New Advances In Technology Reduce The Cost To Gm

Detroit, MI – General Motors [GM] is poised to slash production costs by an estimated 15% over the next three years, thanks to breakthroughs in artificial intelligence [AI] driven manufacturing and advanced materials engineering.

This dramatic reduction stems from a company-wide initiative integrating cutting-edge technologies to streamline operations and minimize material waste, significantly boosting GM's competitive edge in the rapidly evolving automotive market.

AI-Powered Manufacturing Revolution

GM's factories are undergoing a massive overhaul with the deployment of advanced AI systems.

These systems optimize every stage of production, from parts sourcing to assembly line automation. Dr. Anya Sharma, GM's Chief Technology Officer, confirmed the initial success of pilot programs at the Arlington Assembly plant in Texas, resulting in a 7% decrease in defects and a 10% increase in production efficiency.

The AI algorithms analyze real-time data from sensors embedded across the factory floor, predicting potential equipment failures and adjusting production schedules to avoid bottlenecks.

Robotics and Automation Surge

The increased deployment of robots, now equipped with enhanced AI capabilities, is a cornerstone of GM's cost-cutting strategy.

These robots perform complex tasks with greater precision and speed than their predecessors, reducing labor costs and improving overall quality. GM has invested $500 million in upgrading its robotics infrastructure across its North American plants, expecting a full return on investment within five years.

The robots are programmed to automatically adjust their movements based on real-time feedback, minimizing material waste and ensuring consistent product quality.

Advanced Materials Innovation

GM is aggressively pursuing the use of lightweight, high-strength materials to reduce vehicle weight and improve fuel efficiency.

This initiative includes the adoption of advanced alloys and composite materials, decreasing the amount of raw material needed per vehicle. The company has partnered with MIT [Massachusetts Institute of Technology] on research into novel carbon fiber composites, anticipating a 20% reduction in material costs within the next two years.

"We are moving away from traditional steel and aluminum towards more sustainable and cost-effective solutions," stated Mark Reuss, GM President, during a recent investor call.

3D Printing Revolutionizes Prototyping

3D printing, also known as additive manufacturing, plays a crucial role in GM’s cost-reduction efforts.

It significantly reduces the time and expense associated with prototyping new vehicle designs. GM uses 3D printing to rapidly produce custom parts and tools, eliminating the need for costly and time-consuming traditional manufacturing processes.

The company estimates that 3D printing has already saved them over $30 million in prototyping costs in the last year.

Impact on Labor and Workforce Development

The implementation of these technologies will inevitably impact GM’s workforce.

However, the company insists that its focus is on retraining and upskilling employees to adapt to the changing demands of the automotive industry. GM has pledged to invest $100 million in workforce development programs over the next five years, focusing on training employees in areas such as AI programming, robotics maintenance, and data analytics.

Mary Barra, GM CEO, emphasized the company's commitment to its employees, stating that "our goal is to ensure that our workforce has the skills they need to thrive in the future of automotive manufacturing."

Competitive Advantage and Future Outlook

The cost reductions achieved through these technological advancements will significantly enhance GM’s competitive position in the global automotive market.

