How To Recover Gold From Electronics Without Chemicals

The allure of gold, a precious metal valued for millennia, extends beyond jewelry and bullion. Hidden within our discarded electronics lies a surprising amount of it, sparking interest in recovering this valuable resource. But the conventional methods often involve harsh and dangerous chemicals like cyanide, raising significant environmental and safety concerns.

This article delves into the safer, chemical-free techniques for extracting gold from electronic waste (e-waste). We explore methods that prioritize environmental responsibility and personal safety while offering a glimpse into the potential for a more sustainable approach to resource recovery.

The Allure of "Urban Mining"

The term "urban mining" refers to the process of reclaiming valuable materials from discarded products, particularly electronics. E-waste is a rich source of precious metals like gold, silver, platinum, and palladium. The amount of gold in e-waste can sometimes exceed that found in naturally occurring ore deposits.

Extracting these metals offers a dual benefit: reducing reliance on traditional mining practices and mitigating the environmental impact of e-waste disposal. The United Nations estimates that 50 million tons of e-waste are generated globally each year, a figure projected to increase dramatically. Properly managing this waste stream is crucial for a sustainable future.

Why Chemical-Free Extraction Matters

Traditional gold extraction from e-waste relies heavily on chemicals like cyanide, a highly toxic substance. Cyanide leaching, while effective in dissolving gold, poses serious environmental risks. Accidental spills can contaminate soil and water sources, harming ecosystems and human health.

Exposure to cyanide can be fatal, even in small doses. Furthermore, the chemical processes generate hazardous byproducts that require careful management and disposal. The environmental and health costs associated with chemical extraction methods necessitate the exploration of safer alternatives.

Mechanical Separation: The Foundation

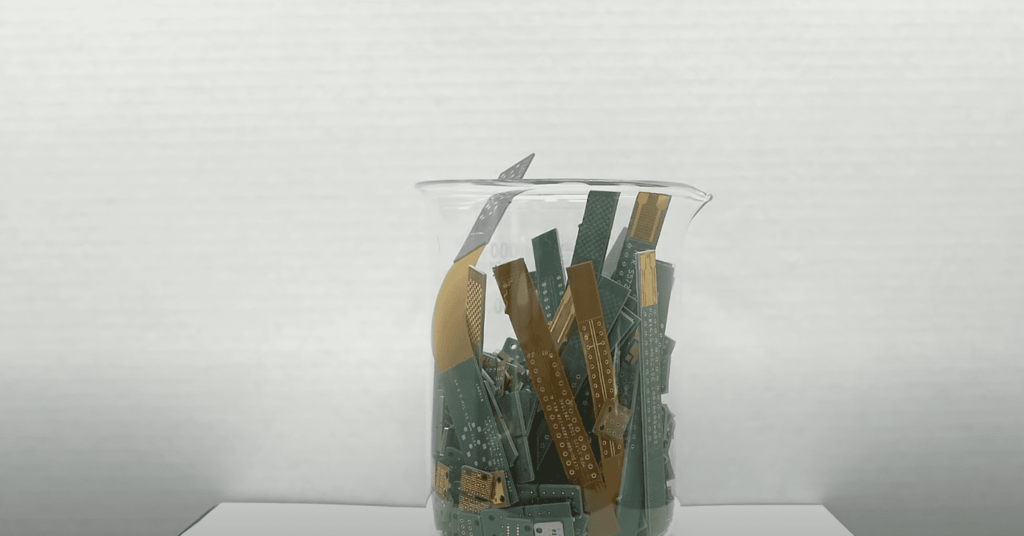

Mechanical separation is the first crucial step in any chemical-free gold recovery process. It involves physically dismantling electronic devices and separating components based on their material composition. This process reduces the volume of material requiring further processing and concentrates the gold-bearing parts.

Manual disassembly is often employed, requiring skilled workers to identify and remove specific components like circuit boards, connectors, and integrated circuits. Automated shredding and sorting systems can also be used for larger volumes of e-waste, though they may be less precise than manual methods.

