How Much Does A Robot Cost

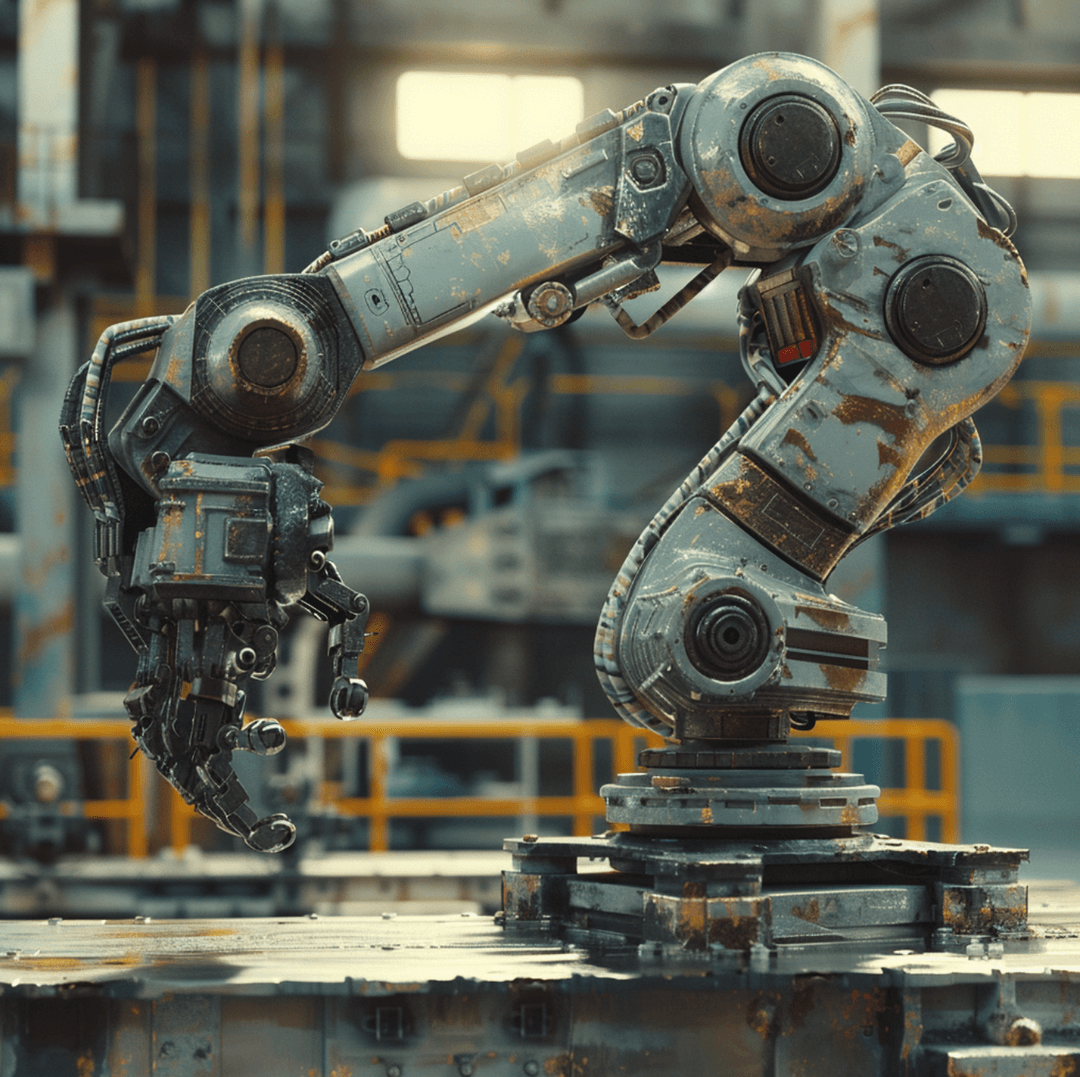

Imagine a bustling factory floor, not filled with rows of human workers, but with sleek, tireless machines moving with precision and speed. These aren't the clunky automatons of science fiction past, but sophisticated robots performing tasks from welding car parts to assembling intricate electronics. The air hums with efficiency, a testament to the increasing role of robotics in modern industry.

The price of these technological marvels, however, is a complex equation. Understanding the factors that determine how much a robot costs – from the type of robot and its capabilities to the software and integration required – is crucial for businesses considering automation, and for anyone curious about the evolving landscape of robotics.

