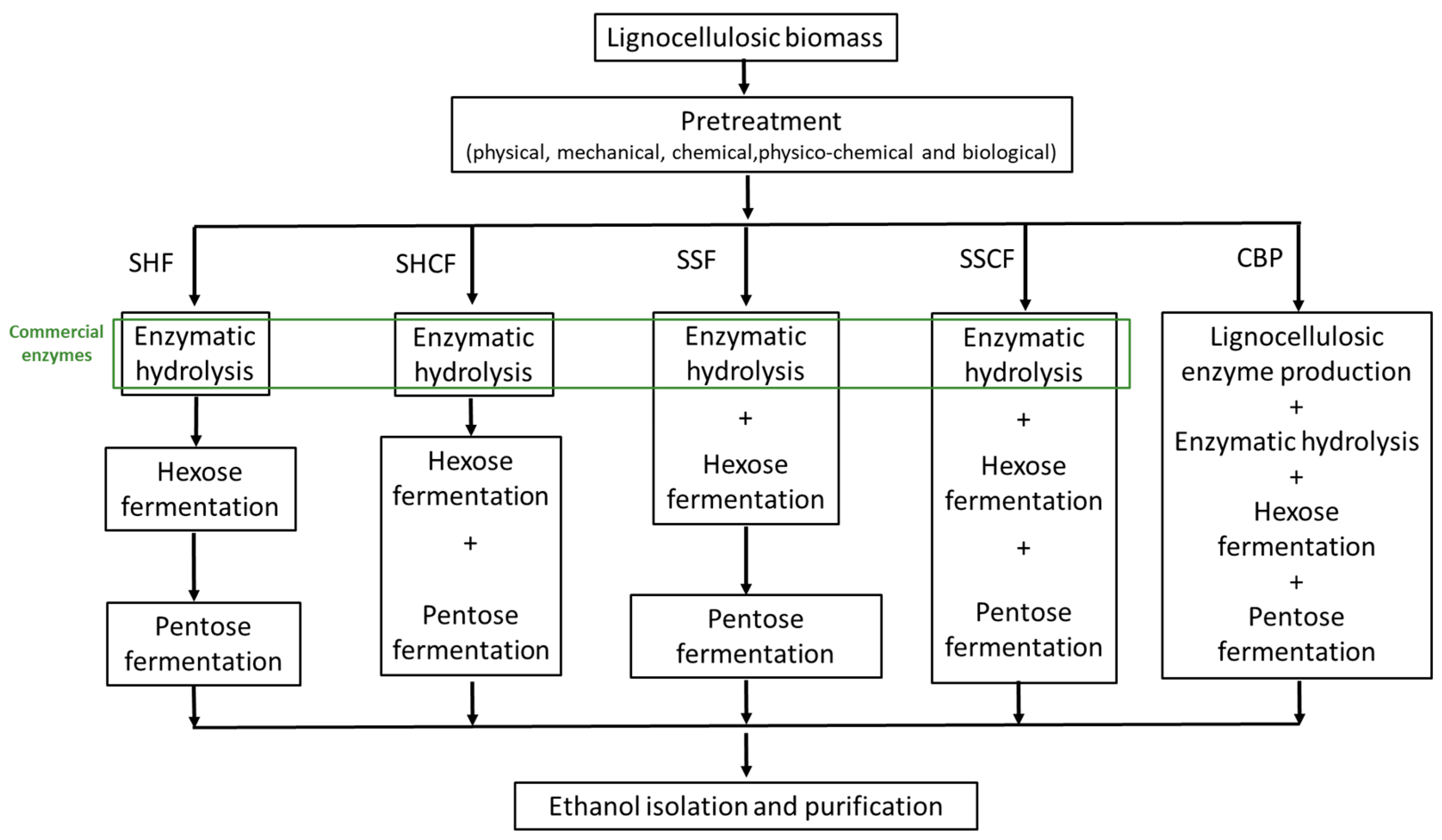

Simultaneous Saccharification and Co-fermentation (SSCF): Streamlining the Process

