An Operations Strategy For Inventory Management Should Work Toward

Companies across industries are increasingly focused on optimizing their inventory management, recognizing it as a crucial lever for profitability and customer satisfaction. A well-defined operations strategy is no longer a mere suggestion, but a necessity in today's competitive landscape.

At the heart of this shift is the understanding that inventory isn't just about stockpiling goods; it’s about striking a delicate balance between meeting demand, minimizing costs, and maximizing efficiency. This article explores the key elements of an effective inventory management operations strategy, highlighting how companies can achieve this crucial equilibrium.

The Core Principles

An effective operations strategy for inventory management revolves around several core principles. These principles act as guideposts, directing decisions and ensuring alignment with overarching business goals.

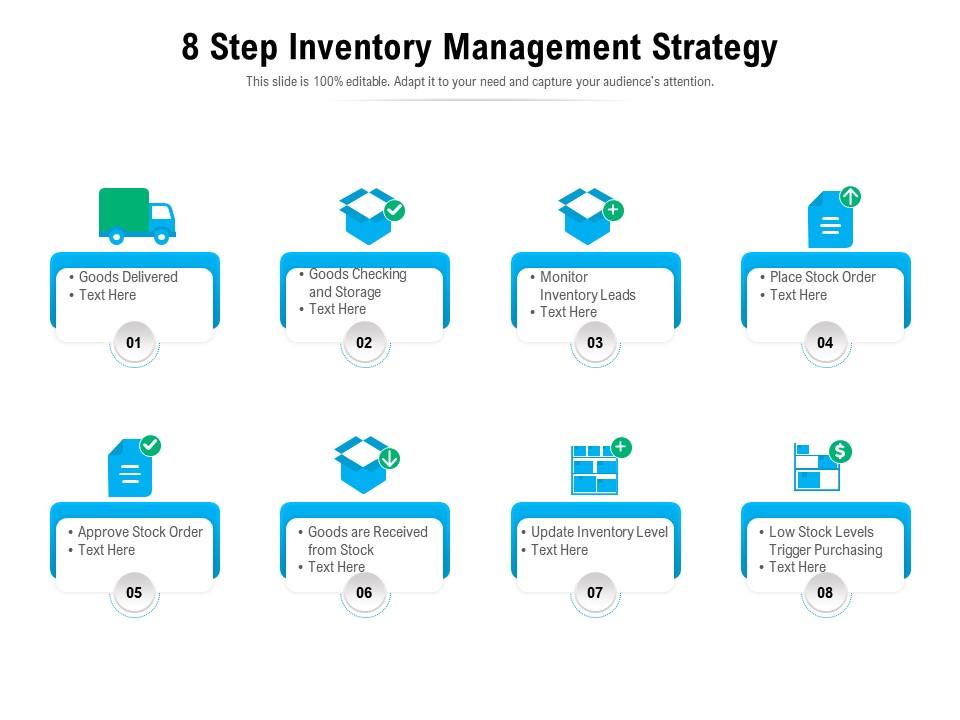

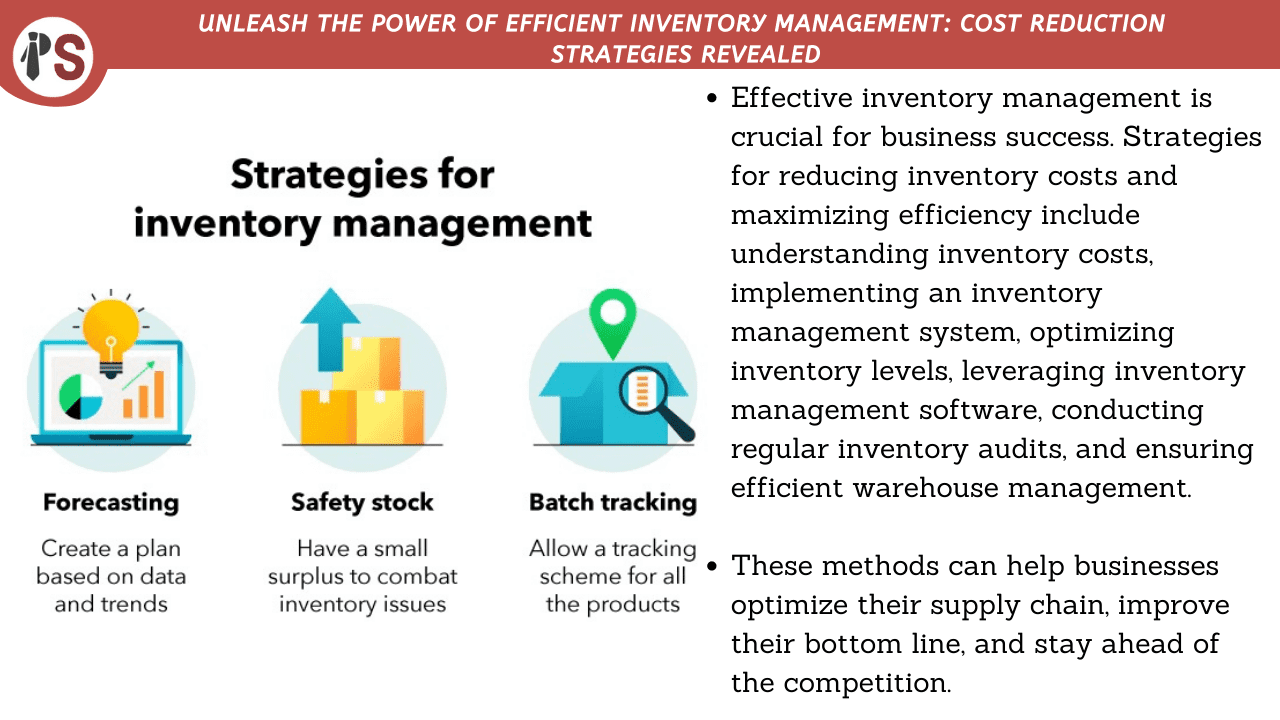

Demand Forecasting is paramount. Accurate predictions of future demand enable businesses to procure or manufacture the right quantity of goods at the right time, avoiding both stockouts and excessive inventory holding costs.

Lead Time Reduction plays a critical role. Reducing the time it takes to replenish inventory streamlines the entire supply chain, allowing for more responsive adjustments to demand fluctuations.

Inventory Classification allows focusing on the most important items. The ABC analysis, for example, categorizes inventory based on value and consumption, enabling businesses to prioritize high-value items.

