If A Food Contact Surface Is In Constant Use

Maintaining food safety in commercial kitchens and food processing plants is a constant battle, and a key question arises frequently: What happens when a food contact surface is in continuous use? The answer, surprisingly, isn't always straightforward, and depends heavily on the specific food, the cleaning protocols, and the regulatory environment.

This seemingly simple scenario opens a complex web of considerations, impacting everything from restaurant operations to large-scale food manufacturing. Understanding these factors is crucial for preventing foodborne illnesses and maintaining public health.

The Continuous Use Conundrum

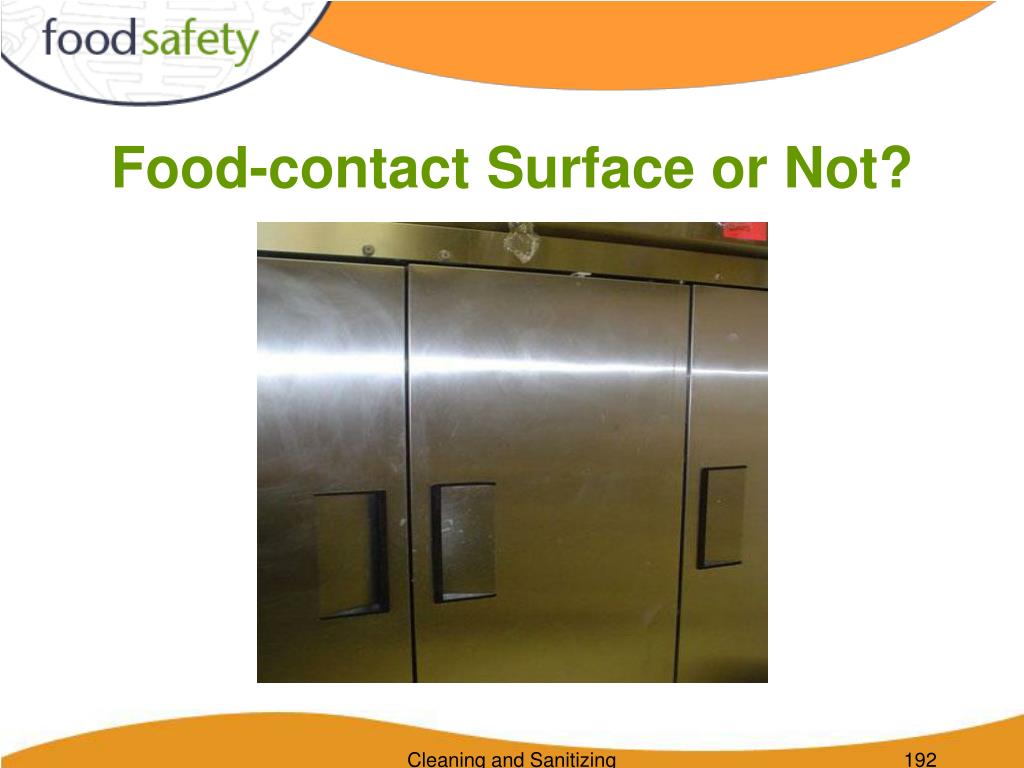

At its core, the challenge lies in balancing operational efficiency with hygiene. Food contact surfaces, such as cutting boards, conveyor belts, and mixing bowls, are constantly exposed to potential contaminants during active food preparation and processing.

The question then becomes: How long can these surfaces remain in use without posing a significant risk of cross-contamination? The U.S. Food and Drug Administration (FDA) offers guidance, but ultimately, the onus is on food operators to implement effective procedures.

FDA Guidelines and Recommendations

While the FDA doesn't prescribe a universal time limit for continuous use, it emphasizes the importance of scheduled cleaning and sanitizing. The FDA Food Code provides recommendations for cleaning frequency based on the type of food being handled.

Generally, surfaces used with raw animal products require more frequent cleaning than those used with ready-to-eat foods. The code also highlights the importance of visual inspection; if a surface appears soiled, it must be cleaned and sanitized immediately, regardless of the scheduled interval.

"Food contact surfaces shall be cleaned and sanitized at a frequency necessary to protect against contamination of food," states the FDA Food Code.

Factors Influencing Cleaning Frequency

Several factors influence the required frequency of cleaning. The type of food being processed is paramount.

High-risk foods, such as raw poultry or seafood, demand more rigorous and frequent sanitation. Temperature is another critical factor; warmer temperatures accelerate bacterial growth.

The type of equipment and its design also play a role. Complex equipment with hard-to-reach areas can be more challenging to clean effectively.

