How Wide Is A Concrete Block

The humble concrete block, a ubiquitous building material found on construction sites worldwide, often fades into the background. But a seemingly simple question about its dimensions – specifically, its width – reveals a surprising complexity and significant implications for construction, design, and cost estimation.

This article delves into the standard widths of concrete blocks, exploring the variations that exist and the reasons behind these differences. We will also examine how these dimensions impact building projects and what factors influence the choice of block size. Understanding the precise width of a concrete block is crucial for accurate planning and execution in any construction endeavor.

Standard Widths and Nominal Sizes

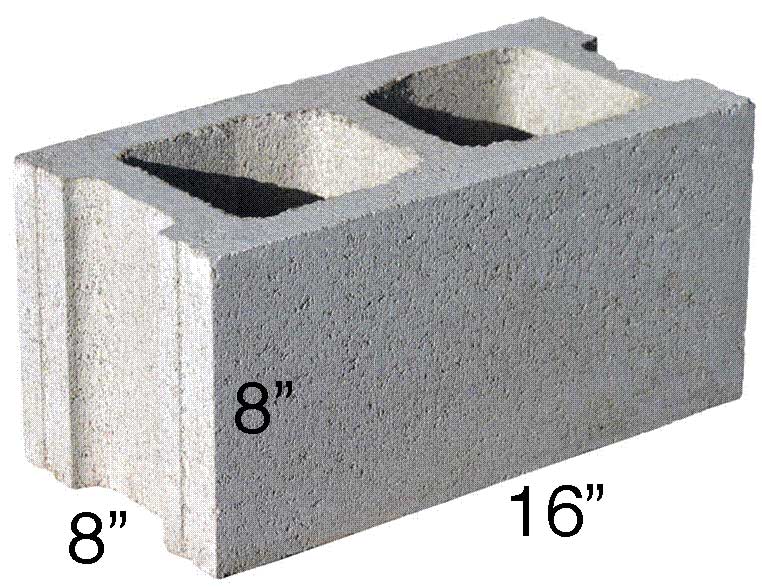

The most common nominal width of a concrete block is 8 inches (203 mm). However, this “8-inch” block is typically manufactured with a width of 7 5/8 inches (194 mm). The difference accounts for the mortar joint, ensuring that the finished wall measures a full 8 inches, or a multiple thereof.

