Why Was The Liquid In The Can Free Of Microbes

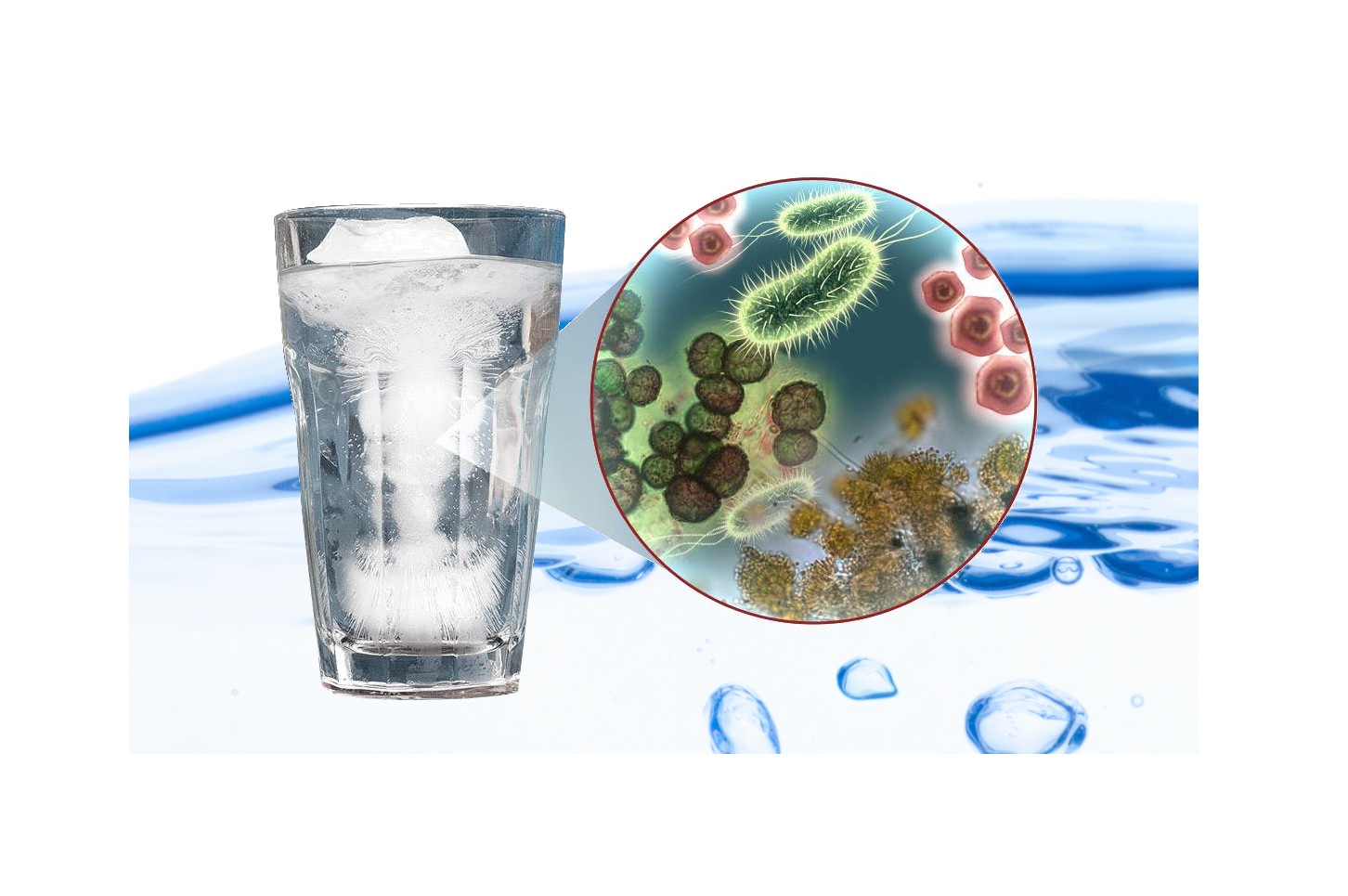

The seemingly mundane act of cracking open a can of soup, soda, or vegetables belies a remarkable feat of engineering and science. Each can contains a liquid, designed for consumption, that's astonishingly free of harmful microbes. This isn't accidental; it's the result of over a century of relentless refinement in food preservation techniques, driven by the need to feed armies, explorers, and ultimately, a global population.

