Price Of Carbon Fibre Per Kg

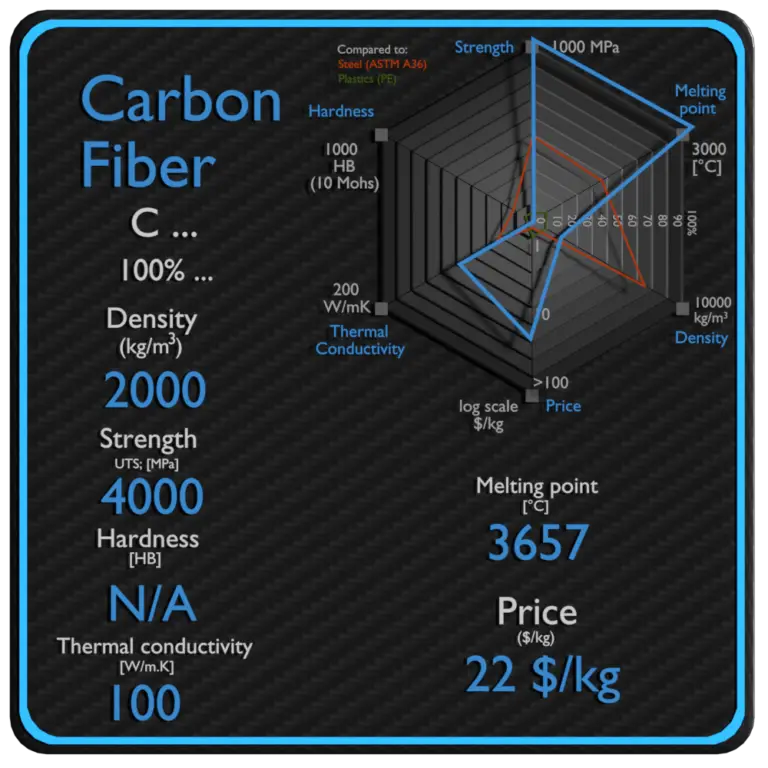

The price of carbon fiber, a material prized for its exceptional strength-to-weight ratio, is a complex and dynamic figure influenced by numerous factors ranging from raw material costs to manufacturing processes and market demand. Understanding these fluctuations is crucial for industries heavily reliant on this advanced material, including aerospace, automotive, and renewable energy.

While pinpointing a single, definitive price per kilogram is challenging due to variations in grade, quantity purchased, and supplier, this article aims to provide a comprehensive overview of the key drivers affecting carbon fiber pricing and its potential implications.

Key Factors Influencing Carbon Fiber Pricing

The cost of carbon fiber production is significantly impacted by the price of its primary precursor: polyacrylonitrile (PAN). Any disruption in the supply chain or increase in the price of PAN inevitably translates to higher carbon fiber costs.

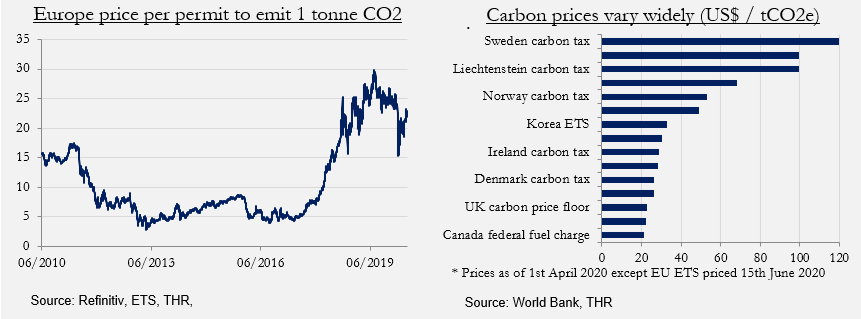

Energy consumption is another substantial factor. The high temperatures required during the carbonization process make carbon fiber manufacturing an energy-intensive undertaking.

Manufacturing processes themselves contribute significantly to the final price. Different production techniques, such as using different grades of PAN, result in different levels of carbon fibre strength.