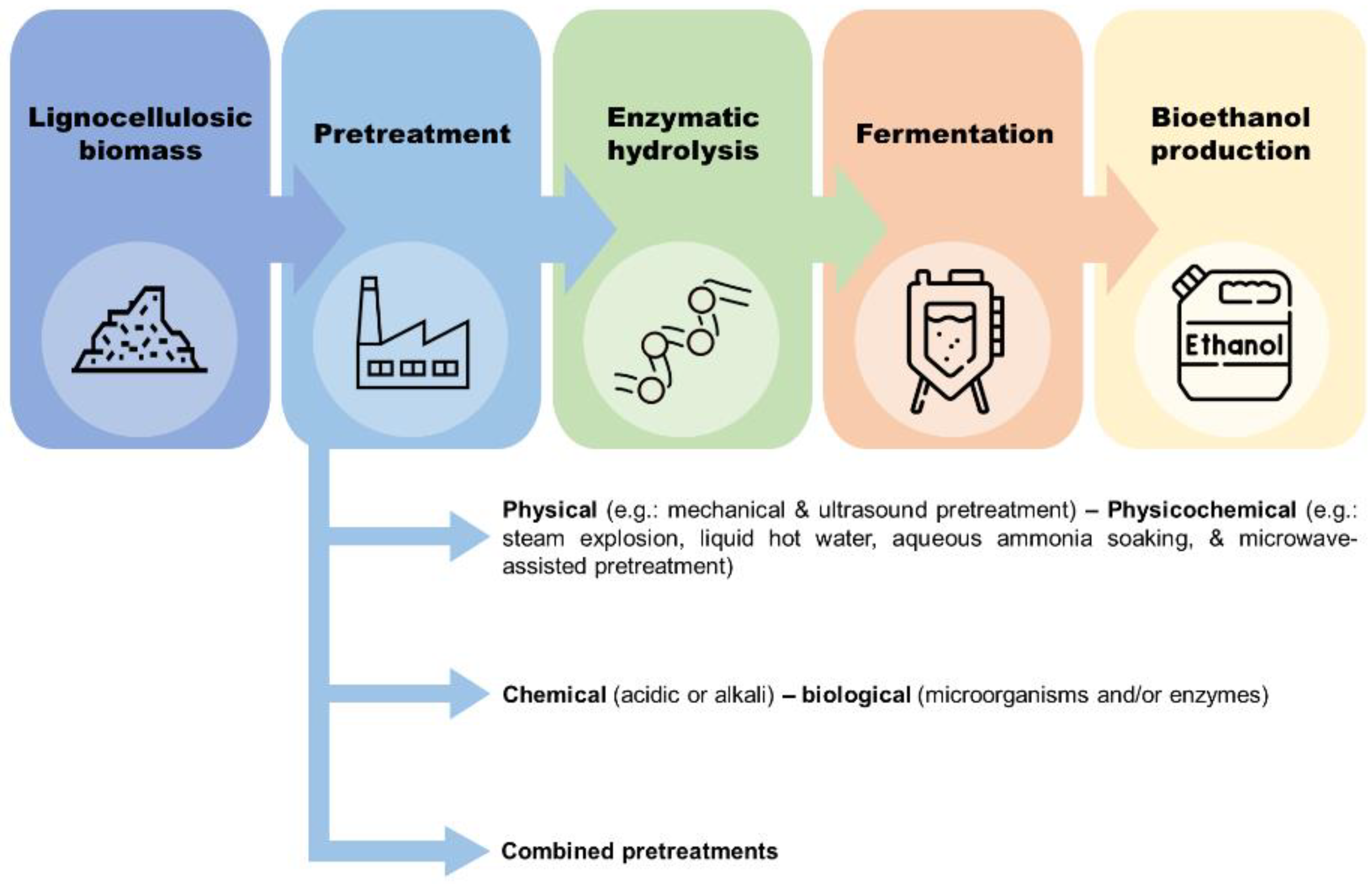

SSCF is a one-pot process that combines the breakdown of complex carbohydrates (like cellulose and hemicellulose) into fermentable sugars (saccharification) with the fermentation of those sugars into ethanol. This innovative approach offers numerous advantages over traditional two-step processes.

By combining these two steps, SSCF reduces the time and energy required for bioethanol production. It also minimizes the risk of contamination and improves overall efficiency. However, successful SSCF relies heavily on the use of robust and efficient yeast and enzyme strains.

