How Long Does Dap Spackle Take To Dry

Home improvement projects often hinge on the seemingly simple task of patching walls. One misstep, however, can lead to delays and frustration. Understanding the drying time of spackle, particularly a popular brand like DAP, is critical for achieving professional-looking results and staying on schedule.

This article delves into the factors influencing the drying time of DAP spackle. It will explore the different types of DAP spackle available, the environmental conditions that affect drying, and best practices for ensuring proper curing, drawing from official product information and expert recommendations. Understanding these nuances can transform a potential headache into a seamless part of any DIY or professional project.

Understanding DAP Spackle Varieties

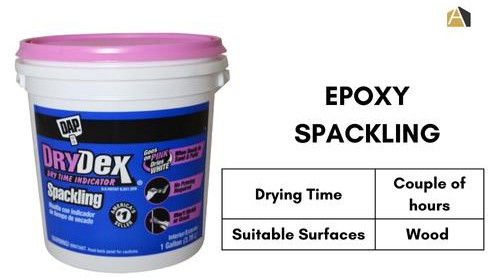

DAP offers a range of spackle products tailored to various needs. Each has its own specific formulation and, consequently, its own drying time characteristics. The most common types include DAP DryDex, DAP Fast N Final Lightweight Spackling, and DAP Plastic Wood Filler, though the latter is primarily for wood repair.

DAP DryDex, known for its color-changing technology (pink when wet, white when dry), typically takes around 30 minutes to a few hours to dry to the touch under ideal conditions. DAP Fast N Final Lightweight Spackling, designed for quick repairs, often boasts a drying time of as little as 15 minutes to an hour. These times, however, are highly dependent on several factors.

Environmental Factors and Their Impact

The ambient environment plays a significant role in determining how quickly DAP spackle dries. Temperature and humidity are the two primary culprits. High humidity levels significantly slow down the evaporation process, extending drying times considerably.

According to DAP's official website, optimal drying conditions involve temperatures between 70-80°F (21-27°C) and relatively low humidity. In cooler temperatures or more humid environments, drying can take significantly longer, even doubling or tripling the estimated time. Poor ventilation further exacerbates the problem.

Furthermore, the thickness of the application is crucial. A thin layer will dry much faster than a thick one. Applying multiple thin coats is generally recommended over a single thick coat for both faster drying and a more durable repair.

Best Practices for Optimal Drying

To ensure DAP spackle dries properly, consider these best practices. First, prepare the surface thoroughly by cleaning and sanding the area to be patched. This promotes better adhesion and even drying.

Next, apply the spackle in thin, even layers. Allow each layer to dry completely before applying the next. Using a fan to increase air circulation can also accelerate the drying process, especially in humid environments.

Avoid applying spackle in extremely cold or humid conditions whenever possible. If unavoidable, consider using a dehumidifier or heater to create a more favorable environment. Always consult the product's instructions for specific recommendations.

Troubleshooting Common Drying Issues

Sometimes, despite following best practices, spackle may not dry as expected. One common issue is cracking. This often occurs when the spackle dries too quickly or when it's applied too thickly.

If cracking occurs, gently sand the surface and reapply a thinner layer of spackle. Another issue is softness or stickiness even after the expected drying time. This usually indicates high humidity or insufficient ventilation.

In such cases, improving air circulation and ensuring the area is dry can help. If the problem persists, consider removing the affected spackle and starting fresh.

Expert Opinions and Recommendations

Professional painters and contractors emphasize the importance of patience when working with spackle. "Rushing the drying process can lead to subpar results and require rework," says Tom Silva, a veteran contractor known from This Old House.

According to Bob Vila's website, allowing ample drying time not only ensures a smooth finish but also prevents future problems like paint peeling or bubbling. This proactive approach saves time and money in the long run.

DAP's customer service representatives also consistently advise users to prioritize proper ventilation and thin applications. These simple steps can significantly improve the overall outcome of any patching project.

Looking Ahead: Innovations in Spackle Technology

The field of spackle technology is constantly evolving. Manufacturers are developing new formulas that dry faster, are more durable, and offer improved ease of use.

Self-priming spackles, for instance, eliminate the need for a separate primer coat, saving time and effort. Additionally, lightweight spackles offer easier sanding and reduced weight on walls, enhancing their appeal.

By staying informed about these innovations, both DIY enthusiasts and professionals can leverage the latest advancements to achieve even better results in their home improvement projects. The future of patching walls looks brighter than ever.