How Much Does It Cost To Make A Water Bottle

Imagine walking through a sun-drenched park, the air alive with laughter and birdsong. You reach into your bag, pull out a chilled water bottle, and take a refreshing sip. It’s a simple pleasure, almost automatic. But have you ever stopped to wonder about the journey of that bottle? From raw materials to your hand, how much does it actually cost to make?

The cost of manufacturing a water bottle is a complex equation, influenced by a multitude of factors, from the type of plastic used to the efficiency of the production line. Understanding these costs sheds light on the often-unseen world of manufacturing and the economics of everyday items.

The Raw Materials: Laying the Foundation

The primary material for most disposable water bottles is polyethylene terephthalate, or PET. It is a type of plastic known for its strength, transparency, and recyclability. The price of PET resin fluctuates based on the price of crude oil, its primary component.

Crude oil prices are notoriously volatile, impacted by geopolitical events, supply and demand, and even weather patterns. Consequently, the cost of PET resin can vary considerably, directly affecting the overall production expense.

Beyond PET, other raw materials enter the equation. These include the plastic for the cap, labels, and any inks used for printing. The sourcing and transportation of these materials also add to the accumulating costs.

Manufacturing Costs: From Resin to Bottle

The manufacturing process itself involves several key steps, each contributing to the final cost. First, PET resin pellets are heated and molded into preforms, small test-tube shaped pieces of plastic.

Next, these preforms are heated and stretched into their final bottle shape through a process called blow molding. This requires specialized machinery and significant energy consumption.

The bottles are then cooled, labeled, filled with purified water, and capped, all on automated production lines. The efficiency of these lines, the speed at which they operate, and the amount of waste they generate all impact the overall manufacturing cost.

Labor costs, including wages for factory workers and quality control personnel, are another important consideration. Factories with more automated systems might have lower labor costs but higher initial investment costs.

The Invisible Costs: Overheads and Distribution

Beyond raw materials and manufacturing, several often-overlooked costs contribute to the final price of a water bottle. These include factory overheads such as rent, utilities, and maintenance of equipment.

Transportation costs are also a significant factor, particularly for companies that distribute their products nationally or internationally. Fuel prices, shipping distances, and logistical complexities all play a role.

Marketing and advertising expenses can also add to the cost. Building brand awareness and attracting customers requires investment in advertising campaigns, promotional materials, and packaging design.

Finally, there are regulatory compliance costs. Water bottle manufacturers must adhere to strict regulations regarding water quality, food safety, and environmental standards. This compliance requires testing, certification, and ongoing monitoring, all of which incur expenses.

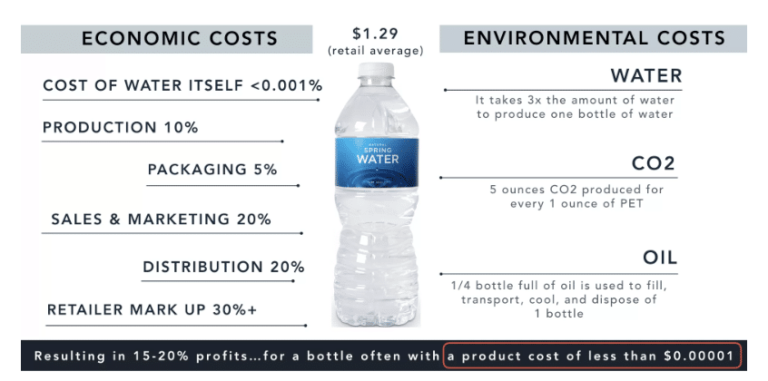

A Closer Look at the Numbers

So, what does all of this translate to in terms of actual cost per bottle? It's difficult to give a precise figure because it depends on factors like production volume, location, and the brand’s operational efficiency. However, we can estimate a range.

According to industry analysts and reports, the cost of producing a standard 16.9-ounce (500ml) disposable water bottle can range from $0.05 to $0.15. This figure encompasses the raw materials, manufacturing, and overhead costs.

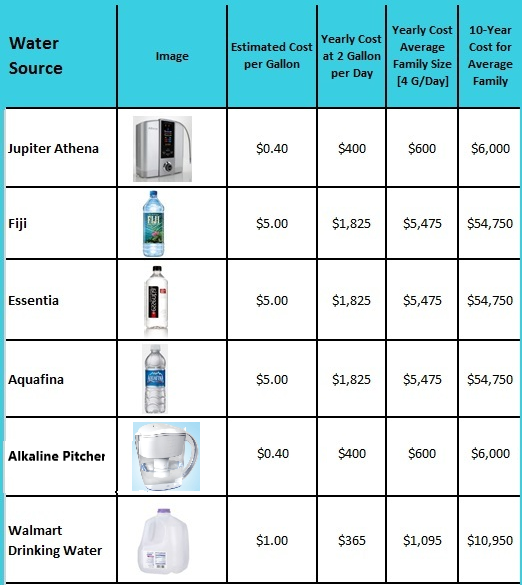

Reusable water bottles, typically made from materials like stainless steel or BPA-free plastic, have a higher initial production cost. The cost of materials alone is higher, and the manufacturing process is often more complex. Therefore the range would be $3.00 to $8.00.

Premium brands, with sophisticated packaging, extensive marketing campaigns, and perhaps higher-quality water sources, will likely have a higher production cost compared to generic brands. This difference reflects the added value they offer to consumers.

It's important to note that these figures represent the cost of production, not the retail price. The retail price includes the manufacturer's profit margin, the distributor's margin, and the retailer's markup.

The Environmental Impact and Sustainable Alternatives

The environmental impact of disposable water bottles is a growing concern, with millions of tons of plastic ending up in landfills and oceans each year. This waste contributes to pollution, harms wildlife, and depletes natural resources.

The manufacturing of PET also requires significant energy consumption, contributing to greenhouse gas emissions. Furthermore, the transportation of water bottles adds to the carbon footprint.

Fortunately, there are more sustainable alternatives available. Reusable water bottles offer a practical and environmentally friendly option, reducing the need for disposable bottles and minimizing plastic waste.

Many companies are also exploring innovative packaging solutions, such as biodegradable or compostable water bottles. These alternatives aim to reduce the environmental impact of single-use packaging.

Looking Ahead: The Future of Water Bottles

The water bottle industry is evolving, driven by consumer demand for more sustainable and environmentally responsible products. Companies are investing in research and development to create innovative materials and manufacturing processes.

We can expect to see more widespread adoption of recycled PET (rPET) in water bottle production. rPET is made from recycled plastic bottles, reducing the need for virgin plastic and minimizing waste.

Additionally, there is growing interest in plant-based plastics, derived from renewable resources such as corn or sugarcane. These materials offer a more sustainable alternative to traditional petroleum-based plastics.

Ultimately, the future of water bottles lies in a combination of sustainable materials, efficient manufacturing processes, and responsible consumer behavior. By choosing reusable bottles, supporting brands committed to sustainability, and properly recycling disposable bottles, we can all contribute to a more environmentally friendly future.

A Final Thought

The next time you reach for a water bottle, take a moment to appreciate the complex journey it has undertaken. From the extraction of raw materials to the intricate manufacturing process, many factors contribute to the final cost. More importantly, consider the impact of your choice. By opting for sustainable alternatives, you can make a small but significant difference in protecting our planet.

The seemingly simple act of staying hydrated can become an opportunity to make a conscious choice, one that reflects your commitment to a healthier planet. And that, ultimately, is a priceless investment.

Understanding the true cost of a water bottle, both economic and environmental, empowers us to make informed choices. - Industry Analyst