What Provides The Best Indicators Of Structural Integrity

Imagine standing at the foot of the Golden Gate Bridge, a majestic symphony of steel and cables against the backdrop of the Pacific. The wind whispers secrets of resilience, of decades braving storms and tides. But what ensures this icon, and structures like it around the world, continue to stand strong, silently safeguarding lives and livelihoods?

This article delves into the crucial realm of structural integrity, exploring the methods and technologies used to assess the health of our bridges, buildings, and infrastructure. Understanding what provides the best indicators of structural integrity is paramount for preventing catastrophic failures and ensuring the longevity and safety of the built environment that shapes our lives.

The Foundation of Safety: Understanding Structural Integrity

Structural integrity, at its core, refers to the ability of a structure to withstand applied loads without failing. This includes not just immediate collapse, but also long-term degradation and the effects of environmental factors. Identifying the right indicators requires a multi-faceted approach, blending traditional techniques with cutting-edge innovations.

Visual Inspection: The First Line of Defense

Often overlooked, visual inspection remains a critical first step. Experienced engineers and inspectors meticulously examine structures for visible signs of damage, such as cracks, corrosion, and deformation. This qualitative assessment provides invaluable context for further, more quantitative analyses.

Consider the work of bridge inspectors, often dangling hundreds of feet above ground, their trained eyes scanning every rivet and beam. Their observations are the initial data points in a complex equation that determines a structure's health.

