R Value Of Rock Wool Insulation

Homeowners and builders face escalating energy costs, demanding immediate action to improve insulation. Rock wool, a popular insulation material, is under scrutiny for its R-value performance as energy efficiency standards tighten.

This article provides a concise overview of rock wool's R-value, its implications for building efficiency, and what consumers need to know to make informed decisions in a rapidly changing energy landscape.

Rock Wool Insulation: Understanding the Basics

Rock wool, also known as mineral wool, is an insulation material made from molten rock or slag that is spun into fibers. It's prized for its fire resistance, sound dampening, and thermal performance.

The R-value measures an insulation material's resistance to heat flow. Higher R-values indicate better insulation, reducing energy loss and lowering heating and cooling costs.

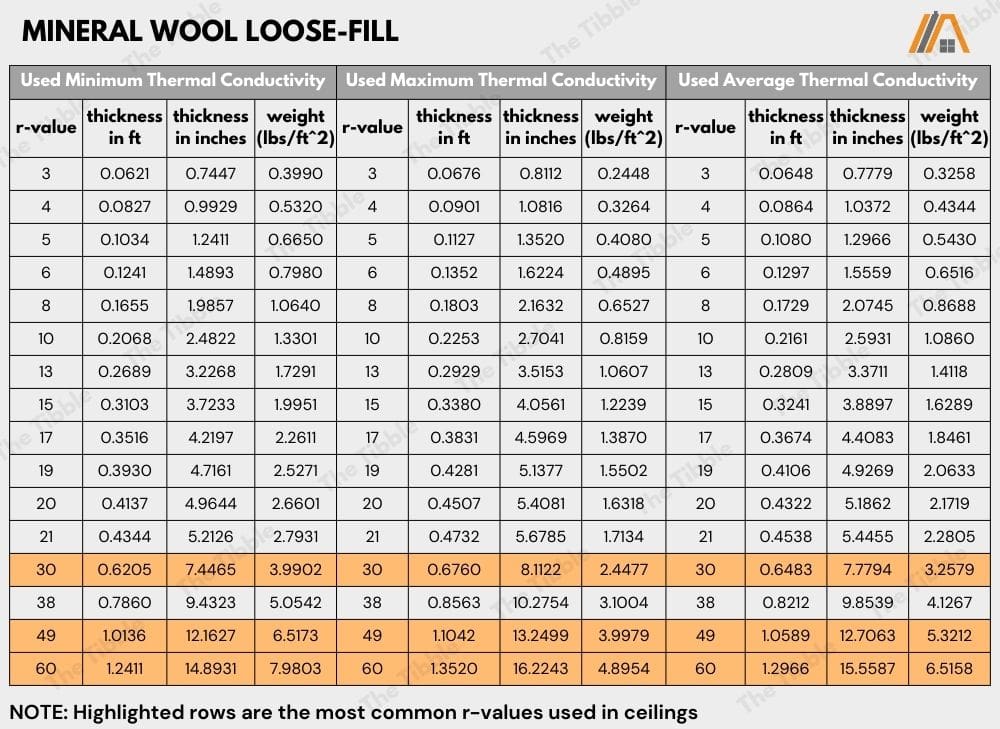

Critical R-Value Data: What You Need to Know

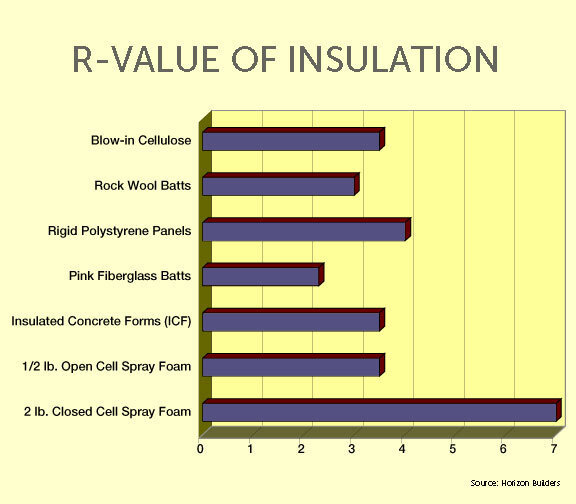

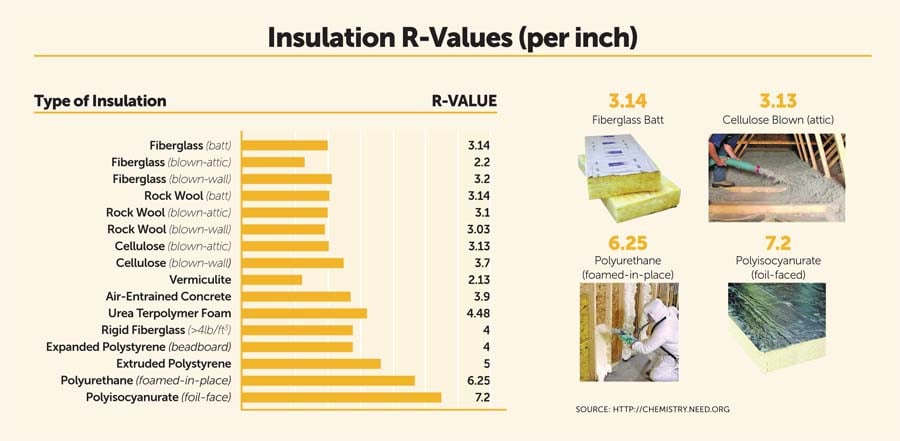

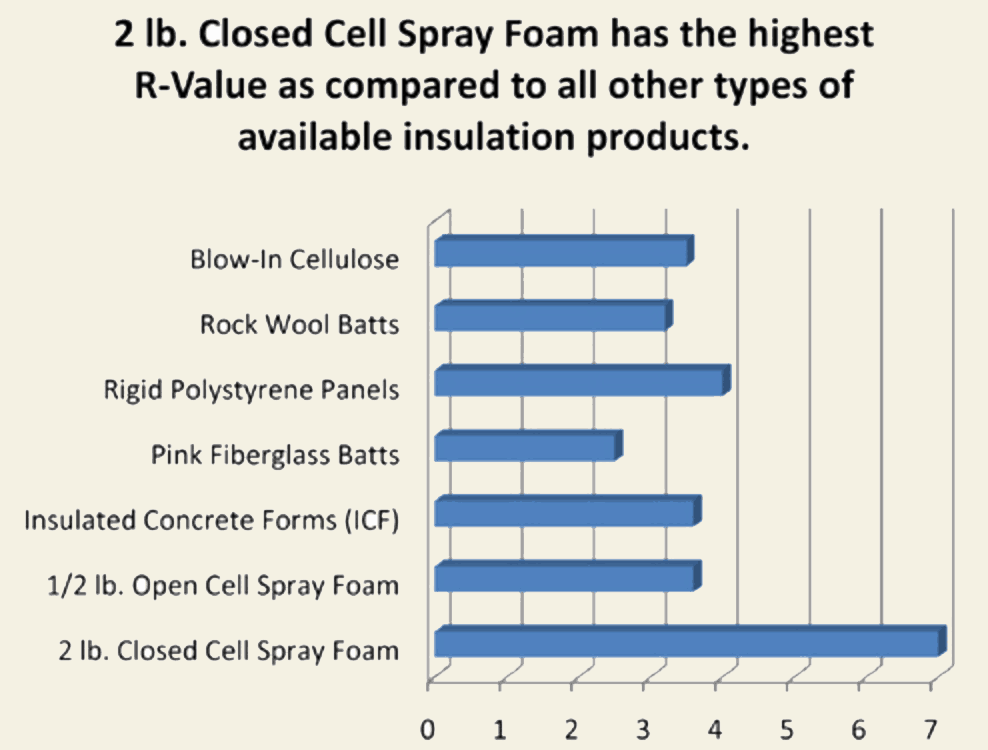

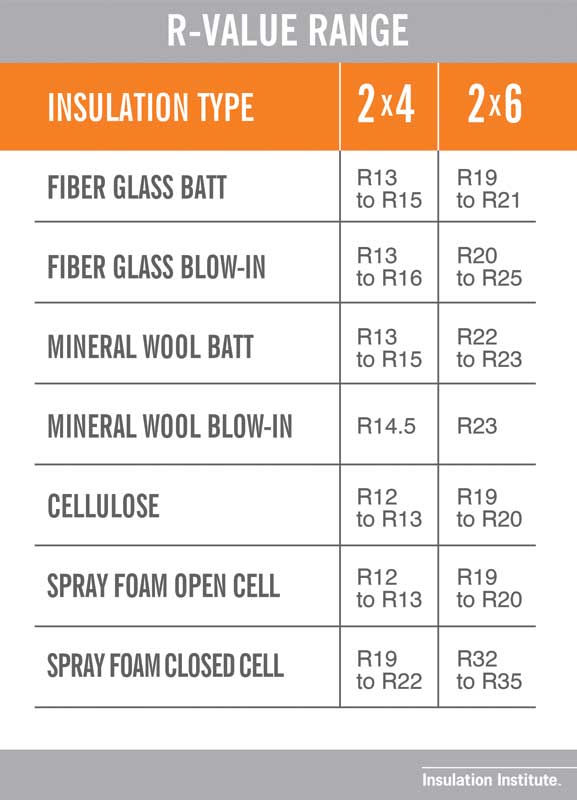

Rock wool typically boasts an R-value between 3.0 and 3.3 per inch of thickness. This figure positions it competitively among other common insulation materials like fiberglass (R-value of 2.2 to 2.9) and cellulose (R-value of 3.1 to 3.7).

However, the actual R-value can vary depending on the density and specific manufacturing process of the rock wool product. Always consult the manufacturer's specifications for accurate data.

Independent testing conducted by organizations like the North American Insulation Manufacturers Association (NAIMA) verifies R-values. Look for products with NAIMA certification for assurance.

The Impact of Density on R-Value

Denser rock wool generally provides higher R-values. Manufacturers offer different densities to suit various applications and building codes.

