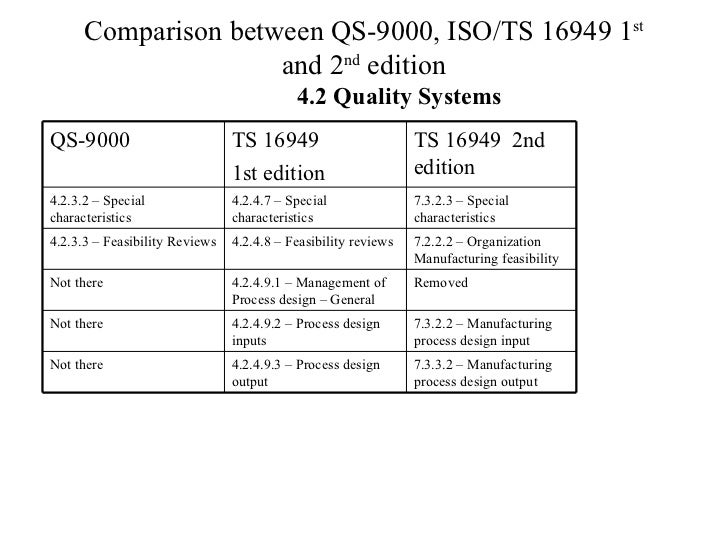

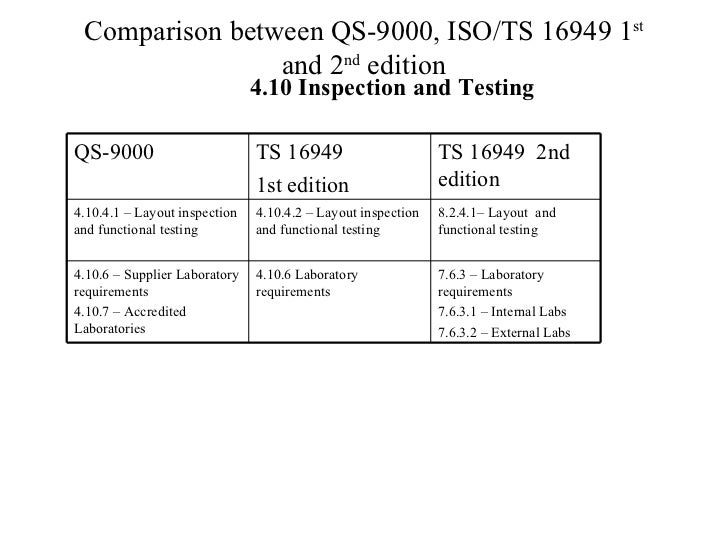

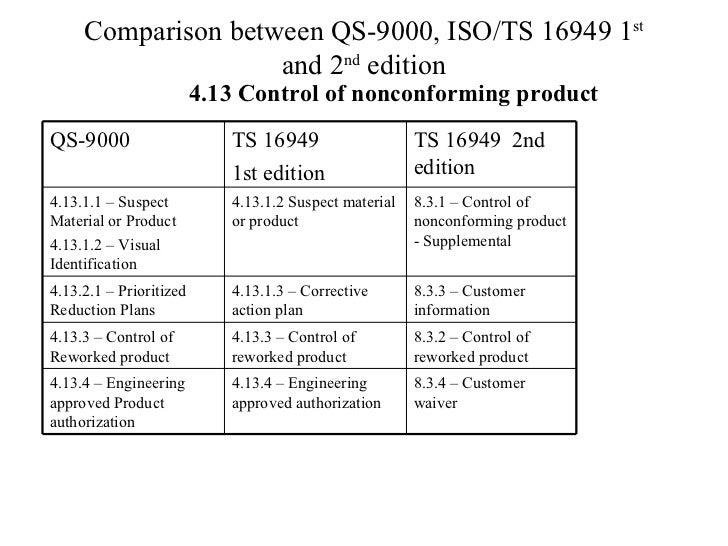

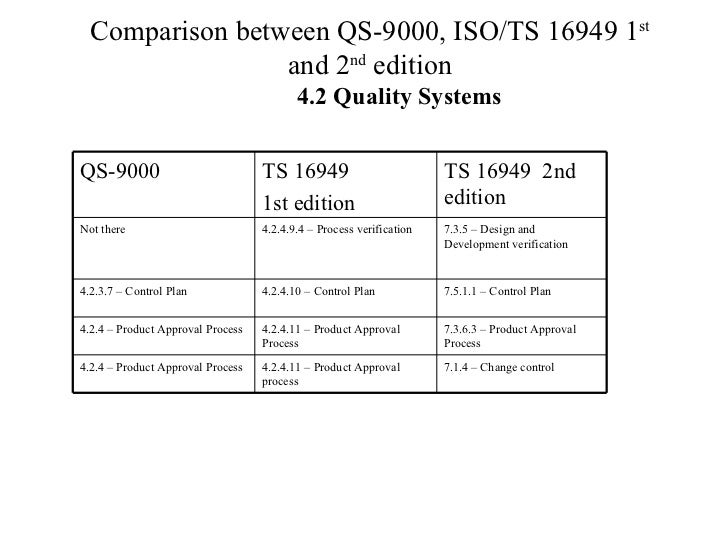

Iso 9001 Ts 16949 Comparison Matrix

In the high-stakes world of manufacturing, particularly within the automotive sector, adherence to stringent quality management systems is not merely a preference, but an absolute necessity. The pursuit of operational excellence and customer satisfaction hinges upon robust frameworks that ensure consistent product quality and continuous improvement. Two prominent standards, ISO 9001 and IATF 16949, often find themselves at the forefront of this pursuit, prompting organizations to meticulously weigh their respective merits.