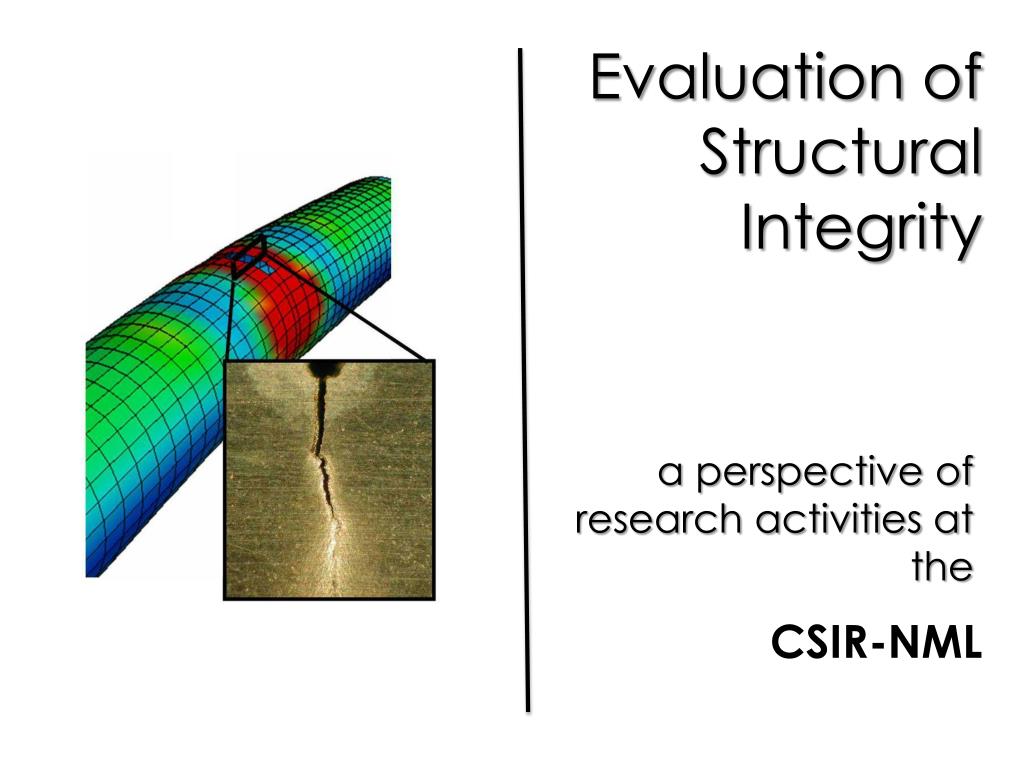

Non-Destructive Testing (NDT): Peeking Beneath the Surface

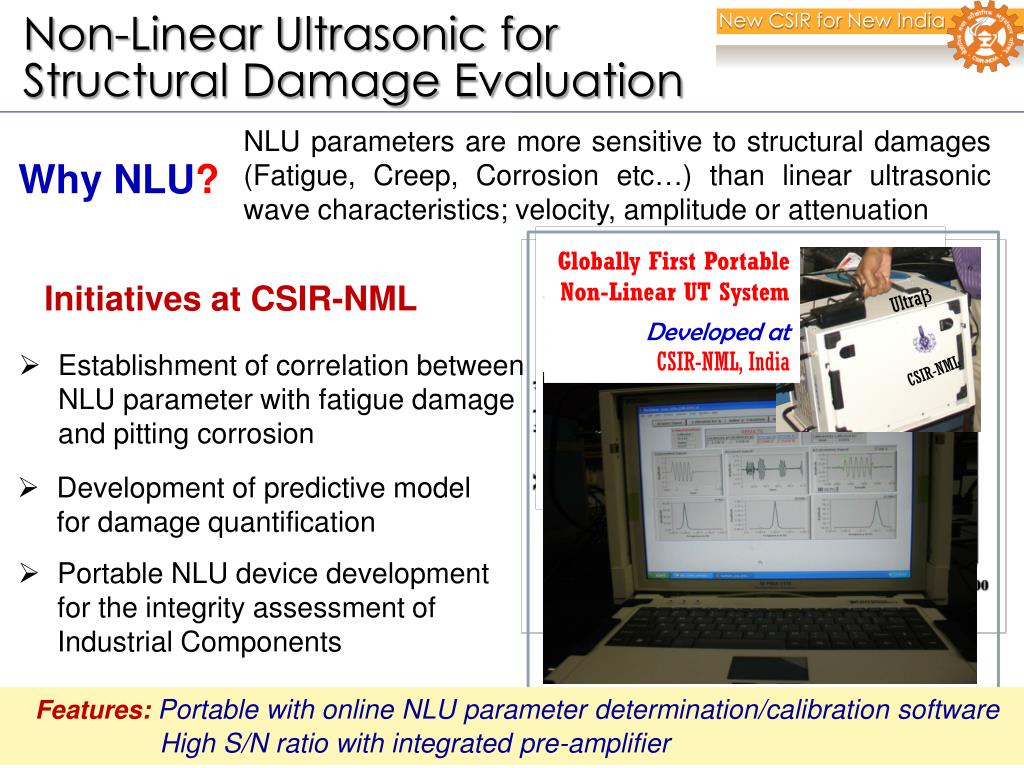

NDT methods allow engineers to evaluate the internal condition of a structure without causing damage. These techniques offer insights that visual inspections alone cannot provide. Think of it as giving a structure a comprehensive physical exam without making any incisions.

Ultrasonic testing uses sound waves to detect internal flaws in materials. Radiography, similar to medical X-rays, reveals hidden cracks and voids. Infrared thermography identifies areas of heat buildup, which can indicate structural weaknesses or insulation failures.

"NDT is essential for identifying hidden defects before they become major problems," explains Dr. Emily Carter, a leading expert in structural health monitoring. "It allows us to proactively address issues and extend the lifespan of our infrastructure."

Strain Gauges and Accelerometers: Measuring Response to Stress

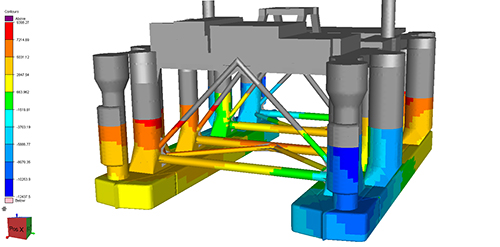

Strain gauges measure the deformation of a material under stress. These small sensors are strategically placed on a structure to monitor how it responds to loads. Accelerometers, on the other hand, measure vibrations and accelerations, providing insights into dynamic behavior.

Data from these sensors can be used to validate computer models and identify potential vulnerabilities. Imagine placing sensors on a bridge to monitor how it bends and sways under the weight of traffic and the force of the wind. This real-time feedback allows engineers to understand the structure's response to various conditions.

