How Did The Bessemer Process Impact Society

The mid-19th century was a period of unprecedented industrial growth, and at the heart of this transformation lay the Bessemer process, a revolutionary steelmaking technique. Its impact reverberated through industries, reshaping infrastructure, architecture, and the very fabric of society.

This article examines how the Bessemer process, invented by Sir Henry Bessemer, fundamentally altered steel production and its profound societal consequences. It analyzes the process itself, its rapid adoption, and the long-term effects it had on everything from railroads and skyscrapers to warfare and global trade.

The Steel Revolution Begins

Prior to the Bessemer process, steel production was a slow, expensive, and laborious task. Wrought iron, though strong, lacked the tensile strength and durability of steel. Consequently, steel was a precious commodity, reserved for specialized applications like tools and weaponry.

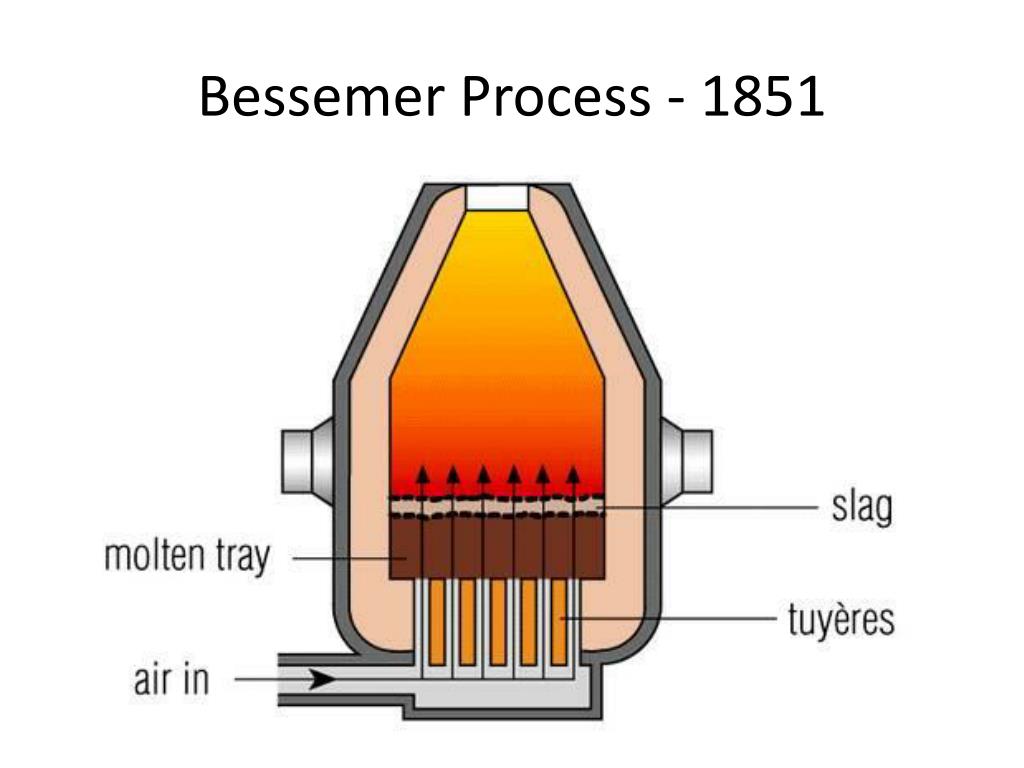

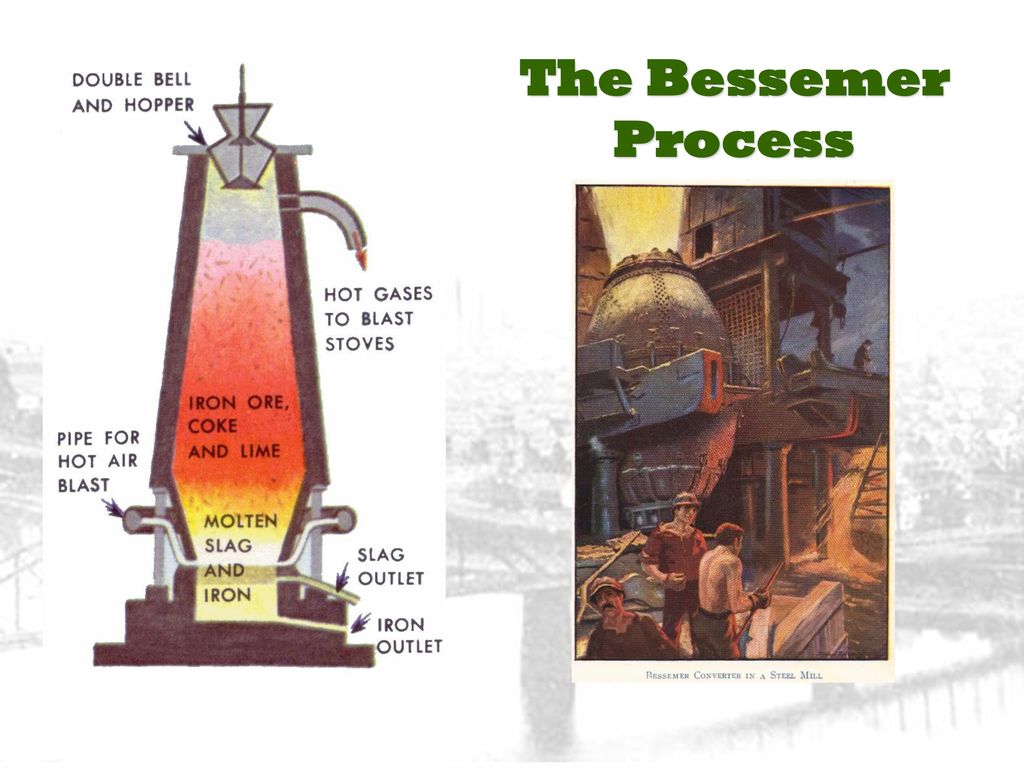

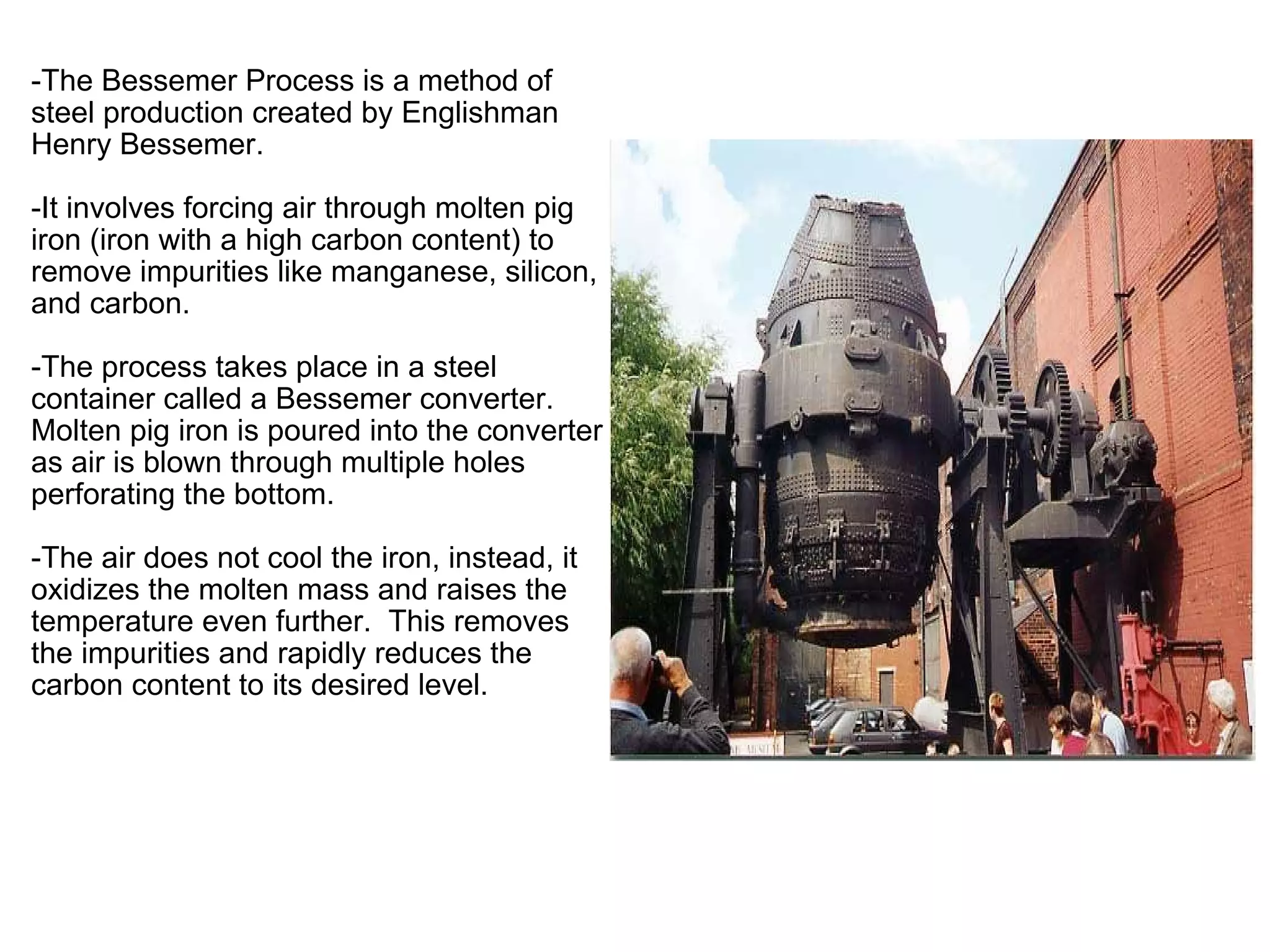

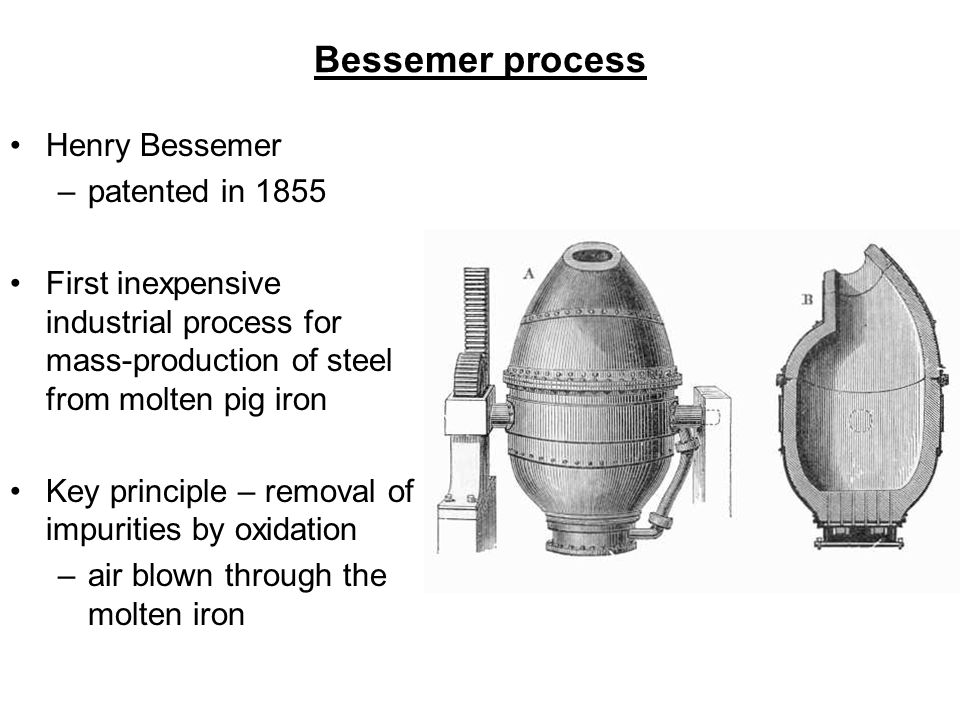

In 1856, Henry Bessemer, an English inventor, patented a method that dramatically streamlined steel production. The Bessemer process involved blowing air through molten pig iron to oxidize impurities like silicon, manganese, and carbon.