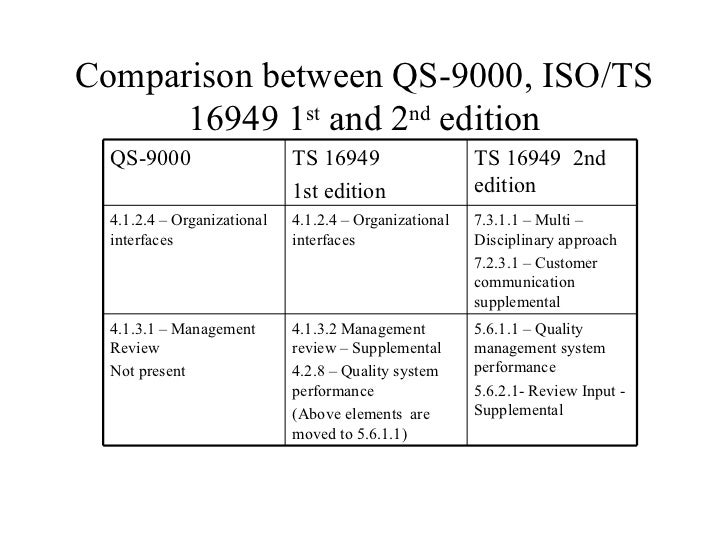

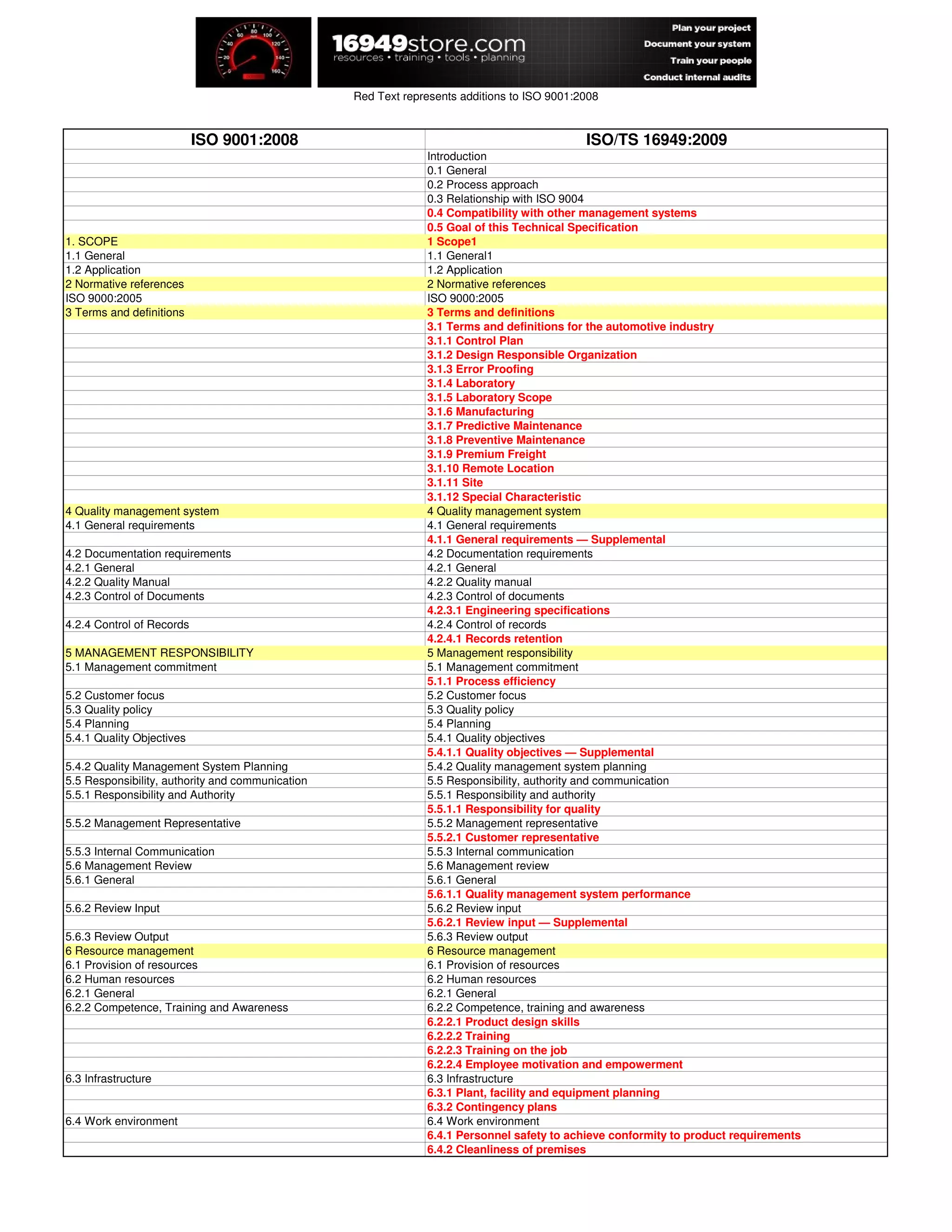

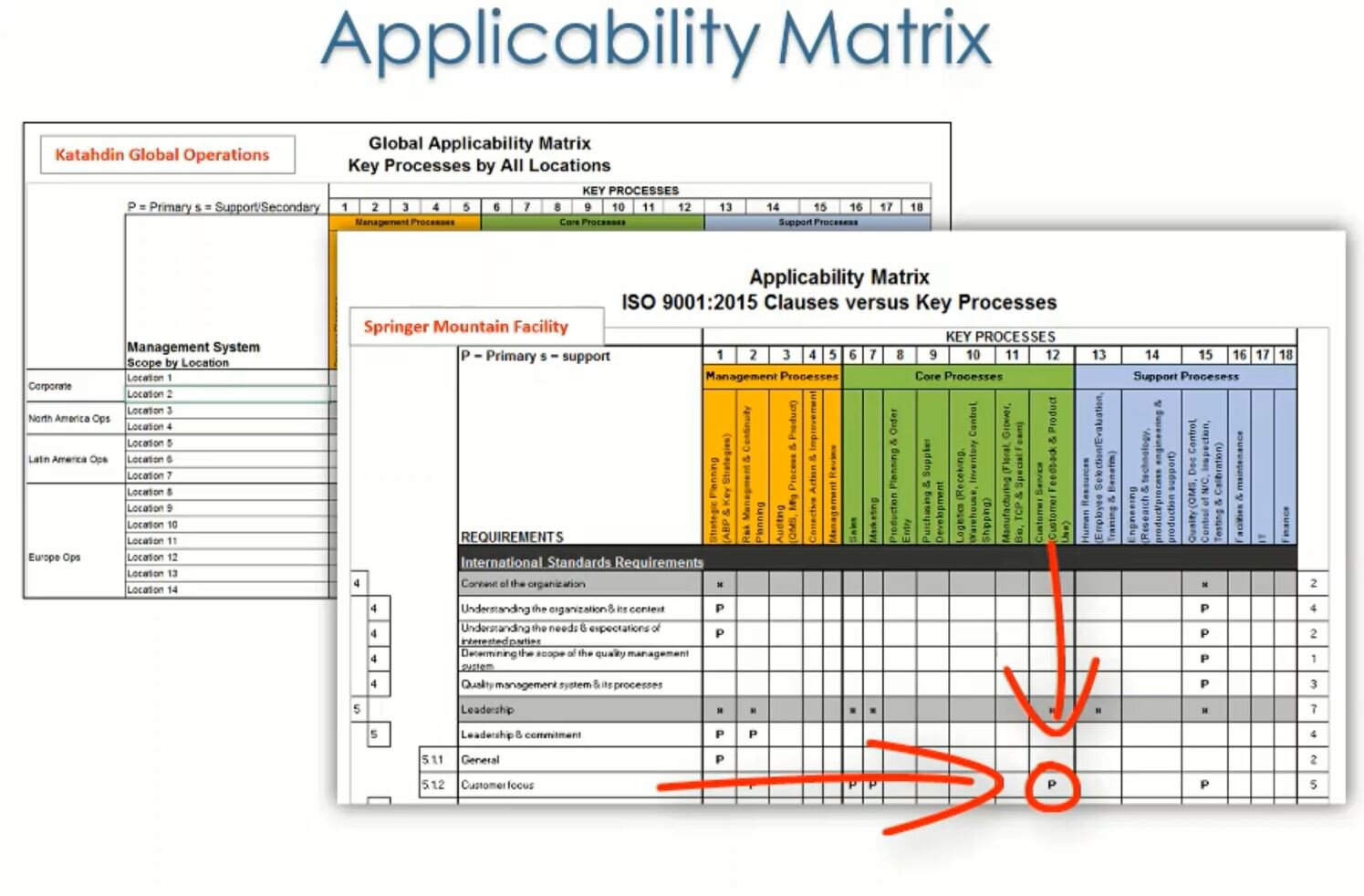

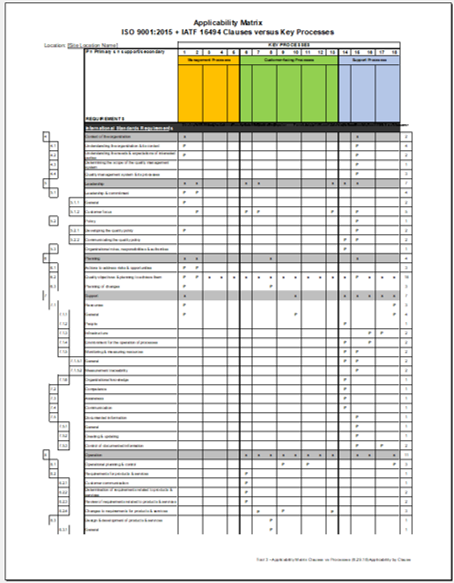

Understanding the nuances between ISO 9001, the globally recognized standard for quality management systems, and IATF 16949, the automotive industry's specialized derivative, is crucial. This article delves into a comprehensive comparison, providing a detailed matrix to elucidate their similarities, differences, and the strategic considerations for choosing the optimal standard for a given manufacturing context. We will explore the key elements of each standard, highlighting their impact on organizational processes, customer satisfaction, and overall business performance.

ISO 9001: The Foundation of Quality Management

ISO 9001, published by the International Organization for Standardization (ISO), serves as a foundational standard applicable to any organization, regardless of size, industry, or