Samsung Electronics Fanuc Corporation Samsung Production Line

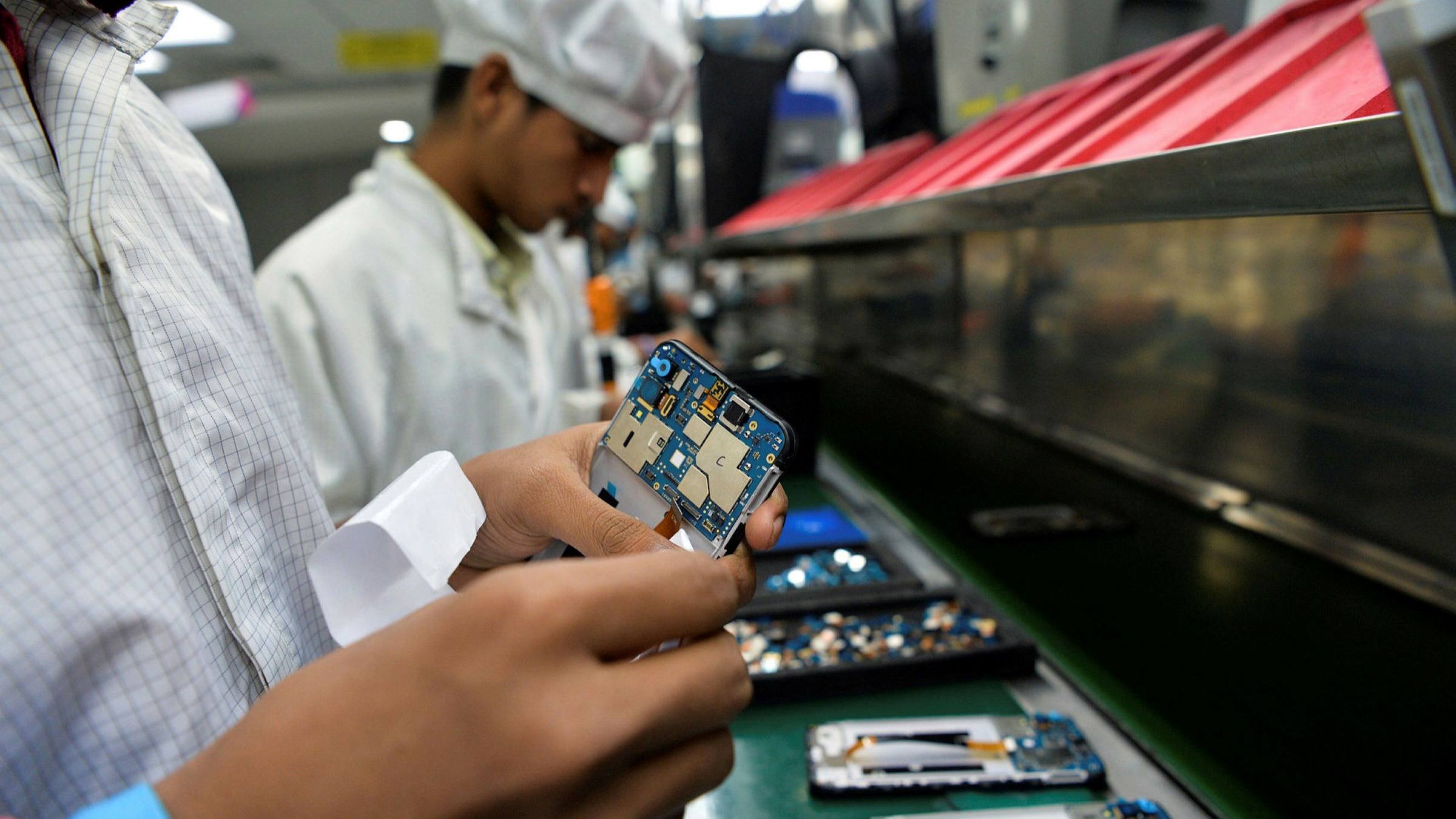

The relentless push for efficiency and precision in electronics manufacturing has reached a new apex, with Samsung Electronics integrating advanced robotics and automation solutions into its production lines. A cornerstone of this integration is the collaboration with Fanuc Corporation, a global leader in industrial automation. This partnership is reshaping how smartphones, semiconductors, and other cutting-edge devices are produced, promising both increased output and enhanced quality, but also raising questions about the future of human labor in the industry.