The Foundation: Understanding Robot Types

The world of robotics is diverse. It encompasses a range of machine types, each designed for specific tasks and environments.

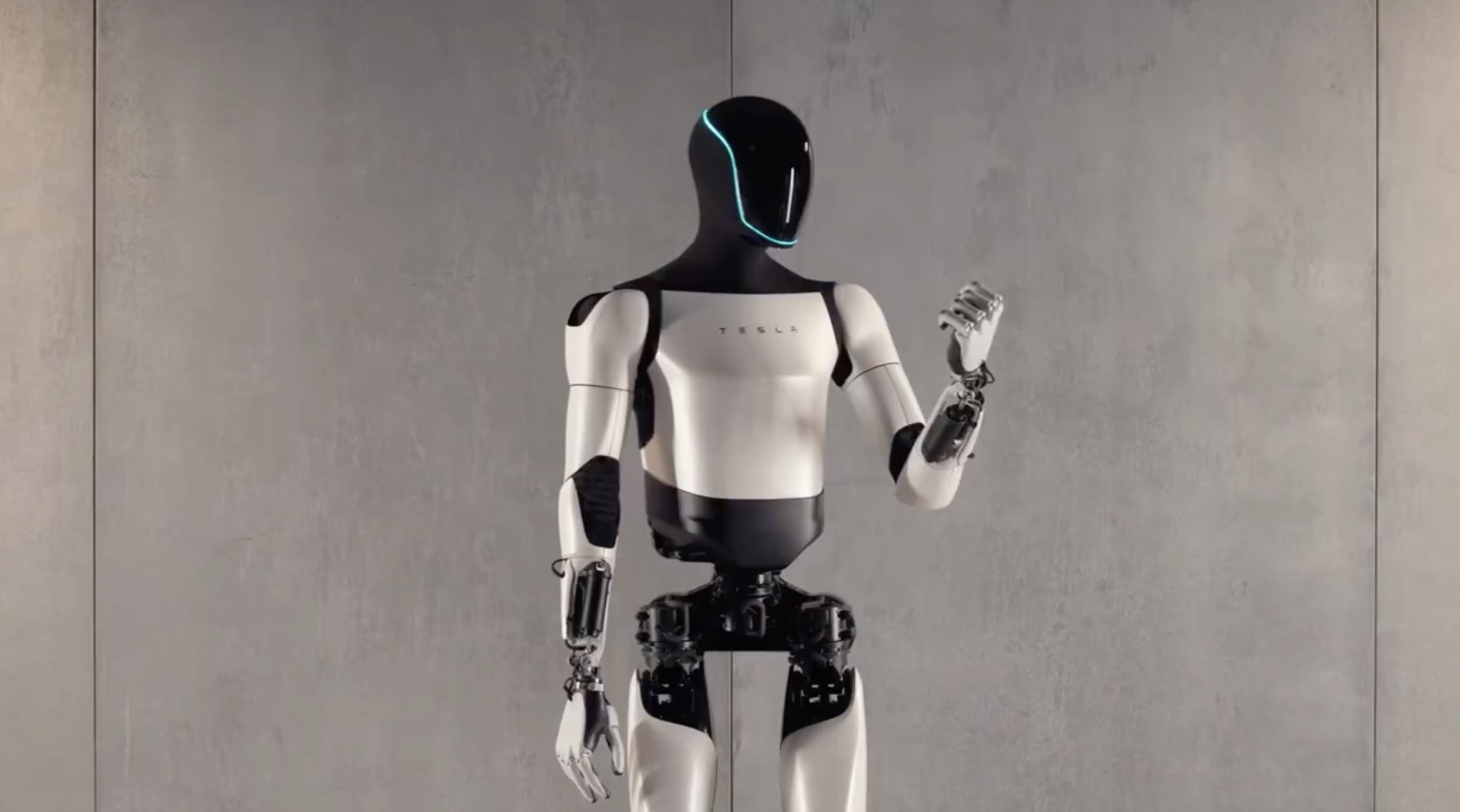

Industrial robots are the workhorses of manufacturing. They come in various forms, including articulated arms, SCARA robots (Selective Compliance Articulated Robot Arm), and delta robots (parallel robots), each with unique strengths in terms of reach, speed, and payload capacity.

Service robots, on the other hand, are designed to assist humans in various sectors, from healthcare and hospitality to logistics and agriculture. Examples include cleaning robots, delivery robots, and even surgical robots.

