8.5 Mm Drill Bit To Standard

A seemingly insignificant change to a tiny tool is causing ripples of debate across industries, from aerospace to dentistry. The standardization of an 8.5 mm drill bit – a decision years in the making – has ignited discussions about precision, efficiency, and the potential disruption of established practices.

At its core, the controversy surrounding the 8.5 mm drill bit standardization boils down to a complex interplay of global trade, manufacturing tolerances, and the deeply ingrained preferences of skilled professionals. This article will delve into the reasons behind this standardization, the industries most affected, and the potential benefits and drawbacks of this seemingly minor, yet impactful, shift.

The Push for Standardization: A Global Perspective

The move to standardize the 8.5 mm drill bit is largely driven by international bodies seeking to streamline manufacturing processes and improve interoperability across global markets. The International Organization for Standardization (ISO) has been instrumental in pushing for this change, citing potential benefits in terms of reduced production costs and improved supply chain efficiency.

According to a statement released by the ISO, "Standardization of key components, such as drill bits, allows for greater interchangeability and reduces the need for manufacturers to maintain a diverse inventory of tools." This, they argue, will ultimately benefit both manufacturers and consumers.

However, not everyone is convinced. Critics argue that forcing a single standard ignores the nuances of various industries and the specific needs of individual professionals. Concerns have been raised about the potential for reduced precision and the need for costly retooling.

Industries on the Front Lines

Several industries are poised to be significantly impacted by the 8.5 mm drill bit standardization, including:

Aerospace Engineering

The aerospace industry, known for its stringent safety standards and reliance on precise measurements, is among the most vocal opponents of the standardization. Aerospace engineers often work with extremely tight tolerances, and some argue that the 8.5 mm drill bit may not always provide the necessary level of accuracy.

A senior engineer at Boeing, speaking on condition of anonymity, stated: "In aerospace, even the smallest deviation can have significant consequences. We need tools that are precisely calibrated for specific tasks, and a universal standard may not always meet those requirements."

Medical Device Manufacturing

Similar concerns are being raised within the medical device manufacturing sector. The creation of implants, surgical tools, and other critical medical devices demands a high degree of precision and quality control. Any deviation from established protocols could potentially compromise patient safety.

"The safety of our patients is our top priority," said Dr. Emily Carter, a leading orthopedic surgeon. "We need to ensure that the tools we use are perfectly suited for the task at hand, and we're not convinced that a one-size-fits-all approach is the best way to achieve that."

Dentistry

The dental industry, which relies on a diverse range of specialized drill bits for various procedures, is also expressing reservations. Dentists argue that the 8.5 mm drill bit may not be suitable for all dental applications, particularly those involving delicate or intricate work.

Some dentists fear that the standardization could lead to a decrease in the quality of dental care, as they may be forced to use tools that are not ideally suited for their specific needs.

Potential Benefits and Drawbacks

While the standardization of the 8.5 mm drill bit has its detractors, it also offers several potential benefits. These include:

Reduced Manufacturing Costs

By streamlining production and reducing the need for a diverse range of drill bit sizes, manufacturers could potentially lower their costs. This, in turn, could lead to lower prices for consumers.

Improved Supply Chain Efficiency

Standardization can simplify supply chain management, making it easier for manufacturers to source and distribute drill bits. This could lead to faster delivery times and reduced inventory costs.

Greater Interoperability

A standardized drill bit would be compatible with a wider range of equipment, making it easier for professionals to switch between different tools and machines. This could increase efficiency and productivity.

However, the potential drawbacks cannot be ignored. These include:

Reduced Precision

As mentioned earlier, some critics worry that the 8.5 mm drill bit may not always provide the necessary level of precision for certain applications. This could be particularly problematic in industries where even the smallest deviation can have significant consequences.

Increased Retooling Costs

Manufacturers may need to invest in new equipment and tooling to accommodate the 8.5 mm drill bit. This could be a significant expense, particularly for smaller businesses.

Resistance from Professionals

Some professionals may be reluctant to switch to a standardized drill bit, particularly if they are already comfortable with their existing tools and methods. This could lead to resistance and a slow adoption rate.

The Road Ahead

The debate surrounding the 8.5 mm drill bit standardization is likely to continue for some time. As the standard is implemented, it will be crucial to monitor its impact on various industries and to address any concerns that may arise.

Open communication and collaboration between manufacturers, industry experts, and standardization bodies will be essential to ensure that the benefits of standardization are realized without compromising quality or safety. Whether the 8.5 mm drill bit becomes a universally accepted standard remains to be seen, but its impact on the global manufacturing landscape is undeniable.

The future will depend on adaptability and a willingness to balance the benefits of standardization with the specific needs of individual industries and professionals. Only time will tell if this seemingly small change will ultimately lead to greater efficiency and innovation, or to unforeseen challenges and compromises.

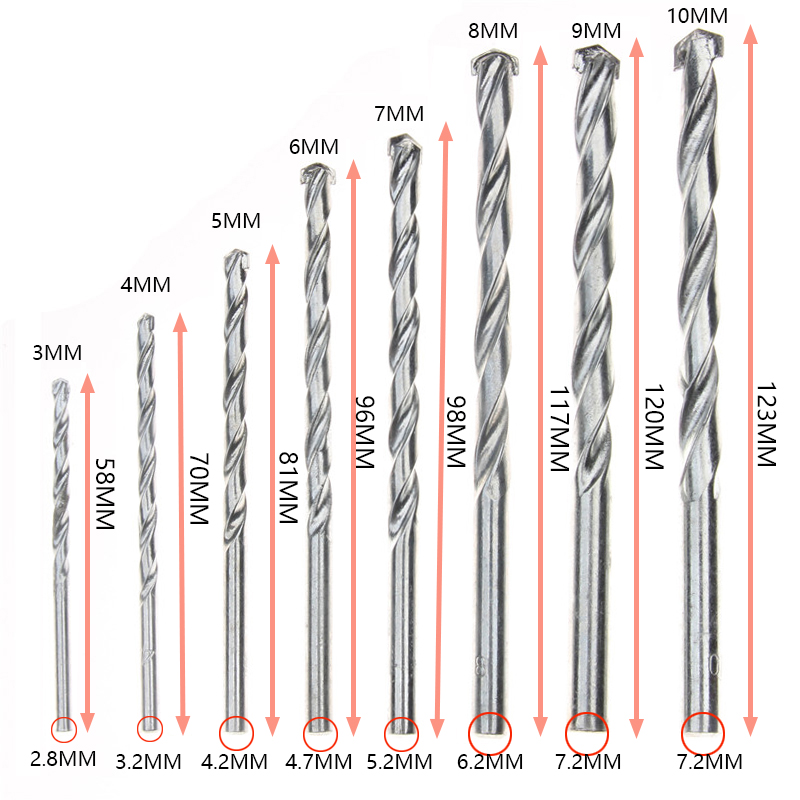

![8.5 Mm Drill Bit To Standard Printable Drill Bit Size Charts [%100 Free + PDF]](https://www.typecalendar.com/wp-content/uploads/2023/08/Free-Drill-Bit-Size-Chart-PDF.jpg)