When Monitoring A Process Distribution Both The

Critical process deviations are occurring across multiple industrial facilities, triggering immediate investigations and emergency safety protocols.

This widespread anomaly, flagged by real-time distribution monitoring systems, demands rapid intervention to prevent potential system failures and environmental hazards.

Urgent Situation Unfolds

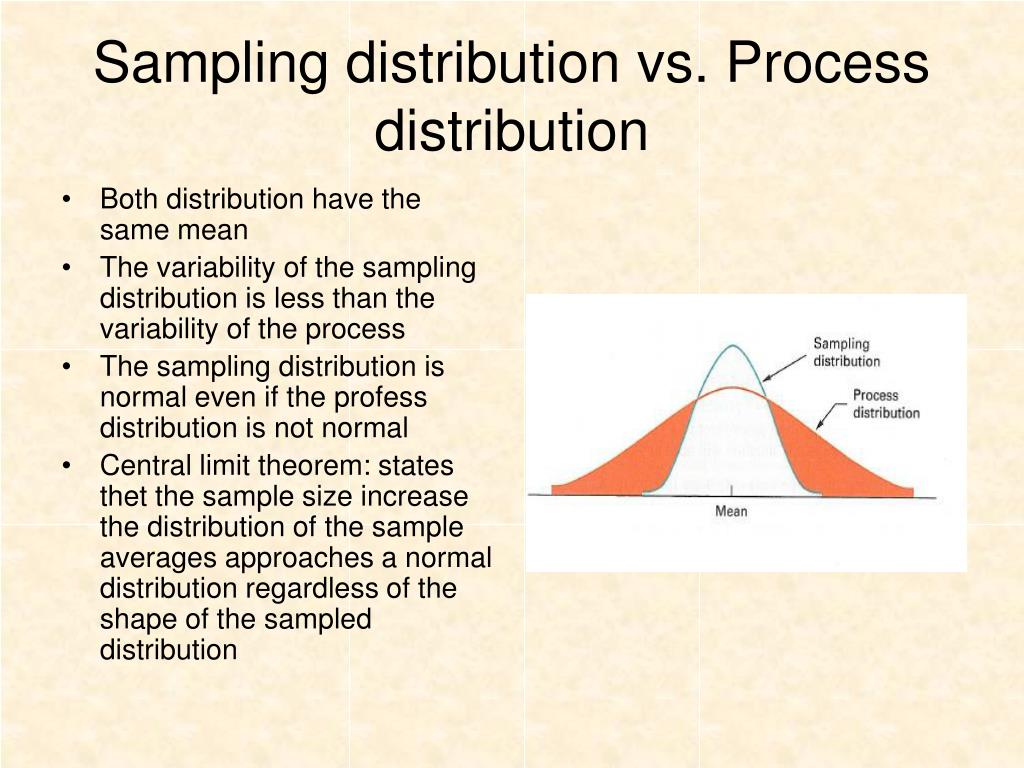

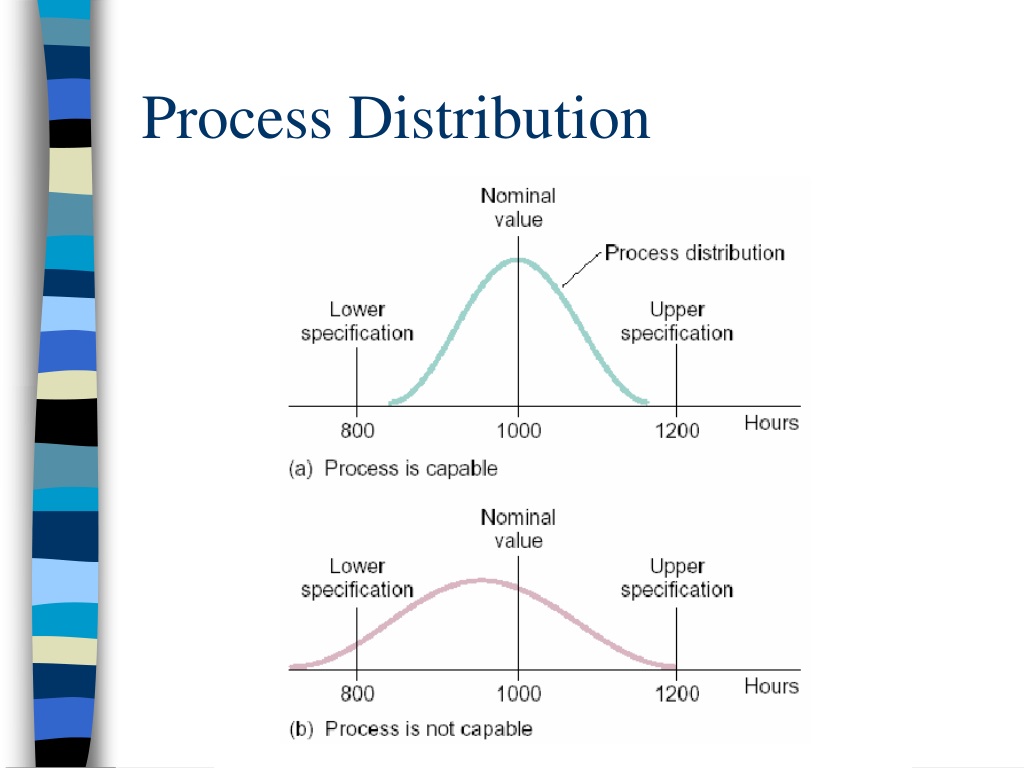

Multiple industrial sites are reporting significant variances in their process distributions.

