Types Of Cinder Blocks In 1930s

The 1930s witnessed a surge in the use of concrete masonry units, commonly known as cinder blocks, as a cost-effective and durable building material. While the modern array of block types is extensive, the options available during this era were more limited, yet instrumental in shaping the architectural landscape of the time.

This article explores the common types of cinder blocks used in the 1930s, examining their composition, manufacturing processes, applications, and significance in the construction industry.

The Rise of Cinder Block Construction

The Great Depression fueled a demand for affordable building solutions. Cinder blocks emerged as a viable alternative to traditional materials like brick and wood, due to their lower cost and ease of production.

The term "cinder block" itself is somewhat of a misnomer. The blocks often contained materials beyond just cinders, depending on local availability and manufacturing practices.

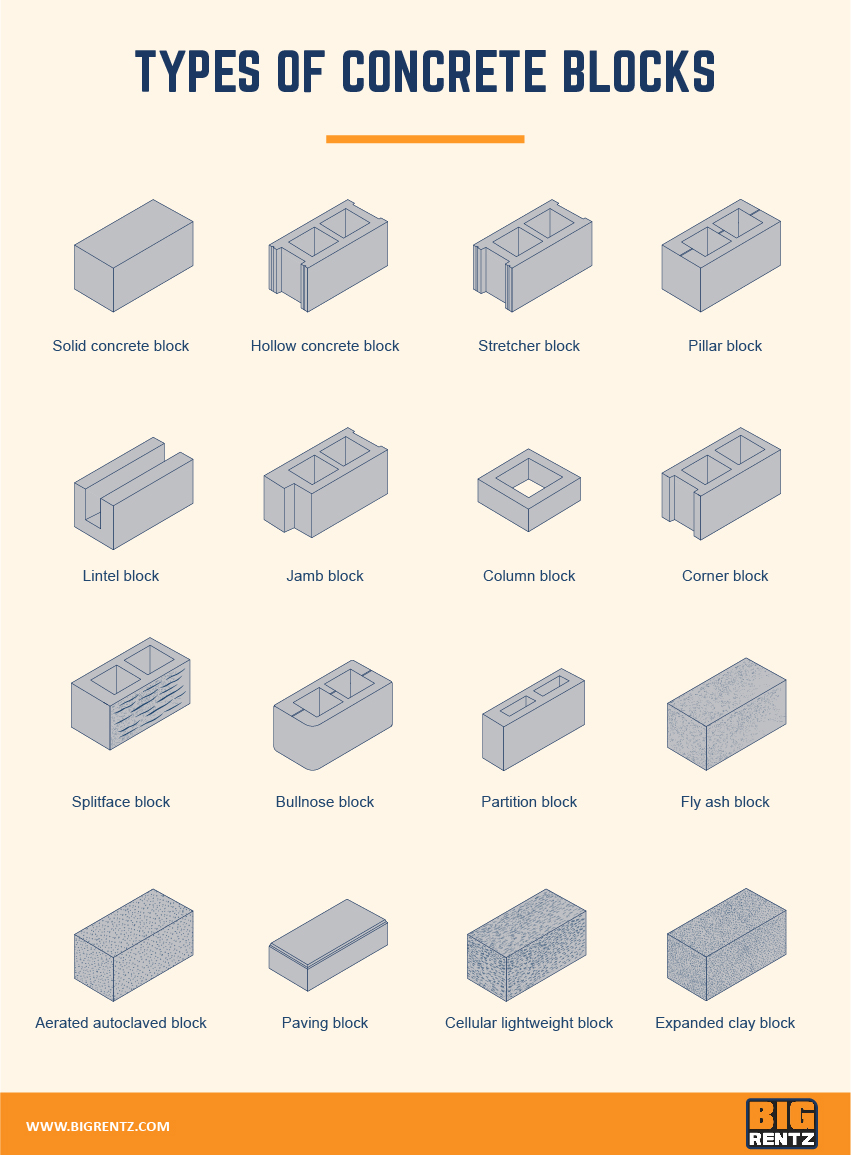

Common Types of Cinder Blocks in the 1930s

Solid Concrete Blocks

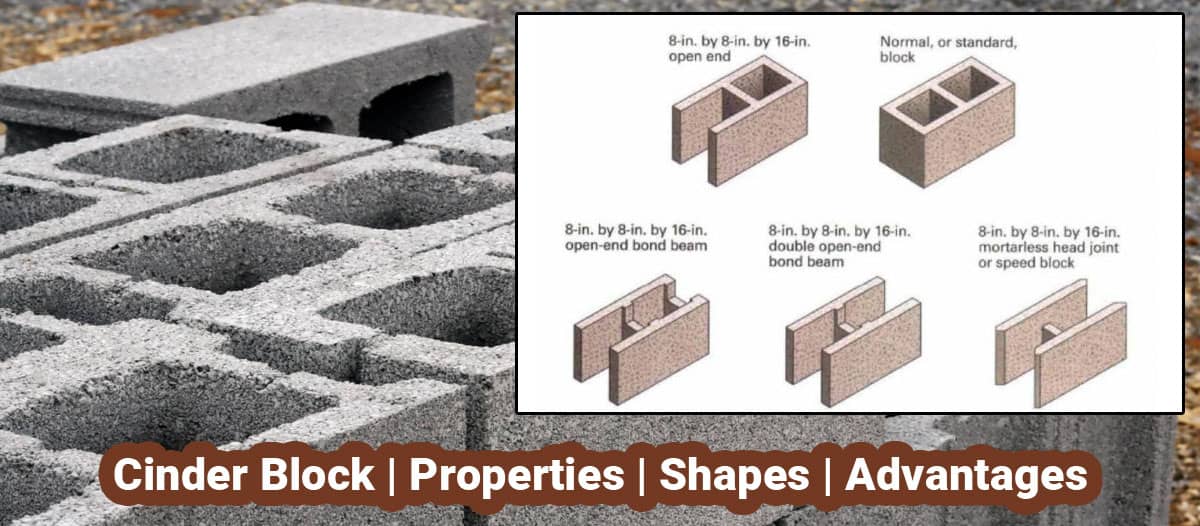

These blocks were typically composed of a mixture of cement, sand, and aggregate, resulting in a dense and heavy unit. Solid blocks offered greater compressive strength, making them suitable for load-bearing walls and foundations.

Their weight, however, presented challenges in handling and installation. These blocks often required more labor and specialized equipment for larger projects.

Hollow Concrete Blocks

Hollow blocks, characterized by their internal cavities, were lighter and required less material than solid blocks. This made them easier to handle and more cost-effective to produce.

They were commonly used for non-load-bearing walls, interior partitions, and backup walls for brick or stone veneers. The voids could also be filled with insulation for improved thermal performance, although this practice was less common in the early 1930s.

Cinder Blocks (True Cinder Blocks)

True cinder blocks incorporated cinders – the residue from burned coal – as a primary aggregate. These blocks were lighter than concrete blocks and offered some insulation properties.

However, cinders could contain impurities that compromised the block's long-term durability. Sulfur content, for example, could lead to corrosion of reinforcing steel.

Slag Blocks

