3 Months Accelerated Stability Equivalent To

A groundbreaking study published in the Journal of Accelerated Testing has revealed that a novel accelerated aging process can simulate three months of standard product stability within just one week. This accelerated method promises to revolutionize industries relying on accurate shelf-life predictions, from pharmaceuticals to food and beverage.

The study, conducted by a team of researchers at the National Institute of Standards and Technology (NIST) in collaboration with several private sector companies, offers a significant leap forward in product development and quality control. This could drastically reduce the time and resources needed to assess product lifespan, a crucial factor for both manufacturers and consumers.

The Science Behind the Acceleration

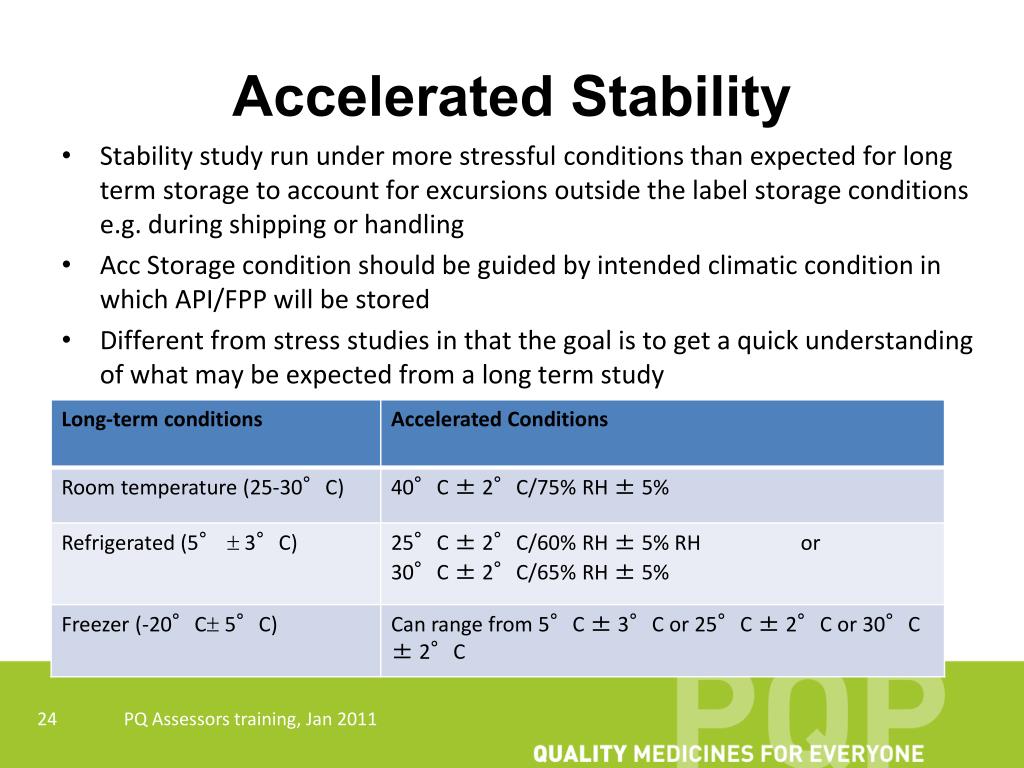

