Def In Diesel Tank Repair Cost

Across the nation, diesel vehicle owners are facing an unwelcome surprise: escalating repair costs related to Diesel Exhaust Fluid (DEF) systems. What was once a relatively minor maintenance issue is now ballooning into a significant financial burden, leaving many questioning the reliability and affordability of modern diesel technology.

The surge in DEF system repair costs is attributed to a confluence of factors, including increased complexity of emission control technology, rising prices for replacement parts, and a shortage of qualified technicians. This translates to truck drivers, fleet operators, and even everyday diesel car owners facing bills ranging from hundreds to thousands of dollars, jeopardizing their livelihoods and impacting the transportation sector.

The Nut Graf: Understanding the DEF System

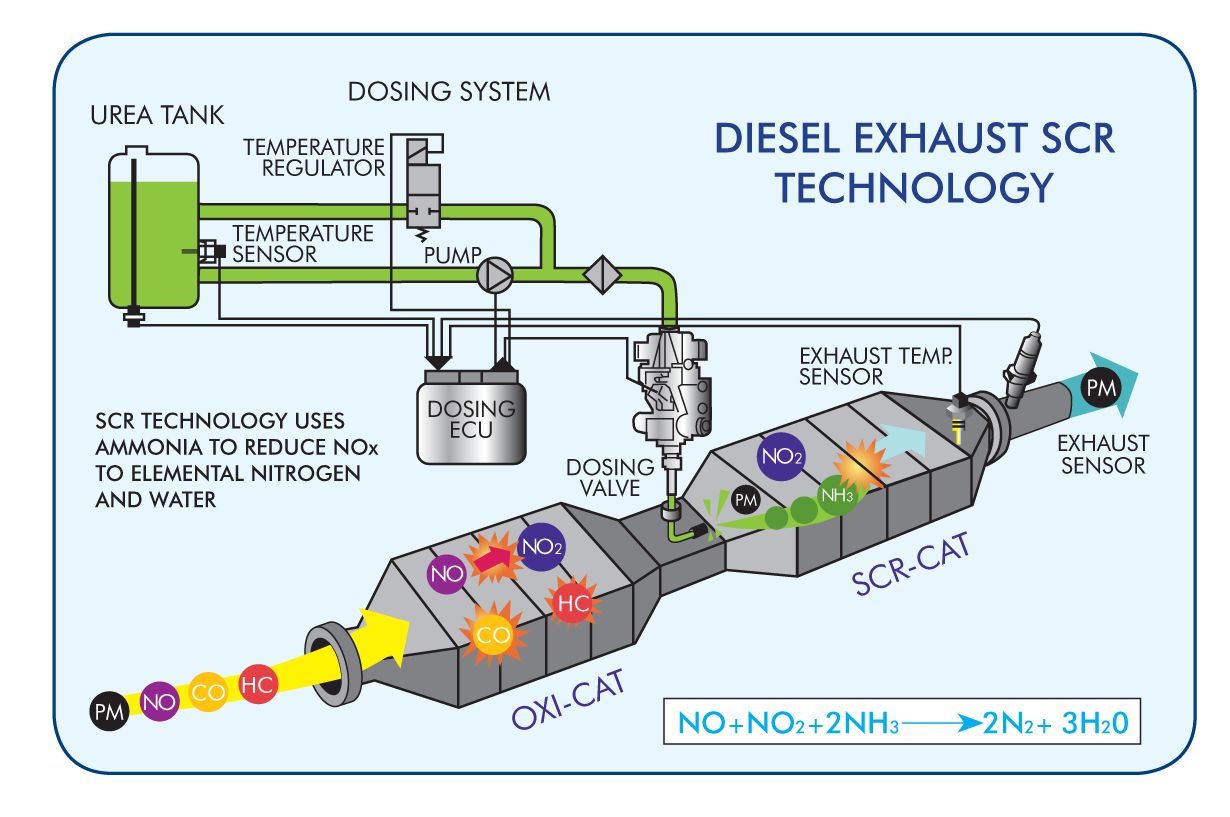

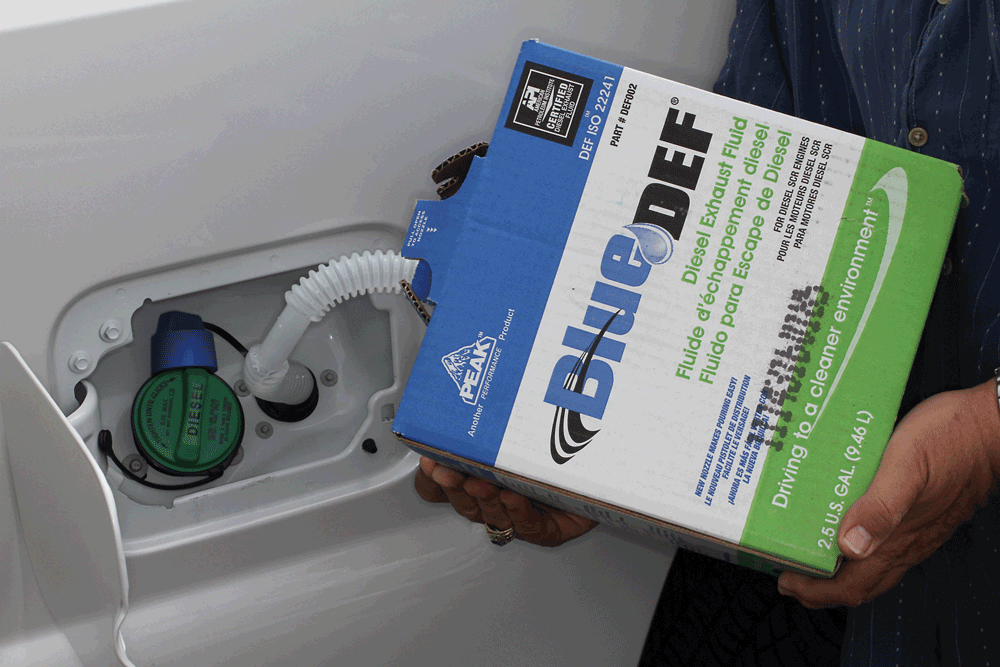

At the heart of the issue lies the DEF system, an integral part of modern diesel engines designed to reduce harmful nitrogen oxide (NOx) emissions. This system injects DEF, a solution of urea and deionized water, into the exhaust stream, where it reacts with NOx in a catalytic converter, converting it into harmless nitrogen and water. While effective in meeting stringent emission standards, the DEF system is proving to be a vulnerable component, susceptible to malfunctions and expensive repairs.