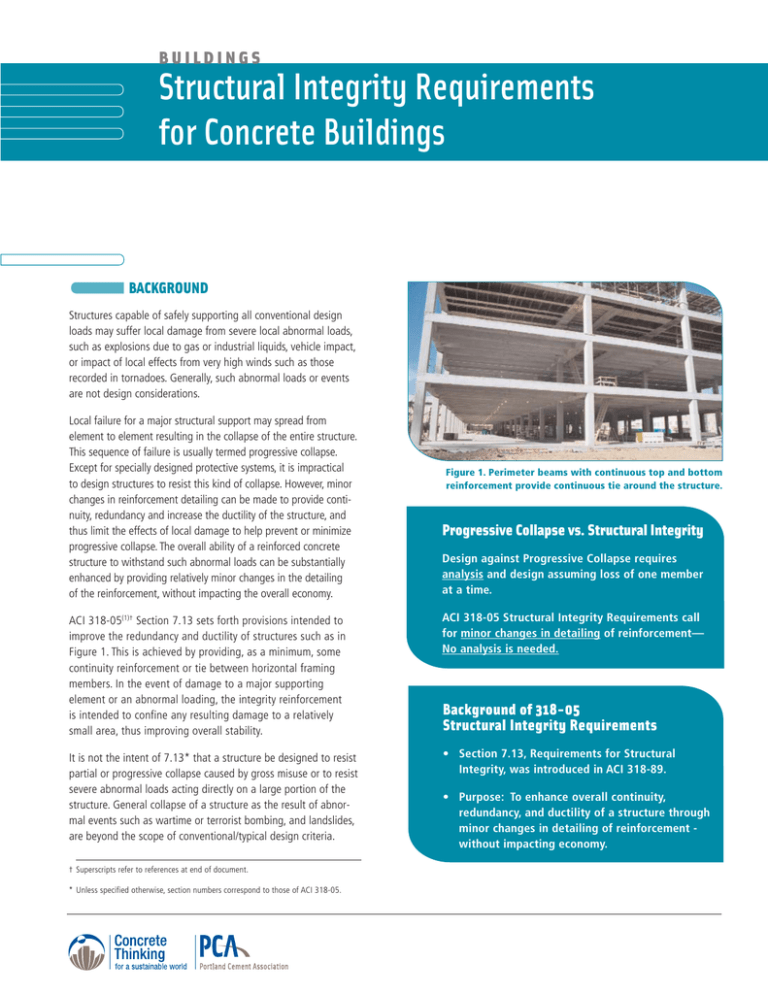

Material Testing: Understanding the Building Blocks

Understanding the properties of the materials used in a structure is fundamental to assessing its integrity. This involves laboratory testing of samples to determine their strength, elasticity, and resistance to corrosion. While destructive, this testing is crucial for validating the assumptions made during the design phase.

For example, concrete core samples can be extracted from a bridge deck and tested to determine their compressive strength. Steel samples can be subjected to tensile testing to assess their yield strength and ductility. These tests provide valuable data about the materials' ability to withstand stress and strain.

Advanced Techniques: Embracing Innovation

Emerging technologies are revolutionizing structural health monitoring. Fiber optic sensors, for example, offer high sensitivity and can be embedded within structures during construction. Drones equipped with high-resolution cameras and thermal imaging capabilities are increasingly used for remote inspections.

Digital twins, virtual replicas of physical structures, are becoming increasingly popular. These models allow engineers to simulate different scenarios and predict how a structure will perform under various conditions. Artificial intelligence and machine learning algorithms are also being used to analyze sensor data and identify patterns that might indicate potential problems.

The Human Element: Expertise and Collaboration

While technology plays a vital role, the expertise of engineers, inspectors, and technicians is indispensable. Their knowledge, experience, and judgment are crucial for interpreting data and making informed decisions. Effective communication and collaboration between different disciplines are also essential for ensuring the safety and longevity of structures.

Consider the intricate work involved in assessing the structural integrity of a historic building. Preserving these cultural treasures requires a delicate balance of scientific analysis and artistic sensitivity. The human element ensures that both the structural soundness and the historical significance are respected.

Beyond the Immediate: Long-Term Monitoring and Prevention

Structural integrity is not a one-time assessment but an ongoing process. Implementing long-term monitoring programs is crucial for detecting changes over time and preventing catastrophic failures. Regular inspections, data analysis, and preventative maintenance are all essential components of a comprehensive structural health management strategy.

By investing in these practices, we can extend the lifespan of our infrastructure and ensure the safety of future generations. Proactive monitoring is not just about identifying problems; it's about preventing them from ever occurring in the first place.

Conclusion: A Future Built on Strength and Resilience

Ensuring structural integrity is a shared responsibility, requiring collaboration between engineers, policymakers, and the public. By embracing advanced technologies, investing in education and training, and prioritizing preventative maintenance, we can build a future where our structures stand strong, silently safeguarding our lives and livelihoods. The quest for understanding and enhancing structural integrity is a continuous journey, one that demands vigilance, innovation, and a deep commitment to safety.