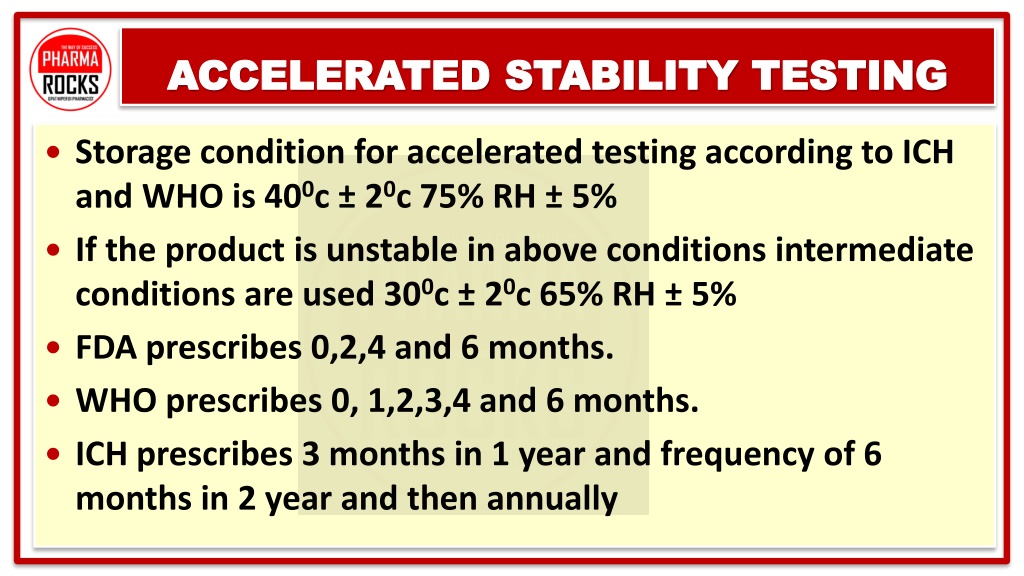

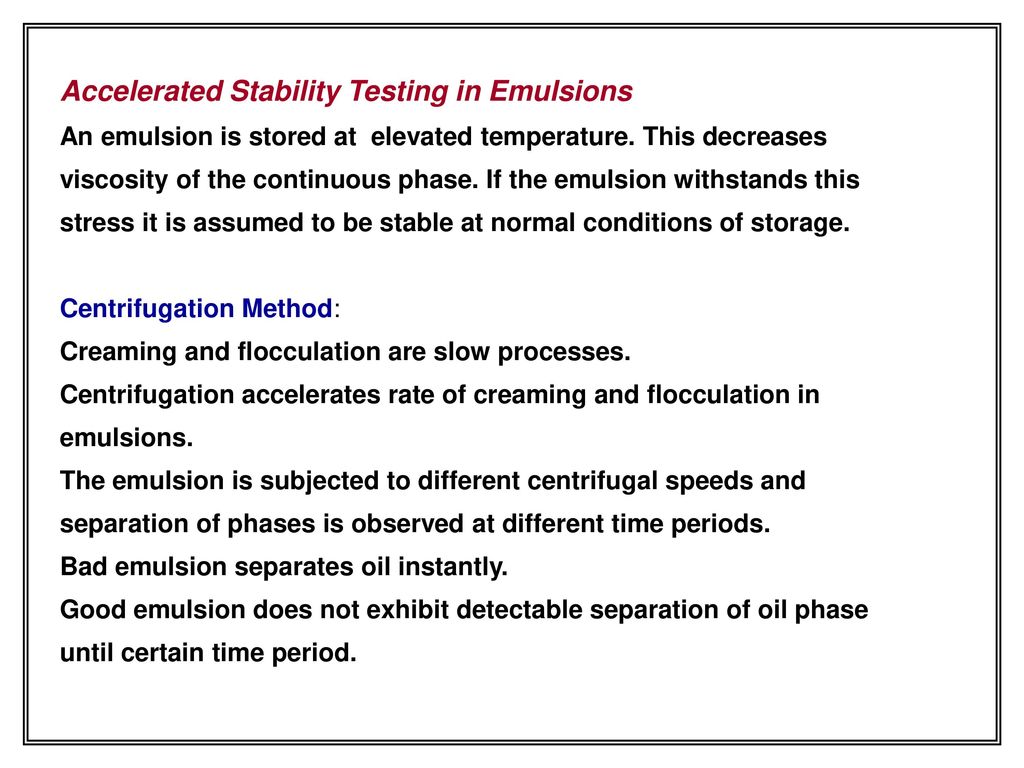

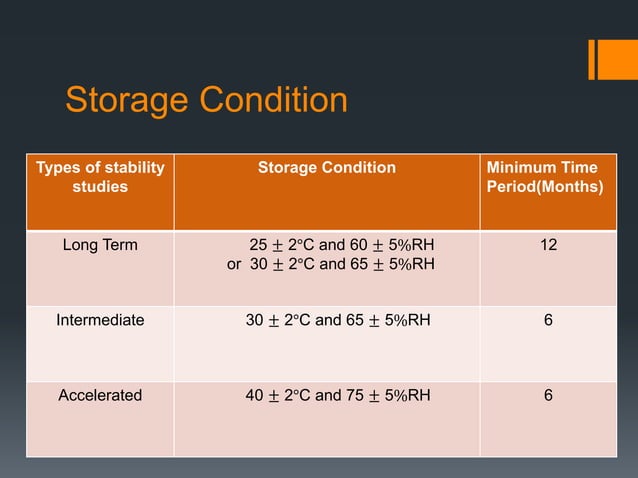

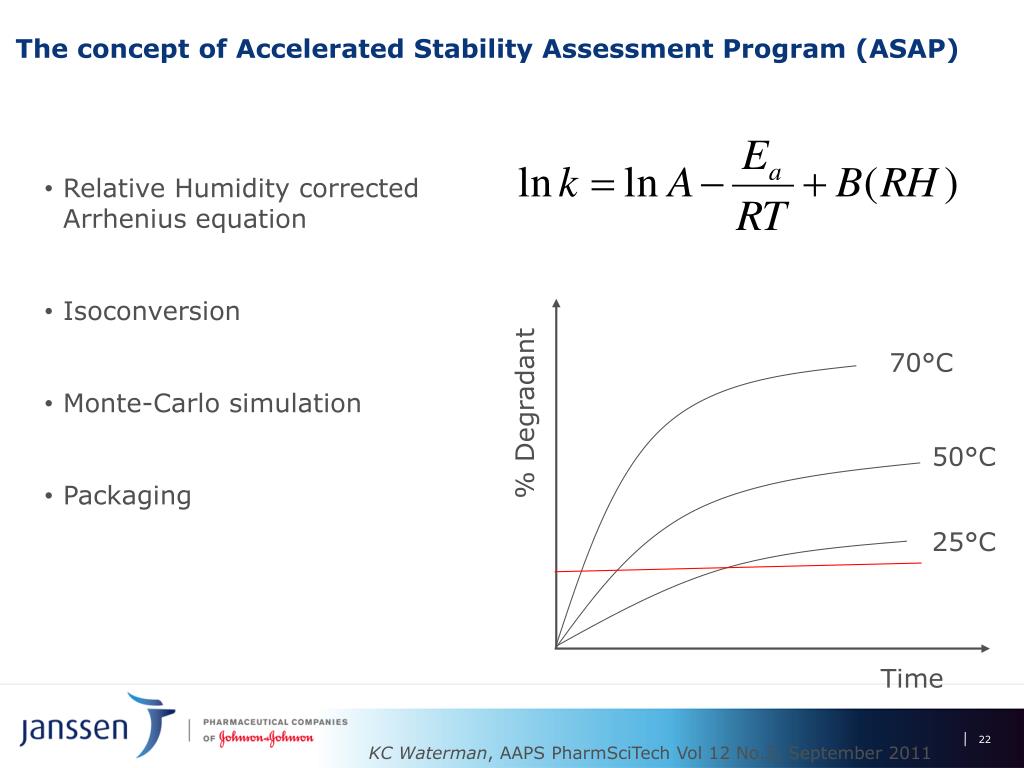

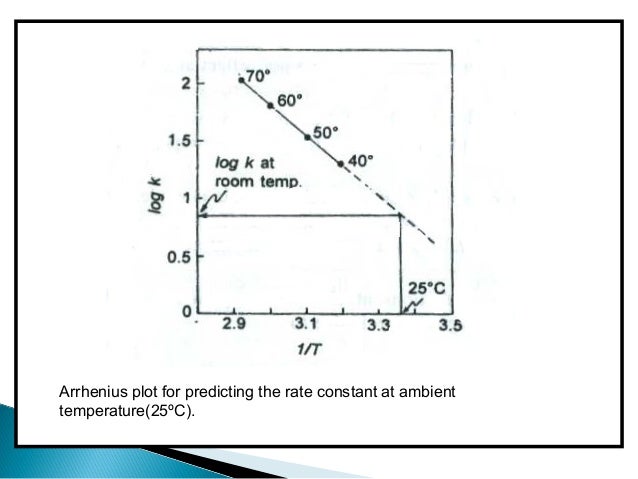

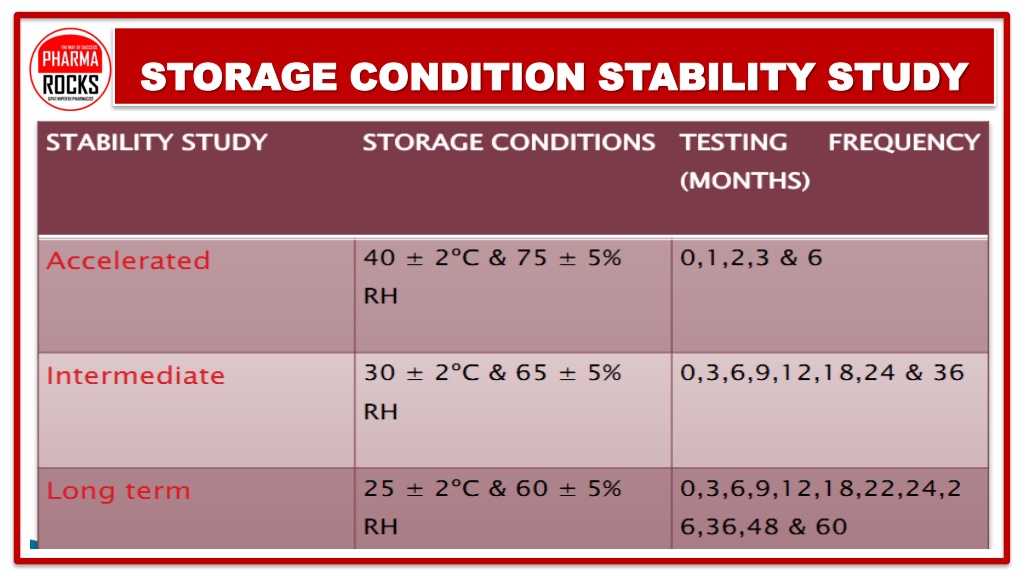

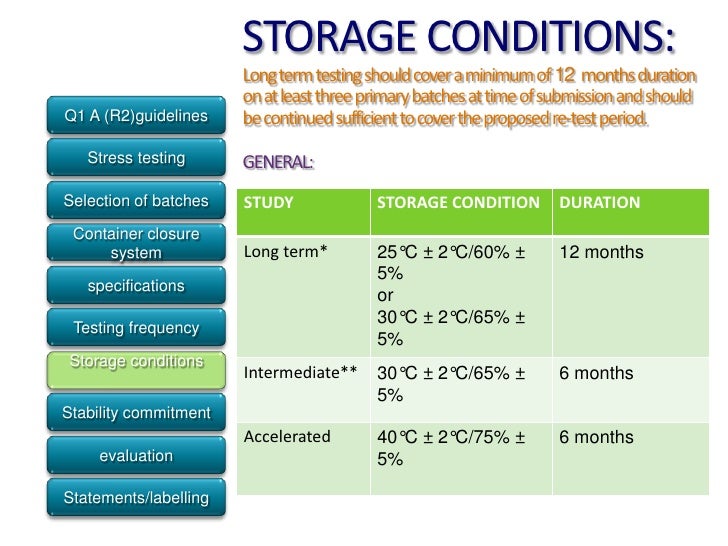

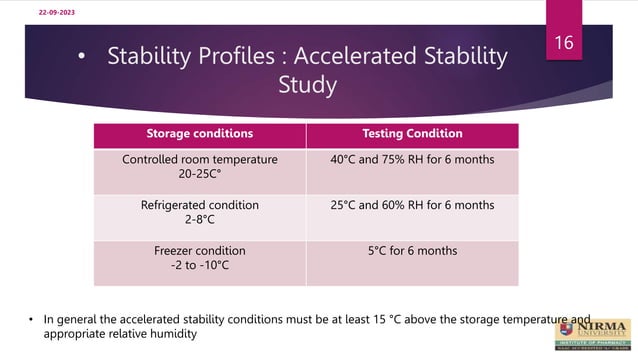

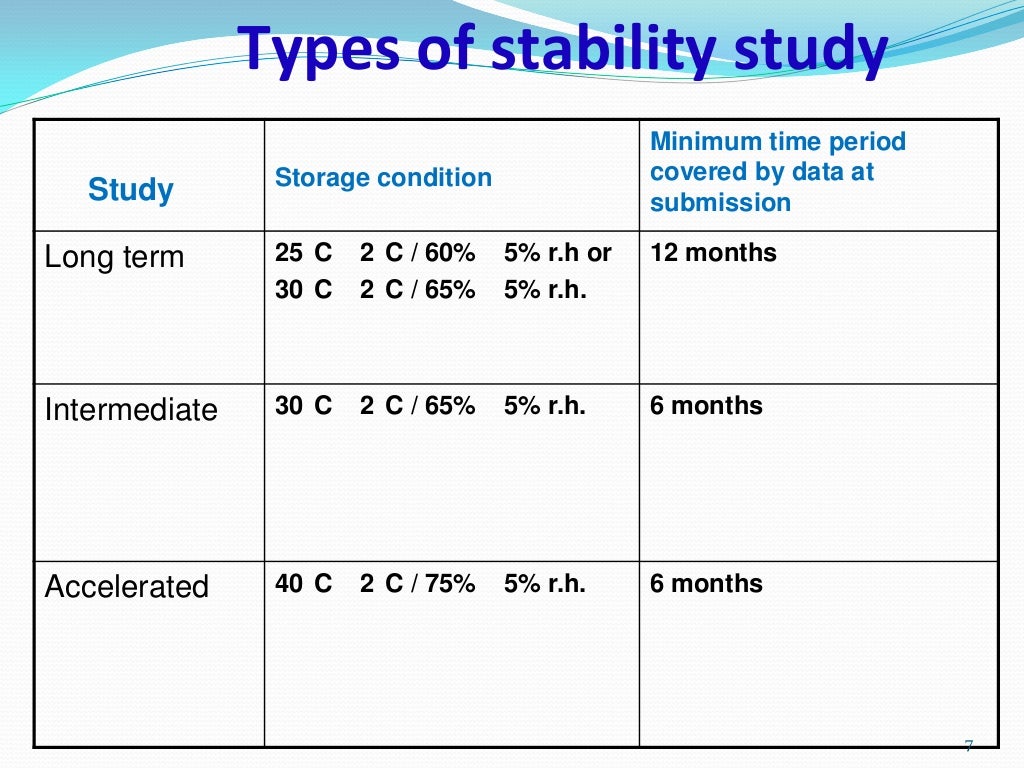

The researchers achieved this accelerated stability assessment by carefully manipulating environmental factors, primarily temperature and humidity. By subjecting products to precisely controlled elevated conditions, they could mimic the degradation processes that typically occur over a much longer period under normal storage conditions.

Dr. Emily Carter, the lead author of the study and a materials scientist at NIST, explained that the key was identifying the specific degradation pathways relevant to each product type. This understanding allowed them to fine-tune the accelerated aging parameters for accurate simulation.

Key Details of the Process

The accelerated aging process involves placing products in specialized chambers where temperature and humidity are precisely controlled. Data loggers continuously monitor these conditions, ensuring consistency and accuracy throughout the testing period.

