Identify The True Statements About Planning Across A Supply Chain

Supply chain planning, the intricate dance of forecasting demand, managing inventory, and coordinating logistics, often seems shrouded in complexity. Misconceptions abound regarding its scope, responsibilities, and even its fundamental objectives. Clarifying the true statements about planning across a supply chain is crucial for businesses aiming to optimize efficiency, reduce costs, and enhance customer satisfaction.

The purpose of this article is to dissect the common assumptions and clarify the realities of supply chain planning. By relying on expert insights and industry best practices, this analysis aims to offer a more accurate understanding of this crucial business function. This understanding can lead to more effective strategies and improved supply chain performance.

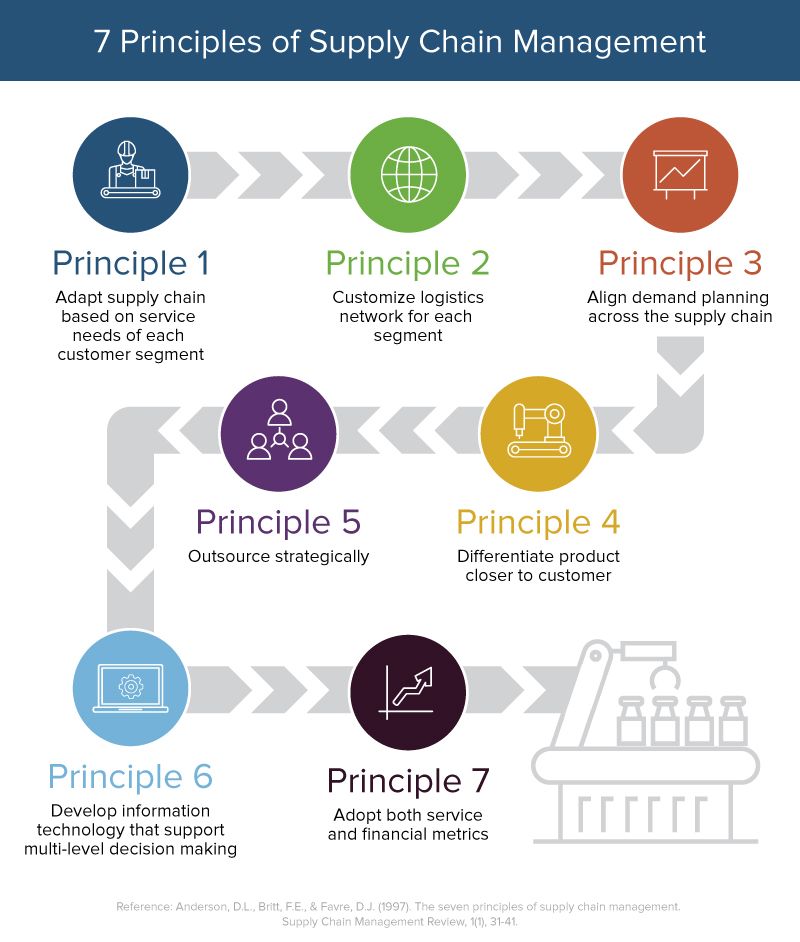

Key Principles of Supply Chain Planning

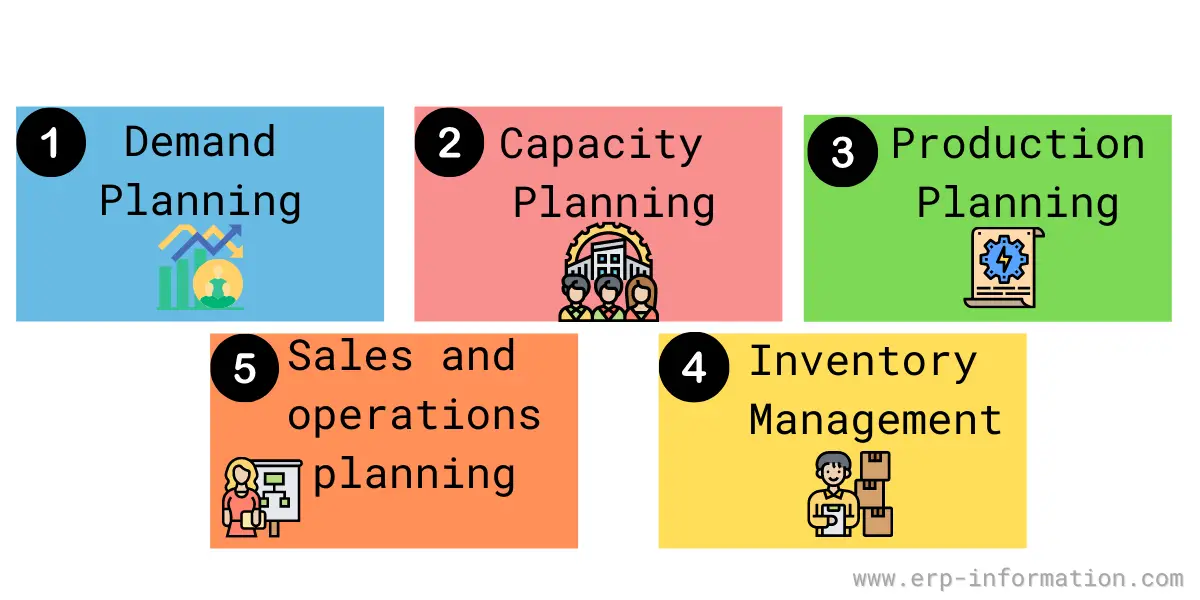

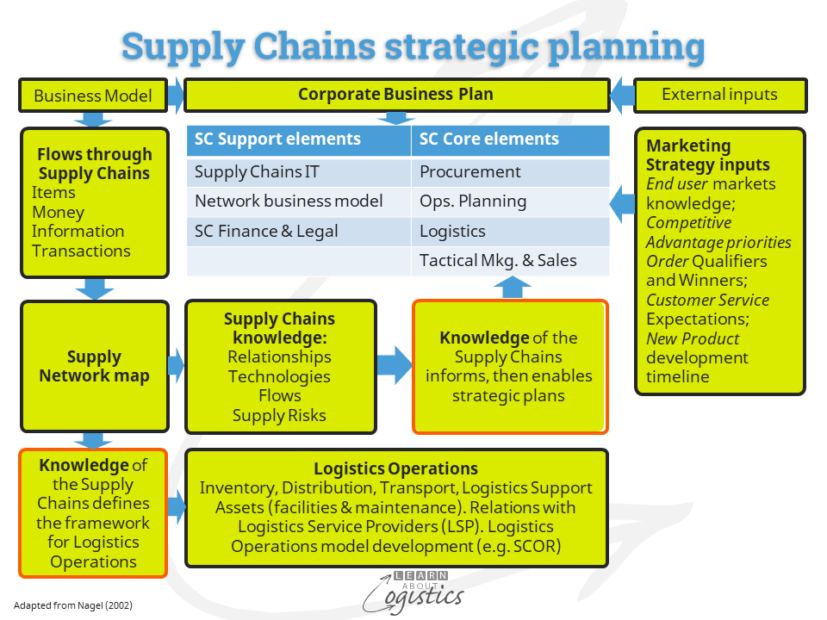

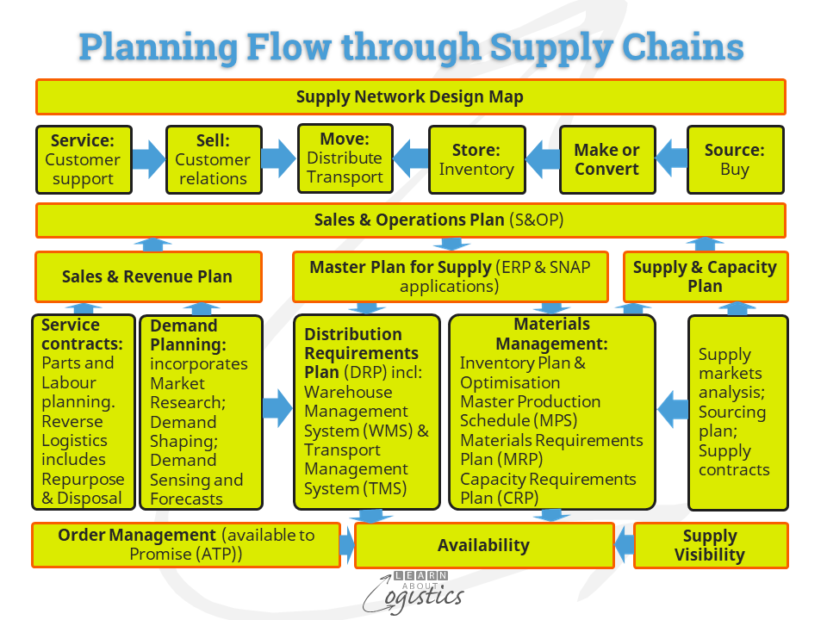

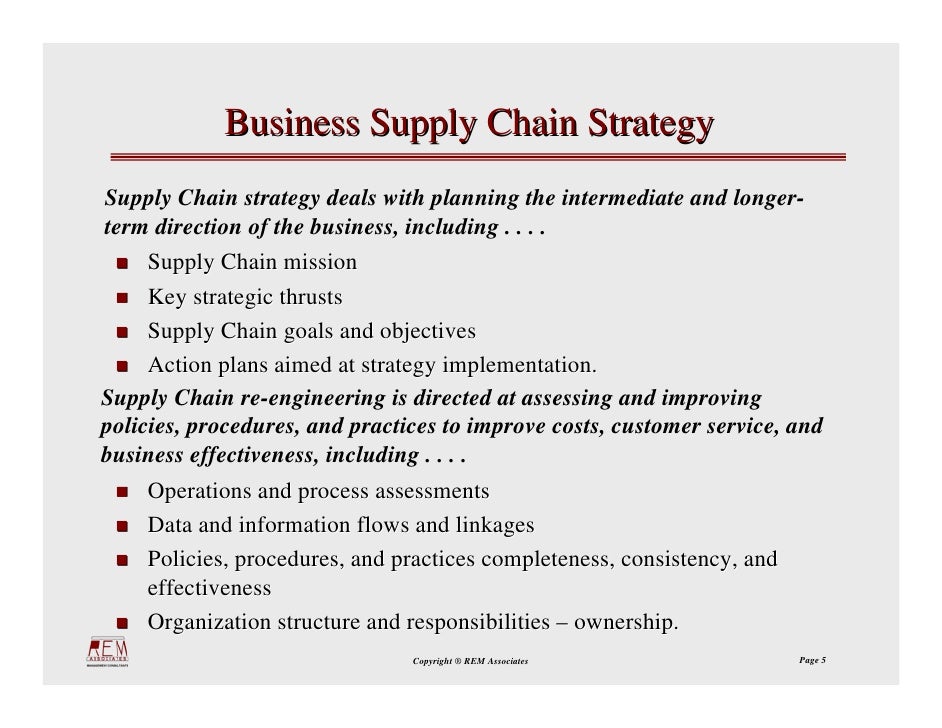

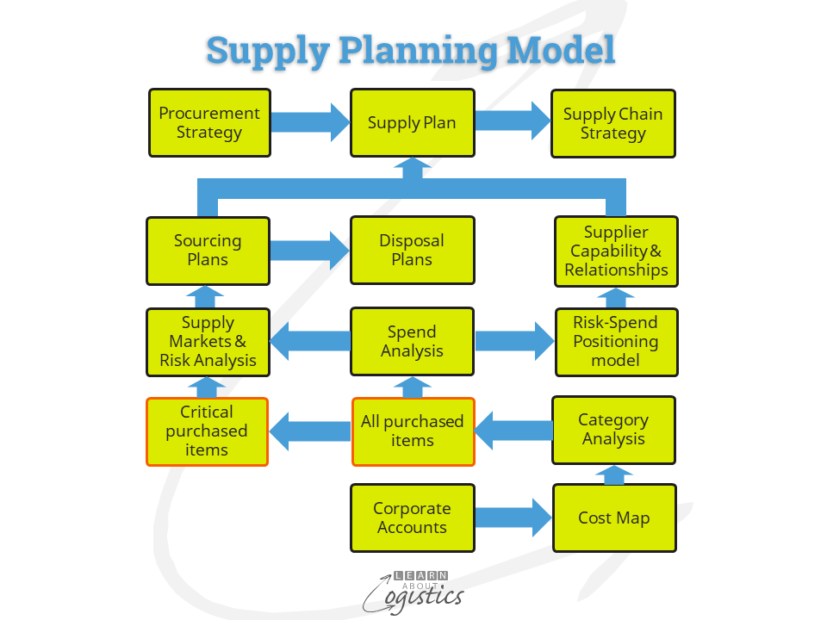

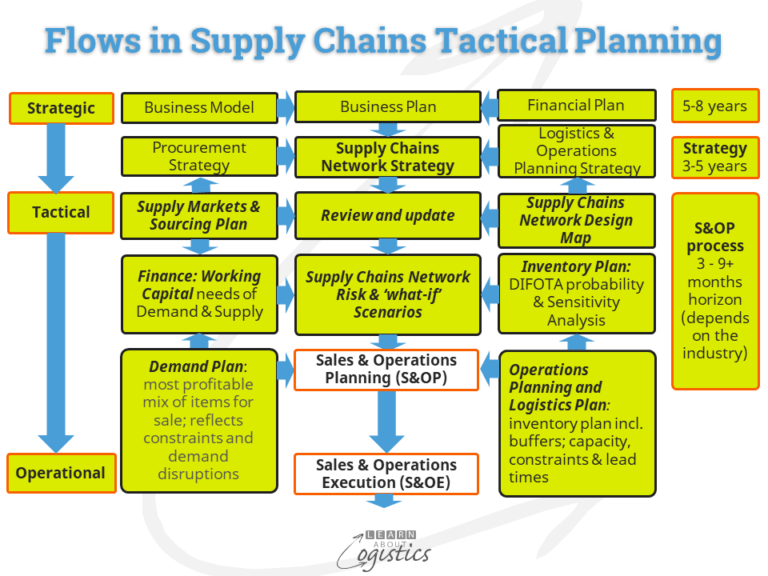

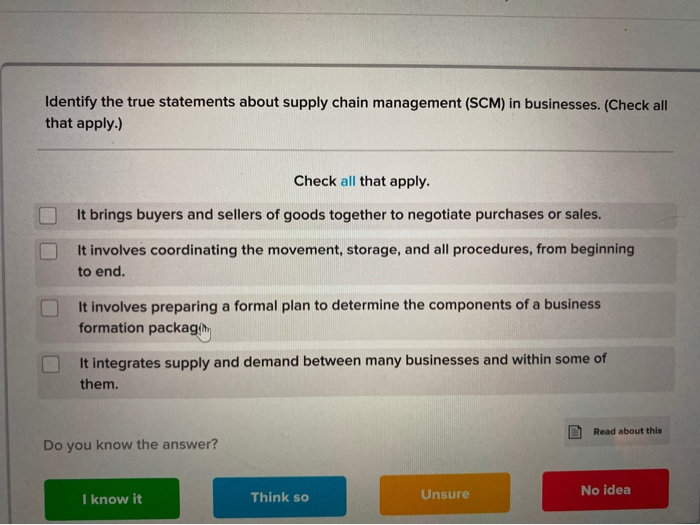

Supply chain planning is not merely about predicting future demand. It's a comprehensive process encompassing demand planning, supply planning, production planning, and distribution planning. Each area requires synchronized efforts for optimal performance.

Effective planning demands cross-functional collaboration. Sales, marketing, operations, and finance teams must communicate effectively and share information. Siloed departments can lead to inaccurate forecasts and misaligned strategies.

