How Do You Get Gold Out Of Quartz

The allure of gold has captivated humanity for millennia, driving exploration, sparking wars, and shaping economies. But for every nugget found glittering in a streambed, countless more remain locked within the unyielding embrace of quartz rock, a seemingly impenetrable barrier to riches.

Extracting gold from quartz is not as simple as panning in a river. It's a complex process involving geological understanding, advanced chemistry, and significant environmental considerations. This article delves into the intricate methods used to liberate gold from its quartz prisons, exploring the science, the technology, and the ethical challenges inherent in this pursuit.

Understanding the Geological Context

Gold's presence in quartz veins isn't accidental. These veins are formed when hydrothermal fluids, superheated water rich in dissolved minerals, circulate through fractures in the Earth's crust. As these fluids cool and pressure decreases, minerals like quartz and, crucially, gold precipitate out, filling the cracks and creating the veins prospectors seek.

The size and distribution of gold particles within the quartz can vary dramatically. Sometimes it exists as visible grains, but often it's present in microscopic form, making extraction even more challenging. Understanding the specific geological formation is paramount to choosing the most effective extraction method.

Sampling and Assaying

Before any extraction takes place, rigorous sampling and assaying are essential. Geologists take core samples from the quartz veins, which are then crushed and analyzed to determine the gold content. This process, often involving fire assay, provides a crucial estimate of the ore's value and helps determine the economic feasibility of the mining operation.

The accuracy of the assay is critical, as it directly impacts investment decisions. Sophisticated techniques like atomic absorption spectroscopy are used to ensure precise measurements of gold concentration.

Extraction Methods: Unlocking the Gold

Several methods are employed to extract gold from quartz, each with its own advantages and disadvantages. The choice of method depends on factors like ore grade, particle size, environmental regulations, and economic considerations.