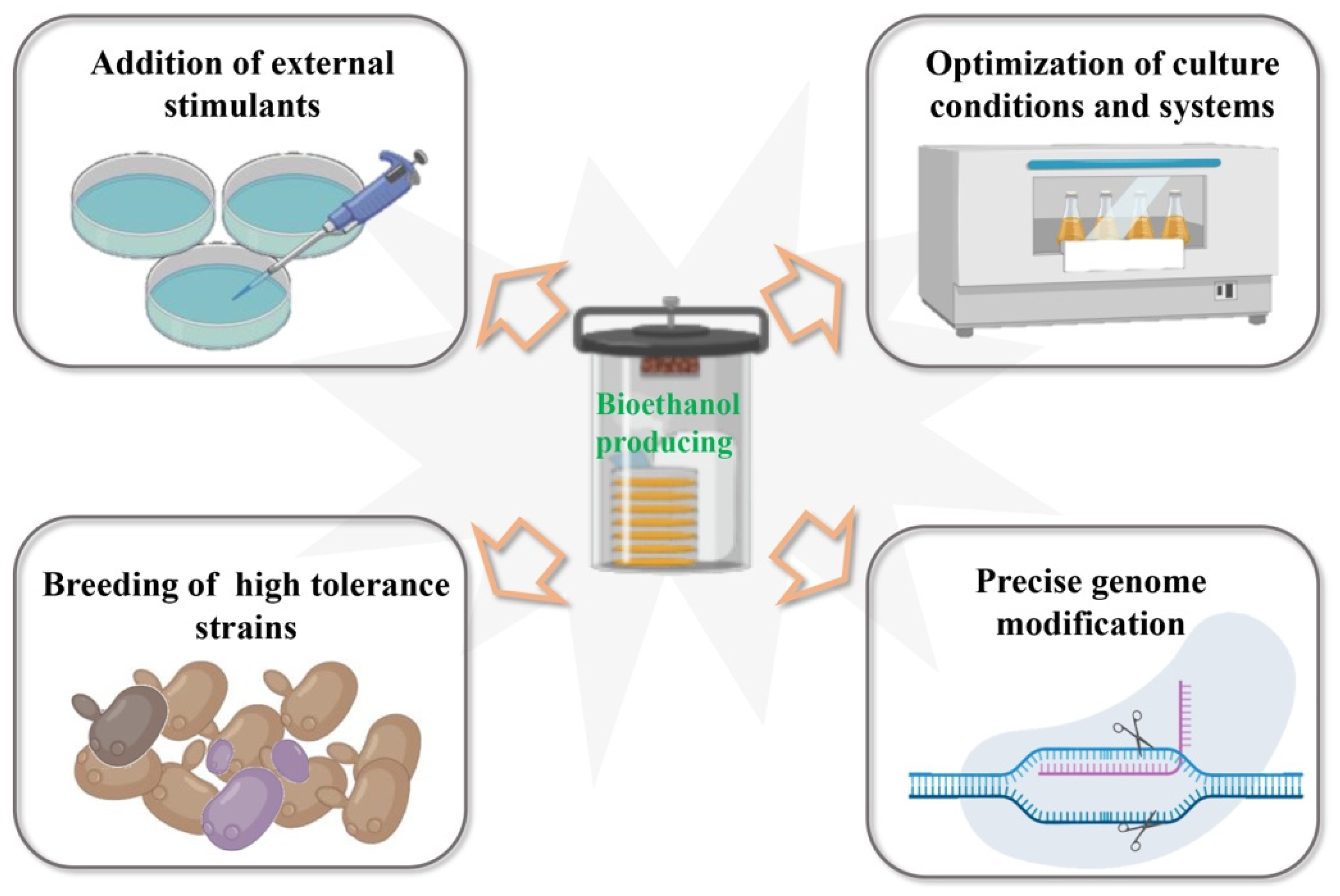

The Breakthrough: Optimized Yeast and Enzyme Strains for SSCF

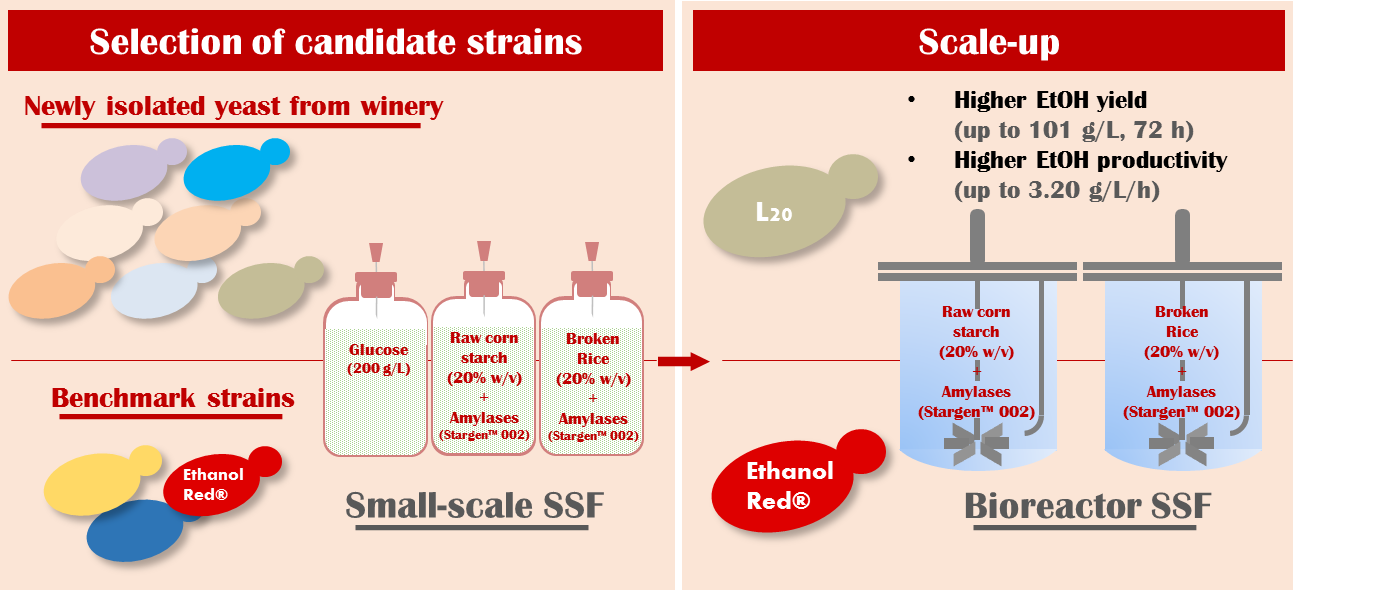

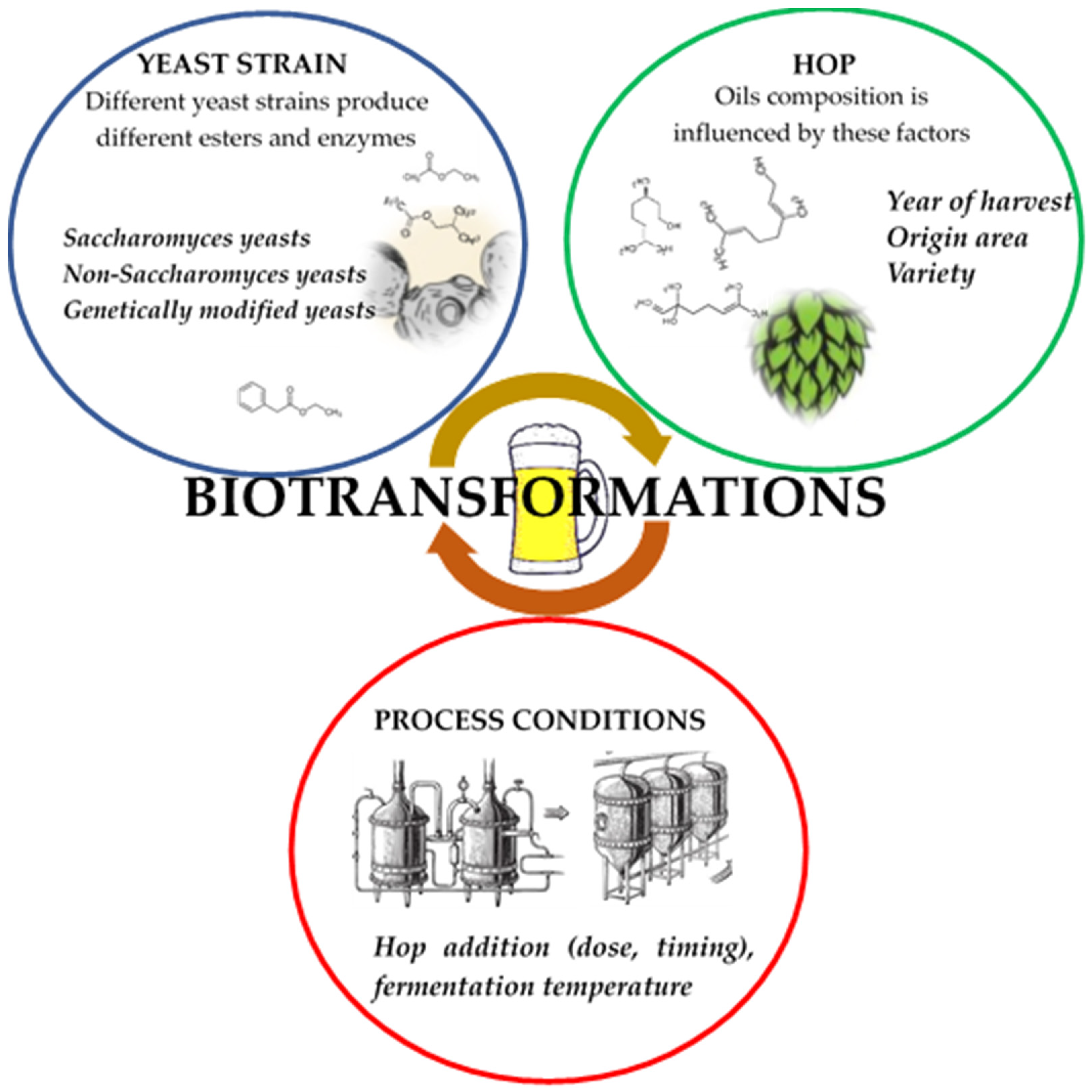

The development of specialized yeast and enzyme strains tailored for SSCF has been a game-changer. Researchers have been working diligently to identify and engineer microorganisms capable of efficiently converting a wide range of sugars into ethanol under the challenging conditions present in SSCF reactors.

These optimized strains are not only more efficient at converting sugars into ethanol, but they are also more tolerant to high ethanol concentrations, temperature fluctuations, and the presence of inhibitory compounds released during biomass pretreatment.

"The availability of these commercially viable strains marks a significant step forward for the bioethanol industry," says Dr. Emily Carter, a leading researcher in biofuels at the Renewable Energy Institute. "They offer the potential to significantly reduce production costs and improve the overall sustainability of bioethanol."