For example, exterior wall insulation often requires higher density rock wool than attic insulation. Proper density selection is crucial for optimal performance.

Consult with a qualified insulation contractor to determine the appropriate rock wool density for your specific project and climate zone.

Installation: A Key Factor in Performance

Even the best rock wool will underperform if improperly installed. Gaps, compressions, and voids significantly reduce the effective R-value.

Proper installation requires careful attention to detail, ensuring a tight fit and eliminating air leakage. Professional installation is highly recommended.

Air sealing around windows, doors, and other penetrations is essential to maximize the benefits of rock wool insulation.

Rock Wool vs. Other Insulation Types: A Comparative Analysis

Compared to fiberglass, rock wool offers superior fire resistance and sound dampening properties. It also tends to be more resistant to moisture.

Cellulose insulation, while offering a similar R-value, is typically treated with chemicals to provide fire resistance. Rock wool is naturally fire resistant.

Spray foam insulation provides higher R-values per inch but is more expensive and may require specialized installation. The cost-benefit analysis varies by project.

Addressing Common Concerns and Misconceptions

Some concerns exist regarding the potential for rock wool to settle over time, reducing its R-value. However, reputable manufacturers produce rock wool that is designed to maintain its integrity.

Dust and fibers released during installation can be irritating. Wearing appropriate personal protective equipment (PPE) is essential during handling and installation.

Claims regarding significantly higher R-values than industry standards should be treated with skepticism. Always verify information with independent sources and manufacturer data sheets.

