Custom Spring Manufacturer For Mining Industry

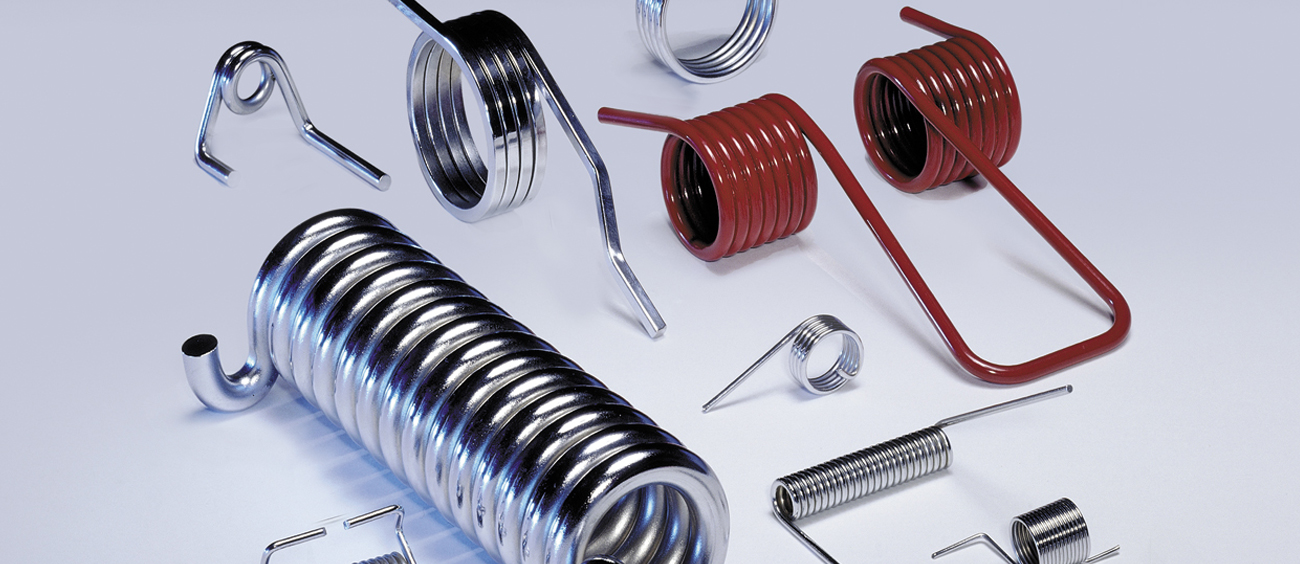

The global mining industry, known for its demanding operational conditions and heavy reliance on durable equipment, is increasingly turning to specialized manufacturers for custom-designed spring solutions. These springs, vital components in a vast array of machinery, are engineered to withstand extreme stress, temperature fluctuations, and corrosive environments, ensuring optimal performance and minimizing costly downtime.

The rise in demand for these customized components highlights a shift towards precision engineering and preventative maintenance within the sector, driven by the need for increased efficiency and safety.

The Role of Custom Springs in Mining Operations

Springs are integral to countless applications in mining, from heavy-duty suspension systems in haul trucks to valve controls in processing plants.

Their ability to absorb shock, store energy, and provide precise force makes them indispensable for ensuring the reliable operation of critical machinery. "The mining environment is incredibly unforgiving," states a technical white paper published by the Mining Equipment Manufacturers of Canada (MEMC). "Components must be robust and specifically engineered for the challenges they will face."

Custom spring manufacturers play a crucial role in meeting these demands by providing solutions tailored to the unique requirements of each application.

Key Players and Their Expertise

Several companies specialize in providing custom spring solutions for the mining industry, offering a range of services from design and prototyping to manufacturing and testing.

These manufacturers often work closely with mining companies and equipment OEMs (Original Equipment Manufacturers) to develop springs that meet specific performance criteria, ensuring optimal integration and reliability. Companies like Kern-Liebers and Wewal have a global presence, offering a wide range of spring types. Smaller, more specialized firms like Peterson Spring and MW Industries also cater to niche markets within the mining sector.

The expertise of these manufacturers extends beyond simply producing springs to providing engineering support and material selection advice.

The Customization Process: From Design to Delivery

The process of creating a custom spring for a mining application typically begins with a thorough assessment of the operating environment, load requirements, and desired performance characteristics.

Engineers use sophisticated software to model and simulate the spring's behavior under various conditions, optimizing its design for maximum durability and efficiency. Material selection is another critical aspect of the customization process, with options ranging from high-strength steel alloys to corrosion-resistant materials like stainless steel and titanium.

Once the design is finalized, the spring is manufactured using precision techniques such as CNC machining, coiling, and heat treating.

Rigorous testing and quality control procedures are then implemented to ensure that the spring meets all specified requirements before being shipped to the customer.

The Significance of Material Selection

The choice of material is paramount when designing springs for the mining industry, given the harsh conditions they must endure. According to data from the Australian Institute of Mining and Metallurgy (AusIMM), corrosion and wear are significant contributors to equipment failure in mining operations.

Therefore, materials with high resistance to these factors are often preferred. High-strength steel alloys, such as chrome vanadium steel and silicon manganese steel, offer excellent fatigue resistance and load-bearing capacity.

For applications where corrosion is a major concern, stainless steel, nickel alloys, and even titanium may be used. The selection process involves carefully considering the specific chemical and environmental conditions to which the spring will be exposed.

The Impact on Efficiency and Safety

The use of custom-designed springs can have a significant impact on the efficiency and safety of mining operations.

By optimizing spring performance, manufacturers can help to reduce equipment downtime, minimize maintenance costs, and improve overall productivity. Reliable spring performance is also crucial for ensuring the safe operation of heavy machinery, preventing accidents and protecting workers.

"A well-designed spring can significantly extend the lifespan of critical components," explains Dr. Emily Carter, a materials scientist specializing in mining equipment, in a recent industry report. "This translates to substantial cost savings and improved safety for mining companies."

Looking Ahead: Trends and Innovations

The field of custom spring manufacturing for the mining industry is constantly evolving, with ongoing research and development focused on improving material properties, design techniques, and manufacturing processes.

One emerging trend is the use of advanced materials, such as composite materials and shape memory alloys, to create springs with even greater performance characteristics. Another area of focus is the development of smart springs that can monitor their own condition and provide early warnings of potential failures.

These innovations promise to further enhance the efficiency, safety, and reliability of mining operations in the years to come. The integration of sensor technology allows real-time monitoring of spring performance, enabling predictive maintenance and preventing catastrophic failures.

This proactive approach minimizes downtime and ensures continuous operation, which is crucial in the demanding mining sector. The Society for Mining, Metallurgy & Exploration (SME) has highlighted the importance of adopting advanced technologies to enhance the competitiveness and sustainability of mining operations.