Supply and Demand Dynamics

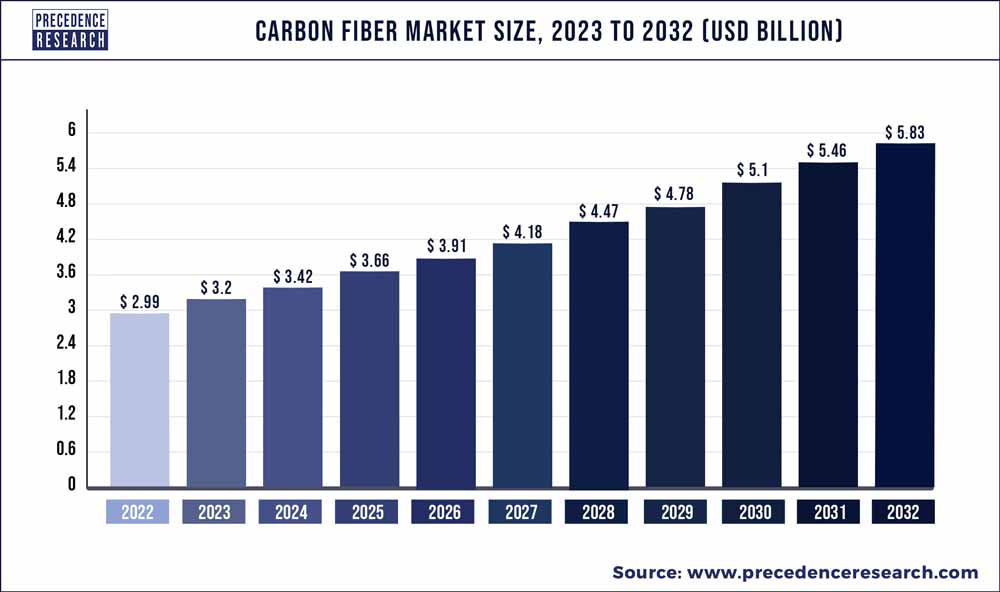

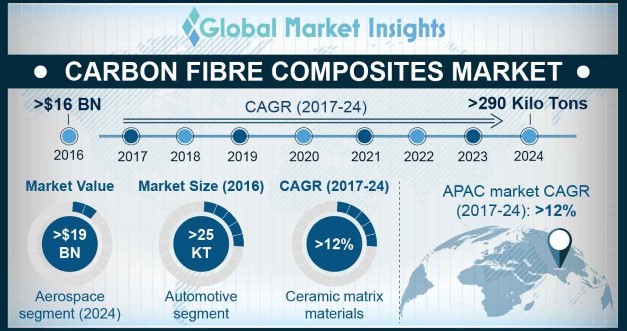

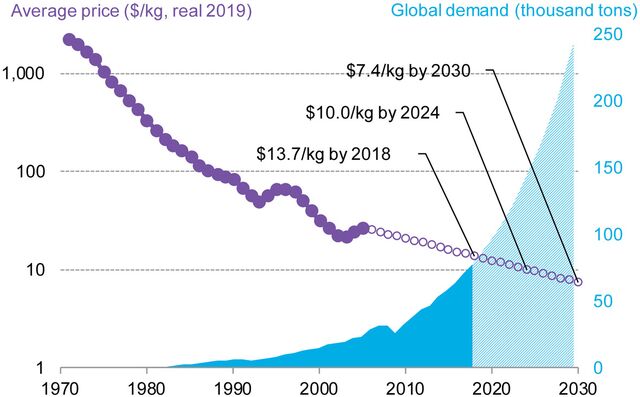

Increased demand from sectors like aerospace (for lighter, more fuel-efficient aircraft) and automotive (for electric vehicles and performance cars) puts upward pressure on prices. Simultaneously, advancements in manufacturing processes and increased production capacity can, conversely, lead to price decreases.

The availability of high-quality carbon fiber also plays a pivotal role. Limited supply, whether due to production constraints or geopolitical factors, will naturally drive prices upward.

Grade and Quality

The strength and stiffness of carbon fiber are directly related to its grade, and higher-grade carbon fiber commands a premium price. Aerospace-grade carbon fiber, for instance, undergoes stringent testing and meets demanding specifications, justifying its higher cost.

Lower-grade, or industrial-grade, carbon fiber is often used in applications where high strength isn't as critical, such as sporting goods or certain automotive components. This naturally results in lower costs.

Current Market Trends

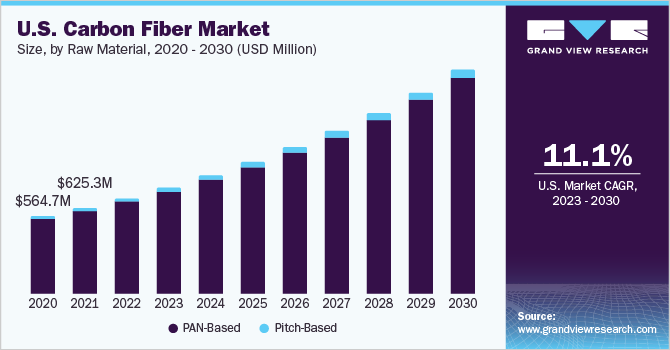

According to a recent report by Lucintel, the global carbon fiber market is projected to reach $5.6 billion by 2028, driven by increasing demand from various end-use industries. This growth suggests a continued upward pressure on prices, although advancements in manufacturing technology may partially offset this trend.