Industrial Robot Costs: More Than Meets the Eye

The sticker price of an industrial robot can vary dramatically. A small, entry-level articulated arm might cost anywhere from $25,000 to $75,000.

Larger, more sophisticated robots with higher payload capacities and longer reaches can easily exceed $100,000 or even $200,000. These prices typically cover the robot arm itself, the controller, and basic software.

However, the total cost of implementing an industrial robot goes far beyond the initial purchase price. Integration costs, which include programming, installation, safety equipment, and tooling, can often equal or even exceed the cost of the robot itself.

“When budgeting for a robot, businesses need to consider the total cost of ownership, not just the initial investment,” explains Dr. Anya Sharma, a robotics engineer at the Advanced Robotics Research Center. “This includes ongoing maintenance, training, and potential software upgrades.”

Service Robot Costs: A Growing Market

The service robot market is rapidly expanding, with costs varying widely depending on the application.

Simple cleaning robots for homes and businesses can be purchased for a few hundred dollars to a few thousand. More sophisticated service robots, such as those used in healthcare or logistics, can cost tens of thousands or even hundreds of thousands of dollars.

Surgical robots, for example, are highly specialized and require significant investment in training and maintenance. These machines can cost upwards of $1 million, making them accessible primarily to large hospitals and medical institutions.

The Driving Factors: What Influences Robot Pricing

Several factors contribute to the cost of a robot.

Payload capacity is a key determinant. Robots designed to lift heavier objects typically require more robust components and more powerful motors, which increases their cost.

Reach and workspace also play a role. Robots with longer arms or the ability to operate in larger areas require more complex designs and materials.

Accuracy and precision are critical for many applications, and robots that can perform tasks with high levels of accuracy often command a higher price. Advanced sensors, sophisticated control systems, and precise actuators all contribute to increased accuracy.

