Identify True Statements About Operations Strategy.

Imagine a bustling bakery, the air thick with the aroma of warm bread and sweet pastries. Each morning, before the city even stirs, bakers are meticulously preparing ingredients, orchestrating ovens, and packaging delights, all working in concert. This symphony of processes, seemingly simple, is underpinned by a carefully crafted strategy – a plan for how the bakery will thrive, compete, and satisfy its customers. It’s more than just baking; it’s a deliberate operational dance.

Understanding operations strategy is crucial for any business, regardless of size or industry. It’s the compass guiding day-to-day actions and long-term investments, ensuring resources are aligned with overarching goals. Mistaking assumptions about its true nature can lead to inefficiency, missed opportunities, and ultimately, a compromised competitive edge.

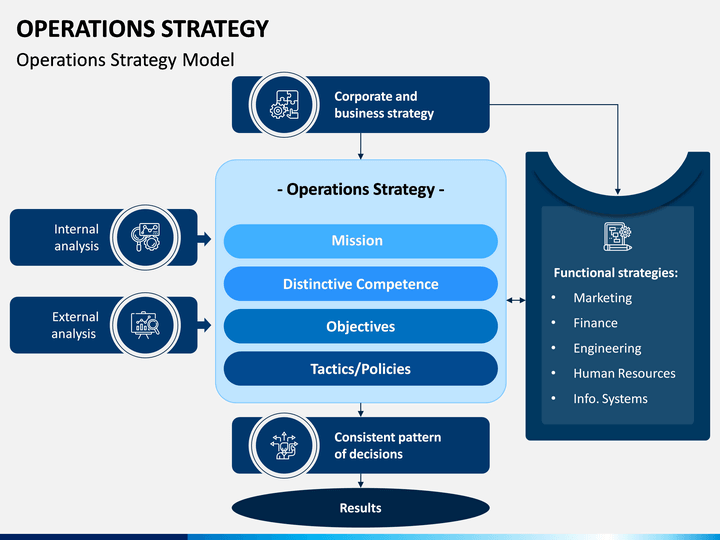

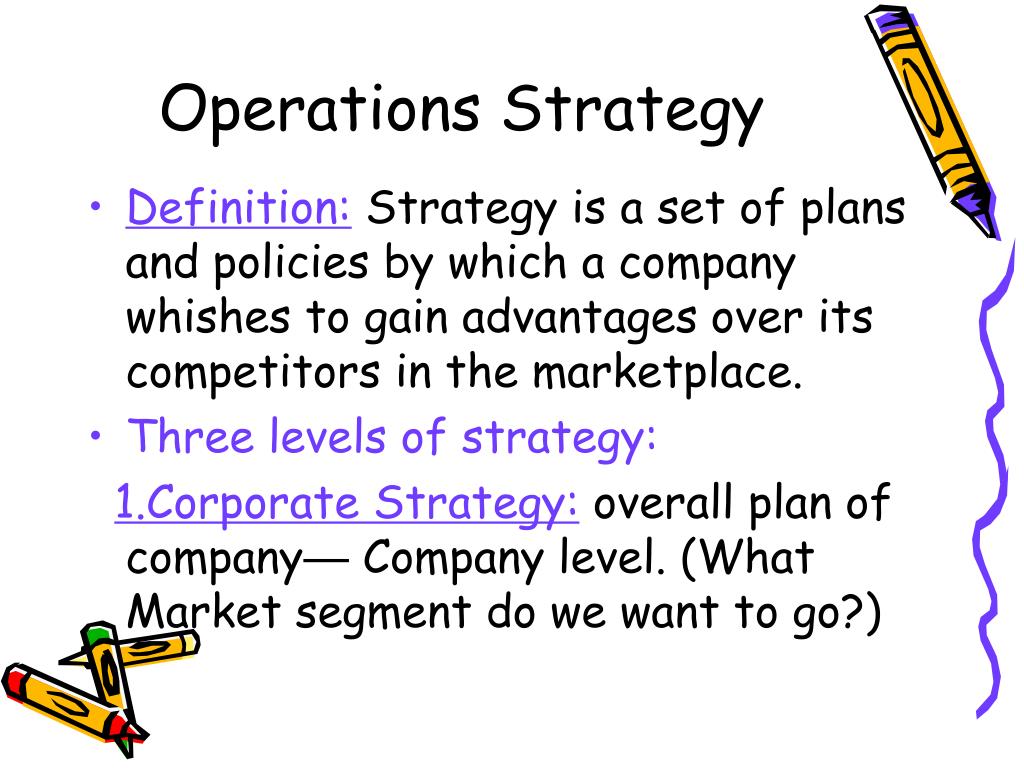

Operations strategy isn't simply about cost-cutting or adopting the latest technology. It is about aligning operational capabilities with the overall business strategy. It’s about making conscious decisions about how the organization will produce goods or services, manage resources, and deliver value to its customers.

The Core Principles of Operations Strategy

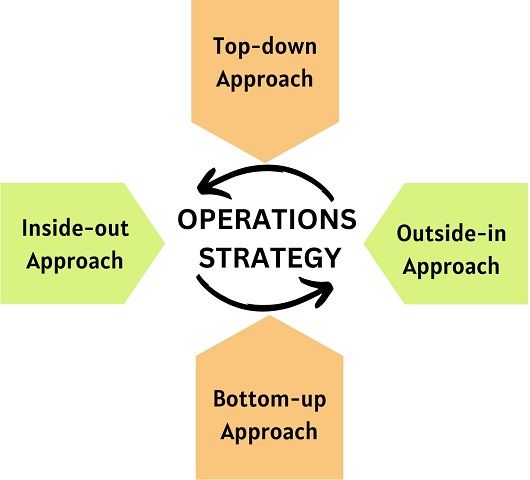

To identify true statements about operations strategy, it's important to understand its core principles. It’s a framework for making strategic decisions that influence the entire organization. Let's break down some of the fundamental aspects.

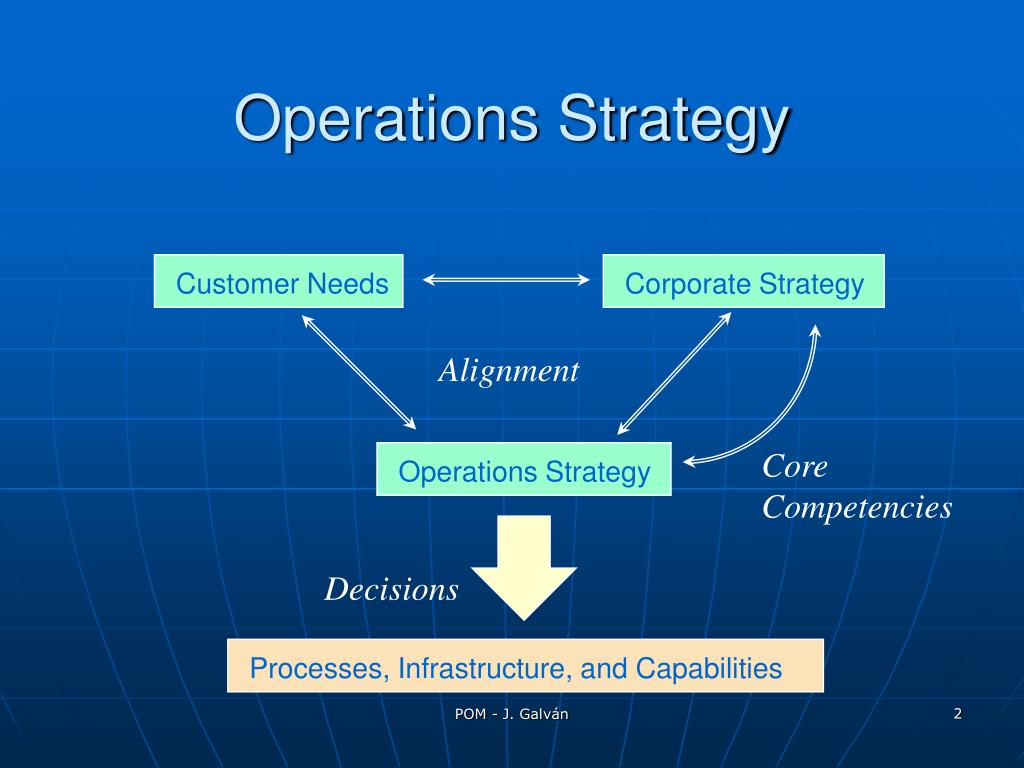

Alignment with Business Strategy is paramount. Operations strategy is not developed in isolation; it must be a direct derivative of the overall business strategy.