Real-World Applications and Case Studies

Numerous case studies demonstrate the effectiveness of rock wool in reducing energy consumption in both residential and commercial buildings. Improved R-values translate to lower utility bills.

Projects incorporating rock wool insulation often qualify for energy efficiency rebates and incentives. Check with your local utility provider for available programs.

Cities like Minneapolis and Denver have seen significant energy savings through city-wide initiatives promoting high-performance insulation, including rock wool.

The Future of Rock Wool: Innovation and Development

Ongoing research and development efforts are focused on improving the R-value and sustainability of rock wool insulation. Manufacturers are exploring new materials and manufacturing processes.

Expect to see advancements in rock wool composition and application techniques. This will further enhance its performance and versatility.

Increased demand for energy-efficient building materials is driving innovation in the rock wool industry, promising even better insulation solutions in the future.

Immediate Action: What Homeowners and Builders Should Do

Assess your current insulation levels and identify areas for improvement. Consult with a qualified insulation contractor to determine the best solution for your needs.

Obtain multiple quotes and compare product specifications, including R-values, densities, and installation requirements. Don't solely focus on price.

Verify certifications and compliance with local building codes. Prioritize quality installation to maximize the benefits of rock wool insulation and ensure long-term energy savings.

![R Value Of Rock Wool Insulation What is the R-Value of Rockwool Insulation? [With Chart] | Quiet Home Life](https://www.quiethome.life/wp-content/uploads/2022/02/What-is-the-R-Value-of-Rockwool-Insulation.jpg)

.png)