How Much Is Crusher Run Per Ton

The rumble of dump trucks and the tireless work of construction crews lay the foundation for our modern world, quite literally. But beneath the asphalt and concrete, a seemingly simple material plays a vital role: crusher run. Understanding its cost per ton is critical for contractors, homeowners, and municipalities alike, as fluctuations can ripple through budgets and project timelines.

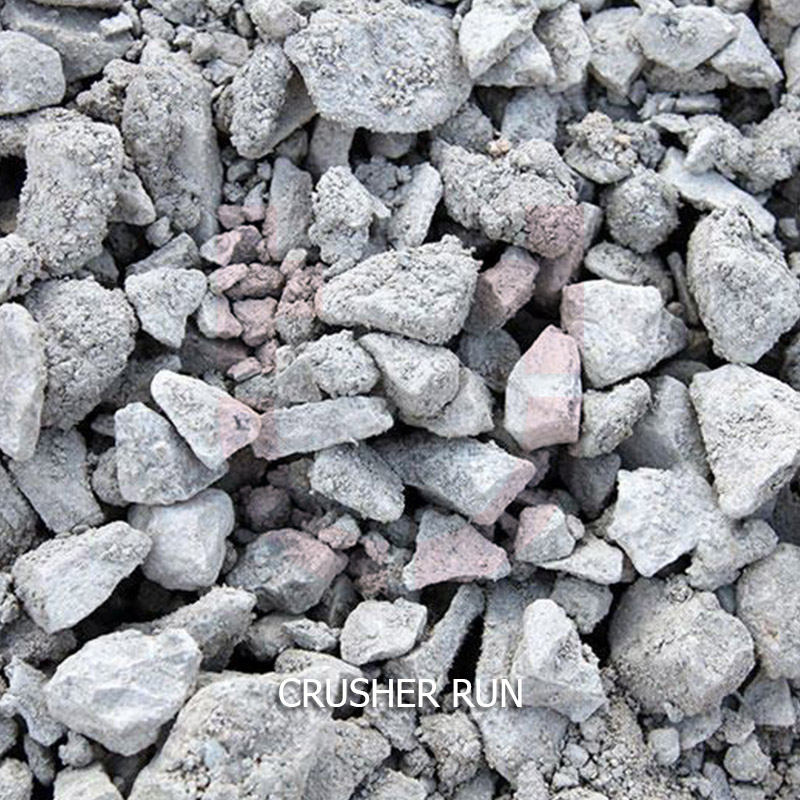

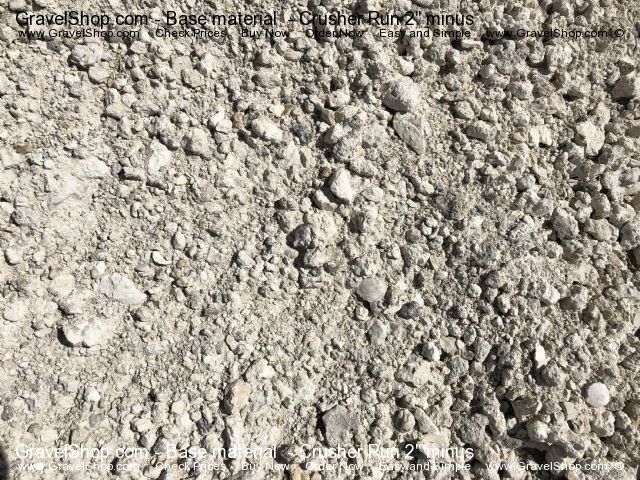

Crusher run, a mixture of broken rock fragments and stone dust, provides a stable base for driveways, patios, roads, and building foundations. Its price, however, isn't fixed. It is affected by factors ranging from quarry location and transportation costs to fuel prices and local demand.

This article delves into the current pricing landscape of crusher run, exploring the variables influencing its cost and offering insights for those seeking to purchase this essential construction material.