Key Advantages of the New Strains

The newly available yeast and enzyme strains offer several key advantages for bioethanol producers:

Enhanced Ethanol Yield: These strains are capable of producing significantly higher ethanol yields compared to traditional strains, maximizing the conversion of biomass into fuel.

Broader Substrate Utilization: They can efficiently ferment a wider range of sugars, including those derived from non-food feedstocks like agricultural residues and energy crops, expanding the potential sources of biomass for bioethanol production.

Improved Tolerance to Inhibitors: The strains exhibit enhanced tolerance to inhibitory compounds present in lignocellulosic biomass hydrolysates, enabling them to perform well even with less-than-ideal feedstock.

Reduced Production Costs: By increasing ethanol yield, reducing the need for pretreatment, and simplifying the overall process, these strains contribute to significant cost savings for bioethanol producers.

Commercial Availability and Industry Impact

Several companies are now offering these optimized yeast and enzyme strains commercially, making them readily accessible to bioethanol producers worldwide. This availability is poised to have a transformative impact on the industry.

By adopting these advanced strains, existing bioethanol plants can significantly improve their efficiency and profitability. Furthermore, the lower production costs enabled by these strains make bioethanol more competitive with gasoline, encouraging greater adoption by consumers.

The increased demand for bioethanol is also expected to stimulate growth in the agricultural sector, creating new opportunities for farmers to cultivate energy crops and supply biomass to bioethanol plants. This can lead to increased rural income and a more sustainable agricultural landscape.