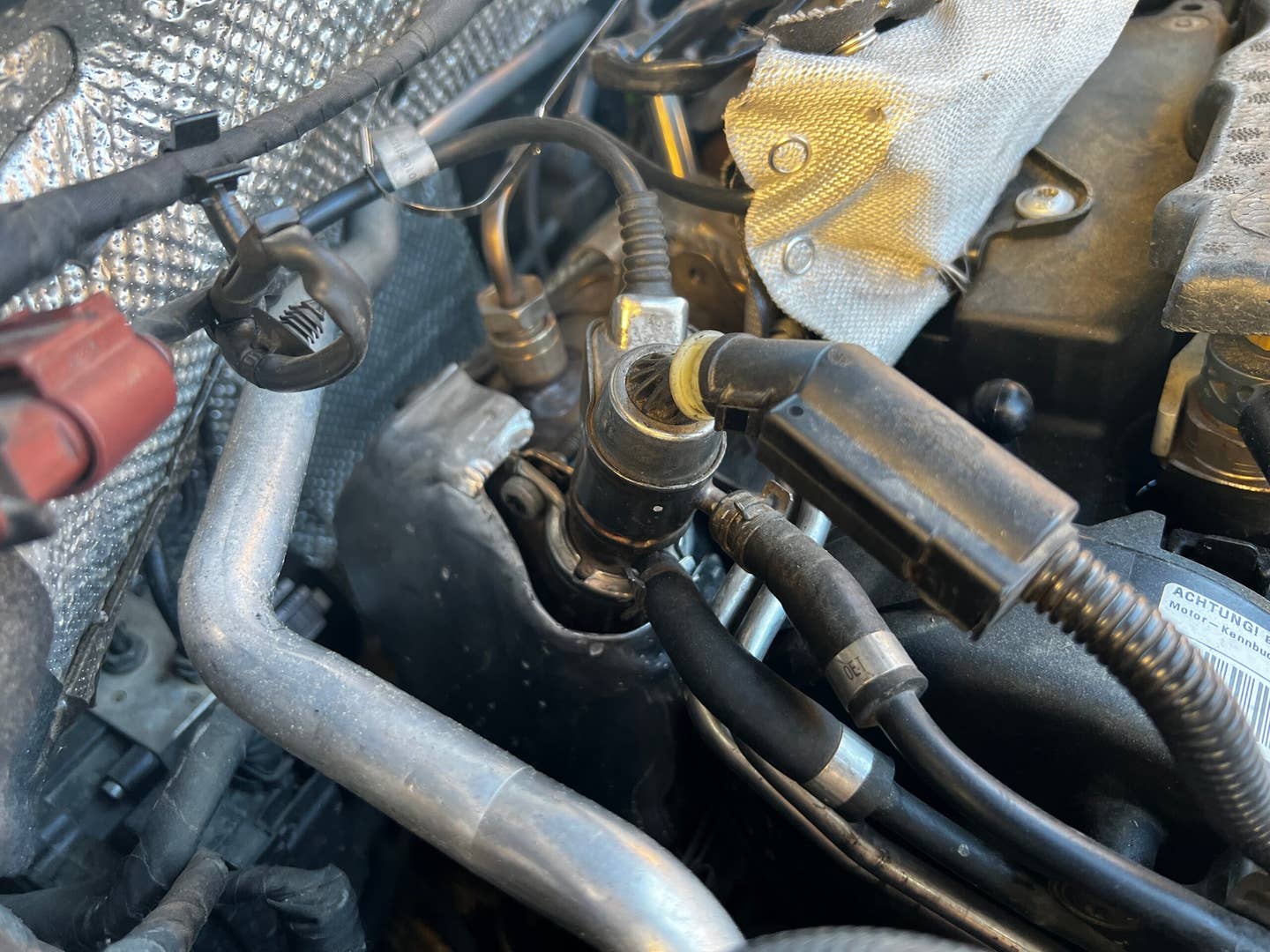

Malfunctions can stem from various sources, including faulty sensors, clogged injectors, crystallized DEF, and malfunctioning pumps. These issues can trigger warning lights, reduce engine power (a “limp mode”), or even prevent the vehicle from starting altogether.

Rising Repair Costs: A Deep Dive

The primary driver of the cost increase is the escalating price of replacement parts. Components like DEF pumps, sensors, and catalytic converters, which are critical to the system's operation, have seen substantial price hikes in recent years. This is partially attributed to supply chain disruptions, inflation, and the increasing complexity of these parts. Industry analysts report that some DEF pump prices have doubled in the last two years.

Another contributing factor is the specialized labor required to diagnose and repair DEF systems. The intricate nature of these systems demands experienced technicians with specialized tools and knowledge. With a nationwide shortage of qualified diesel mechanics, the demand for these services is high, leading to increased labor costs.

The American Trucking Associations (ATA) has expressed concerns about the impact of these rising repair costs on the trucking industry. They point out that independent owner-operators and small fleets are particularly vulnerable, as they often lack the financial resources to absorb unexpected expenses.

The DEF Fluid Itself: A Potential Culprit?

The quality of DEF fluid can also play a significant role in the longevity and performance of the system. Contaminated or substandard DEF can lead to crystallization, clogged injectors, and damage to other components. The ISO 22241 standard specifies the purity and composition requirements for DEF fluid, and using fluid that doesn't meet these standards can void warranties and lead to costly repairs.

Drivers are advised to purchase DEF from reputable suppliers and to store it properly in sealed containers to prevent contamination. Checking the DEF fluid's specific gravity with a refractometer can also help ensure its quality.

Impact on Consumers and Fleets

For individual diesel car owners, unexpected DEF system repairs can be a significant financial blow. Many are questioning the long-term cost-effectiveness of owning a diesel vehicle, especially if frequent repairs are required. Some are even considering selling their diesel cars and switching to gasoline or electric vehicles.