Furthermore, planning extends beyond internal operations. It necessitates close collaboration with suppliers and customers, including sharing forecasts and capacity information. This collaborative approach strengthens the entire supply chain.

Debunking Common Myths

A prevalent myth is that sophisticated software alone guarantees successful planning. While technology plays a vital role, it is merely a tool. Effective planning hinges on accurate data, robust processes, and skilled personnel.

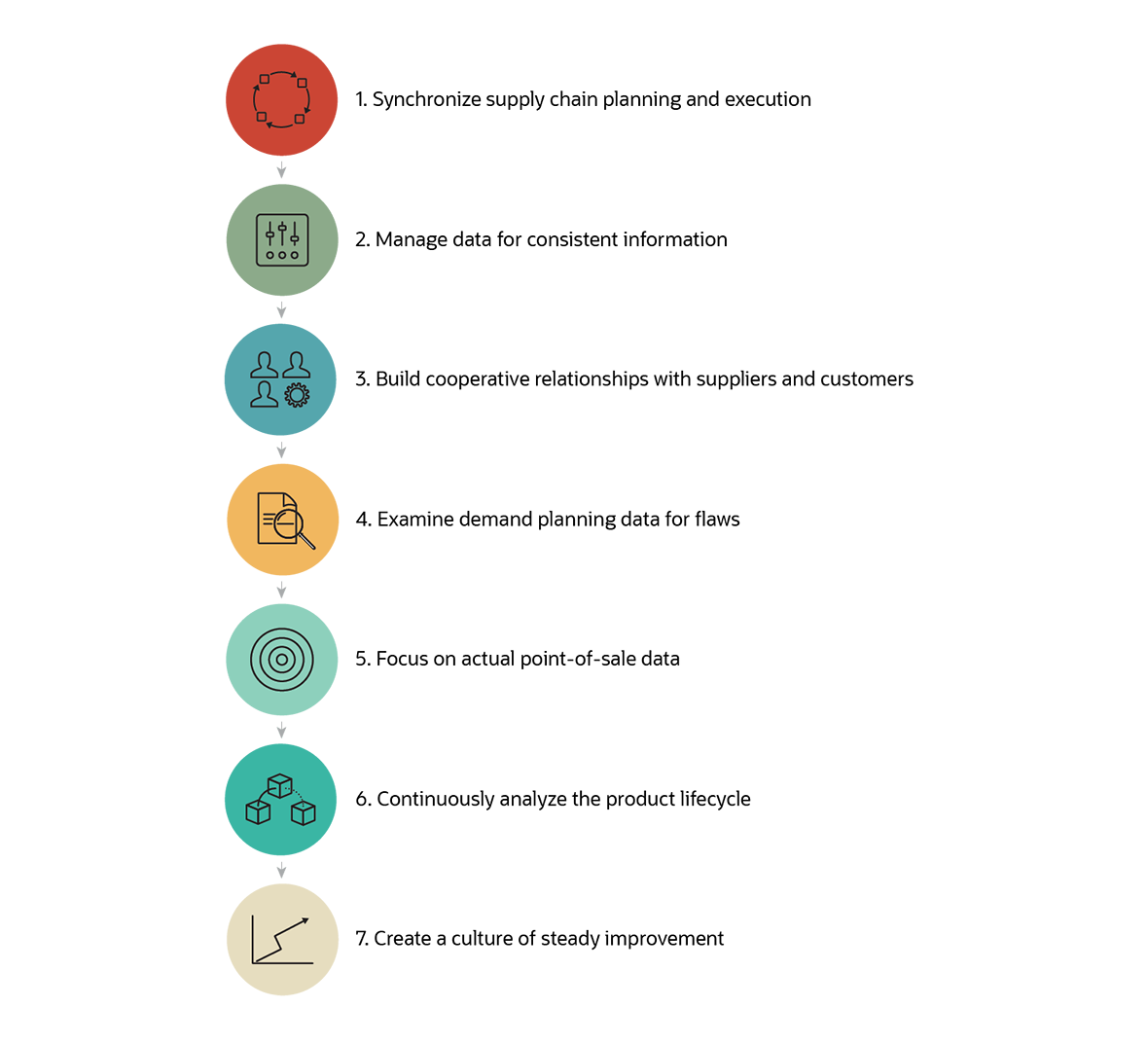

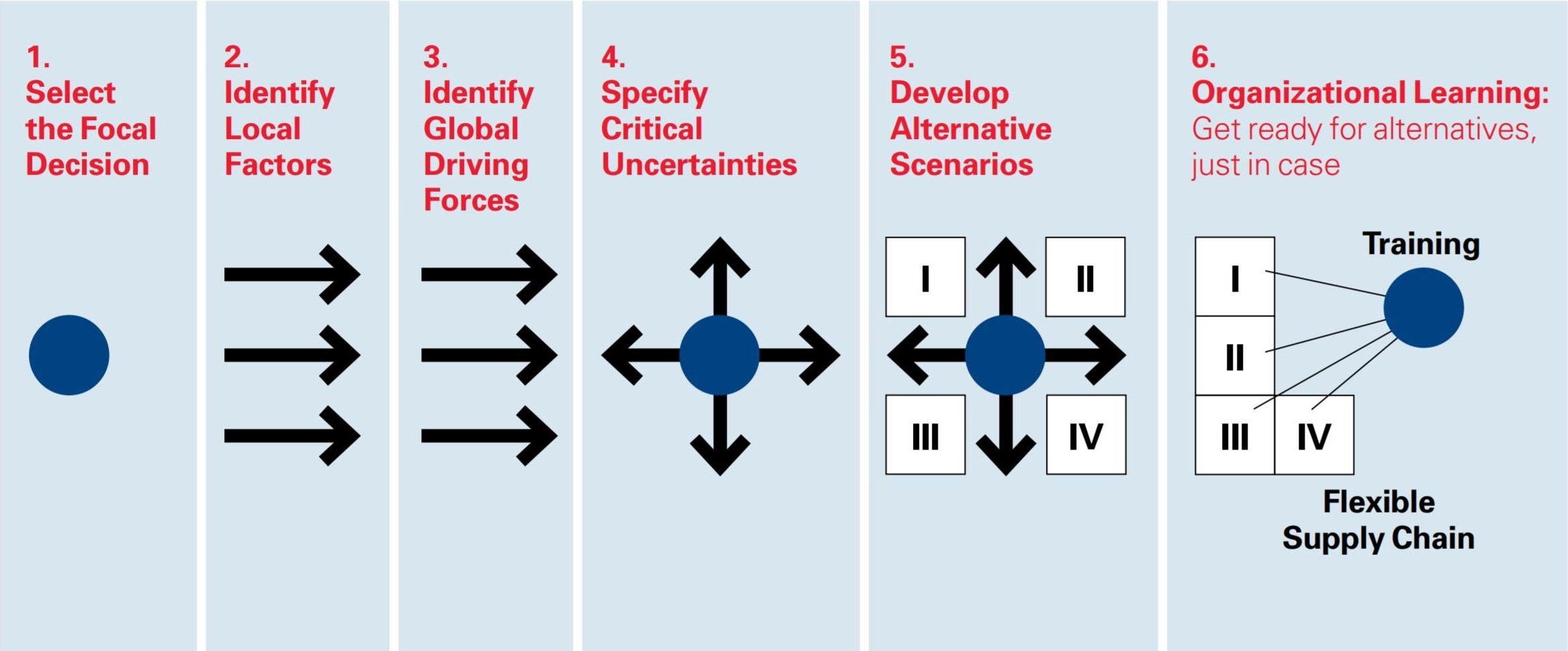

Another misunderstanding is that supply chain planning is a one-time event. In reality, it is an iterative process, requiring constant monitoring and adjustments. Market conditions, customer preferences, and unforeseen disruptions necessitate flexibility and responsiveness.

Static planning is a recipe for disaster. Supply chains must adapt quickly to change to remain competitive and efficient.

