How To Build A Trophy Truck

The roar of a heavily modified engine, the crunch of metal against unforgiving terrain, and the spectacle of a machine defying gravity – these are the hallmarks of trophy truck racing. But beneath the adrenaline-fueled excitement lies a complex engineering feat, a testament to human ingenuity and relentless pursuit of off-road dominance. Building a trophy truck is not simply about bolting on bigger tires; it's a meticulous process demanding expertise in fabrication, suspension dynamics, and powertrain management, all pushed to the absolute limit.

This article delves into the intricate world of trophy truck construction, exploring the key components, engineering principles, and specialized skills required to create these desert racing titans. We'll examine the chassis design, suspension systems, engine selection, and crucial safety features that define a competitive trophy truck, offering a glimpse behind the scenes into the demanding process of building a machine capable of conquering the world's toughest off-road courses.

Chassis: The Foundation of Strength

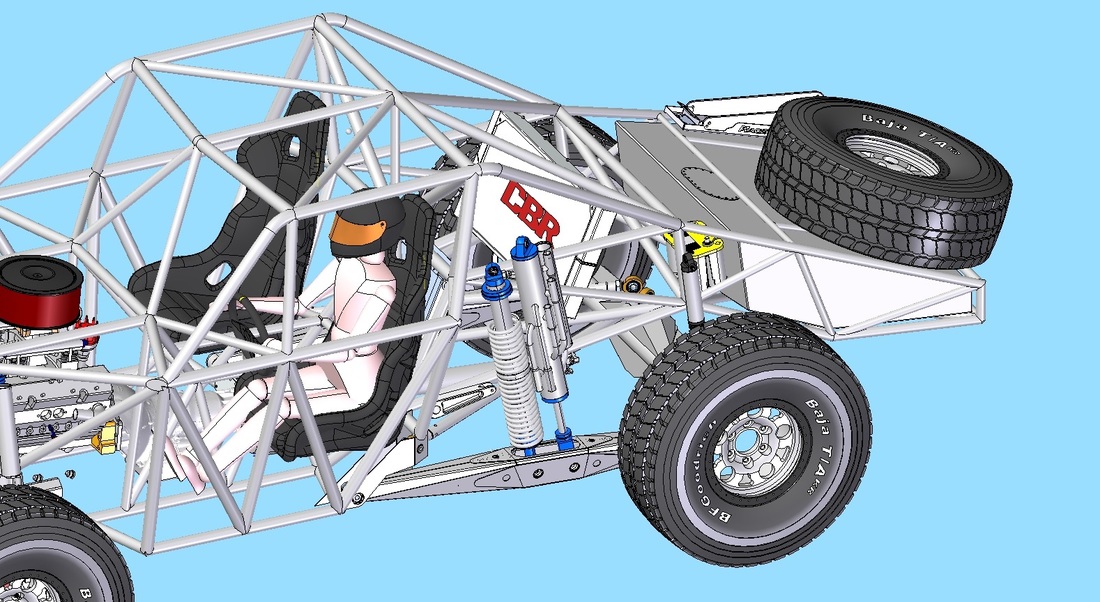

The chassis is the backbone of any trophy truck, providing the structural integrity necessary to withstand extreme forces. Unlike production vehicles, trophy trucks utilize custom-fabricated space frames constructed from high-strength steel alloys, typically 4130 chromoly. Chromoly offers an exceptional strength-to-weight ratio, crucial for maximizing performance and minimizing vehicle mass.

The design process involves sophisticated CAD (Computer-Aided Design) software and finite element analysis to optimize structural rigidity and minimize stress points. Tube diameter and wall thickness are carefully calculated based on anticipated loads and impact forces. The goal is to create a chassis that is both incredibly strong and relatively lightweight, providing a safe and stable platform for the suspension and powertrain.

Welding is a critical aspect of chassis construction, requiring highly skilled and certified welders. Precise welds are essential to ensure the integrity of the frame and prevent cracking under stress. Many builders utilize TIG (Tungsten Inert Gas) welding for its precision and clean welds.