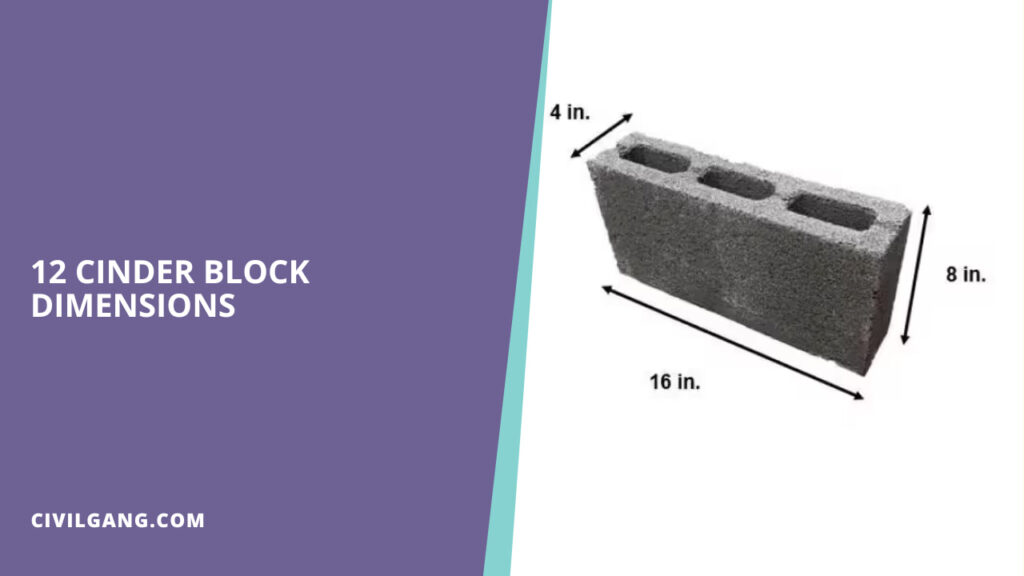

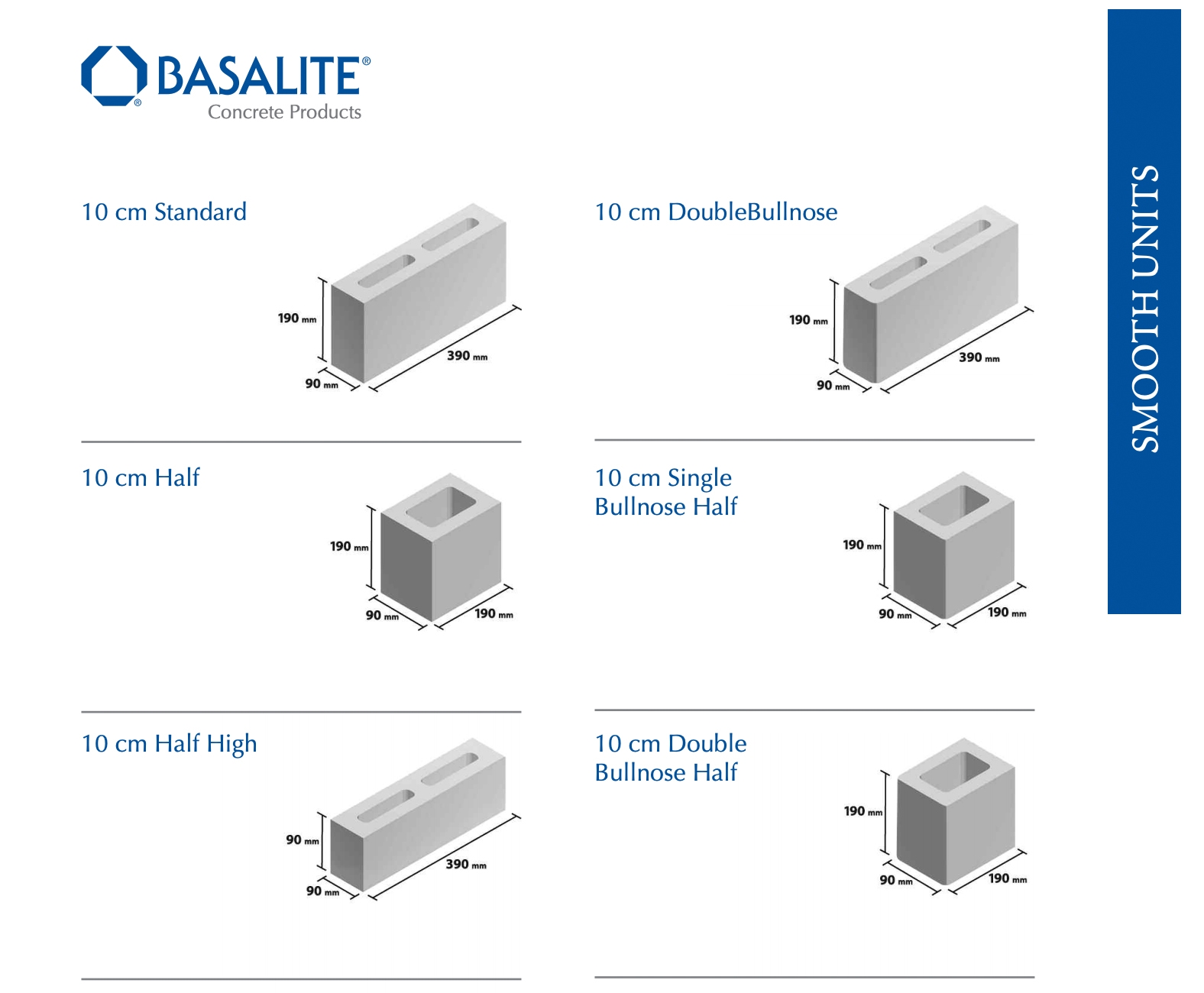

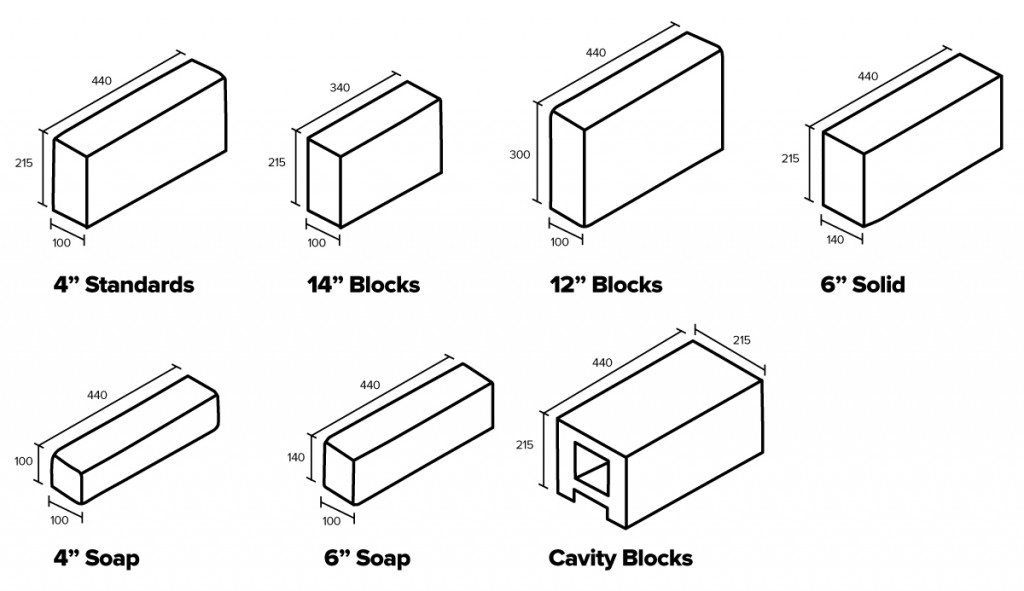

Other standard nominal widths exist, including 4-inch (102 mm), 6-inch (152 mm), 10-inch (254 mm), and 12-inch (305 mm) blocks. Again, the actual manufactured width is slightly less to accommodate the mortar joint. For example, a “4-inch” block will typically measure 3 5/8 inches (92 mm) wide.

Why the Variations?

The primary reason for the difference between nominal and actual widths is the mortar joint. A standard mortar joint is typically 3/8 inch (9.5 mm) thick. Subtracting this from the nominal size provides the actual manufactured size of the block.

This system allows builders to easily calculate the number of blocks needed for a wall of a specific length. Without this system, calculations would be significantly more complex and prone to error. This mortar joint, though small, plays a crucial role in structural integrity and weather resistance.