geographic location. It provides a framework for establishing, implementing, maintaining, and continually improving a quality management system (QMS). The standard is based on seven quality management principles, including customer focus, leadership, engagement of people, process approach, improvement, evidence-based decision making, and relationship management.

Its widespread adoption stems from its generic nature, offering a structured approach to consistently meeting customer requirements and enhancing customer satisfaction. ISO 9001 certification demonstrates a commitment to quality and provides a competitive advantage in the global marketplace. Many organizations use ISO 9001 as a stepping stone before pursuing more specialized industry standards.

IATF 16949: Automotive-Specific Excellence

IATF 16949, developed by the International Automotive Task Force (IATF), is a technical specification for automotive quality management systems. It is specifically designed to meet the unique challenges and requirements of the automotive industry. IATF 16949 builds upon the principles of ISO 9001, incorporating automotive-specific requirements related to continuous improvement, defect prevention, and reduction of variation and waste in the supply chain.

Compliance with IATF 16949 is often a prerequisite for doing business with major automotive manufacturers. It focuses heavily on risk management, error-proofing, and robust product design. The standard emphasizes the importance of customer-specific requirements and aims to create a culture of quality throughout the entire automotive supply chain.

Comparison Matrix: Key Differences and Similarities

Scope and Applicability

ISO 9001: Applicable to all organizations, regardless of industry.

IATF 16949: Specifically designed for automotive manufacturers and their suppliers.

Customer-Specific Requirements

ISO 9001: Addresses customer requirements in a general sense.