Beyond Corn: Expanding Feedstock Options

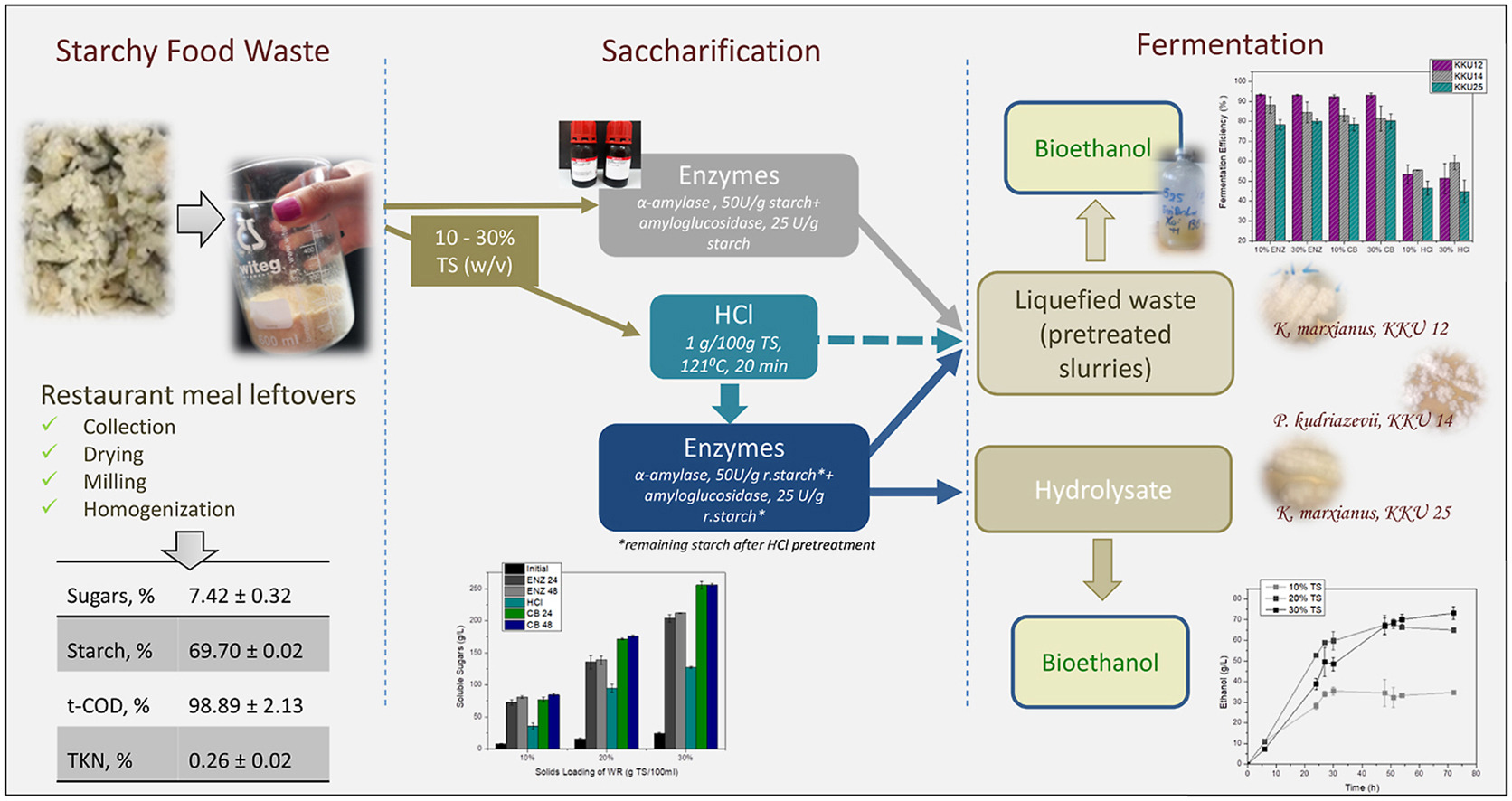

While corn has traditionally been the primary feedstock for bioethanol production in the United States, the new yeast and enzyme strains open up the possibility of utilizing a wider range of biomass sources.

Lignocellulosic biomass, such as agricultural residues (corn stover, wheat straw), forestry waste, and dedicated energy crops (switchgrass, miscanthus), represents a vast and underutilized resource for bioethanol production. These materials are abundant, renewable, and do not compete with food production.

The ability to efficiently convert lignocellulosic biomass into ethanol is crucial for achieving truly sustainable and large-scale bioethanol production. The new yeast and enzyme strains are a key enabler of this transition.

Challenges and Future Directions

While the advancements in yeast and enzyme strains are promising, challenges remain in the quest for cost-effective and sustainable bioethanol production.

Further research is needed to optimize the pretreatment of lignocellulosic biomass to improve its accessibility to enzymes. Additionally, efforts are underway to develop even more robust and efficient strains that can tolerate even higher ethanol concentrations and a wider range of inhibitors.

The development of advanced biorefineries that can produce a variety of biofuels and bioproducts from biomass is also a key priority. These integrated facilities will maximize the value of biomass and contribute to a more circular and sustainable economy.

A Sustainable Future Fueled by Innovation

The commercial availability of optimized bioethanol yeast and enzyme strains for SSCF represents a major milestone in the development of sustainable biofuels. These advancements are paving the way for a future where bioethanol plays a significant role in reducing our reliance on fossil fuels, mitigating climate change, and promoting rural economic development.

While challenges remain, the continued innovation in biotechnology and engineering is driving us closer to a future where our cars are powered by the sun, captured and converted into fuel by the ingenuity of science.

The road ahead is full of potential, and with each scientific breakthrough, we move closer to a greener, more sustainable world. The future of fuel may very well be growing in a field near you.