This article delves into the intricacies of the Samsung-Fanuc collaboration, examining the specific technologies deployed, the impact on production efficiency and product quality, and the broader implications for the workforce. It explores how Samsung is leveraging Fanuc's expertise to stay ahead in the fiercely competitive electronics market while also considering the potential societal consequences of increased automation.

The Power Couple: Samsung and Fanuc

Samsung Electronics, a titan in the electronics industry, constantly seeks innovative ways to optimize its manufacturing processes. To achieve this, they have increasingly turned to automation solutions provided by companies like Fanuc.

Fanuc Corporation, renowned for its industrial robots, CNC systems, and factory automation solutions, has become a crucial partner for Samsung. Their collaboration facilitates the creation of highly efficient and precise production lines.

Specific Technologies in Play

Fanuc's contributions to Samsung's production lines are multifaceted, encompassing a range of advanced technologies. These technologies are designed to tackle various challenges in electronics manufacturing.

One key element is the implementation of high-speed robotic arms. These arms are designed for intricate tasks such as component placement, soldering, and assembly of small parts, operations where precision and speed are paramount.

Samsung also utilizes Fanuc's CNC (Computer Numerical Control) systems. These systems precisely control machine tools, enabling the creation of complex and highly accurate components for electronic devices.

Furthermore, the integration of advanced vision systems allows the robots to "see" and identify defects, ensuring only high-quality products proceed further in the manufacturing process. These systems are key to minimizing errors and waste.

Finally, Fanuc provides sophisticated software for production line management and optimization. This software helps Samsung monitor and control the entire manufacturing process, identifying bottlenecks and improving overall efficiency.

Impact on Production Efficiency and Quality

The integration of Fanuc's technologies has had a significant impact on Samsung's production efficiency and product quality. The increased automation leads to faster production cycles, reducing lead times and enabling Samsung to respond more quickly to market demands.

Robots work continuously without fatigue, allowing Samsung to operate its factories for longer periods, potentially around the clock, maximizing output. Fanuc's automation solutions also contribute to improved product quality.

The precision and consistency of robots minimizes errors and defects, resulting in higher quality products and reduced waste. This translates to increased customer satisfaction and reduced costs associated with rework and returns.

Samsung has reported significant improvements in both throughput and defect rates since implementing these advanced automation systems. The adoption of these technologies strengthens Samsung's competitive edge in the global market.

The Human Factor: Workforce Implications

The increasing automation of Samsung's production lines raises concerns about the impact on the workforce. The introduction of robots inevitably leads to a reduction in the number of human workers required for certain tasks.

This can result in job displacement, particularly for workers performing repetitive or manual labor. However, Samsung argues that automation also creates new opportunities, particularly in areas such as robot maintenance, programming, and data analysis.

“We are committed to retraining and upskilling our workforce to adapt to the changing needs of the manufacturing industry,”stated a Samsung spokesperson in a recent press release.

Whether these efforts will be sufficient to fully mitigate the negative impacts of automation on employment remains to be seen. There is an ongoing debate about the need for social safety nets and government policies to support workers displaced by automation.

Beyond Efficiency: Strategic Implications

Samsung's investment in automation goes beyond simply improving efficiency and quality. It also reflects a broader strategic shift towards greater resilience and flexibility in its supply chain.

By automating key manufacturing processes, Samsung reduces its reliance on human labor, mitigating the risk of disruptions caused by labor shortages or geopolitical instability. Increased automation allows Samsung to quickly adapt its production lines to changing market demands, introducing new products and features with greater agility.

This strategic flexibility is crucial in the fast-paced electronics industry, where consumer preferences and technological advancements are constantly evolving.

Moreover, Samsung's advanced manufacturing capabilities, enabled by Fanuc's technologies, serve as a competitive differentiator. It allows them to produce increasingly complex and sophisticated devices, staying ahead of rivals in the innovation race.

Looking Ahead

The collaboration between Samsung Electronics and Fanuc Corporation exemplifies the growing trend towards automation in the electronics manufacturing industry. The integration of robots, CNC systems, and advanced software is driving significant improvements in efficiency, quality, and flexibility.

As automation technologies continue to evolve, we can expect to see even greater levels of integration in Samsung's production lines. This will further amplify the benefits of automation, but also intensify the challenges related to workforce displacement and the need for retraining initiatives.

The future of electronics manufacturing will likely be characterized by a closer collaboration between humans and machines, where humans focus on higher-level tasks such as design, innovation, and problem-solving, while robots handle the more repetitive and physically demanding aspects of production. The key to success will be finding the right balance between automation and human labor, ensuring both economic prosperity and social well-being.