This means if the company aims to be a premium provider, the operations strategy must prioritize quality and innovation, even if it entails higher costs. Conversely, a business focused on affordability will need an operations strategy that emphasizes efficiency and cost reduction.

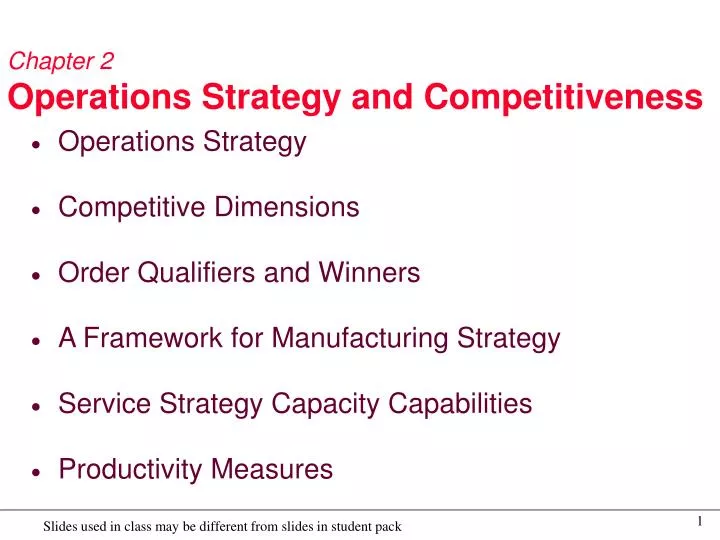

Defining Competitive Priorities

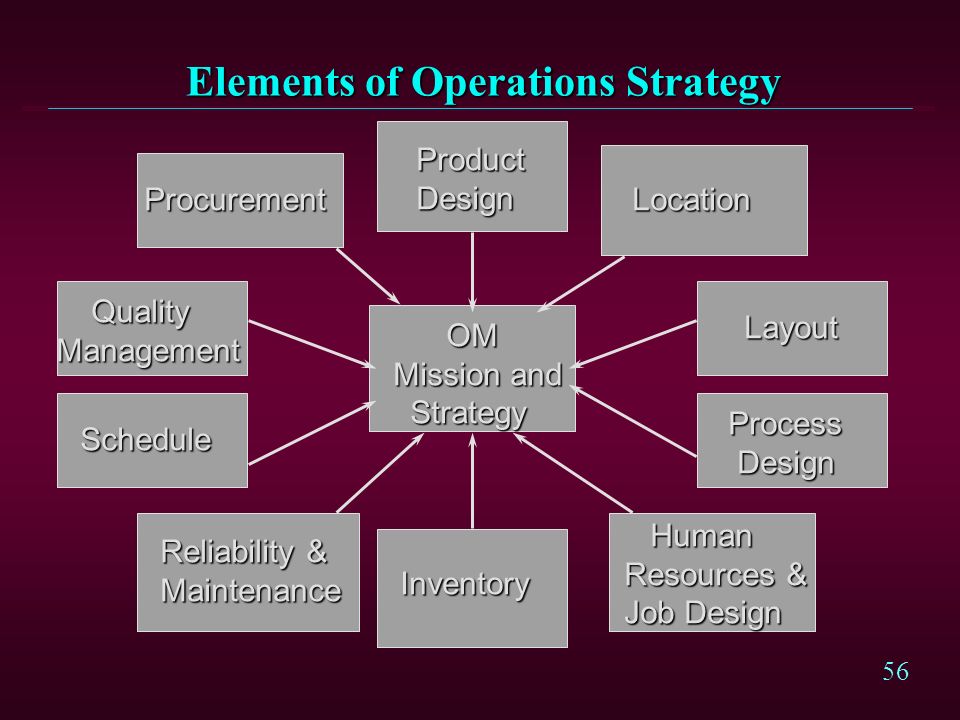

Central to operations strategy is the identification and prioritization of competitive capabilities. These are the areas where the organization seeks to excel in order to attract and retain customers.

Key competitive priorities often include cost, quality, speed, flexibility, and innovation. A company can't be the best at everything; trade-offs are inevitable.