Warehouse Management is crucial for efficiency. Optimizing layout and processes within the warehouse ensures quick and accurate order fulfillment, minimizing errors and maximizing throughput.

Technology's Role in Optimization

Technology is no longer a luxury, but an indispensable tool in modern inventory management. Sophisticated software solutions offer real-time visibility and control over inventory levels across the entire supply chain.

Enterprise Resource Planning (ERP) systems integrate various business functions, including inventory management, providing a comprehensive view of operations. This integration allows for informed decision-making and streamlined workflows.

Warehouse Management Systems (WMS) optimize warehouse operations, from receiving and put-away to picking and shipping. They improve accuracy, reduce cycle times, and enhance overall efficiency.

Radio Frequency Identification (RFID) technology enables real-time tracking of inventory items, improving accuracy and reducing losses. RFID provides a much more granular level of visibility than traditional barcode scanning.

The Human Element

While technology plays a crucial role, the human element remains vital to the success of any inventory management operations strategy. Skilled personnel are needed to analyze data, make informed decisions, and oversee the entire process.

Training and Development are essential for equipping employees with the knowledge and skills needed to manage inventory effectively. A well-trained workforce can leverage technology and implement best practices.

Cross-Functional Collaboration fosters seamless communication and coordination across departments. Collaboration between sales, marketing, and operations ensures that inventory decisions are aligned with market demand and business goals.

