Is An Agitator Or Impeller Better

Imagine a bustling brewery, the sweet, malty aroma thick in the air. Stainless steel tanks gleam under the bright lights, each one humming with activity. Inside, a silent battle rages: which device will best coax the flavors from the grain, ensuring the perfect pint? The contenders? The agitator and the impeller.

This seemingly simple question of whether an agitator or impeller reigns supreme in mixing processes has far-reaching implications across industries, from food and beverage production to pharmaceuticals and wastewater treatment. Understanding the nuances of each device, their strengths, and their limitations, is crucial for optimizing efficiency, consistency, and ultimately, the quality of the final product.

The Rise of Mixing: A Historical Perspective

Mixing, in its most rudimentary form, has been a part of human civilization for millennia. Early humans used simple tools like paddles and sticks to combine ingredients for food, medicine, and construction materials.

As technology advanced, so did the methods of mixing. The industrial revolution saw the development of more sophisticated mechanical mixers, paving the way for the modern agitators and impellers we use today.

Agitators: The Gentle Giant

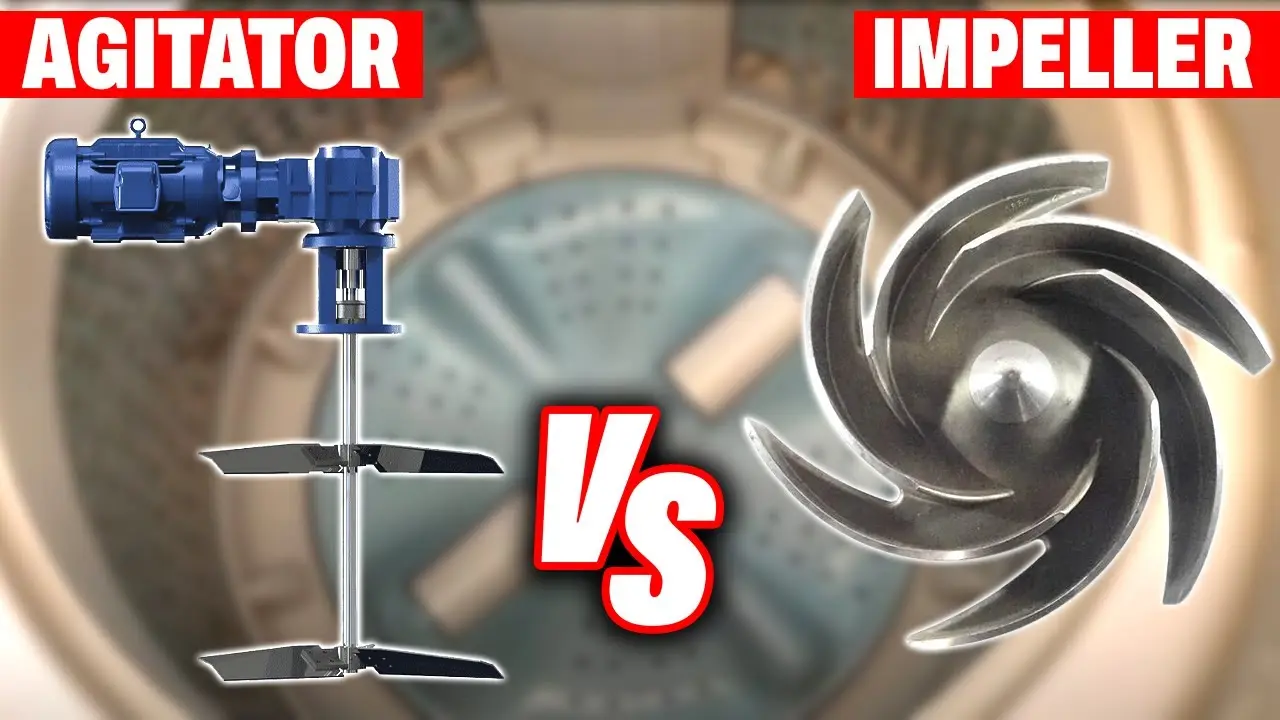