Crushing and Grinding

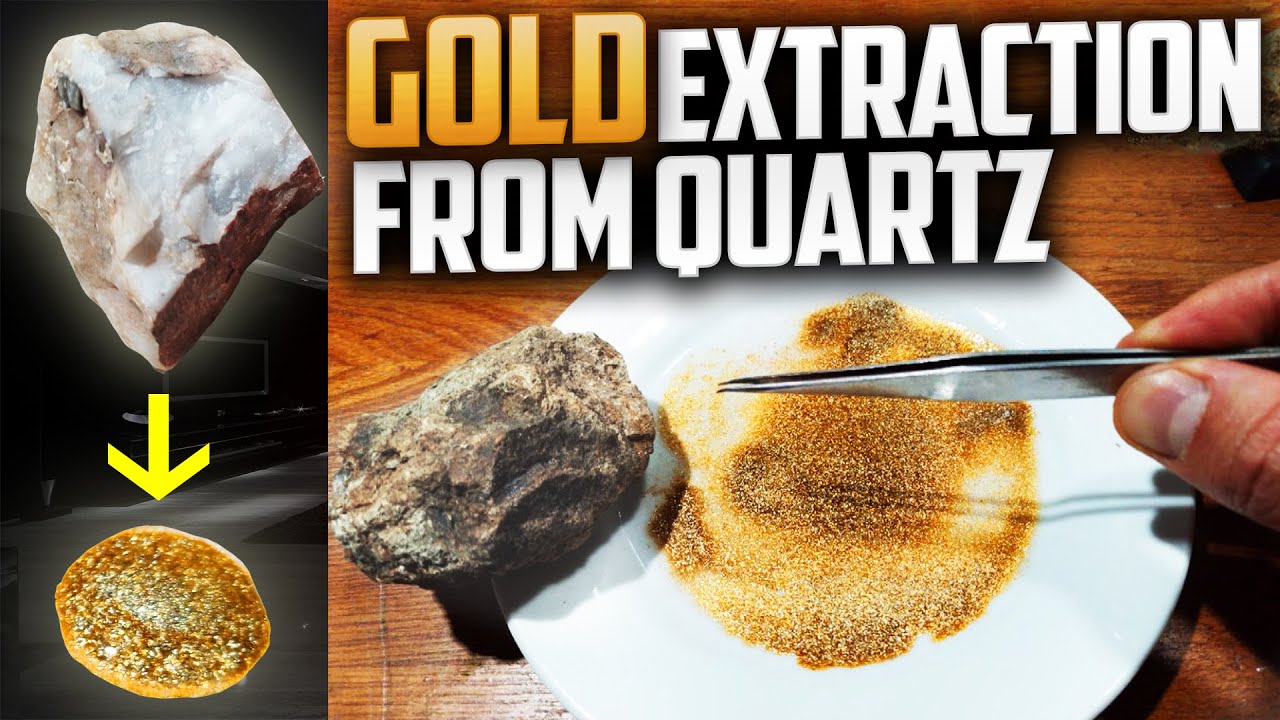

The first step in most extraction processes is to reduce the size of the quartz ore. This is achieved through crushing and grinding, using powerful machinery like jaw crushers and ball mills. The goal is to liberate the gold particles from the surrounding rock matrix, increasing their surface area for subsequent chemical treatment.

The finer the grind, the more gold is exposed, but finer grinding also increases energy consumption and can create dust hazards. Finding the optimal balance is crucial for efficient and cost-effective extraction.

Cyanidation: A Chemical Key

Cyanidation is the most widely used method for gold extraction. It involves leaching the crushed ore with a cyanide solution, which dissolves the gold to form a gold-cyanide complex. This complex is then separated from the solid waste through processes like carbon adsorption or the Merrill-Crowe process, which uses zinc to precipitate the gold.

While effective, cyanidation raises significant environmental concerns due to the toxicity of cyanide. Modern mining operations implement strict safety protocols and environmental controls to minimize the risk of spills and leaks.

"The responsible use of cyanide is paramount. We must prioritize the environment and the safety of our communities above all else." - Statement from the World Gold Council on sustainable mining practices.

Gravity Concentration: A Natural Approach

Gravity concentration is a more environmentally friendly method that relies on the difference in density between gold and quartz. Techniques like spirals, jigs, and shaking tables use gravity to separate the heavier gold particles from the lighter waste material.

Gravity concentration is often used as a pre-treatment step to reduce the volume of ore that needs to be processed using more intensive methods like cyanidation. This reduces the overall environmental impact of the mining operation.

Flotation: Surface Chemistry at Work

Flotation is another method that exploits the surface properties of gold particles. Chemicals called collectors are added to the slurry of crushed ore, making the gold particles hydrophobic (water-repelling). Air is then bubbled through the mixture, and the gold particles attach to the air bubbles, rising to the surface where they can be collected.

Flotation is particularly useful for processing ores containing fine gold particles that are difficult to recover using gravity concentration. It requires careful control of pH and chemical concentrations to optimize gold recovery.

Environmental and Ethical Considerations

Gold mining, including the extraction of gold from quartz, carries significant environmental and ethical responsibilities. The use of cyanide, the potential for water contamination, and the disruption of ecosystems are all major concerns that must be addressed.

Modern mining companies are increasingly adopting sustainable practices, such as water recycling, waste rock management, and habitat restoration. Independent certifications, such as the Responsible Jewellery Council (RJC), help ensure that gold is sourced ethically and responsibly.

Furthermore, community engagement and benefit-sharing agreements are essential for ensuring that local communities benefit from mining activities and are not negatively impacted by them. Transparency and accountability are crucial for building trust and fostering sustainable development.

The Future of Gold Extraction

The future of gold extraction from quartz is likely to be driven by technological innovation and increasing environmental awareness. Research is underway to develop alternative leaching agents that are less toxic than cyanide, such as thiosulfate and glycine.

Bioleaching, which uses microorganisms to dissolve gold, is another promising technology that could offer a more environmentally friendly alternative to traditional chemical methods. Advances in sensor technology and data analytics are also improving the efficiency and precision of gold extraction processes.

Ultimately, the challenge lies in finding ways to extract gold from quartz in a manner that is both economically viable and environmentally sustainable. This requires a collaborative effort involving governments, industry, researchers, and local communities to ensure that the pursuit of gold does not come at the expense of the planet.