Understanding Crusher Run and Its Uses

Crusher run, sometimes called dense grade aggregate or DGA, consists of angular rock fragments ranging in size from dust to about three-quarters of an inch. The mixture compacts tightly, creating a solid and durable surface.

Its primary applications include creating a base layer for paving projects, constructing driveways and walkways, and providing a stable foundation for patios and sheds. It's also used in landscaping for drainage and erosion control.

Factors Influencing the Price of Crusher Run

The price of crusher run is not static; it’s a dynamic figure influenced by a confluence of factors. These factors can either drive the price up or down, depending on the prevailing market conditions.

Location, Location, Location: The proximity of the quarry to the job site is a major determinant of price. The further the material needs to be transported, the higher the transportation costs, which directly translate to a higher price per ton for the end-user.

Fuel costs are directly correlated to transportation expenses. Surges in fuel prices inevitably lead to increases in the cost of hauling crusher run.

Local demand plays a significant role. Periods of high construction activity often lead to increased demand for crusher run, pushing prices upward. Conversely, during slower periods, prices may decrease due to lower demand.

The type of rock used to produce crusher run can also influence its price. Some rock types are more readily available and easier to crush, leading to lower production costs. Harder or rarer rock types may command a premium.

Quarries often operate seasonally. Inclement weather, especially during winter months in colder climates, can restrict quarry operations, reducing supply and potentially increasing prices. Weather conditions also affect transportation.

Current Market Prices and Regional Variations

Nationwide, the price of crusher run can vary considerably. Generally, prices range from $12 to $35 per ton when purchased directly from a quarry. Prices are often significantly higher when purchased from retail suppliers.

Prices tend to be lower in areas with abundant rock quarries and lower transportation costs. Conversely, areas with limited local sources or higher transportation costs will likely see higher prices.

According to recent data from industry publications like Rock Products Magazine and feedback from contractors across the country, some regions are experiencing higher prices than others due to supply chain issues and increased demand.

Comparing Prices: Quarry vs. Retail Supplier

Purchasing directly from a quarry can often result in significant savings. However, this option is usually only feasible for large projects requiring bulk quantities of crusher run.

Retail suppliers offer convenience and smaller quantities, but typically at a higher price per ton. They also provide delivery services, which can be valuable for smaller projects or those without access to heavy equipment.

Ultimately, the best option depends on the specific needs of the project. Considering factors like quantity required, delivery needs, and budget constraints is essential.

Tips for Obtaining the Best Price on Crusher Run

Plan Ahead: Avoid last-minute purchases. Giving yourself ample time to research and compare prices can help secure a better deal.

Get Multiple Quotes: Contact several quarries and retail suppliers to obtain quotes. Be sure to specify the exact type and quantity of crusher run required.

Consider Bulk Discounts: If your project requires a large quantity, inquire about bulk discounts. Many suppliers offer reduced prices for larger orders.

Negotiate: Don't be afraid to negotiate. Suppliers may be willing to adjust prices, especially during slower periods.

Factor in Delivery Costs: When comparing quotes, be sure to factor in delivery costs. Some suppliers may offer free delivery for larger orders, while others may charge a separate fee.

Consider Off-Season Purchases: Prices may be lower during the off-season (e.g., winter months in colder climates) due to reduced demand.

The Future of Crusher Run Prices

The future price of crusher run is subject to the same economic forces that influence other construction materials. Monitoring fuel prices, economic indicators, and local construction activity can provide insights into potential price fluctuations.

The increasing focus on sustainable construction practices may also impact the industry. Recycled aggregates, which can sometimes be used as a substitute for crusher run, are gaining popularity. Recycled aggregate prices will factor into decisions.

Furthermore, infrastructure spending initiatives at the federal and state levels could significantly increase demand for crusher run, potentially driving prices upward. Staying informed about these developments is crucial for anyone involved in construction or landscaping projects.

Understanding the factors influencing the price of crusher run empowers consumers and contractors to make informed purchasing decisions. By considering location, demand, transportation costs, and seasonal variations, it is possible to navigate the market effectively and secure the best possible price for this essential construction material.