Suspension: Mastering the Terrain

The suspension system is arguably the most crucial element of a trophy truck, responsible for absorbing massive impacts, maintaining traction, and providing the driver with control at high speeds. Trophy trucks typically employ long-travel independent suspensions, allowing for wheel travel exceeding 30 inches.

Independent front suspension (IFS) and independent rear suspension (IRS) designs are common, utilizing double wishbones and massive coilover shocks. These shocks are often multi-stage, incorporating bypass tubes and adjustable compression and rebound damping to fine-tune the suspension's response to varying terrain conditions. Internal bypass shocks allow oil to flow around the piston on the compression and rebound strokes, providing position-sensitive damping and incredible control over wheel movement.

Tuning the suspension is an iterative process, requiring extensive testing and data analysis. Teams use sophisticated sensors and data loggers to monitor suspension travel, shock temperatures, and vehicle dynamics, allowing them to make precise adjustments to optimize performance for specific courses.

Powertrain: Unleashing Raw Power

Trophy trucks are powered by high-performance engines, typically naturally aspirated V8s producing upwards of 900 horsepower. These engines are designed for extreme durability and reliability, capable of withstanding sustained high RPM operation in harsh environments. Engine displacement often ranges from 400 to 450 cubic inches, with a focus on generating massive torque across the entire RPM range.

Engine management systems (EMS) play a critical role in optimizing engine performance and fuel efficiency. Modern EMS systems utilize sophisticated sensors and algorithms to precisely control fuel injection, ignition timing, and other engine parameters. Custom-fabricated headers and exhaust systems are designed to maximize exhaust flow and minimize backpressure, further enhancing engine power.

The drivetrain typically consists of a robust transmission, often a three-speed automatic, coupled with a heavy-duty transfer case and axles. The transmission must be capable of handling the engine's immense torque output, while the transfer case allows the driver to select between two-wheel drive and four-wheel drive. Strong and reliable axles are vital for transmitting power to the wheels and withstanding the immense forces generated during off-road racing.

Safety: Prioritizing Driver Protection

Safety is paramount in trophy truck racing, given the extreme speeds and inherent risks involved. Trophy trucks are equipped with a comprehensive array of safety features, including a full roll cage constructed from high-strength steel tubing. This cage is designed to protect the driver and co-driver in the event of a rollover or impact. SFI-approved racing seats, five-point harnesses, and head and neck restraints provide additional protection, securing the occupants within the vehicle.

Fire suppression systems are mandatory, providing a means to quickly extinguish fires in the engine compartment or cockpit. These systems typically utilize automatic nozzles that spray fire-retardant chemicals in the event of a fire. Communication systems, including radios and intercoms, allow the driver and co-driver to communicate effectively with each other and with their pit crew. Navigation systems, such as GPS units, help the team stay on course and monitor their progress during long-distance races.

The Cost of Victory

Building a competitive trophy truck is a significant investment, with costs ranging from several hundred thousand dollars to well over a million. The cost of parts, labor, and fabrication can quickly add up, and ongoing maintenance and repairs are also a major expense. Teams often rely on sponsorships and partnerships to help offset these costs.

Beyond the financial investment, building a trophy truck requires a significant time commitment and a dedicated team of skilled professionals. Fabricators, welders, mechanics, and engineers all play a crucial role in the design, construction, and maintenance of these complex machines. The entire process, from initial design to final testing, can take several months or even years to complete.

The Future of Trophy Truck Technology

The evolution of trophy truck technology is ongoing, with teams constantly seeking new ways to improve performance, reliability, and safety. Developments in areas such as suspension design, engine management, and materials science are driving innovation in the sport. Electric powertrains are being explored as a potential alternative to traditional combustion engines, offering the potential for increased efficiency and reduced emissions.

Data acquisition and analysis are playing an increasingly important role in optimizing vehicle setup and performance. Teams are using sophisticated sensors and software to monitor everything from suspension travel to tire pressure, allowing them to make precise adjustments based on real-time data. The future of trophy truck racing promises even more advanced technology, pushing the boundaries of what is possible in off-road competition.