How Many Rockets For Sheet Metal Roof

The question of using rockets to install or repair sheet metal roofs may seem absurd, yet the underlying physics has sparked considerable interest in online communities and among amateur science enthusiasts. While clearly impractical, exploring the theoretical feasibility of such a concept reveals interesting insights into the forces involved and the sheer absurdity of the proposition.

This article delves into the mathematical and physical considerations necessary to even begin contemplating the use of rockets for sheet metal roof work. It will demonstrate why the concept is deeply flawed, but also highlight the principles that make it so outlandish.

The Absurdity of Rocket-Powered Roofing

The core idea, as floated in various online discussions, is whether small rockets could be used to lift, position, or even temporarily secure sheet metal panels during roofing projects. This article will address the impossibility of that idea.

Forces and Calculations: A Theoretical Dive

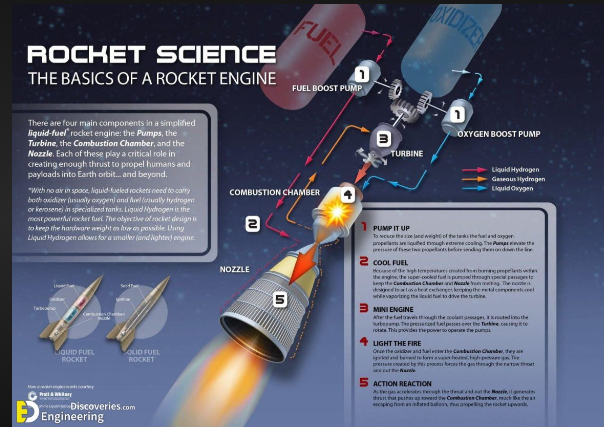

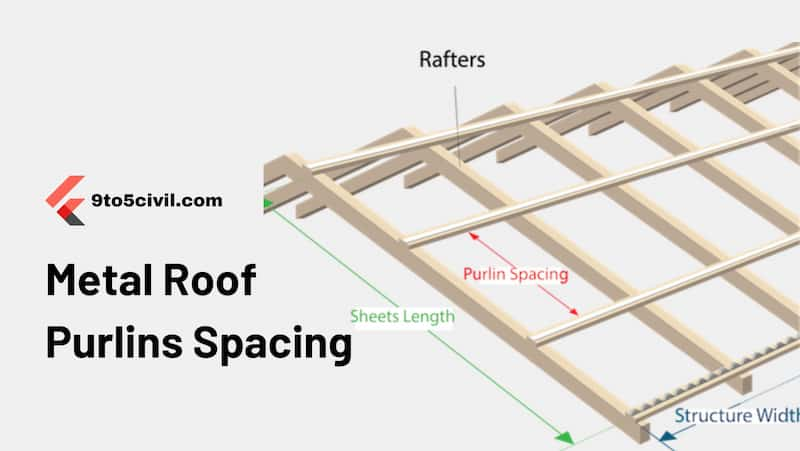

To even entertain the thought, one must consider the forces involved. The weight of a standard sheet metal panel must be overcome by the thrust of a rocket, but controlled acceleration and precision placement would be impossible in the real world.

Consider a typical 4'x8' sheet of 26-gauge steel, weighing roughly 40 pounds. A rocket would need to produce at least 40 pounds of thrust to lift it. More importantly, it would need to be precisely controlled with delicate manipulation of the rocket.

The real challenge lies in controlling that thrust. Rockets produce immense power. The level of control required for something like maneuvering a roof panel is very fine and complex.

Stability and Precision: Mission Impossible

A stable platform is crucial for any roofing operation. Rockets, by their nature, are inherently unstable, especially in close proximity to structures and other panels. The margin of error using rockets would be extreme.

Even with advanced guidance systems, the turbulent exhaust and sudden bursts of power make them completely unsuitable for precise movements like those required to carefully place roof panels. The result would be chaos and damaged materials.

"The precision required for roofing is simply incompatible with the raw power and inherent instability of rockets," explains Dr. Emily Carter, a professor of mechanical engineering at the Massachusetts Institute of Technology.

Safety Considerations: A Recipe for Disaster

Safety is paramount in any construction project. Using rockets on a roof poses an immediate and unacceptable risk of fire, explosion, and structural damage.

The hot exhaust of a rocket engine could easily ignite flammable roofing materials, cause burns, or even set the entire structure ablaze. The risk of debris falling and injuring workers or bystanders is also unacceptably high.

Cost and Efficiency: Exorbitant and Impractical

Even if technically feasible, the cost of using rockets for roofing would be astronomical. The price of the rockets themselves, the necessary control systems, and the inevitable damage would far exceed the cost of conventional methods.

Traditional roofing techniques, like manual lifting and mechanical hoists, are far more efficient, cost-effective, and safe. They are also safer.

Furthermore, the environmental impact of launching multiple rockets for a single roofing project would be significant, releasing pollutants into the atmosphere. Rockets are a high cost, high impact option compared to the methods already in use.

The Verdict: A Fantasy, Not a Reality

The idea of using rockets to install sheet metal roofs is firmly rooted in the realm of science fiction. It is not practical.

While the thought experiment provides an amusing look at the forces and calculations involved, the practical, safety, and economic barriers are insurmountable. Standard roofing methods remain the only viable option.

Ultimately, the best advice is to leave the rockets to the rocketeers and stick to traditional tools for roofing.