These fluctuations, outside established operational parameters, raise alarms about the stability and safety of ongoing operations.

Affected Sites and Initial Findings

Locations include a chemical processing plant in Texas, a pharmaceutical manufacturing facility in New Jersey, and a wastewater treatment center in California.

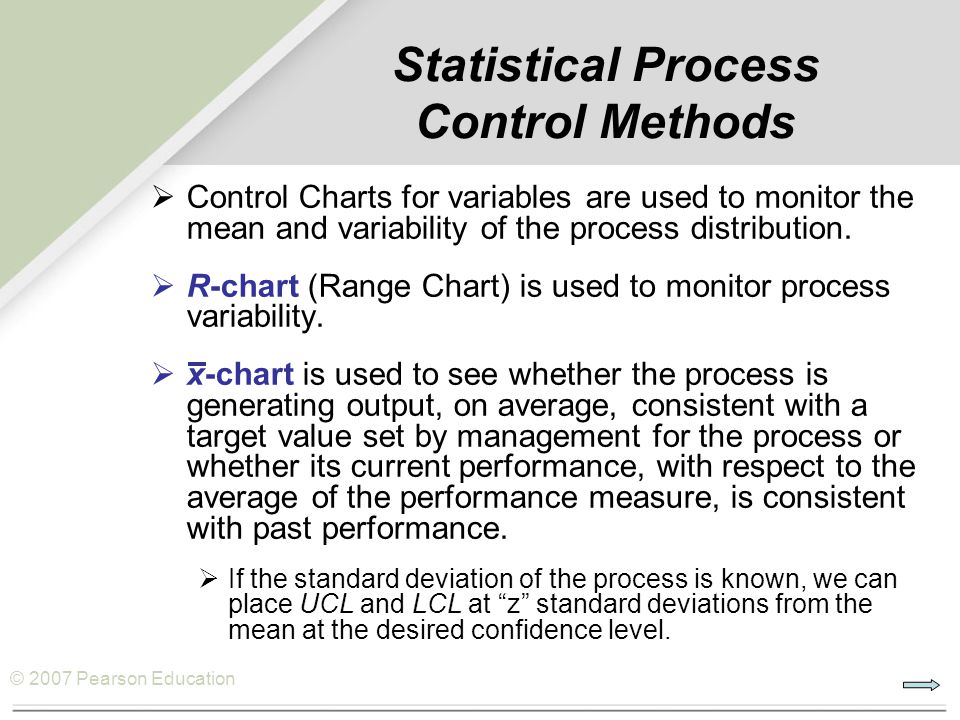

Initial assessments suggest the deviations involve temperature, pressure, and chemical concentration levels within critical processes.

Data logs from the monitoring systems reveal a simultaneous spike in irregularities across all three locations, a pattern that has prompted high-level investigation.