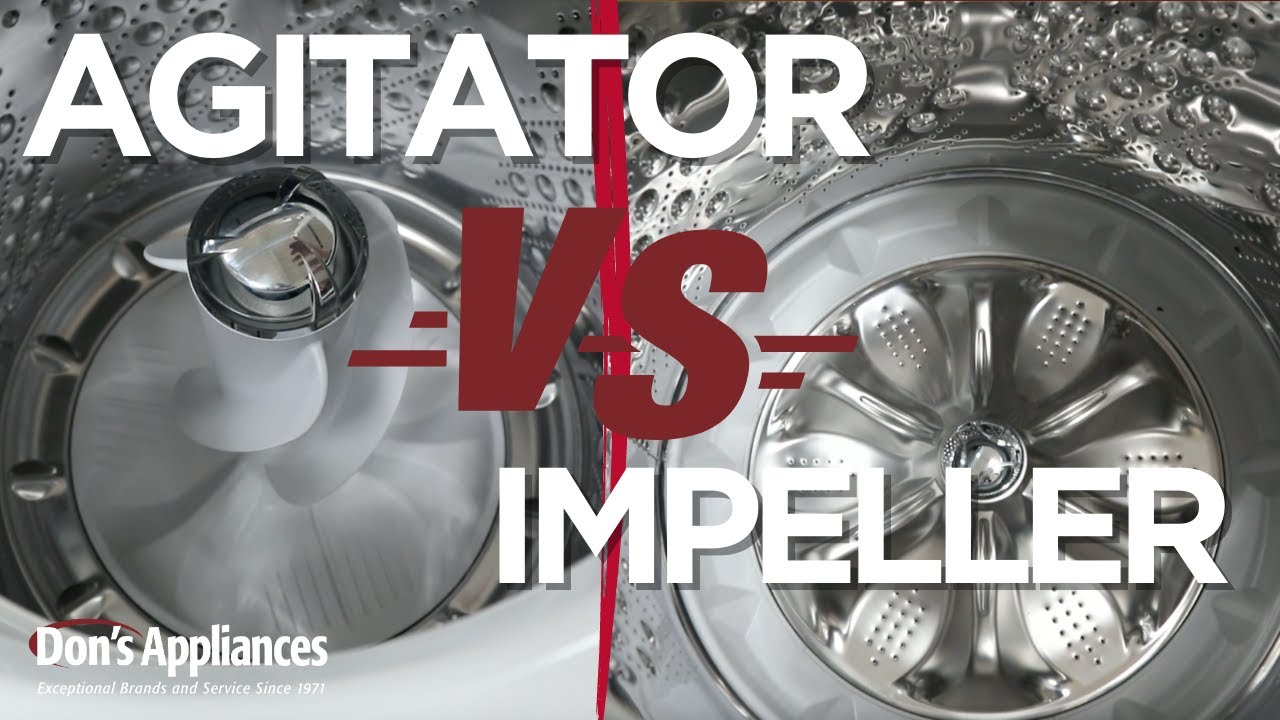

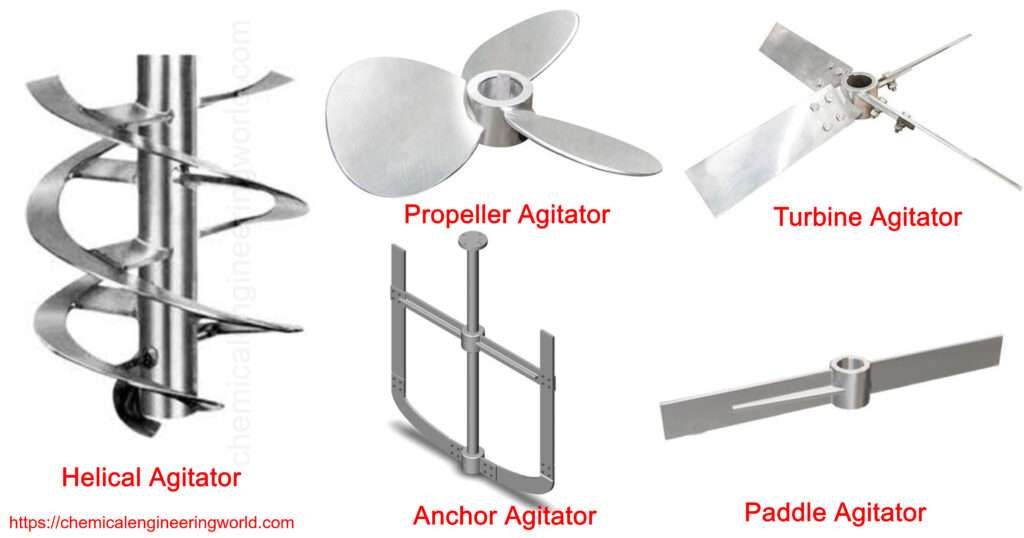

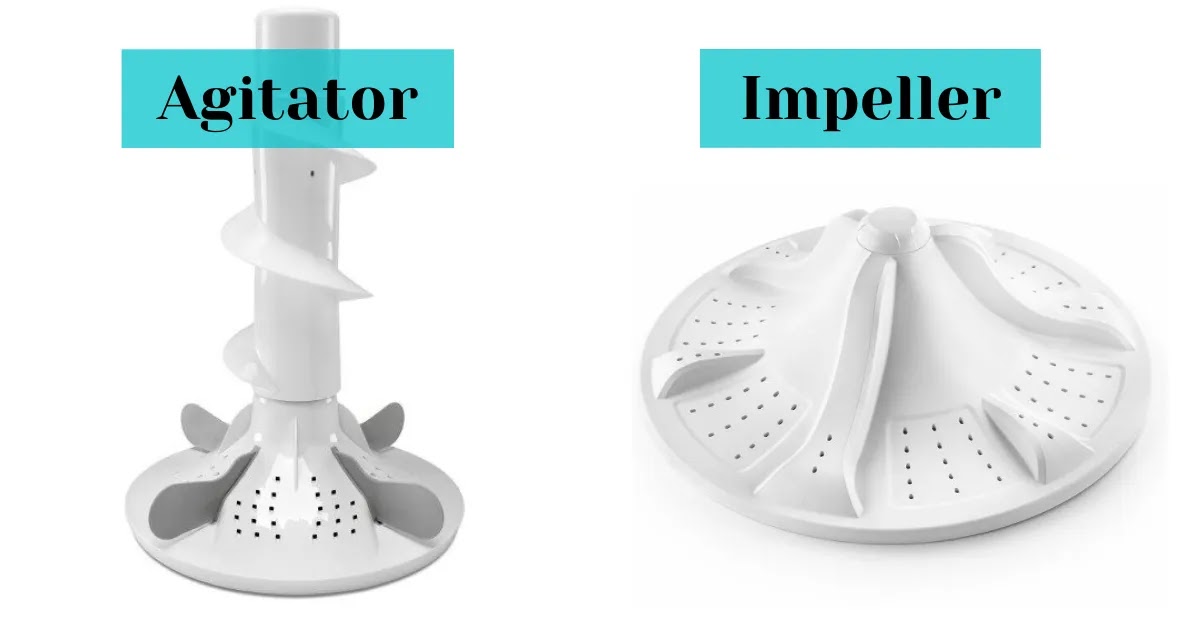

Agitators are typically characterized by their larger size and slower rotational speeds. Their primary function is to create bulk fluid movement within a tank.

Think of a large paddle sweeping through a swimming pool – that’s the general idea. They are particularly effective in processes where maintaining the integrity of the materials being mixed is paramount.

For example, in the production of certain delicate yogurt cultures, an agitator ensures even distribution of nutrients without damaging the fragile microorganisms.