At the heart of this microbial tranquility lies a combination of carefully controlled heat, airtight seals, and sometimes, clever manipulation of the liquid's chemical environment. This article delves into the science behind sterile canned goods, exploring the key processes that eliminate microbial life and prevent its return, ensuring that the contents remain safe to consume months, or even years, after packaging. Understanding these processes sheds light on a critical aspect of food safety that we often take for granted.

The Canning Process: A Multi-Layered Defense

The foundation of safe canned goods is the canning process itself, a technique pioneered by Nicolas Appert in the early 19th century. Appert's initial method involved sealing food in glass jars and then heating them in boiling water. While rudimentary, it proved remarkably effective in preventing spoilage, laying the groundwork for the modern canning industry.

Modern canning relies on metal cans, which offer superior durability and heat transfer compared to glass. The process generally involves filling the can with the product, removing air, sealing the can hermetically (airtight), and then heating it to a specific temperature for a specific time.

Heat Treatment: The Microbial Eliminator

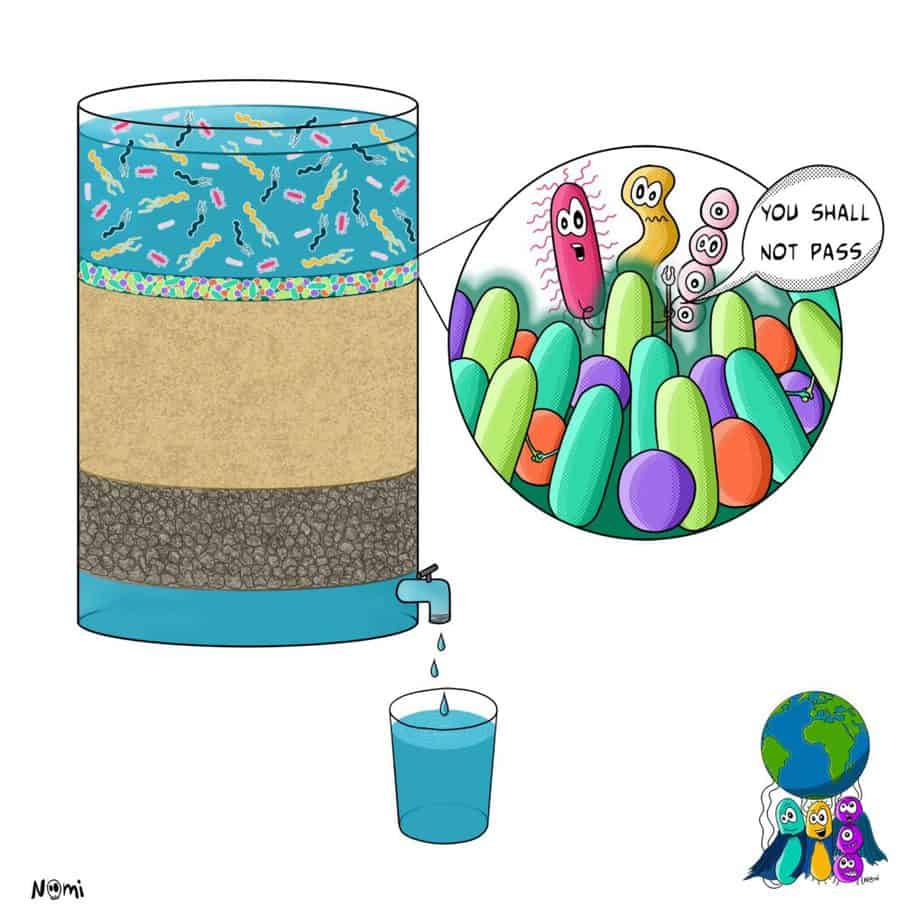

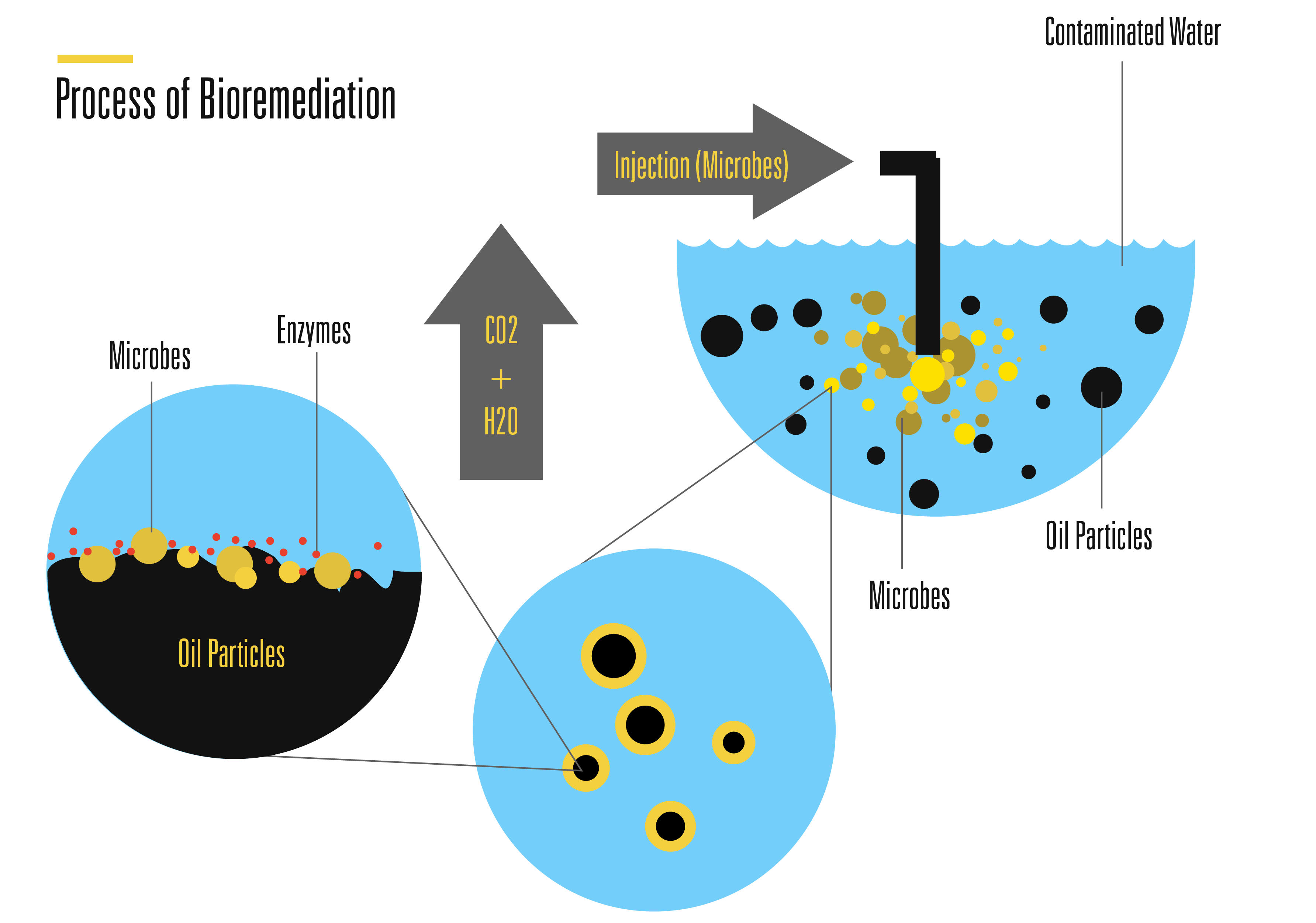

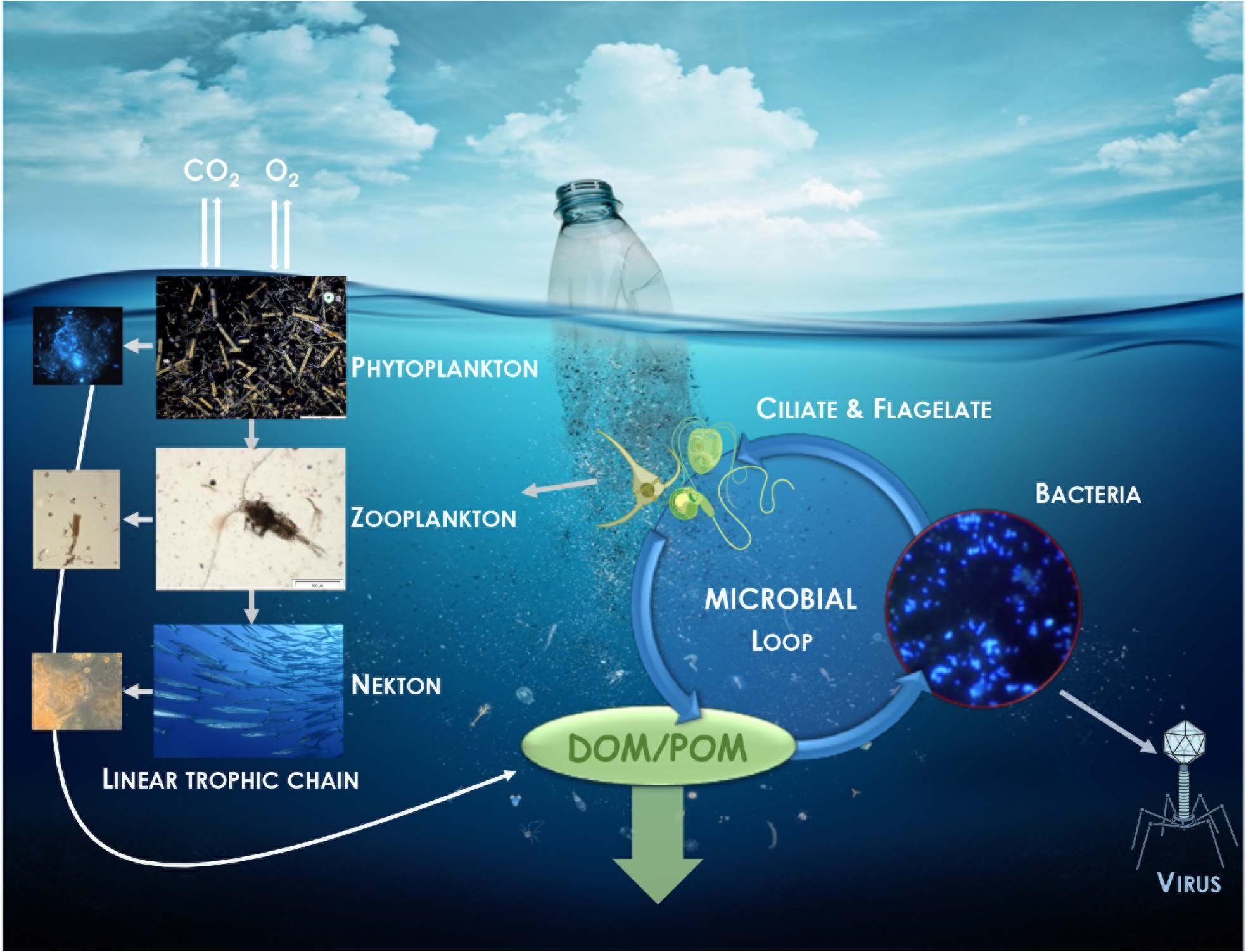

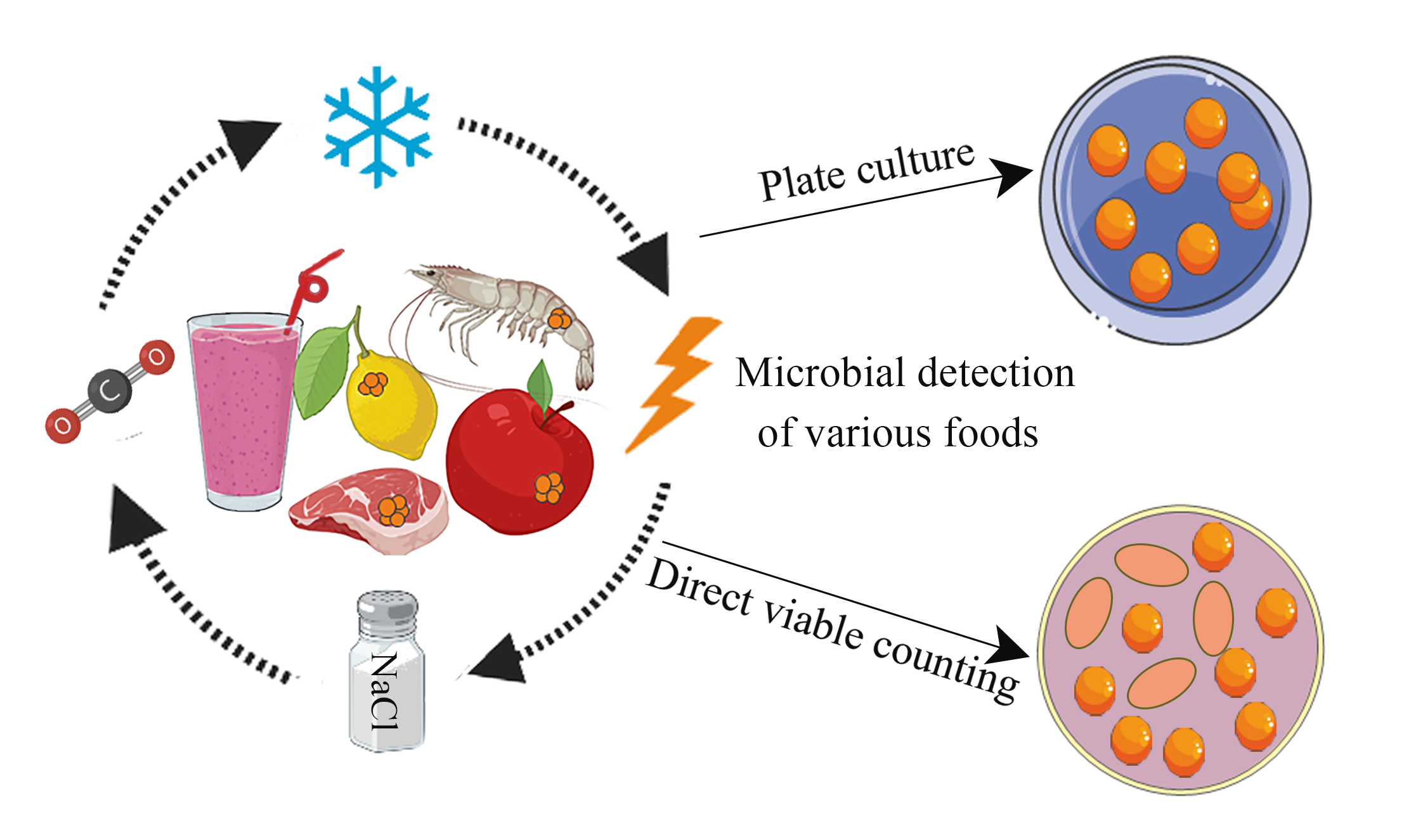

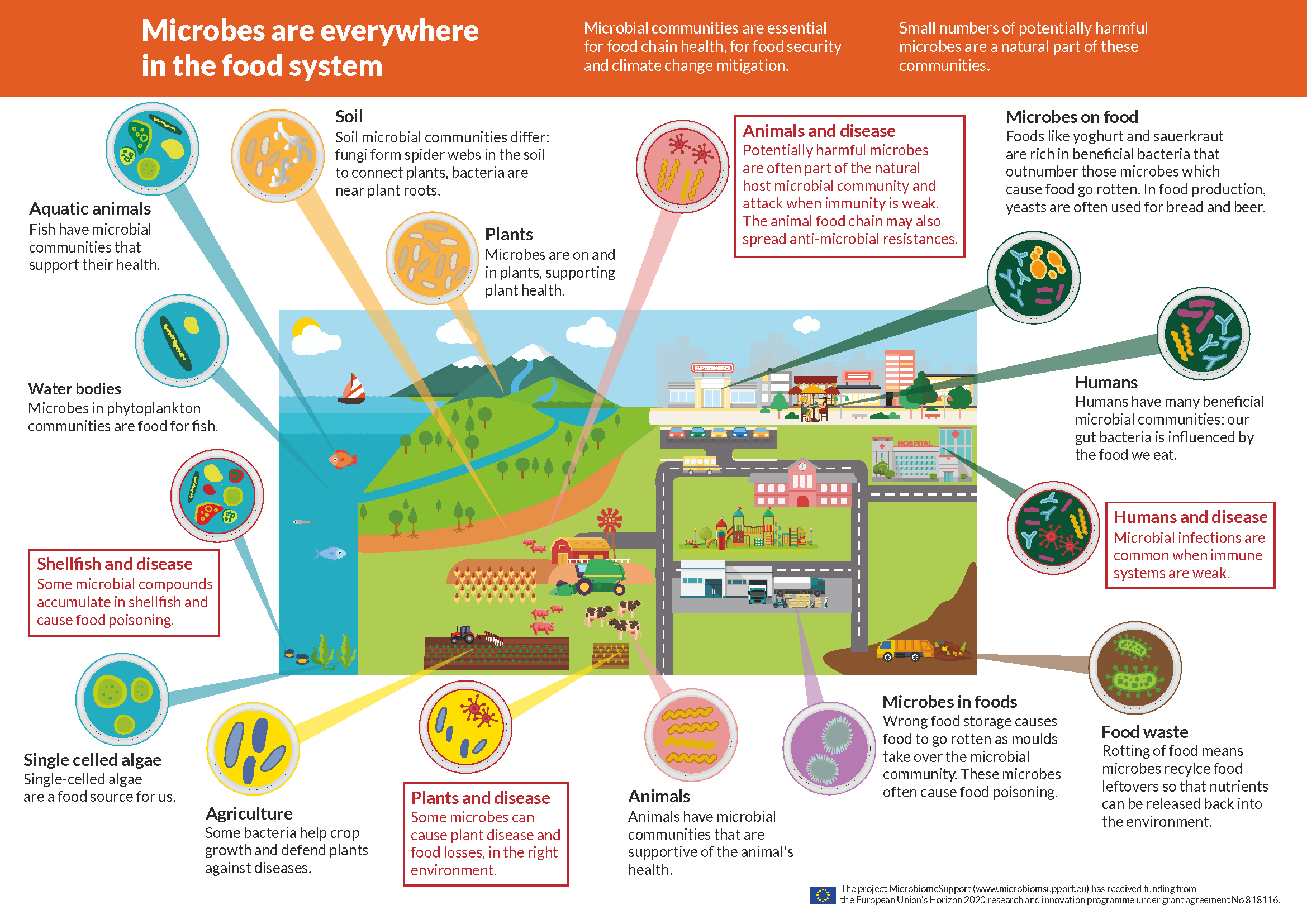

The crucial step in canning is the heat treatment, also known as thermal processing. The goal here is to eliminate or significantly reduce the number of microorganisms that could cause spoilage or pose a health risk, such as Clostridium botulinum, the bacterium responsible for botulism.