Slag, a byproduct of smelting processes, was another alternative aggregate used in block manufacturing. Slag blocks possessed good fire resistance and were relatively lightweight.

The quality and consistency of slag varied depending on the source, potentially affecting the block's strength and durability. Similar to cinder blocks, the presence of certain chemical compounds could also pose long-term problems.

Manufacturing Processes

The production of cinder blocks in the 1930s was generally more manual than modern automated processes. Mixes were often prepared by hand or with basic machinery.

Blocks were typically formed in molds and then cured in open-air yards, relying on natural elements for hydration and hardening. This resulted in variations in block quality and consistency.

Applications and Significance

Cinder blocks found widespread use in residential, commercial, and industrial construction. They provided a durable and affordable building solution for homes, factories, warehouses, and agricultural structures.

The use of cinder blocks helped to accelerate the pace of construction, especially in the face of economic hardship. The blocks also fostered innovative architectural designs and construction techniques.

Challenges and Limitations

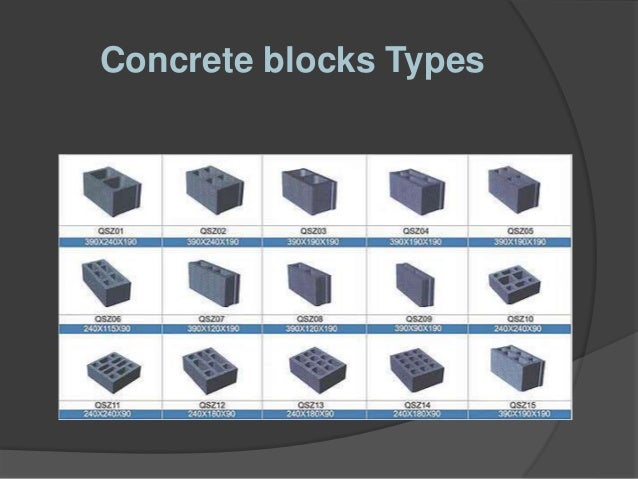

Despite their advantages, cinder blocks in the 1930s faced certain limitations. Quality control was often inconsistent, leading to variations in strength and durability.

The lack of standardized sizes and shapes also posed challenges for builders. Moisture penetration and efflorescence (the appearance of white, powdery deposits on the surface) were also common concerns.

Conclusion

The cinder blocks used in the 1930s, while simpler than their modern counterparts, played a crucial role in shaping the built environment during a period of economic challenge and innovation. These blocks offered an affordable and readily available building solution, contributing to the rapid expansion of towns and cities across the nation.

Understanding the types of cinder blocks used during this era provides valuable insights into the construction practices and material science of the time. It highlights the resourcefulness of builders and manufacturers in meeting the demands of a rapidly changing society.

![Types Of Cinder Blocks In 1930s 15+ Types Of Concrete Blocks Used In Construction [Civil Planets]](https://civilplanets.com/wp-content/uploads/2020/06/Typical-Shapes-of-Concrete-Blocks.jpg)