The Importance of Continuous Improvement

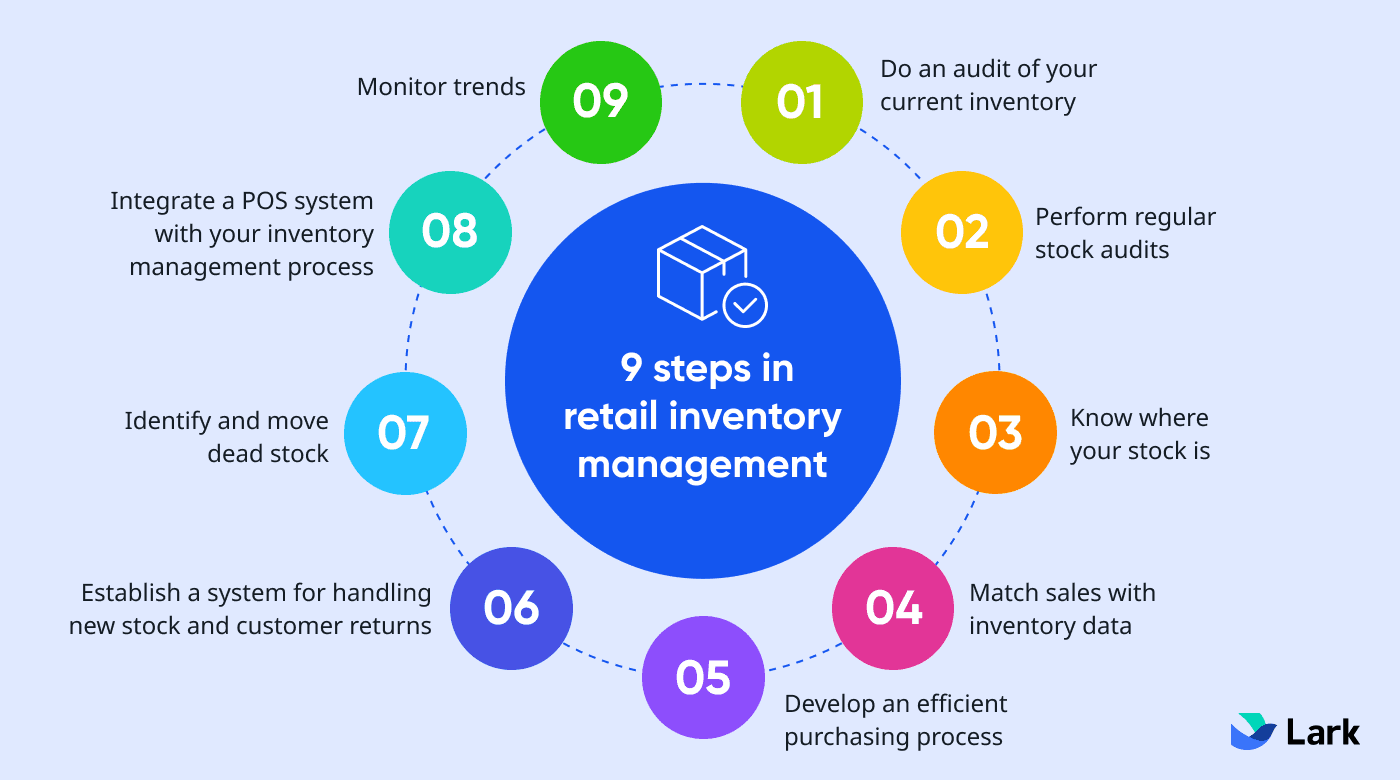

An effective inventory management operations strategy is not a one-time project but a continuous process of improvement. Regular monitoring, analysis, and adjustments are needed to adapt to changing market conditions and evolving business needs.

Key Performance Indicators (KPIs), such as inventory turnover, fill rate, and order accuracy, provide valuable insights into the effectiveness of the operations strategy. Tracking these KPIs allows businesses to identify areas for improvement and measure the impact of changes.

Regular Audits help identify inefficiencies and ensure compliance with established procedures. Internal and external audits can uncover hidden problems and ensure that inventory management practices are aligned with best practices.

Feedback Mechanisms allow employees and customers to provide valuable input for improving inventory management processes. Capturing feedback from various stakeholders can uncover blind spots and lead to innovative solutions.

A Case Study

Consider a hypothetical mid-sized electronics manufacturer, ElectroTech Inc. Faced with rising inventory costs and increasing stockouts, ElectroTech implemented a comprehensive inventory management operations strategy.

They invested in an ERP system to integrate their supply chain, improved demand forecasting through data analytics, and optimized their warehouse layout. Consequently, they saw a 20% reduction in inventory holding costs and a 15% improvement in fill rates within the first year.

Potential Impacts

The effective execution of an inventory management operations strategy can have a profound impact on a company's bottom line and overall competitiveness. Lower inventory costs, improved customer service, and increased operational efficiency are just some of the potential benefits.

Businesses that embrace these principles and invest in the right technologies and people are well-positioned to thrive in today's dynamic and competitive market. Those who ignore this critical aspect of operations risk falling behind.

Looking Ahead

As businesses navigate an increasingly complex global supply chain, a robust and adaptable inventory management operations strategy will only become more critical. The ability to anticipate demand, optimize processes, and leverage technology will differentiate the winners from the losers.

By prioritizing operations strategy and embracing continuous improvement, companies can unlock significant value and achieve sustainable growth. The future belongs to those who master the art and science of inventory management.