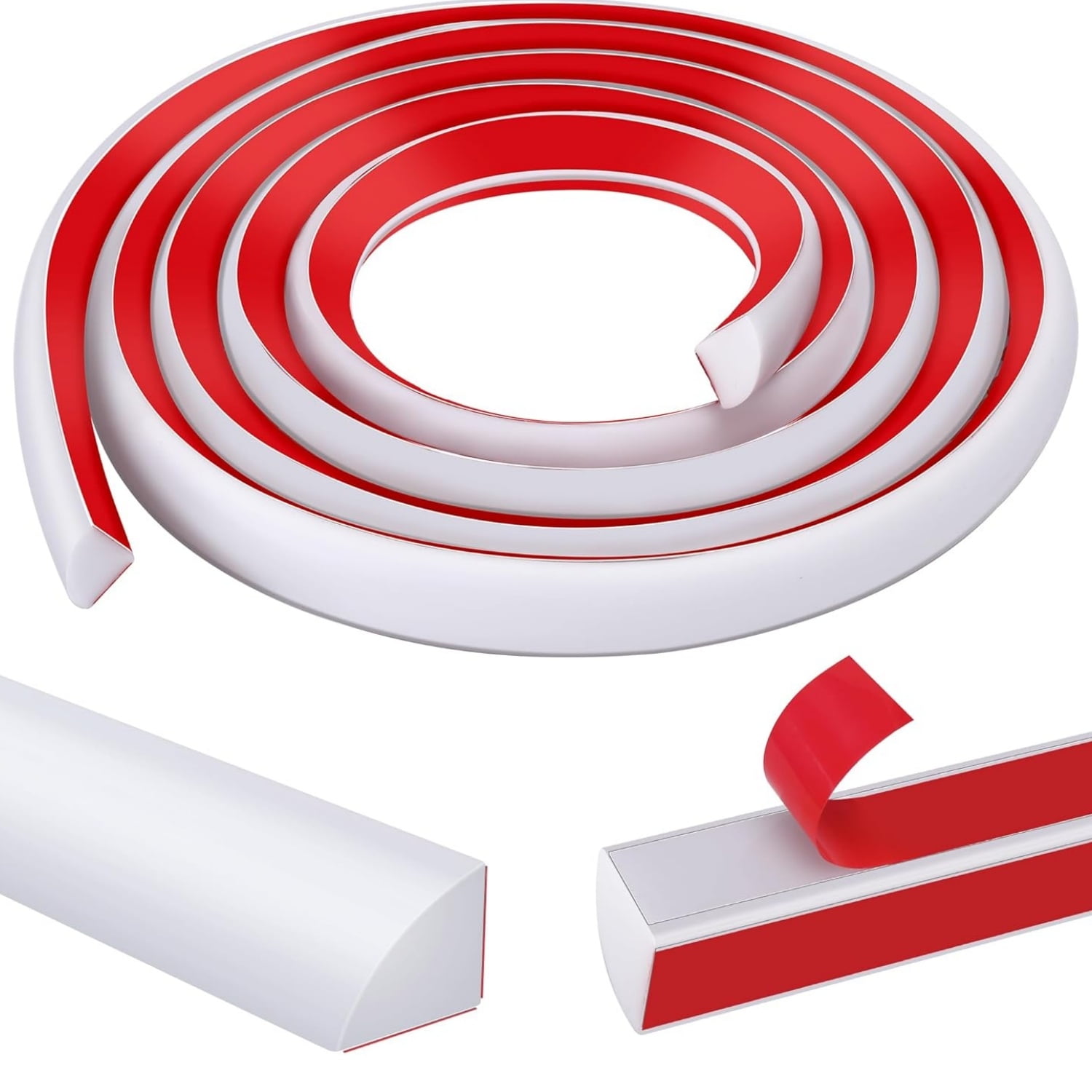

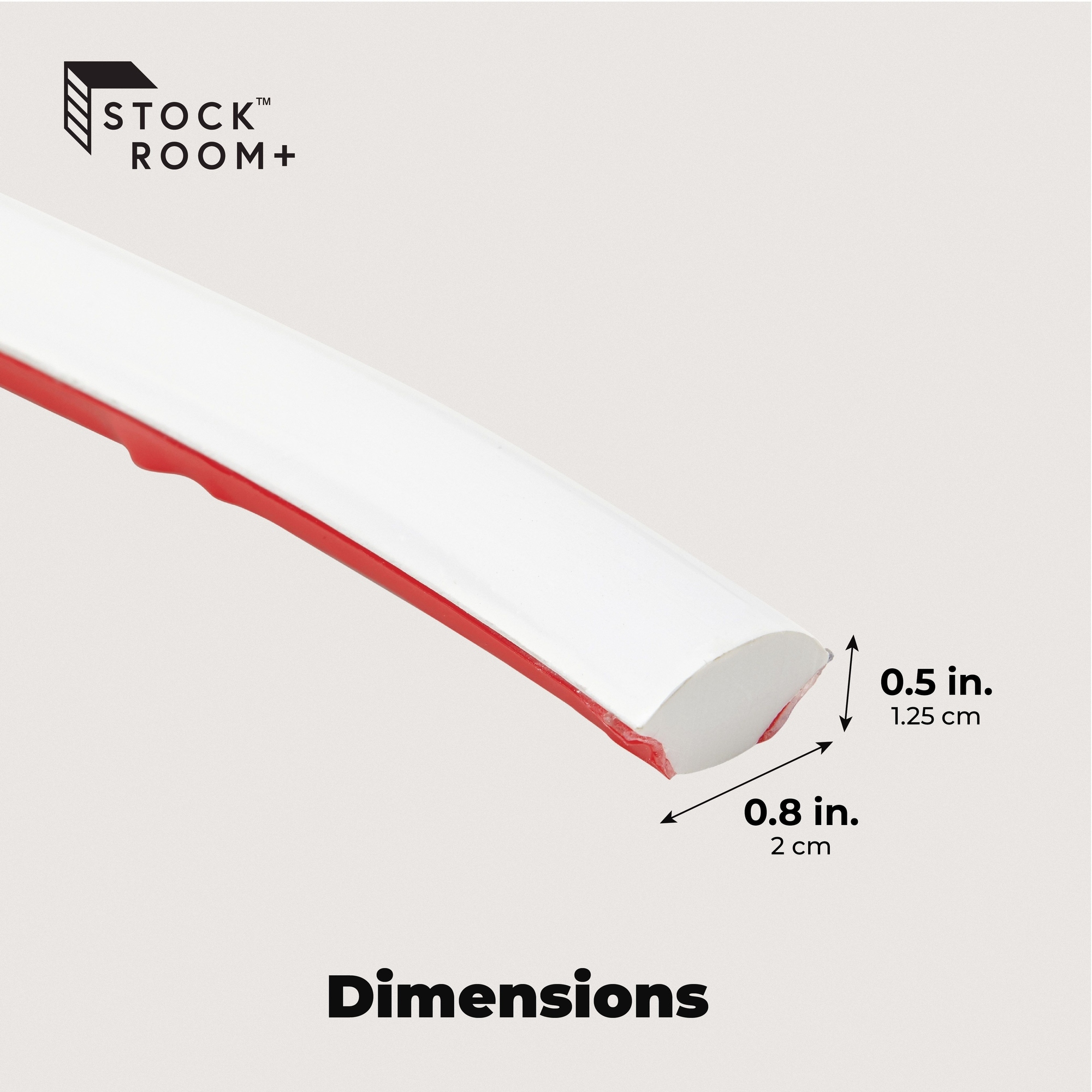

Flexible Quarter Round Molding White

The subtle curve of a staircase, the gentle arc of a bay window – these architectural nuances have long presented a challenge to homeowners and builders alike when it comes to finishing details. Traditional wood molding, rigid and unforgiving, often requires intricate cuts and painstaking piecing to achieve a seamless, professional look. However, a new generation of flexible quarter round molding, particularly in white, is rapidly changing the landscape of interior trim.