Essential Elements of Accurate Planning

Data accuracy is paramount in supply chain planning. Garbage in, garbage out: flawed data will inevitably lead to flawed forecasts and poor decisions. Implementing robust data governance policies is vital.

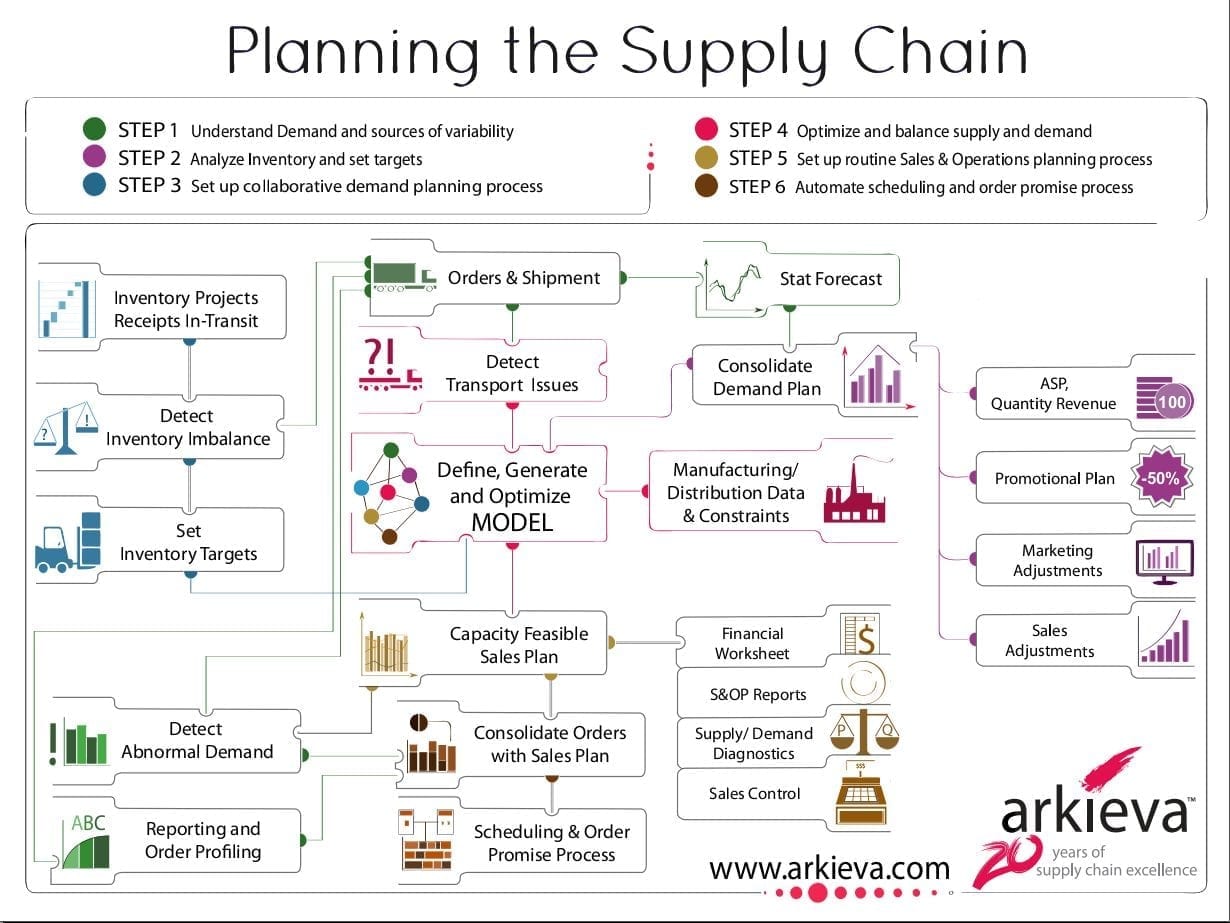

Demand forecasting should be based on a blend of historical data, market intelligence, and statistical modeling. Over-reliance on any single factor can introduce bias and inaccuracies. Consider incorporating external factors like economic indicators.