The goal is to isolate the components most likely to contain gold, such as those with gold-plated connectors or gold bonding wires. By focusing on these specific parts, the subsequent extraction processes become more efficient.

Targeting Gold-Rich Components

Printed circuit boards (PCBs) are a prime target for gold recovery due to their extensive use of gold plating on connectors and traces. Central processing units (CPUs), memory chips, and other integrated circuits also contain significant amounts of gold in their internal wiring and connections.

Connectors, such as those found in computer cables and peripheral devices, are often gold-plated to ensure reliable electrical conductivity. By carefully separating these components, the concentration of gold in the remaining material is significantly increased.

Physical Extraction Techniques

Once the gold-rich components are isolated, physical extraction techniques can be employed to further separate the gold. These methods rely on mechanical forces and material properties to liberate the gold from its surrounding matrix.

One common technique is grinding or milling, which reduces the size of the components and exposes the gold particles. This is followed by gravity separation, where heavier gold particles are separated from lighter materials using water or air currents.

Electrostatic Separation

Electrostatic separation utilizes differences in electrical conductivity to separate materials. A high-voltage electric field is applied to a mixture of materials, causing conductive particles (like gold) to become charged and attracted to an electrode.

Non-conductive materials remain unaffected. This method can effectively separate gold from plastics, ceramics, and other non-conductive components in e-waste.

The Smelting Option (With Caveats)

Smelting, while technically not entirely chemical-free, can be considered if emissions are strictly controlled and proper environmental safeguards are in place. The process involves heating the gold-rich material to high temperatures in a furnace, melting the gold and allowing it to separate from other materials.

Modern smelting facilities often employ advanced emission control technologies to minimize air pollution and capture hazardous byproducts. However, smelting still requires significant energy input and careful management of waste products. Therefore, it’s important to do your research and only use reputable smelters with proven environmental safeguards.

Emerging Technologies

Researchers are continuously developing innovative chemical-free methods for gold extraction. One promising area is bioleaching, which uses microorganisms to dissolve gold from e-waste.

Certain bacteria and fungi can oxidize gold, converting it into a soluble form that can be easily recovered. Bioleaching is generally considered more environmentally friendly than cyanide leaching, as it does not involve harsh chemicals and produces fewer hazardous byproducts. However, bioleaching can be a slower process and requires careful control of environmental conditions to optimize microbial activity.

Another emerging technology involves using supercritical fluids, such as carbon dioxide, to dissolve and extract gold. Supercritical fluids have properties intermediate between liquids and gases, allowing them to penetrate materials and dissolve substances that are insoluble in ordinary solvents.

Responsible E-Waste Management

Recovering gold from e-waste is only one aspect of responsible e-waste management. Proper collection, sorting, and recycling of electronic devices are essential to minimize environmental impact and maximize resource recovery. Many countries and regions have implemented regulations to ensure the safe and responsible disposal of e-waste.

Consumers can contribute by recycling their old electronics through certified e-waste recyclers. These recyclers adhere to strict environmental standards and ensure that valuable materials are recovered responsibly. Supporting e-waste recycling programs helps to reduce pollution, conserve resources, and create a more sustainable future.

Before recycling, ensure personal data is securely erased from devices to protect privacy. This includes wiping hard drives, removing SIM cards, and resetting devices to factory settings.

The Future of Gold Recovery

The shift towards chemical-free gold extraction from e-waste is gaining momentum, driven by growing environmental concerns and technological advancements. As research continues and new technologies emerge, we can expect to see more efficient and sustainable methods for recovering gold and other valuable materials from electronic waste.

By embracing responsible e-waste management practices and supporting the development of innovative extraction technologies, we can unlock the potential of "urban mining" and create a more circular and sustainable economy. The future of gold recovery lies in minimizing environmental impact and maximizing resource utilization.