IATF 16949: Emphasizes strict adherence to customer-specific requirements and expectations.

Continuous Improvement

ISO 9001: Promotes continuous improvement as a core principle.

IATF 16949: Requires a more rigorous and documented approach to continuous improvement, including specific tools and techniques like APQP and PPAP.

Risk Management

ISO 9001: Addresses risk management at a high level.

IATF 16949: Requires a more comprehensive and formalized risk management process, including FMEA (Failure Mode and Effects Analysis).

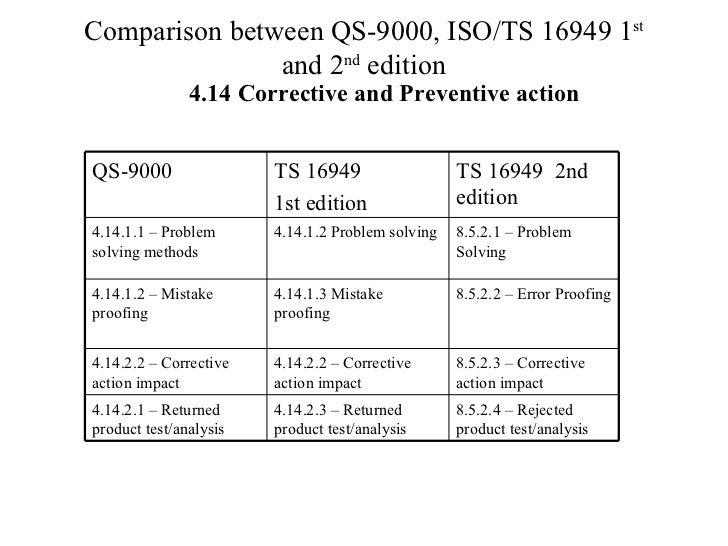

Defect Prevention

ISO 9001: Focuses on preventing defects through process control.

IATF 16949: Requires proactive defect prevention measures and error-proofing techniques.

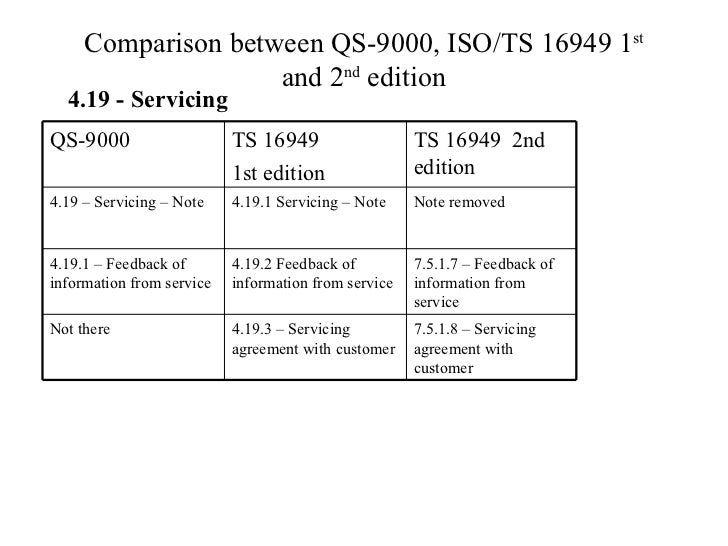

Supply Chain Management

ISO 9001: Addresses supply chain management in a general manner.

IATF 16949: Places a strong emphasis on supply chain control and supplier development.

Strategic Considerations: Choosing the Right Standard

The decision of whether to pursue ISO 9001 or IATF 16949 hinges on several key factors. Organizations that primarily serve the automotive industry should strongly consider IATF 16949, as it is often a contractual requirement. Companies operating in other sectors may find ISO 9001 sufficient to demonstrate their commitment to quality.

Furthermore, organizations can consider ISO 9001 as a foundational step towards IATF 16949. Organizations that have already achieved ISO 9001 certification may find the transition to IATF 16949 smoother. Consider the cost and resources required for implementation and certification for both standards.

The Future of Quality Management in Manufacturing

As the manufacturing landscape continues to evolve, both ISO 9001 and IATF 16949 will remain critical benchmarks for quality management systems. The rise of Industry 4.0 and advanced manufacturing technologies will likely drive further refinements and adaptations to these standards. Expect an increased focus on data analytics, automation, and real-time monitoring in future revisions. The continuous pursuit of excellence will necessitate a deeper integration of these standards with emerging technologies.

.JPG)

.JPG)