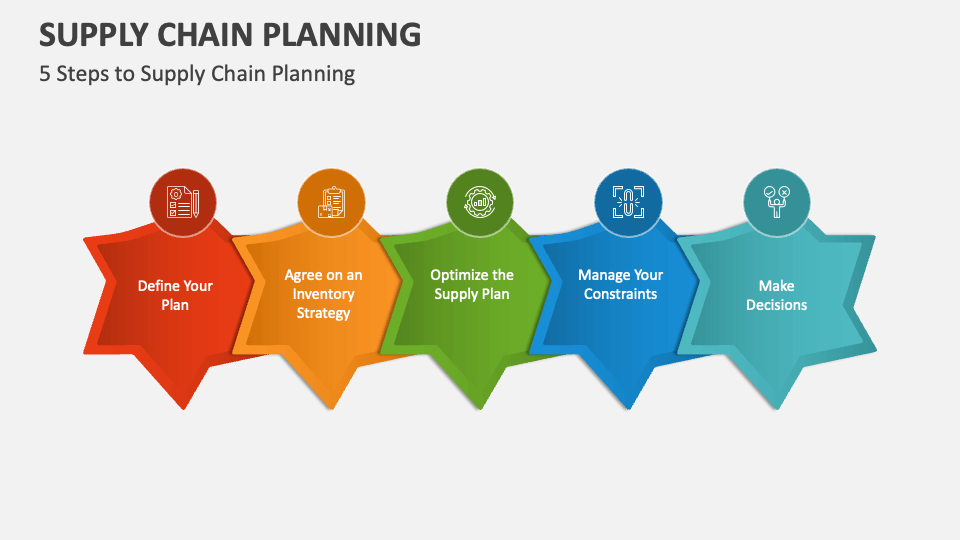

Scenario planning allows for the exploration of different potential futures and their corresponding impact on the supply chain. This proactive approach prepares businesses for various contingencies. What-if analysis can highlight vulnerabilities and opportunities.

The Role of Technology

Supply chain planning software offers valuable capabilities. This includes improved data visibility, automated forecasting, and optimized inventory management. However, it's crucial to select the right tools for the specific needs and complexities of the business.

Cloud-based solutions provide scalability and accessibility, enabling real-time collaboration across different locations. They also facilitate the integration of data from various sources.

Advanced analytics and machine learning are increasingly being used to enhance demand forecasting and optimize inventory levels. These technologies can identify patterns and trends that humans might miss.

Impact on Business Performance

Effective supply chain planning translates directly into improved business performance. Benefits include reduced inventory costs, minimized stockouts, and enhanced customer service. It can also lead to increased profitability and market share.

Optimized planning reduces waste and improves resource utilization. This aligns with sustainability goals and contributes to a more environmentally responsible operation.

Poor planning, conversely, can result in significant financial losses. Stockouts lead to lost sales and customer dissatisfaction. Excess inventory ties up capital and increases storage costs.

Human Element in Planning

While technology is important, the human element remains critical. Skilled supply chain planners are needed to interpret data, make informed decisions, and manage complex situations.

Training and development are essential to equip personnel with the necessary skills. They need to learn how to use planning tools effectively and to collaborate with stakeholders.

Ultimately, successful supply chain planning requires a combination of technology, robust processes, and skilled people. Ignoring any of these elements can undermine the entire effort.

Looking Ahead

The future of supply chain planning will likely be shaped by increasing data availability and advanced analytics. Businesses will need to adapt to these changes to stay competitive. This includes embracing digital transformation.

Resilience and agility will be increasingly important in the face of global disruptions. Supply chains must be designed to withstand unforeseen events and recover quickly. Redundancy and diversification are key strategies.

By focusing on data accuracy, collaboration, and continuous improvement, businesses can unlock the full potential of supply chain planning. This will enable them to optimize operations, reduce costs, and deliver exceptional customer value. Remember: a well-planned supply chain is a competitive advantage.