The automotive industry's shift towards electric vehicles (EVs) is also a significant driver. Carbon fiber's lightweight properties can significantly improve the range and performance of EVs, but it also increases demand.

Toray Industries, a leading carbon fiber manufacturer, has announced investments in expanding production capacity, indicating a strategic move to meet growing demand and potentially stabilize prices in the long run.

Price Ranges and Estimates

While precise figures are constantly fluctuating, general estimates can be provided. Industrial-grade carbon fiber can range from $10 to $25 per kilogram. Aerospace-grade carbon fiber, due to its superior properties and stringent manufacturing processes, typically commands a price of $70 per kilogram or more.

These are broad estimates, and specific pricing will depend on the factors outlined above. Bulk discounts and long-term contracts can also influence the final price.

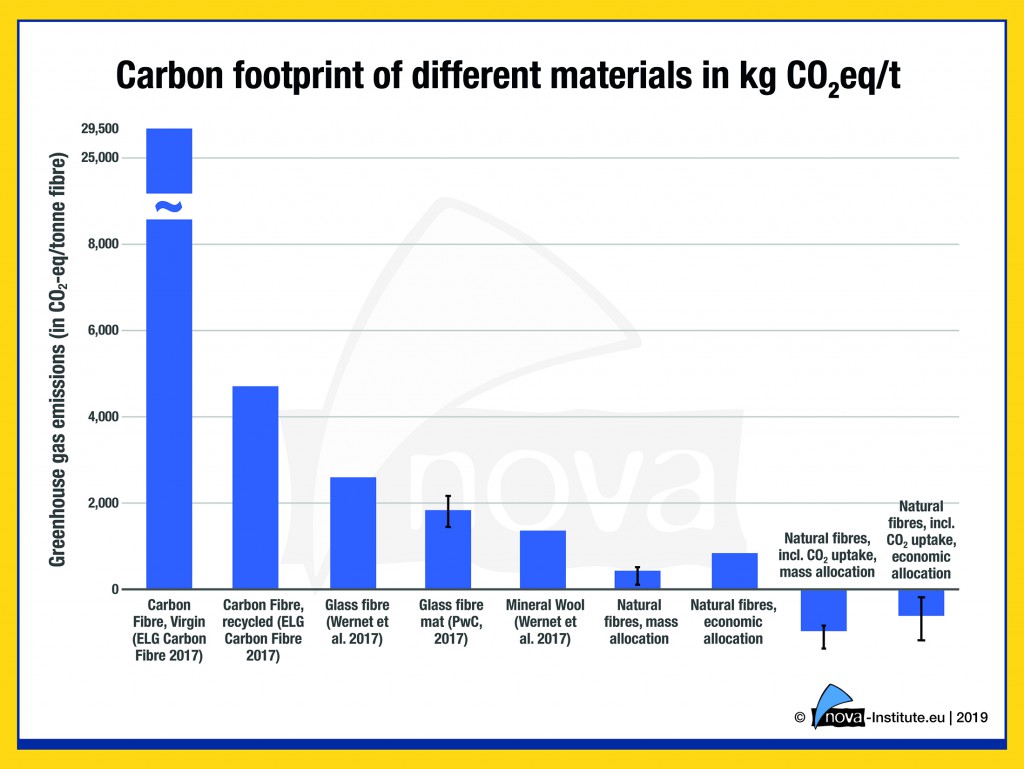

It’s important to note that recycled carbon fiber is emerging as a more sustainable and cost-effective alternative. The price of recycled carbon fiber is significantly lower, typically ranging from $5-$15 per kg.

Impact on Industries and Consumers

The price of carbon fiber directly impacts the cost of products and services in various industries. Higher carbon fiber costs can translate to higher prices for aircraft, automobiles, wind turbine blades, and sporting goods.

For consumers, this means potentially higher purchase prices for goods containing carbon fiber. However, the benefits of using carbon fiber, such as improved fuel efficiency in vehicles or enhanced performance in sporting equipment, can sometimes outweigh the higher initial cost.

The increasing use of recycled carbon fiber may help mitigate these higher costs, providing a more affordable and sustainable alternative.

The Future of Carbon Fiber Pricing

The future price of carbon fiber is likely to be shaped by several key trends. Technological advancements in manufacturing processes could lead to lower production costs and increased supply.

The growing demand for lightweight materials in various industries will continue to exert upward pressure on prices. The adoption of sustainable manufacturing practices, including the use of recycled carbon fiber, could help to stabilize prices and reduce the environmental impact of carbon fiber production.

Monitoring these trends and understanding the key drivers of carbon fiber pricing is essential for businesses and consumers alike. The ongoing evolution of this advanced material will continue to shape the future of various industries, from aerospace to automotive and beyond.