Cylinder Head Resurfacing Machine Price

The cost of cylinder head resurfacing machines, essential tools for automotive repair and engine rebuilding, is currently in flux, influenced by factors ranging from technological advancements to global supply chain dynamics. Understanding the price points and the factors impacting them is crucial for automotive shops, educational institutions, and individual engine enthusiasts looking to invest in this equipment.

This report examines the current market landscape for cylinder head resurfacing machines, providing an overview of pricing tiers, technological trends, and the key factors that determine the final cost.

Market Overview: Price Range and Key Players

The market for cylinder head resurfacing machines is segmented by price, features, and capacity. Entry-level machines, typically manually operated and suitable for smaller workshops or DIY enthusiasts, can range from $3,000 to $8,000. These machines often prioritize affordability and ease of use over advanced features.

Mid-range machines, offering a blend of automation and precision, are generally priced between $8,000 and $25,000. These models cater to professional automotive shops and engine rebuilders seeking increased efficiency and versatility.

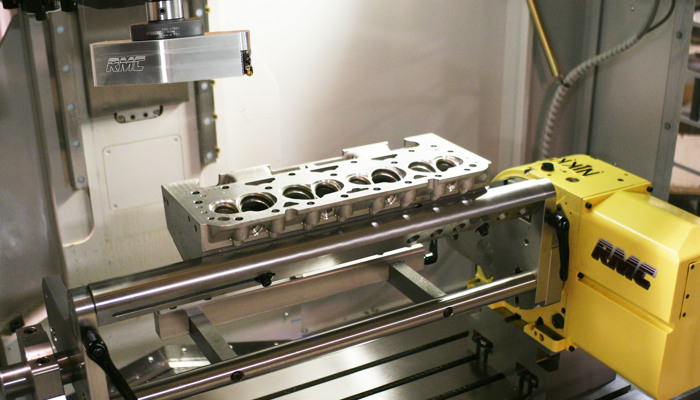

High-end, fully automated CNC (Computer Numerical Control) machines can cost upwards of $25,000, potentially reaching $100,000 or more depending on the specifications. These machines are designed for high-volume production and offer the highest levels of accuracy and automation.

Key players in the cylinder head resurfacing machine market include established manufacturers like Rottler Manufacturing, Serdi Corporation, and Comec Srl. These companies offer a wide range of machines to suit various needs and budgets. Smaller, regional manufacturers also contribute to the market, often specializing in specific types of machines or catering to niche markets.

Factors Influencing Price

Several factors contribute to the price of cylinder head resurfacing machines. The level of automation is a significant determinant. Machines with CNC capabilities and automated feeding systems command a higher price than manual models.

Machine capacity, referring to the maximum size of cylinder head that can be accommodated, also plays a role. Larger machines designed for heavy-duty engines are typically more expensive.

Material quality and construction are critical factors. Machines built with robust materials and precision engineering tend to be more durable and reliable, justifying a higher price point.

Technological features such as digital displays, variable speed controls, and advanced cooling systems can also impact the cost. Brand reputation and after-sales support also influence pricing decisions.

Supply chain disruptions, particularly those affecting the availability of raw materials and electronic components, have contributed to price fluctuations. Global economic conditions and currency exchange rates can also impact the final cost, especially for imported machines.

Impact on Automotive Repair Businesses

The price of cylinder head resurfacing machines has a direct impact on the operational costs of automotive repair businesses. Investing in a high-quality machine can improve efficiency, reduce labor costs, and enhance the quality of work, leading to increased customer satisfaction and profitability.

However, the initial investment can be a significant barrier for smaller shops or startups. Many businesses explore financing options or consider purchasing used machines to mitigate the financial burden.

The ability to offer cylinder head resurfacing services can be a competitive advantage for automotive shops. It allows them to provide comprehensive engine repair solutions, attracting a wider customer base and increasing revenue streams. Staying abreast of the latest technologies in cylinder head resurfacing can also help businesses remain competitive.

Future Trends

The market for cylinder head resurfacing machines is expected to continue to evolve, driven by technological advancements and changing demands in the automotive industry. There is a growing trend toward more automated and user-friendly machines.

The incorporation of Industry 4.0 technologies, such as remote monitoring and predictive maintenance, is also gaining traction. As demand for electric vehicles increases, the need for cylinder head resurfacing may decrease in some segments. However, it will remain relevant for internal combustion engines for many years.

The availability of financing options and the emergence of new business models, such as equipment leasing, may make these machines more accessible to a wider range of businesses and individuals.

Ultimately, the price of a cylinder head resurfacing machine is a complex equation, reflecting a range of factors from technology and materials to global economic forces. Understanding these factors is critical for making informed purchasing decisions and ensuring long-term return on investment.