Factors Influencing Block Width Choice

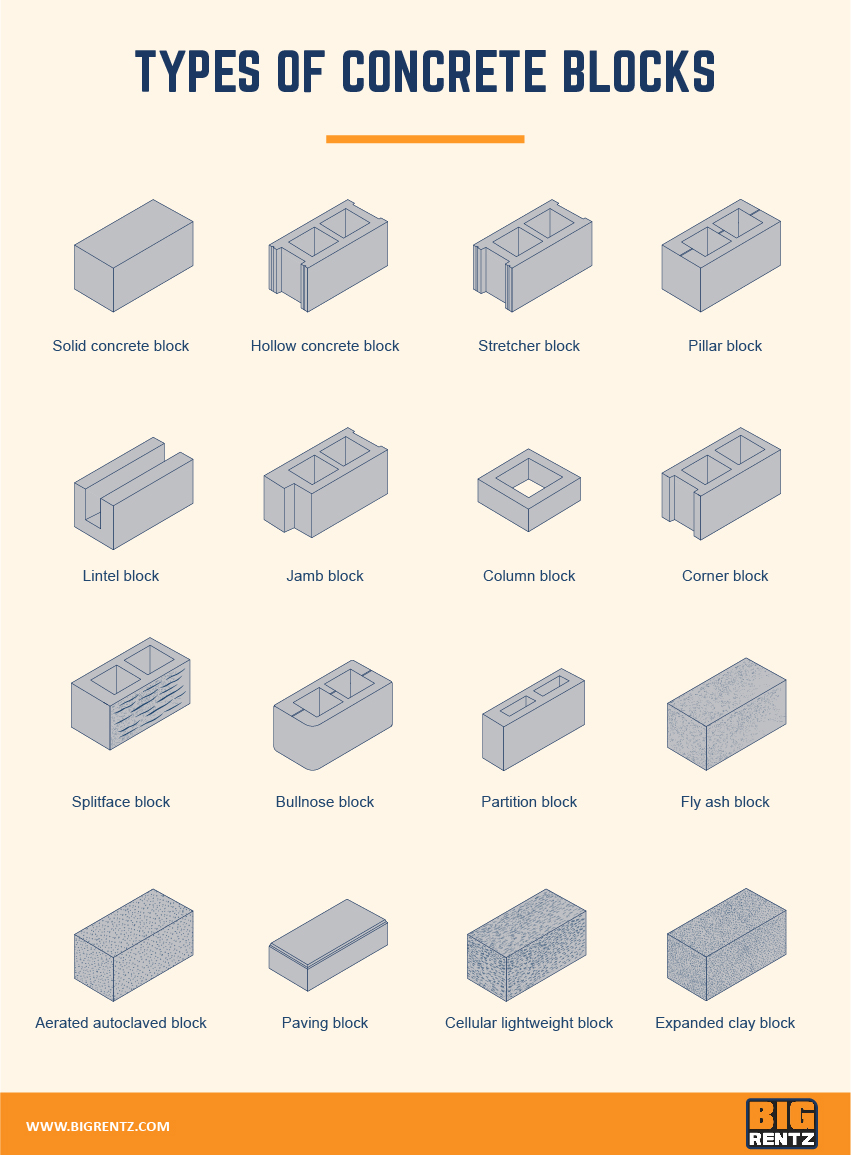

Several factors influence the choice of concrete block width for a particular project. Structural requirements are paramount, with thicker blocks offering greater load-bearing capacity. Walls needing to withstand heavy loads or serve as retaining walls will generally require wider blocks.

Cost considerations are also important. Thicker blocks require more material, resulting in higher costs per block. Builders often balance structural needs with budgetary constraints to find the most cost-effective solution. The choice also depends on the location since transport and labor cost should be considered.

Insulation requirements play a role, particularly in exterior walls. Wider blocks provide more space for insulation, improving the energy efficiency of the building. Building codes often mandate specific insulation levels, influencing the selection of block width. This regulation can vary widely based on location.

Impact on Construction Projects

Understanding the actual width of concrete blocks is critical for accurate project planning and cost estimation. Incorrect assumptions about block dimensions can lead to errors in material calculations. This ultimately causes delays and budget overruns.

For instance, ordering too few blocks due to underestimating their actual size can halt construction until additional materials arrive. Conversely, ordering too many blocks results in wasted resources and increased costs. Precise measurements are crucial for avoiding these pitfalls.

Furthermore, accurate dimensions are essential for ensuring the structural integrity of the wall. Proper alignment and mortar joint thickness depend on knowing the precise width of the blocks being used. The Mortar joint affects the wall's ability to resist water penetration and withstand seismic forces.

The Human Element: Accuracy and Craftsmanship

While machines manufacture the blocks, human expertise is crucial in laying them. Bricklayers must maintain consistent mortar joint thickness to ensure the wall is plumb, level, and structurally sound. This demands a high level of skill and attention to detail.

Experienced bricklayers develop a "feel" for the proper mortar thickness and can quickly adjust their technique to compensate for slight variations in block dimensions. Their craftsmanship ensures the long-term durability and aesthetic appeal of the finished wall. A skilled bricklayer can enhance the overall aesthetic.

Stories abound of projects delayed or compromised by unskilled labor or inaccurate measurements. These examples highlight the importance of both accurate material specifications and skilled execution. The success of any construction project relies on the interplay of planning and expertise.

Conclusion

The seemingly simple question of "how wide is a concrete block?" reveals a nuanced reality with significant implications for the construction industry. While the nominal width provides a convenient reference point, understanding the actual manufactured width, the role of the mortar joint, and the factors influencing block selection are crucial for project success. This seemingly small detail impacts everything from cost estimation to structural integrity.

By appreciating the subtle complexities of this ubiquitous building material, architects, engineers, and construction professionals can make informed decisions that lead to more efficient, cost-effective, and structurally sound buildings. The careful consideration of block dimensions, combined with skilled craftsmanship, ensures that these structures stand the test of time. Therefore, attention to detail is vital for a successful construction project.