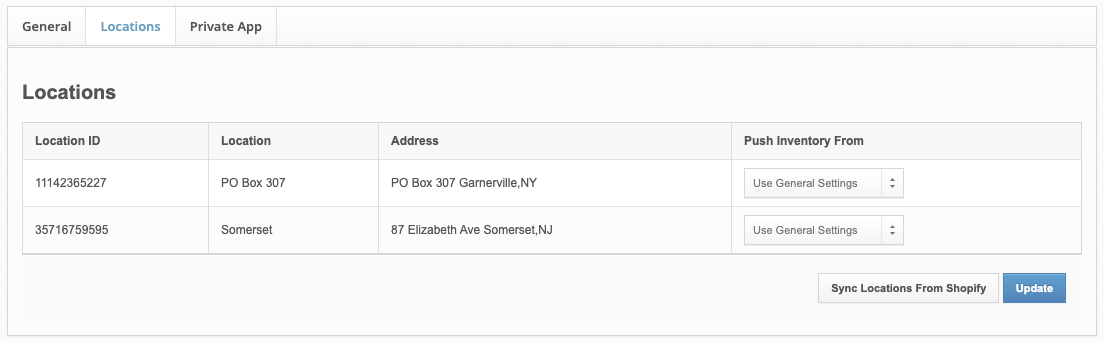

Opush Inventory From Specific Warehouse Shipheor

The global supply chain is once again facing turbulence as a significant disruption hits the distribution of goods from a specific warehouse belonging to Shipheor, a major international logistics firm. Retailers and manufacturers worldwide are bracing for potential delays and inventory shortages as the situation unfolds, sparking concerns across various sectors.

The incident, confirmed by Shipheor in an official statement released earlier today, centers around its primary distribution hub located in Rotterdam, Netherlands. This so-called "Opush Inventory" issue, as internal documents refer to it, appears to be stemming from a combination of factors, including a recent cyberattack, labor disputes, and an unforeseen surge in demand, creating a perfect storm of logistical challenges.

The Rotterdam Hub: A Critical Node

The Rotterdam warehouse serves as a crucial point in Shipheor's network, handling a substantial volume of goods destined for Europe, North America, and Asia. Its strategic location and advanced automation systems have made it a cornerstone of the company’s global operations. Any interruption at this facility sends ripples throughout the entire system.

According to data from the Port of Rotterdam Authority, the warehouse processes approximately 15% of all inbound and outbound cargo passing through the port annually. This highlights the sheer scale of its operations and the potential impact of any disruptions.

The Genesis of the Opush Inventory Problem

Multiple factors contributed to the current bottleneck. Shipheor acknowledged a sophisticated ransomware attack that targeted its inventory management systems last week. While the company asserts that sensitive customer data was not compromised, the attack severely hampered its ability to track and process shipments accurately.

Recovery efforts are ongoing, but system glitches continue to plague operations. Furthermore, a series of labor disputes related to wage negotiations and working conditions further exacerbated the problem.

These disputes led to intermittent work stoppages and slower processing times. Finally, a sudden surge in demand for electronics components, particularly semiconductors, placed additional strain on the already stressed infrastructure.

Impact on Businesses and Consumers

The Opush Inventory issue is already impacting businesses of all sizes. Many retailers are reporting delays in receiving critical merchandise, leading to empty shelves and frustrated customers. “We were expecting a large shipment of winter apparel next week, but Shipheor just informed us that it will be delayed indefinitely,” said Sarah Chen, owner of a boutique clothing store in Chicago.

“This could severely impact our holiday sales.” Manufacturers are also struggling to secure the raw materials and components needed for production. A spokesperson for a major automotive manufacturer stated that the delays are forcing them to consider temporary plant closures.

The increased wait times could lead to higher consumer prices. The uncertainty in the supply chain contributes to inflationary pressures. A recent report by the International Monetary Fund warned that persistent supply chain disruptions could lead to a further increase in global inflation rates.

Shipheor's Response and Mitigation Efforts

Shipheor is actively working to resolve the Opush Inventory problem. The company has deployed a team of cybersecurity experts to restore its systems and bolster its defenses against future attacks.

"We are committed to resolving this issue as quickly as possible and minimizing the impact on our customers,"stated Mark Olsen, CEO of Shipheor, in a press conference.

They are collaborating with local law enforcement and international cybersecurity agencies to investigate the attack. In addition, Shipheor is engaging in negotiations with labor unions to resolve the ongoing disputes and restore normalcy to its workforce.

The company is exploring alternative transportation routes and distribution centers to bypass the Rotterdam bottleneck. Shipheor has invested heavily in additional trucking capacity and is temporarily rerouting some shipments through alternative ports in Antwerp and Hamburg.

Potential Long-Term Solutions and Implications

The current crisis highlights the need for greater resilience and diversification in global supply chains. Companies are re-evaluating their reliance on single points of failure and exploring strategies to mitigate future disruptions. Nearshoring and reshoring initiatives are gaining traction as businesses seek to bring production closer to home.

The incident also underscores the importance of cybersecurity and the need for robust defenses against cyberattacks. Companies must invest in advanced threat detection and prevention technologies. They should conduct regular security audits and provide comprehensive training to their employees.

Looking ahead, the Opush Inventory problem at Shipheor’s Rotterdam hub serves as a stark reminder of the fragility of the interconnected global economy. The situation may lead to lasting changes in supply chain management and logistics.