Impellers: The Dynamic Dynamo

Impellers, on the other hand, are generally smaller and rotate at higher speeds. They excel at creating localized turbulence and shear within a fluid.

Imagine a small, rapidly spinning propeller in a boat – it creates a strong, focused stream of water. This intense mixing action is ideal for processes requiring emulsification or dispersion of solids into liquids.

Consider the production of paint, where pigments need to be uniformly dispersed throughout the base. An impeller's high shear action effectively breaks down agglomerates, resulting in a smooth, consistent color.

Key Differences: Unveiling the Nuances

The choice between an agitator and an impeller hinges on several factors, including the viscosity of the fluid, the size of the tank, and the specific requirements of the mixing process.

Agitators are generally preferred for large tanks with viscous fluids, where bulk fluid movement is more important than intense mixing. They are also often used when gentle mixing is required to prevent damage to sensitive materials.

Impellers are better suited for smaller tanks and less viscous fluids, where high shear and localized turbulence are needed. They are also more effective at dispersing solids and creating emulsions.

Another crucial factor is power consumption. Agitators typically require less power than impellers, making them a more energy-efficient option for certain applications.

Real-World Applications: A Diverse Landscape

The applications of agitators and impellers are incredibly diverse, spanning a wide range of industries. In the food and beverage industry, they are used to mix ingredients for everything from sauces and dressings to beer and wine.

In the pharmaceutical industry, they play a critical role in the production of drugs and vaccines, ensuring consistent and homogenous mixtures. Wastewater treatment plants rely on agitators and impellers to mix chemicals and promote biological activity in treatment tanks.

Even in the cosmetics industry, these devices are used to create everything from lotions and creams to shampoos and conditioners. According to a report by Freedonia Group, the global market for industrial mixers is projected to reach billions of dollars in the coming years, highlighting the continued importance of these essential pieces of equipment.

Beyond the Basics: Advanced Mixing Technologies

While agitators and impellers remain the workhorses of the mixing industry, advancements in technology have led to the development of more specialized mixing devices.

Static mixers, for example, use a series of baffles or elements within a pipe to create turbulence and promote mixing as fluid flows through them. These devices are particularly useful for continuous mixing applications where a constant flow rate is maintained.

Magnetic mixers, which use a rotating magnetic field to drive a mixing element within a closed container, are often used in sterile or hazardous environments where contact between the mixing device and the fluid must be avoided.

Making the Right Choice: A Balancing Act

Ultimately, the "better" choice between an agitator and an impeller depends entirely on the specific application. There is no one-size-fits-all solution.

Careful consideration must be given to the properties of the fluid being mixed, the size and shape of the tank, the desired level of mixing, and the energy efficiency requirements.

Consulting with experienced engineers and conducting thorough testing can help ensure that the optimal mixing device is selected for each individual process. Selecting the right mixing equipment is not just about choosing a device; it's about understanding the chemistry, physics, and engineering principles that govern the mixing process.

The Future of Mixing: Innovation and Sustainability

The future of mixing technology is likely to be driven by a growing emphasis on efficiency, sustainability, and automation.

Researchers are exploring new impeller designs and mixing strategies that can reduce energy consumption and improve mixing performance. There's a growing focus on developing more compact and efficient mixing systems that can be easily integrated into existing production lines.

Moreover, the rise of Industry 4.0 is leading to the development of smart mixing systems that can be remotely monitored and controlled, optimizing performance and minimizing downtime.

As we look ahead, the quest for the perfect mix will continue to drive innovation in the field of mixing technology. Whether it's an agitator gently coaxing delicate flavors or an impeller vigorously dispersing pigments, these essential devices will continue to play a vital role in countless industries around the globe.

The gentle churn of an agitator, the energetic whirl of an impeller: each a testament to the power of controlled movement. As we close the lid on this exploration, perhaps you'll look at the smoothly blended products in your own life with a newfound appreciation for the science, and the subtle art, of mixing.