Compared To A Common Drill An Impact Driver Has

Power tool users are drastically underestimating the capabilities of impact drivers compared to traditional drills, leading to project delays and equipment damage. Understanding the fundamental differences is now critical for both professionals and DIY enthusiasts.

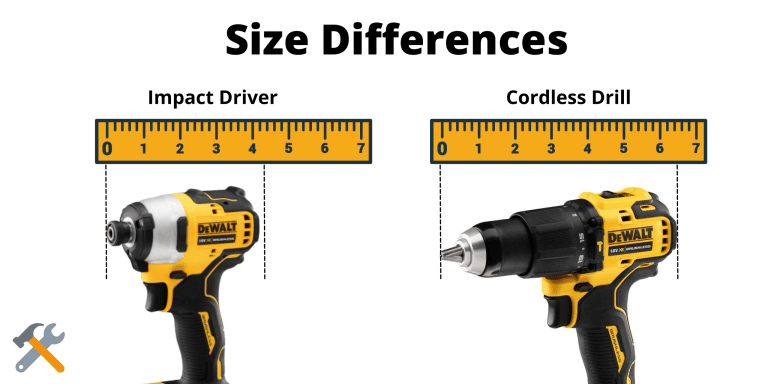

The core distinction lies in the mechanism: while drills offer consistent rotational force, impact drivers deliver rotational force in bursts, providing significantly higher torque. This translates to the ability to drive larger screws and bolts with ease, but comes with a learning curve to avoid overtightening.

Understanding the Torque Difference

Torque, the rotational force, is where impact drivers shine. A standard drill might offer 200-500 inch-pounds of torque. In contrast, impact drivers can readily deliver 1,500 inch-pounds or more. This difference is crucial when dealing with dense materials or long fasteners.

Who is affected? Everyone from professional carpenters to homeowners tackling weekend projects. What is happening? A widespread misunderstanding of power tool capabilities. When did this become a pressing issue? As power tools become more accessible and DIY projects increase in complexity. Where is this misinformation prevalent? Online forums, hardware stores, and job sites across the country.

Drills: Precision and Versatility

Drills excel at creating clean, accurate holes. They are ideal for tasks like drilling pilot holes, driving small screws, and mixing paint. Key features include adjustable speed settings and a chuck that accepts various drill bit sizes.

Drills provide a more delicate approach, suitable for materials where excessive force could cause damage. Consider drilling into soft woods or installing small trim pieces. Using an impact driver in these situations could lead to split wood or stripped screw heads.

Impact Drivers: Power and Efficiency

Impact drivers are designed for driving screws and bolts quickly and efficiently. The impact mechanism delivers bursts of rotational force, preventing cam-out (when the driver bit slips out of the screw head).

This feature makes them perfect for tasks like deck building, framing, and installing large fasteners. They are especially effective when working with tough materials like hardwoods and pressure-treated lumber. The quick-change chuck is also a significant time-saver.

Identifying the Right Tool for the Job

Choosing the correct tool depends entirely on the task at hand. For precision drilling and light-duty fastening, a drill is the superior choice. When faced with demanding fastening tasks, an impact driver is the clear winner.

Incorrect tool selection leads to damaged materials, wasted time, and increased frustration. Professionals experiencing these issues are recommending increased training and better communication on job sites. Homeowners are urged to research before starting any project.

Case Studies: Real-World Consequences

Reports from construction sites detail instances where workers, unfamiliar with impact drivers, stripped screws and damaged framing lumber. In one case, a significant portion of a deck had to be rebuilt due to improper fastener installation using a standard drill.

Similarly, homeowners attempting to drive large lag bolts with drills have burned out motors and damaged drill chucks. These incidents highlight the financial and time costs associated with misusing these tools.

Avoiding Common Mistakes

The most common mistake is attempting to drive large fasteners with a drill that lacks the necessary torque. This often results in stripped screws, damaged materials, and a frustrated user. Conversely, using an impact driver on delicate materials can lead to overtightening and splitting.

Always use the correct bit size and type. A worn or incorrect bit can exacerbate cam-out and damage the screw head. Start with a low speed setting and gradually increase until you find the optimal torque for the task. Remember to always wear safety glasses when operating power tools.

Educating yourself on the proper tool selection and usage is crucial for project success and personal safety.

"A little knowledge can save you a lot of trouble," says Bob Vila, renowned home improvement expert.

Next Steps and Ongoing Developments

Hardware stores are starting to offer more comprehensive tool demonstrations and training sessions. Online resources are also becoming more readily available, providing detailed comparisons and usage tips.

Manufacturers are continuously developing new models with improved features and ergonomics. Keeping abreast of these advancements will help users make informed decisions and maximize the efficiency of their power tools. Increased accessibility and training should minimize future errors.