For example, a fast-fashion retailer might prioritize speed and flexibility to quickly respond to changing trends, accepting slightly higher costs. An aircraft manufacturer, on the other hand, prioritizes quality and reliability above all else, willing to invest heavily in rigorous testing and meticulous production processes.

The Role of Processes and Technology

Operations strategy is inextricably linked to the design and management of processes and the selection and implementation of technology. Process design should be tailored to support the chosen competitive priorities.

If a company prioritizes speed, it might invest in automation and streamlined workflows. If it prioritizes customization, it might implement flexible manufacturing systems.

Technology is an enabler, but not the strategy itself. Simply adopting the latest software or machinery won't guarantee success without a clear understanding of how it will contribute to the overall operational goals.

Debunking Common Misconceptions

Many misconceptions surround operations strategy. These inaccuracies can lead to misguided decisions and suboptimal performance. Let’s clarify some common misunderstandings.

Misconception 1: Operations Strategy is Just About Cost Reduction. While cost efficiency is often a consideration, it’s not the sole focus. Operations strategy encompasses a wider range of capabilities, including quality, speed, flexibility, and innovation.

Overemphasizing cost reduction at the expense of other priorities can lead to lower quality, slower delivery times, and reduced customer satisfaction. A balanced approach is essential.

Misconception 2: Operations Strategy is a One-Time Event. Operations strategy is not a static document; it’s a dynamic process that must evolve alongside the business and the competitive landscape.

Regular review and adjustments are necessary to ensure the operations strategy remains aligned with the company's goals and adapts to changing market conditions. Companies should consider developing scenario plans to prepare for potential disruptions.

Misconception 3: Operations Strategy is Only Relevant to Manufacturing. Although operations strategy originated in the manufacturing sector, its principles apply to all types of organizations, including service providers, healthcare institutions, and non-profits.

Any organization that delivers a product or service has an operations strategy, whether it's formally documented or simply implied in its actions. A deliberate and well-defined strategy is always preferable.

Identifying True Statements: A Checklist

So, how can you identify true statements about operations strategy? Here's a practical checklist to guide you:

Check for Alignment: Does the statement reflect the interconnectedness between operations strategy and the overall business strategy? A true statement will highlight how operational decisions support the broader strategic objectives.

Consider Competitive Priorities: Does the statement acknowledge the importance of defining and prioritizing competitive capabilities? It should recognize the trade-offs involved in excelling in different areas.

Examine Process and Technology: Does the statement correctly portray the role of processes and technology as enablers of the operations strategy? It should emphasize that technology is a tool, not the strategy itself.

Look for a Dynamic Perspective: Does the statement acknowledge that operations strategy is a dynamic process that requires ongoing review and adaptation? It should avoid portraying it as a static document.

Real-World Examples

Consider Toyota's legendary production system. Their operations strategy is deeply rooted in lean manufacturing principles, focusing on waste reduction, continuous improvement, and just-in-time inventory management.

This approach aligns perfectly with their broader business strategy of delivering high-quality, reliable vehicles at competitive prices. Their operational excellence has become a major source of competitive advantage.

Another example is Zara, the fast-fashion giant. Their operations strategy prioritizes speed and flexibility, allowing them to quickly respond to emerging trends and introduce new designs to their stores in a matter of weeks.

They have invested heavily in a responsive supply chain and a vertically integrated production system to achieve this agility. This allows them to quickly adapt to changing consumer preferences and maintain a competitive edge.

The Importance of Continuous Learning

Operations strategy is a complex and evolving field. Staying informed about the latest trends, best practices, and research findings is essential for success.

Organizations should encourage continuous learning and professional development for their operations managers. This could involve attending industry conferences, reading relevant publications, or pursuing advanced degrees.

By staying informed and embracing a culture of continuous improvement, companies can ensure their operations strategy remains effective and supports their long-term goals. Remember the bakery, constantly refining its recipes and techniques to delight customers? The principle is the same.

Ultimately, understanding operations strategy is not just about mastering a set of tools or techniques. It's about developing a strategic mindset that allows you to align your operational capabilities with your business goals, create value for your customers, and achieve a sustainable competitive advantage. It's about building a resilient and adaptable organization that can thrive in an ever-changing world.

.png)