Best Practices for Continuous Use Scenarios

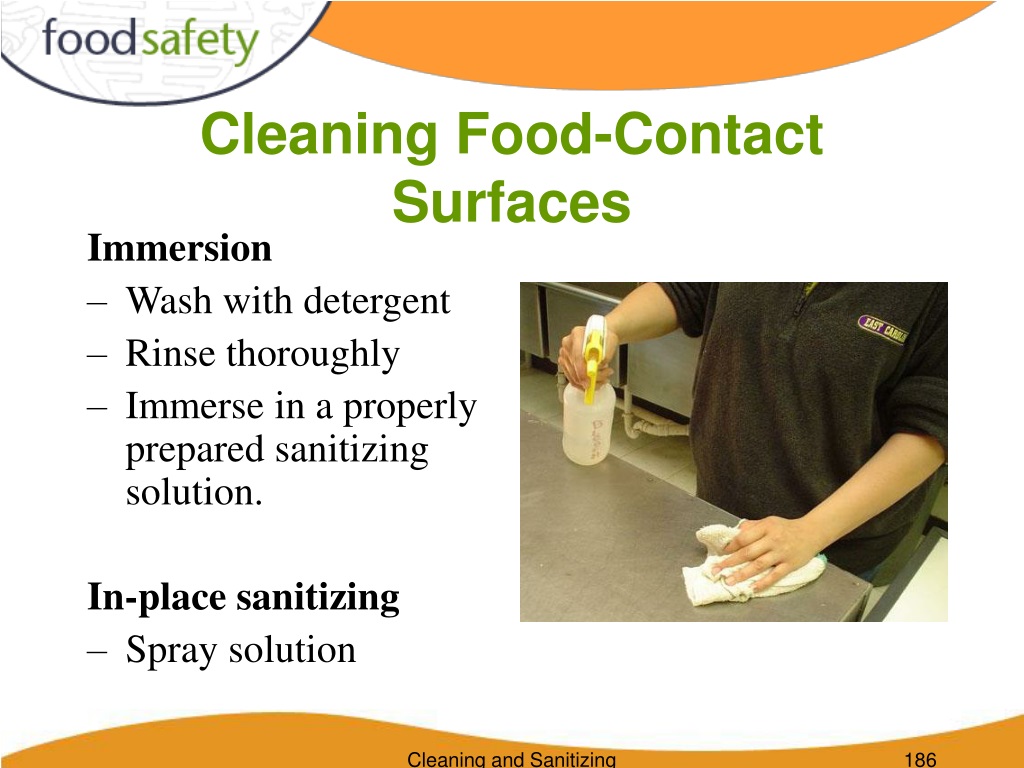

To manage food safety risks effectively during continuous use, food establishments should implement several key practices. These include creating and adhering to a strict cleaning schedule.

Using approved cleaning and sanitizing agents according to manufacturer instructions is crucial. Regularly inspecting and maintaining equipment to ensure it is cleanable and in good repair is also important.

Training staff on proper cleaning and sanitation procedures is paramount. Proper documentation of cleaning activities provides a record of compliance and helps identify potential issues.

The Human Element: Training and Compliance

Even with the best protocols in place, human error can compromise food safety. Thorough training is essential to ensure that staff understands the importance of cleaning and sanitation.

Regular refresher courses and spot checks can help reinforce best practices. Creating a culture of food safety, where employees feel empowered to report potential hazards, is vital.

This includes employees feeling comfortable stopping production if a surface is visibly soiled or if the cleaning schedule has not been followed.

Consequences of Non-Compliance

Failure to properly clean and sanitize food contact surfaces can have severe consequences. Foodborne illnesses can result, leading to customer sickness, reputational damage, and potential legal action.

Health inspections can lead to fines, temporary closures, or even permanent revocation of operating permits. Ultimately, neglecting food safety puts public health at risk.

A recent outbreak linked to improperly cleaned processing equipment serves as a stark reminder of the potential dangers. The outbreak resulted in dozens of illnesses and a widespread product recall, costing the company millions of dollars and severely damaging its brand image.

Balancing Efficiency and Safety

While frequent cleaning may seem disruptive to operations, it is a non-negotiable aspect of food safety. Finding the right balance between efficiency and safety requires careful planning and execution.

Implementing strategies such as having backup equipment available during cleaning periods can minimize downtime. Using rapid cleaning and sanitizing methods can also help maintain productivity without compromising hygiene.

The National Sanitation Foundation (NSF) offers certification for food equipment, ensuring it meets specific cleanability standards.

Technological Advancements

Emerging technologies are offering new solutions for maintaining food contact surface hygiene. Automated cleaning systems can streamline the cleaning process and reduce the risk of human error.

Antimicrobial coatings can inhibit bacterial growth on surfaces, providing an extra layer of protection. Real-time monitoring systems can track cleaning activities and alert staff to potential issues.

These innovations promise to make food safety more efficient and effective in the years to come.

The question of how long a food contact surface can be in continuous use without cleaning remains a nuanced one. While no single answer applies to all situations, a combination of stringent cleaning schedules, proper training, and the adoption of best practices are critical. By prioritizing food safety, establishments can protect public health and maintain consumer confidence.