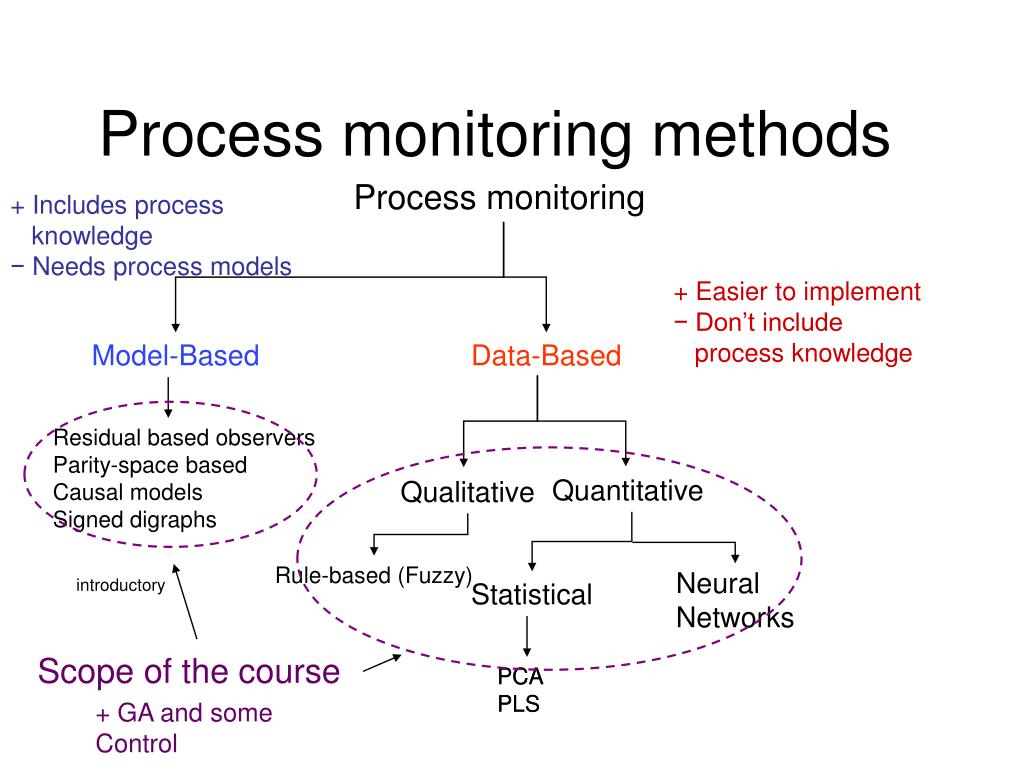

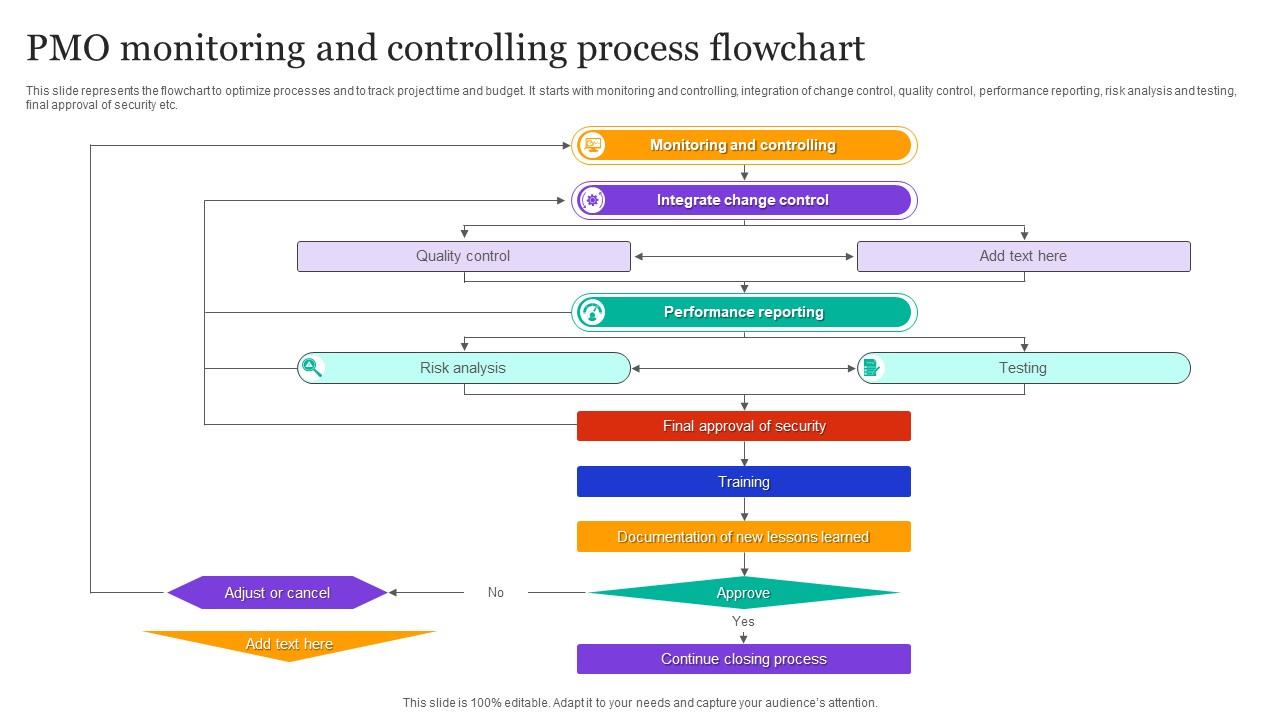

Monitoring System Anomalies

The Advanced Process Control (APC) systems, designed to maintain process integrity, triggered the initial warnings.

Anomalous readings indicate a potential compromise in the system’s ability to accurately track and control process distributions.

Cybersecurity experts are currently investigating the possibility of a coordinated cyberattack targeting these control systems.

Potential Impact and Risks

Uncontrolled fluctuations in temperature and pressure can lead to equipment malfunctions or explosions.

Variations in chemical concentrations could result in the release of hazardous materials.

Environmental agencies have been notified and are on standby to respond to any potential spills or emissions.

Immediate Actions and Emergency Protocols

All affected facilities have implemented emergency shutdown procedures, halting operations to mitigate risks.

Personnel are evacuating key areas to ensure safety, while specialized teams work to stabilize the systems and identify the root cause.

The Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) are actively involved in the investigation.

The Human Element

No injuries have been reported as of this time.

Facility managers and safety officers are working closely to ensure the well-being of all personnel involved.

Counselling services are available for affected employees.