The intensity and duration of the heat treatment depend on several factors, including the type of food, the size of the can, and the potential presence of heat-resistant spores. Low-acid foods (pH above 4.6), such as vegetables, meats, and seafood, require higher temperatures (typically above 240°F / 116°C) to destroy Clostridium botulinum spores.

This high-temperature processing is often achieved using pressure cookers or retorts, which allow the food to be heated above the boiling point of water. Acidic foods (pH below 4.6), such as fruits and pickles, can be safely processed at lower temperatures (around 212°F / 100°C) because the acidity inhibits the growth of Clostridium botulinum.

The Hermetic Seal: Preventing Recontamination

The airtight seal of the can is just as important as the heat treatment. This seal prevents microorganisms from entering the can after processing and contaminating the food. The can itself is typically made of steel or aluminum, often coated with a food-grade lacquer to prevent corrosion and interaction with the food.

The can's lid is crimped onto the can body using a double-seam process, creating an extremely tight and reliable seal. This seal is designed to withstand the pressure changes that occur during heating and cooling, ensuring that the can remains airtight throughout its shelf life. The integrity of the seal is regularly monitored by manufacturers through quality control checks.

Beyond Heat: Other Preservation Strategies

While heat treatment and hermetic sealing are the primary methods for ensuring the sterility of canned goods, other factors can also contribute to microbial control. These include adjusting the pH, adding preservatives, and modifying the water activity of the food.

pH Adjustment: As mentioned earlier, acidity inhibits the growth of many microorganisms. Some canned foods, such as tomatoes and pickles, are naturally acidic, while others may have acid added to lower their pH.

Preservatives: Some canned foods contain preservatives, such as sodium benzoate or potassium sorbate, which further inhibit microbial growth. These preservatives are typically used in small amounts and are considered safe for consumption at those levels.

Water Activity: Water activity (aw) refers to the amount of unbound water available for microbial growth. Reducing the water activity of a food can prevent microorganisms from multiplying. This can be achieved by adding salt, sugar, or other solutes, as is commonly done in jams and jellies.