Fleet operators face even greater challenges. With numerous vehicles requiring maintenance, DEF system repairs can lead to significant downtime and lost revenue. The increased costs also affect their profitability and competitiveness in the transportation market.

Testimonial: The Frustration of a Truck Driver

"I had to replace my DEF pump last month, and it cost me over $2,000," said John Smith, an independent truck driver from Ohio. "That's a huge hit to my income, and it's happening more and more often. It's getting to the point where I'm questioning whether I can even afford to stay in business."

Potential Solutions and Mitigation Strategies

Several solutions are being explored to address the rising DEF system repair costs. These include developing more robust and reliable DEF system components, improving the availability of qualified technicians, and promoting the use of high-quality DEF fluid.

Some manufacturers are investing in improved diagnostic tools and training programs for technicians to help them quickly and accurately diagnose DEF system problems. Others are exploring alternative emission control technologies that are less susceptible to malfunctions.

The Environmental Protection Agency (EPA) is also monitoring the situation and considering potential regulatory changes to address the issue. This includes potentially strengthening quality control standards for DEF fluid and promoting the development of more durable DEF system components.

Looking Ahead: The Future of Diesel Technology

The escalating DEF system repair costs pose a significant challenge to the future of diesel technology. While diesel engines remain a popular choice for heavy-duty applications due to their fuel efficiency and power, the increasing cost of maintenance could drive consumers and fleet operators towards alternative powertrains, such as electric and hybrid vehicles.

Addressing the DEF system reliability and cost issues is crucial to ensuring the long-term viability of diesel technology. Collaboration between manufacturers, regulators, and the industry is essential to develop solutions that are both environmentally friendly and economically sustainable. Without intervention, the financial strain on diesel vehicle owners will continue to mount, potentially accelerating the transition to alternative fuel sources.