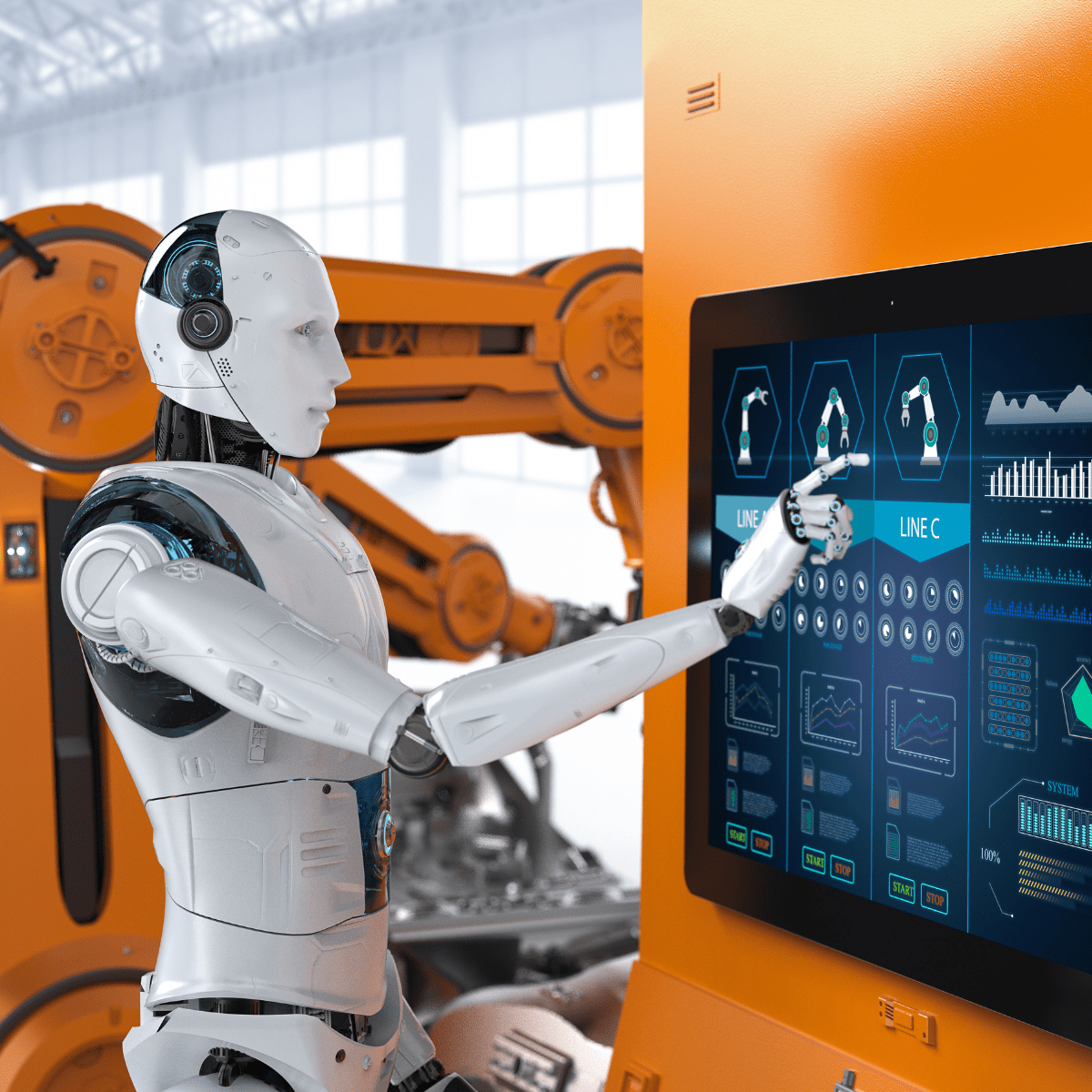

Software and programming are essential for controlling a robot’s movements and interactions. Sophisticated software packages, including vision systems and artificial intelligence (AI) algorithms, can significantly increase the overall cost.

Safety features are paramount, especially in collaborative robot (cobot) applications where robots work alongside humans. Features such as force sensors, safety-rated controllers, and emergency stop mechanisms add to the cost but are crucial for ensuring a safe working environment.

“The key is to carefully assess your needs and choose a robot that is appropriately sized and equipped for the task,” says Michael Chen, a robotics consultant at Robotics Solutions Group. “Overspending on features you don't need can be a costly mistake.”

The Broader Impact: Automation and the Future of Work

The increasing adoption of robotics has profound implications for the future of work.

While some fear that robots will replace human workers, others argue that they will create new opportunities by automating repetitive and dangerous tasks, allowing humans to focus on more creative and strategic roles.

A report by the World Economic Forum suggests that while automation will displace some jobs, it will also create many new ones in areas such as robotics engineering, software development, and data analysis. Investing in education and training programs that equip workers with the skills needed to thrive in a robotics-driven economy is essential.

The affordability of robots is also becoming a critical factor in the competitiveness of businesses. As robot prices continue to decline and their capabilities increase, more and more companies are investing in automation to improve efficiency, reduce costs, and enhance product quality.

This trend is particularly pronounced in small and medium-sized enterprises (SMEs), which often struggle to compete with larger companies that have already invested heavily in automation.

Beyond the Price Tag: Measuring the Value of Robotics

Ultimately, the value of a robot extends beyond its initial cost.

Businesses that successfully implement robotics can achieve significant improvements in productivity, quality, and safety. Robots can work tirelessly around the clock, performing tasks with consistent accuracy and reducing the risk of human error.

Moreover, robotics can enable businesses to adapt more quickly to changing market demands. Robots can be reprogrammed and retooled to perform different tasks, allowing companies to respond rapidly to new opportunities and challenges.

Consider a small manufacturing company that invested in a collaborative robot to assist with assembly tasks. The robot not only increased production output but also reduced employee strain and injuries, leading to improved morale and reduced healthcare costs.

Such anecdotal evidence, coupled with data-driven analysis, increasingly shows the potential for robots to be a worthwhile investment.

The Road Ahead: Continued Innovation and Accessibility

The field of robotics is constantly evolving. New technologies, such as AI, machine learning, and advanced sensors, are driving innovation and expanding the capabilities of robots.

As robots become more intelligent and autonomous, they will be able to perform more complex tasks with less human intervention. This will open up new opportunities for automation in a wide range of industries.

Furthermore, the cost of robotics is expected to continue to decline as manufacturing processes become more efficient and competition increases. This will make robots more accessible to smaller businesses and individuals.

The future of robotics is bright, and the potential for these machines to transform our lives is immense.

Whether you're a business owner considering automation, a student exploring a career in robotics, or simply someone curious about the future of technology, understanding how much a robot costs is an essential first step in navigating this exciting and rapidly evolving field.