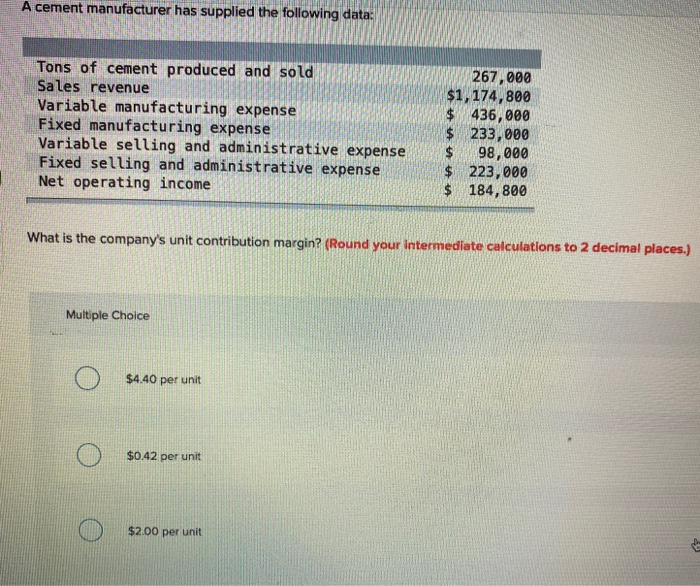

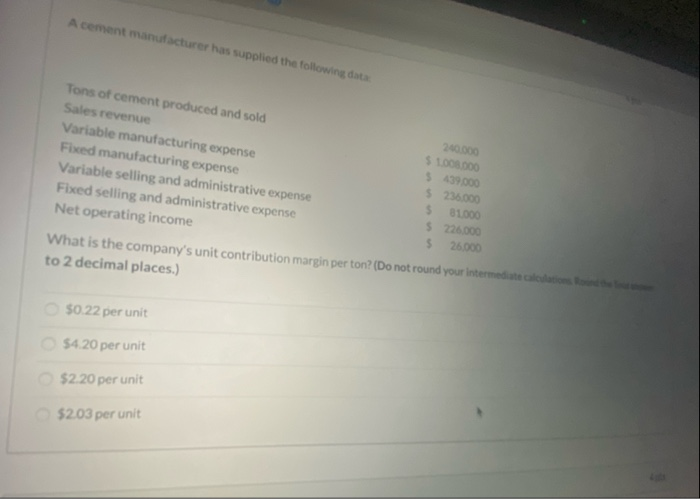

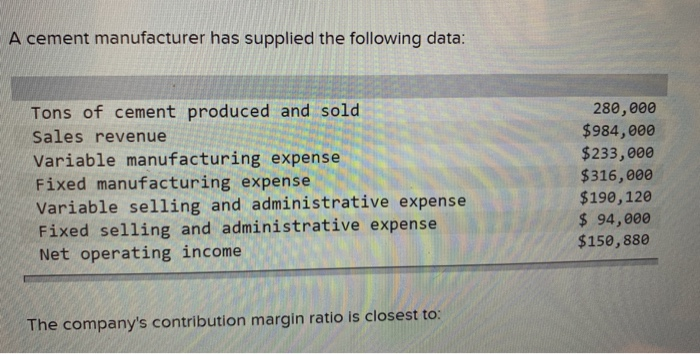

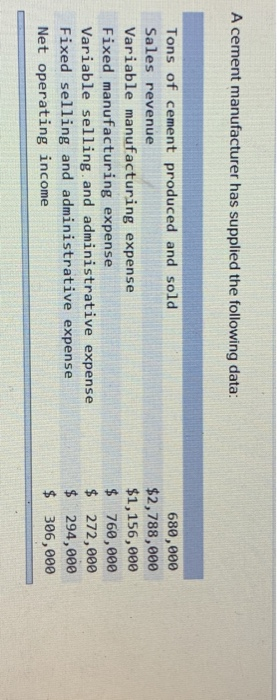

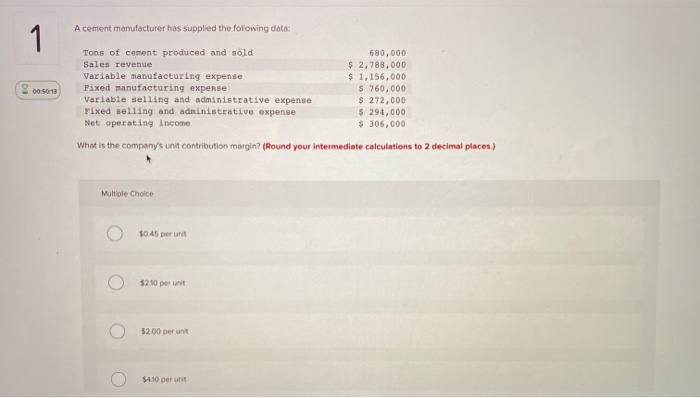

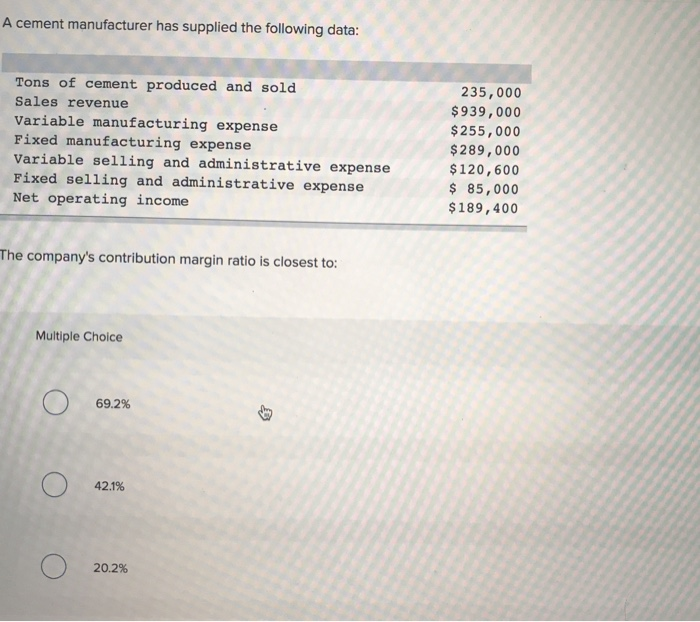

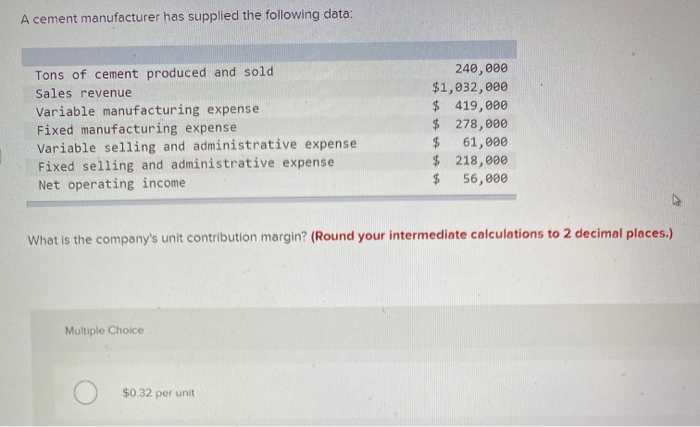

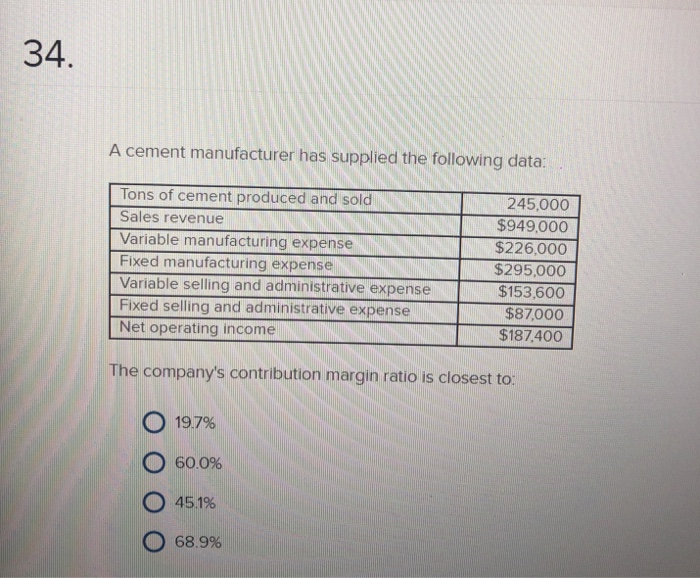

A Cement Manufacturer Has Supplied The Following Data

Imagine a landscape sculpted by human hands, dotted with structures that stand as testaments to our ingenuity and progress. From towering skyscrapers that pierce the clouds to the humble homes that shelter families, cement forms the very foundation of our modern world. But behind this ubiquitous material lies a complex story of resource management, environmental impact, and a constant drive for innovation.

The LafargeHolcim cement manufacturing plant, a major player in the global construction materials industry, has recently supplied comprehensive data on its operations. This information provides a crucial window into the company’s efforts to balance production demands with environmental responsibility, offering a snapshot of both the challenges and opportunities within the cement manufacturing sector.

A Deep Dive into LafargeHolcim's Data

LafargeHolcim's data submission encompasses a wide range of metrics, including raw material sourcing, energy consumption, emissions levels, and waste management practices. It paints a multifaceted picture of the complex processes involved in cement production. Understanding this data is critical for assessing the industry’s current standing and charting a course towards a more sustainable future.

The Significance of Transparency

Transparency is paramount in fostering accountability and driving positive change within any industry, especially one with the environmental footprint of cement manufacturing. By sharing this data, LafargeHolcim opens itself to scrutiny and provides stakeholders – including governments, researchers, and the public – with valuable insights. These insights are vital for informed decision-making and collaborative efforts to mitigate environmental impacts.