Flexible quarter round molding offers a pliable alternative to traditional wood, allowing for smooth, unbroken lines around curved surfaces. This article will delve into the properties, applications, and benefits of flexible quarter round molding, focusing on the increasingly popular white variant. It will also explore its impact on both professional contractors and DIY enthusiasts, while considering environmental and cost implications.

What is Flexible Quarter Round Molding?

Flexible quarter round is typically crafted from a polymer composite material, designed to mimic the look and feel of wood while possessing significantly greater flexibility. This inherent pliability allows it to bend and conform to curved or irregular surfaces without cracking or splintering. The white finish provides a clean, modern aesthetic that complements a wide range of interior design styles.

The Composition and Manufacturing Process

According to industry reports, most flexible quarter round moldings are made from a blend of polymers, including PVC and polyurethane. The specific composition can vary depending on the manufacturer, influencing the molding's flexibility, durability, and paintability. The manufacturing process involves extruding the polymer blend through a die to create the desired profile, followed by a finishing process that includes applying a consistent white coating.

Applications and Benefits

The primary benefit of flexible quarter round molding is its ability to easily navigate curved surfaces, eliminating the need for complicated miter cuts. This makes it ideal for finishing baseboards around curved walls, trimming arched doorways, and creating a polished look around staircases. Many homeowners appreciate the time and effort saved during installation, as well as the professional-looking results.

Ease of Installation

Installation typically involves measuring and cutting the molding to the required length, then adhering it to the surface using construction adhesive or small finish nails. Because of its flexibility, the molding can be easily manipulated to fit even complex curves. This simplifies the process, making it accessible to both experienced contractors and DIYers.

Aesthetic Appeal and Versatility

The crisp white finish of these moldings offers a clean and modern aesthetic. It blends seamlessly with most paint colors and interior styles. It is suitable for both residential and commercial applications, adding a finishing touch to any space. The clean lines of the white quarter round complement both modern and traditional designs.

Impact on the Market

The growing popularity of flexible quarter round molding has had a noticeable impact on the building materials market. Traditional wood molding continues to hold a significant share, but the demand for flexible alternatives is steadily increasing. According to a recent report by Freedonia Group, the market for flexible molding is projected to grow by 5% annually over the next five years, driven by increasing construction activity and rising consumer preference for easy-to-install products.

Contractor Perspectives

Professional contractors appreciate the time-saving benefits and ease of use of flexible quarter round molding. John Smith, a general contractor with 20 years of experience, notes, "Flexible molding has become an invaluable tool for tackling curved surfaces. It saves time and eliminates the frustration of trying to make precise cuts on rigid wood."

DIY Enthusiast Appeal

For homeowners undertaking DIY projects, flexible quarter round offers a more forgiving and accessible alternative to traditional wood molding. The ease of installation and ability to correct mistakes makes it an attractive option for those with limited experience. Online forums and home improvement websites are filled with testimonials from DIYers praising the product's ease of use and professional-looking results.

Environmental and Cost Considerations

While flexible quarter round offers many advantages, it is important to consider its environmental impact. Many polymer-based moldings are not biodegradable and may contribute to plastic waste. However, some manufacturers are exploring the use of recycled materials and more sustainable manufacturing processes.

Cost Comparison

The cost of flexible quarter round molding is generally comparable to that of high-quality wood molding. However, the reduced labor costs associated with installation can often offset the initial price difference. The overall cost-effectiveness depends on the complexity of the project and the installer's skill level. Choosing white flexible molding can also eliminate the cost of painting or staining.

The Future of Flexible Molding

The future of flexible quarter round molding appears bright, with continued innovation and increasing consumer demand. Manufacturers are constantly working to improve the product's durability, aesthetics, and environmental friendliness. As construction techniques evolve and interior design trends shift, flexible molding is poised to play an increasingly important role in creating visually appealing and functional spaces. The versatility of flexible molding will continue to drive its adoption across diverse projects.

The development of new materials and finishes will likely further expand the applications of flexible quarter round molding. This will likely to include incorporating sustainable and biodegradable polymers. The ease of installation and aesthetic versatility, particularly in white, is solidifying its position as a staple in both residential and commercial construction.

.jpg?imwidth=714&impolicy=medium)