Mullen Automotive Advanced Manufacturing Engineering Center

The future of electric vehicle (EV) manufacturing is being forged not on sprawling assembly lines of the past, but in concentrated centers of innovation. Mullen Automotive, an emerging electric vehicle manufacturer, is betting big on this future with its Advanced Manufacturing Engineering Center (AMEC) in Tunica, Mississippi. The center represents a significant investment in the company's ambition to bring EV production to American soil, but also faces considerable scrutiny given Mullen's past financial and production challenges.

Mullen's AMEC is designed to be the nexus of its manufacturing processes, focusing on prototyping, testing, and refining the assembly techniques for its various EV models. This facility is crucial for Mullen's long-term viability, as it aims to optimize production efficiency, reduce costs, and ensure the quality of its vehicles. The center's success, however, hinges on Mullen's ability to overcome its past financial hurdles and demonstrate its capacity to deliver on its ambitious production goals amidst a fiercely competitive EV market.

The Vision Behind the AMEC

The AMEC, spanning over 120,000 square feet, is envisioned as a hub where advanced manufacturing technologies converge. Mullen Automotive intends to use this facility to develop and implement innovative assembly processes. This includes leveraging robotics, automation, and data analytics to enhance production speed and accuracy.

The center will also focus on validating the manufacturability of new vehicle designs. This includes identifying and resolving potential production bottlenecks early in the development process. By addressing these challenges proactively, Mullen aims to avoid costly delays and quality issues during mass production.

According to official statements from Mullen, the AMEC will play a vital role in training its workforce. Employees will receive hands-on experience with the latest manufacturing technologies. This will help them develop the skills necessary to operate and maintain the advanced equipment used in the production process.

Key Technologies and Processes

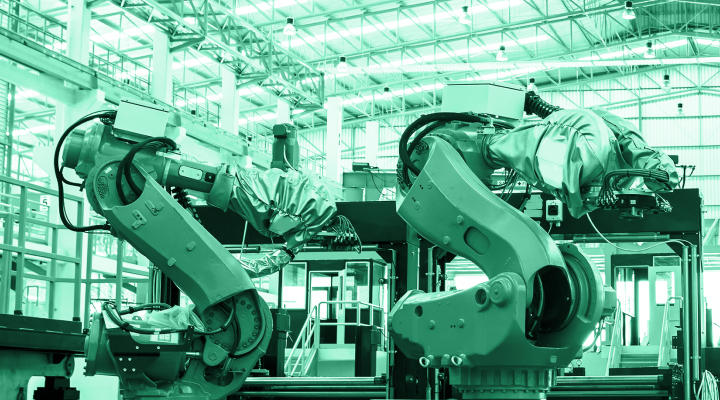

The AMEC integrates a range of cutting-edge technologies to optimize EV manufacturing. Advanced robotics are deployed for tasks such as welding, painting, and component assembly. These robots are programmed to perform repetitive tasks with high precision, reducing the risk of human error.

Automation plays a key role in streamlining the material handling process. Automated guided vehicles (AGVs) transport parts and components between different workstations. This minimizes manual labor and improves the overall efficiency of the production line.

Data analytics are utilized to monitor and optimize the performance of the manufacturing processes. Sensors collect data on various parameters, such as temperature, pressure, and vibration. This data is then analyzed to identify potential problems and optimize the manufacturing process in real-time. The use of machine learning algorithms helps predict equipment failures and prevent costly downtime.

Challenges and Opportunities

Despite the ambitious vision, the AMEC faces significant challenges. Mullen Automotive has a history of financial difficulties. Concerns remain about the company's ability to secure the necessary funding to fully realize the center's potential.

Competition in the EV market is intensifying, with established automakers and new entrants vying for market share. Mullen must differentiate itself through innovation, quality, and cost-effectiveness to succeed. The AMEC is intended to address cost effectiveness, but its success is not guaranteed.

However, the AMEC also presents significant opportunities for Mullen. It allows the company to control its manufacturing processes more directly. This can lead to improved quality, reduced costs, and faster time-to-market for its vehicles.

The Role of Government Incentives

Government incentives play a crucial role in supporting the development of EV manufacturing in the United States. Both federal and state governments offer tax credits, grants, and other incentives to attract EV manufacturers.

Mullen has sought and received some incentives to support the AMEC's development. The ability to successfully leverage these incentives will be critical to the facility's long-term success. How these incentives will play out for Mullen remains to be seen.

Impact on the Local Economy

The AMEC has the potential to create hundreds of jobs in the Tunica, Mississippi area. This would provide a significant boost to the local economy, which has struggled with unemployment in recent years. Mullen Automotive has projected job creation numbers that will require substantial and sustained production activity.

The presence of a high-tech manufacturing facility could also attract other businesses to the region. This can lead to the development of a broader ecosystem of suppliers and support services. The influx of skilled workers and investment could further stimulate economic growth.

The impact on the local economy depends on the AMEC's long-term success. If Mullen can achieve its production goals, the facility could become a major driver of economic development in the region. However, if the company struggles, the economic benefits may be limited.

Looking Ahead

The success of Mullen's AMEC hinges on several factors. The company must secure the necessary funding to fully equip and operate the facility. It must also execute its production plans effectively and overcome the challenges of a competitive EV market.

Mullen Automotive aims to use the AMEC as a model for future manufacturing facilities. This suggests that the company envisions expanding its production capacity in the coming years. These plans are dependent on demonstrating the viability of the AMEC model.

Ultimately, the AMEC represents a significant gamble for Mullen. Whether it pays off will depend on the company's ability to deliver on its promises and establish itself as a viable player in the rapidly evolving electric vehicle industry. The future of Mullen, and potentially a slice of the American EV manufacturing landscape, may well be determined within the walls of this ambitious center in Tunica, Mississippi.