The decision to share such detailed information underscores a commitment to openness and a recognition of the company’s role in addressing global sustainability challenges. It reflects a growing trend within the industry to embrace transparency as a core value and a catalyst for innovation.

The Cement Manufacturing Process: A Quick Overview

Cement production is an energy-intensive process that begins with the extraction of raw materials, primarily limestone, clay, and marl. These materials are then crushed, ground, and mixed in precise proportions. This mixture is fed into a rotary kiln, a massive furnace heated to temperatures exceeding 1,450 degrees Celsius.

Inside the kiln, a chemical reaction called calcination occurs, transforming the raw materials into clinker, small, hard nodules that are the intermediate product. The clinker is then cooled and ground into a fine powder, with the addition of gypsum to control setting time, resulting in the final product: cement.

The use of alternative fuels, such as waste materials or biomass, can partially displace traditional fossil fuels, reducing carbon emissions. Additionally, incorporating supplementary cementitious materials (SCMs), such as fly ash or slag, can further lower the clinker-to-cement ratio.

Key Data Points and Their Implications

One of the most crucial data points is the company’s CO2 emissions per ton of cement produced. Cement production is a significant contributor to greenhouse gas emissions, accounting for roughly 8% of global CO2 emissions, according to the Global Cement and Concrete Association (GCCA). Reductions in this area are essential for meeting global climate targets.

The data also reveals the company’s progress in reducing its clinker-to-cement ratio. Lowering this ratio, through the use of SCMs, can significantly decrease the environmental impact of cement production. The trend suggests a move towards more resource-efficient practices.

Waste management practices are also highlighted, including the reuse and recycling of materials within the production process. Minimizing waste generation and maximizing resource recovery are critical for promoting circular economy principles within the industry.

Innovations and Future Directions

The data sheds light on LafargeHolcim's investment in research and development, particularly in the area of low-carbon cement technologies. This includes the development of alternative binders, carbon capture and storage technologies, and innovative construction techniques. These innovations hold the potential to transform the cement industry and significantly reduce its environmental footprint.

Carbon capture and storage (CCS) technologies are gaining traction as a promising solution for mitigating CO2 emissions from cement plants. CCS involves capturing CO2 from flue gases and storing it permanently underground, preventing it from entering the atmosphere.

Another area of focus is the development of geopolymers, alternative binders that can replace traditional cement in certain applications. Geopolymers are produced from industrial byproducts, such as fly ash and slag, offering a sustainable alternative to clinker-based cement.

Challenges and Opportunities

While the data paints a generally positive picture of progress, it also underscores the challenges faced by the cement industry in its pursuit of sustainability. The high energy intensity of the production process remains a significant hurdle. Balancing environmental responsibility with economic viability is a constant balancing act for manufacturers.

However, the industry also faces numerous opportunities for innovation and improvement. Investing in new technologies, adopting circular economy principles, and collaborating with stakeholders are key to unlocking these opportunities. This collaboration extends to governments, research institutions, and other industry players.

Consumer demand for sustainable construction materials is also driving change within the industry. As consumers become more aware of the environmental impact of construction, they are increasingly seeking out products and practices that minimize their footprint.

The Broader Context: Global Sustainability Goals

The efforts of LafargeHolcim and other cement manufacturers are directly linked to the achievement of broader global sustainability goals, such as the United Nations Sustainable Development Goals (SDGs). In particular, SDG 9 (Industry, Innovation, and Infrastructure) and SDG 13 (Climate Action) are closely intertwined with the cement industry’s efforts to reduce its environmental impact.

The data provided by LafargeHolcim contributes to a more comprehensive understanding of the industry’s progress towards these goals. It provides a baseline for measuring future improvements and identifying areas where further action is needed. This data can inform policy decisions and guide investment strategies.

The cement industry plays a crucial role in building sustainable infrastructure and resilient communities. By embracing innovation and prioritizing environmental responsibility, the industry can contribute to a more sustainable future for all.

A Path Forward: Collaboration and Continuous Improvement

The journey towards sustainable cement manufacturing is an ongoing process that requires continuous improvement and collaboration. Transparency, innovation, and a commitment to environmental stewardship are essential ingredients for success. The data shared by LafargeHolcim serves as a valuable resource for stakeholders and a catalyst for positive change.

The data is not just a collection of numbers; it represents a commitment to a better future. It’s a roadmap that can guide the industry toward more responsible and sustainable practices. It reinforces the notion that the future of construction is inextricably linked to the future of the planet.

As we continue to build and develop our world, the cement industry has a vital role to play in ensuring that our structures are not only strong and durable, but also environmentally sound. By embracing innovation and prioritizing sustainability, we can create a built environment that benefits both present and future generations.

![A Cement Manufacturer Has Supplied The Following Data [Solved] A cement manufacturer has supplied the fo | SolutionInn](https://dsd5zvtm8ll6.cloudfront.net/si.experts.images/questions/2022/02/6216069809f2e_64762160697ae2fb.jpg)