This oxidation generated intense heat, keeping the steel molten and eliminating the need for external fuel. The process converted large quantities of pig iron into high-quality steel in a matter of minutes, a feat previously unimaginable.

Key Details: Who, What, Where, When, Why, How

Who: Sir Henry Bessemer, an English inventor and engineer, is credited with inventing the Bessemer process.

What: The Bessemer process is a steelmaking technique that involves blowing air through molten pig iron to oxidize impurities, producing steel quickly and efficiently.

Where: The Bessemer process was initially developed and implemented in England, but its adoption quickly spread across Europe and the United States.

When: The Bessemer process was patented in 1856, and its impact on steel production was felt most significantly during the late 19th and early 20th centuries.

Why: The Bessemer process addressed the growing demand for steel driven by industrial expansion, particularly in railway construction and manufacturing.

How: The process involved a large pear-shaped container, known as a Bessemer converter, into which molten pig iron was poured. Air was then blown through the molten iron from the bottom, oxidizing impurities and increasing the carbon content to the desired level for steel.

Transforming Infrastructure and Architecture

The most immediate impact of the Bessemer process was the drastic reduction in the cost of steel. Steel, once a luxury, became an affordable and readily available material for construction and manufacturing.

This, in turn, spurred a massive expansion of the railway network. Stronger steel rails allowed for heavier locomotives and increased freight capacity, facilitating trade and transportation across vast distances.

Furthermore, the Bessemer process revolutionized architecture. Steel's superior tensile strength enabled the construction of taller and more durable buildings, paving the way for the skyscraper era.

Cities like Chicago and New York witnessed a rapid vertical expansion as steel-framed buildings soared to unprecedented heights. The Home Insurance Building in Chicago, completed in 1885, is often cited as the first skyscraper made possible by the availability of affordable steel.

Impacting Warfare and Global Trade

The Bessemer process also had significant implications for military technology. Stronger steel allowed for the production of more powerful artillery and more robust warships.

Navies around the world adopted steel-hulled ships, replacing ironclads with vessels capable of withstanding greater firepower. The arms race that defined the late 19th and early 20th centuries was, in part, fueled by the increased availability of high-quality steel.

The increased production and reduced cost of steel also played a crucial role in the expansion of global trade. Steel was used to build larger and more efficient ships, enabling the transportation of goods across oceans and continents.

Furthermore, steel was essential for manufacturing tools, machinery, and other industrial products that were traded internationally, driving economic growth and globalization.

Human Cost and Labor

While the Bessemer process ushered in an era of progress and prosperity, it also brought about significant challenges for workers. Steel mills were dangerous environments, with workers facing the risk of accidents, burns, and exposure to toxic fumes.

Long hours, low wages, and harsh working conditions were common in the steel industry. Labor disputes and strikes were frequent, as workers fought for better treatment and fair compensation.

The exploitation of immigrant labor was also a significant issue, with many steel mills relying on immigrant workers who were willing to work for lower wages. The story of the Bessemer process is not just one of technological triumph, but also one of human struggle and resilience.

Legacy of the Bessemer Process

The Bessemer process, while eventually superseded by more advanced steelmaking techniques like the open-hearth process and the basic oxygen furnace, left an indelible mark on society. It democratized steel production, making it accessible to a wider range of industries and applications.

The impact on infrastructure, architecture, warfare, and global trade was profound and far-reaching. The modern world, with its towering skyscrapers, extensive railway networks, and globalized economy, owes a considerable debt to the ingenuity of Sir Henry Bessemer and the transformative power of his invention.

Even though the Bessemer process is no longer the dominant method of steel production, its legacy continues to shape our world. It stands as a testament to the power of technological innovation to reshape society and drive progress, for better and for worse.

+Bessemer+Process+Developed+by+Henry+Bessemer+around+1850..jpg)