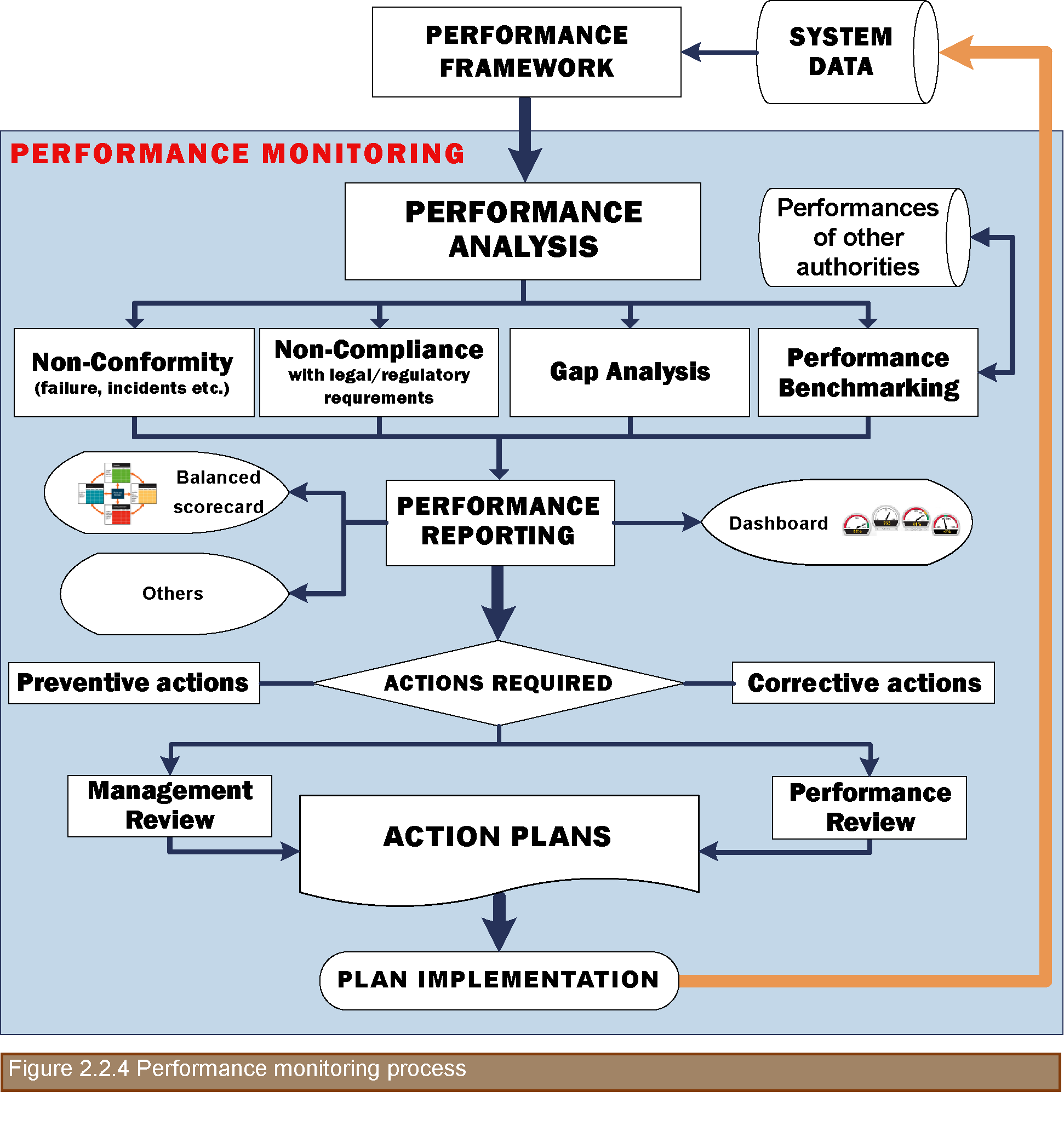

Investigation Underway

A joint task force comprised of engineers, cybersecurity specialists, and government regulators is leading the investigation.

The task force aims to determine the cause of the simultaneous anomalies, rectify system vulnerabilities, and prevent future incidents.

They are analyzing system logs, conducting physical inspections, and interviewing personnel to gather comprehensive data.

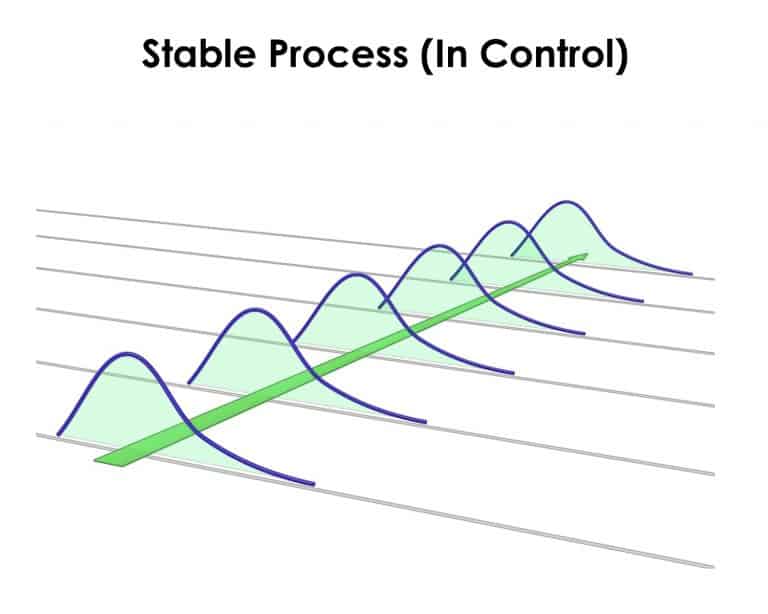

The Distribution Pattern

The affected processes are all distribution-centric.

Process Distribution Network (PDN) are all affected at once.

This means the issue is coming from a common source.

Next Steps and Ongoing Developments

The investigation remains ongoing, with preliminary findings expected within 48 hours.

Facilities will remain offline until systems are fully assessed, repaired, and validated.

Regular updates will be provided to the public as more information becomes available.