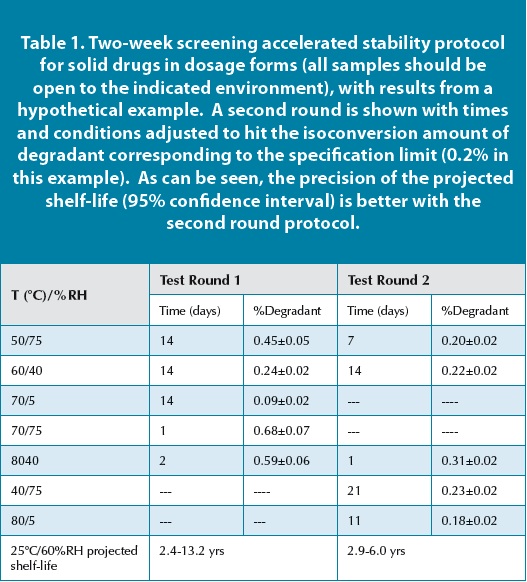

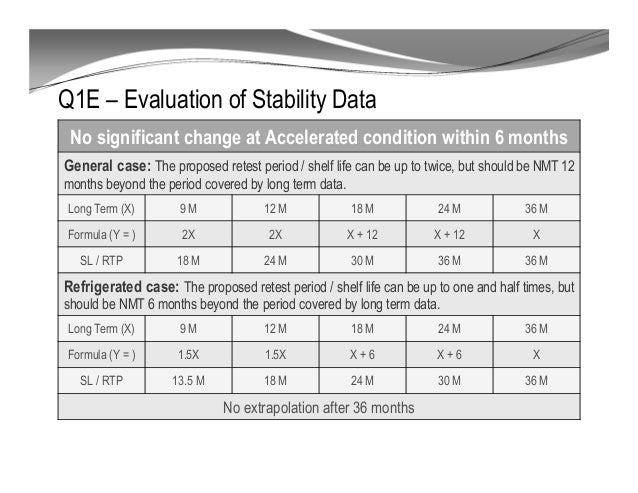

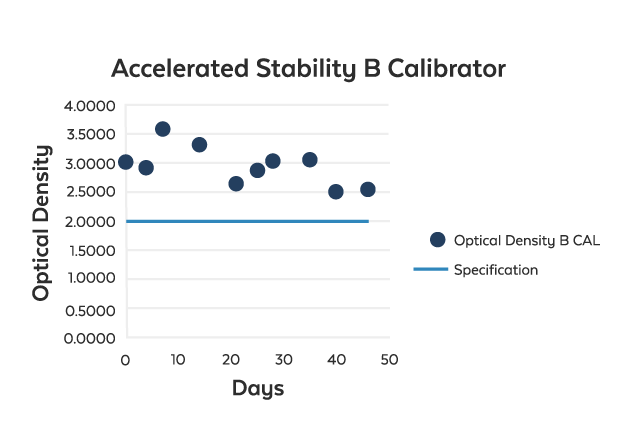

The researchers then analyze the products at regular intervals, assessing changes in physical properties, chemical composition, and other relevant indicators of degradation. This data is then extrapolated to predict the product's expected shelf life under normal conditions.

Specifically, the study focused on three product categories: a common over-the-counter pain reliever, a packaged snack food, and an industrial adhesive. The results consistently demonstrated a strong correlation between the accelerated aging data and the actual stability observed over a three-month period in standard storage conditions.

Impact on Industries

The implications of this research are far-reaching. Pharmaceutical companies, for example, could significantly reduce the time it takes to bring new drugs to market, ensuring that medications remain effective throughout their labeled shelf life.

"This technology has the potential to save pharmaceutical companies considerable amounts of time and money in stability testing. It will allow manufacturers to optimize the safety and quality of pharmaceuticals and other products.” – Dr. Mark Thompson, CEO of PharmaTest Solutions

Similarly, the food and beverage industry could use this accelerated testing method to optimize packaging, improve product formulations, and minimize waste. This also allows companies to react quicker to customer's taste, improving product formulations based on the need.

Industrial manufacturers could benefit by ensuring the longevity of their products, reducing warranty claims, and improving customer satisfaction.

Potential Benefits and Challenges

Beyond reduced time and cost, the accelerated stability assessment offers several other potential benefits. It allows for more rapid identification of potential product flaws, enabling manufacturers to make necessary adjustments early in the development process.

Furthermore, it provides a more robust and reliable method for verifying the accuracy of product shelf life claims, building consumer trust and confidence.

However, there are also challenges to consider. The accelerated aging process may not be suitable for all types of products, particularly those with complex degradation mechanisms. Careful validation and calibration are essential to ensure the accuracy of the predictions.

A Human-Interest Angle

For Sarah Miller, a single mother who relies on affordable over-the-counter medications for her family, the potential of this technology is personal. "Knowing that the medications I buy are guaranteed to be effective gives me peace of mind," she said. "Anything that makes those medications more reliable and affordable is a win for families like mine."

The research team at NIST is actively working to refine and expand the application of the accelerated aging process to a wider range of products. They are also developing standardized protocols to ensure consistency and accuracy across different industries.

This breakthrough in accelerated stability testing holds immense promise for transforming product development and quality control. By reducing the time and resources needed to assess product lifespan, it can drive innovation, improve product quality, and ultimately benefit consumers worldwide.