The Role of Research and Regulation

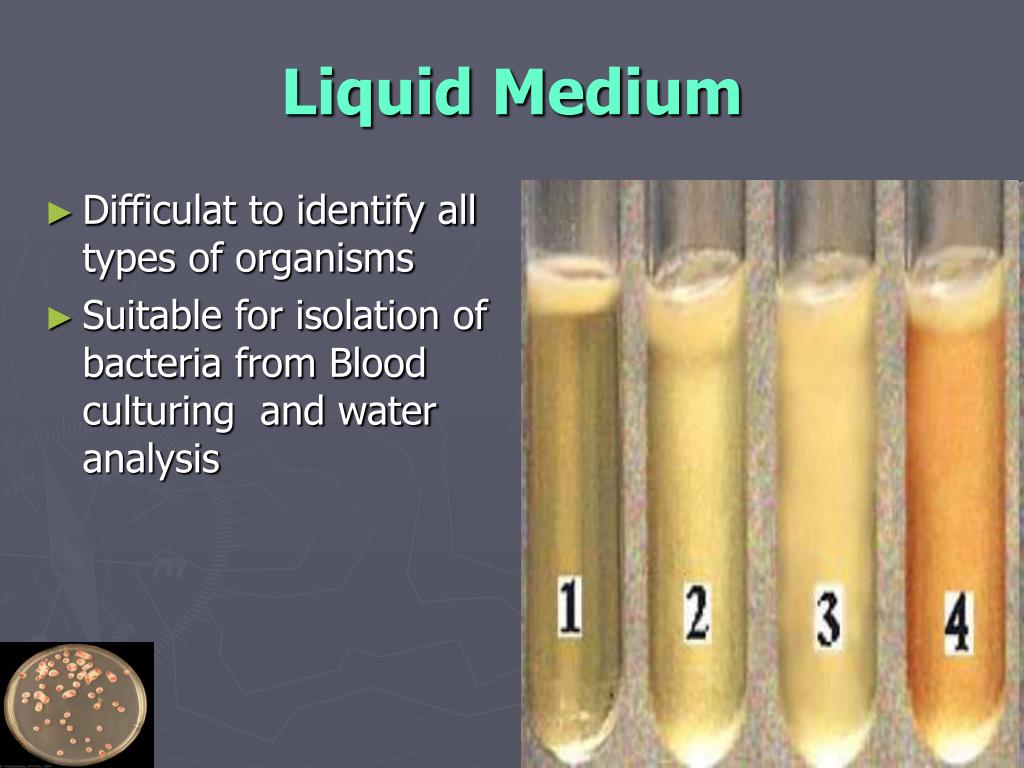

The safety of canned foods is constantly being improved through ongoing research and stringent regulations. Food scientists are continually studying the behavior of microorganisms in food and developing new methods for controlling their growth.

Regulatory agencies, such as the U.S. Food and Drug Administration (FDA), set strict standards for the canning industry. These standards cover everything from the design and construction of canning equipment to the processing and labeling of canned foods. Manufacturers are required to adhere to these standards to ensure the safety of their products.

The FDA also conducts regular inspections of canning facilities to verify compliance with regulations. These inspections help to identify and correct any potential safety hazards.

Consumer Confidence and Future Trends

The low incidence of foodborne illness associated with commercially canned goods speaks volumes about the effectiveness of modern canning techniques. However, consumer confidence is crucial, and maintaining it requires ongoing vigilance and transparency.

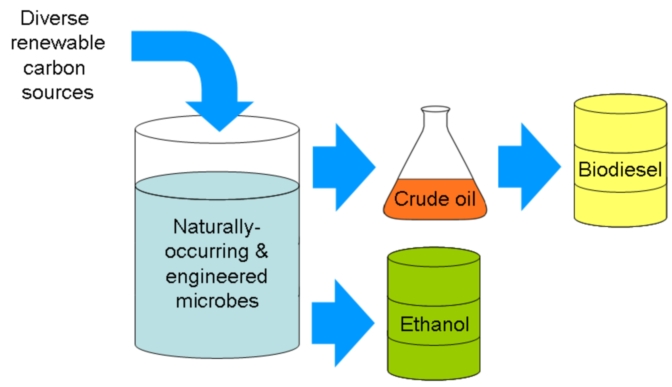

There's a growing trend towards more natural and minimally processed foods, which presents a challenge to the canning industry. Researchers are exploring new technologies, such as pulsed electric fields and high-pressure processing, that could reduce the need for high-temperature treatments while still ensuring food safety.

Ultimately, the future of canned foods lies in finding a balance between preserving food safely and meeting consumer demand for healthier and more sustainable products. Through continued research, innovation, and rigorous regulation, the canned food industry can continue to provide a safe and convenient source of nutrition for people around the world.