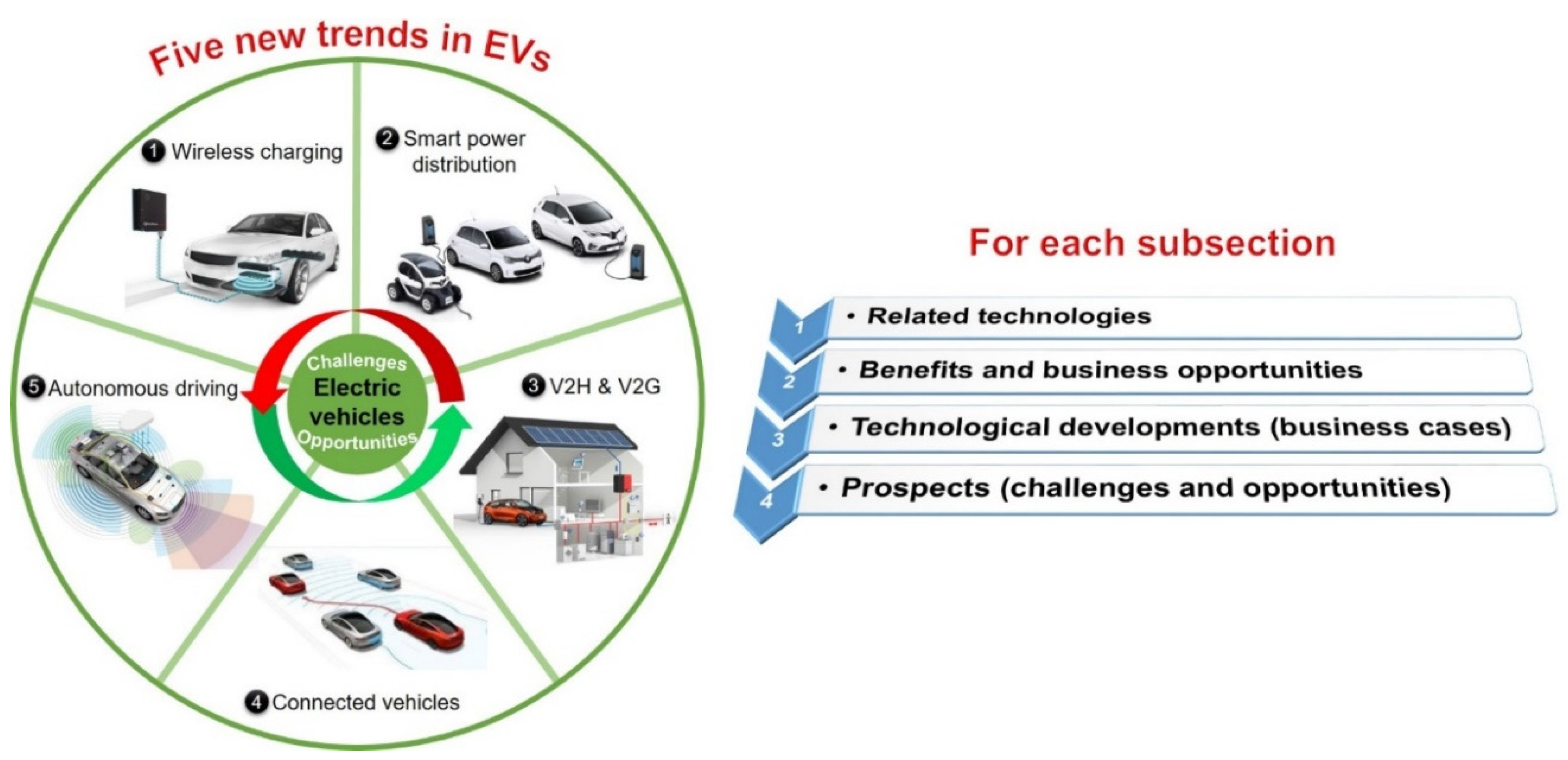

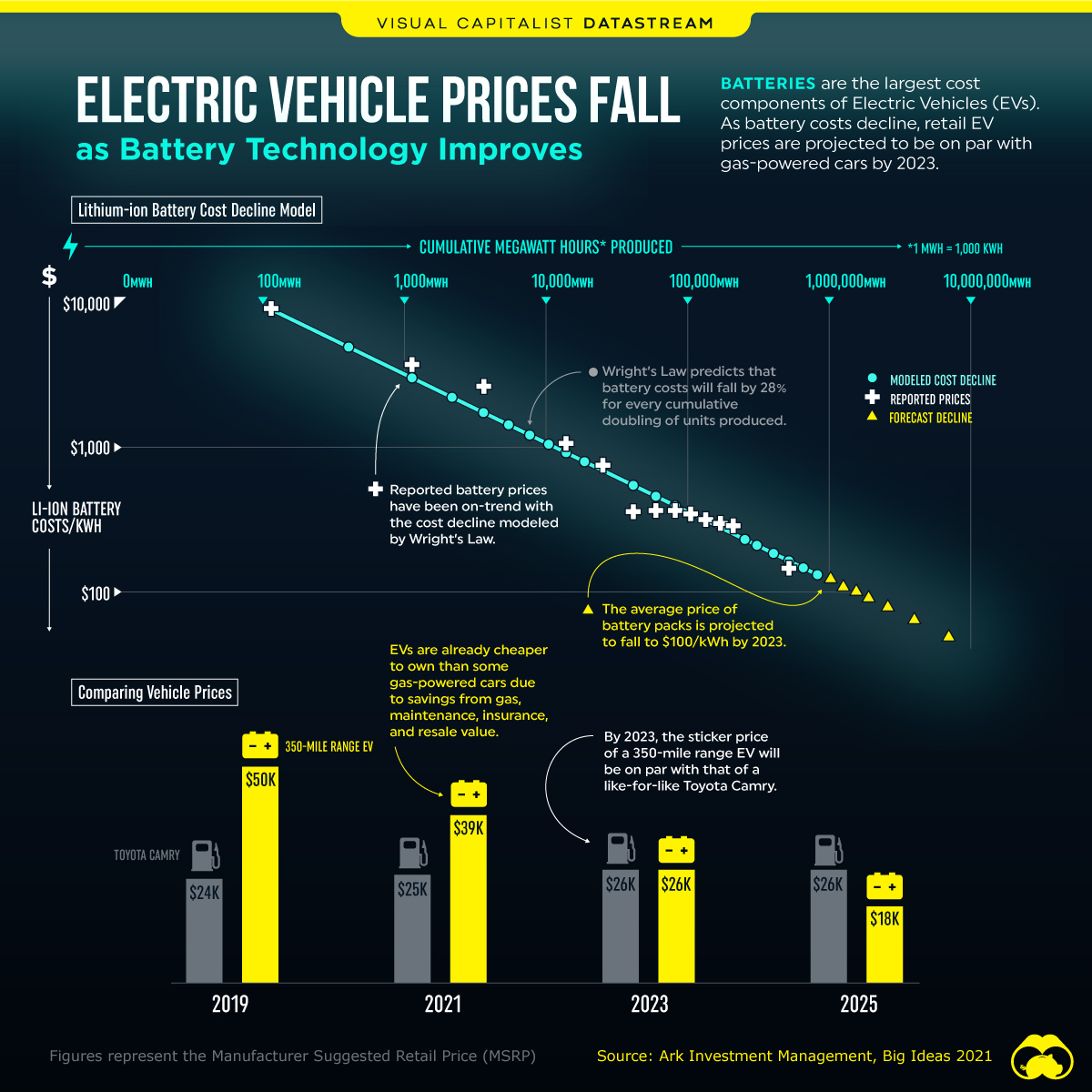

The savings will allow GM to invest more heavily in research and development, accelerating the development of electric vehicles [EVs] and autonomous driving technologies. The company is also planning to use the savings to offer more competitive pricing on its vehicles, attracting a wider customer base.

GM anticipates that these changes will contribute significantly to its long-term profitability and sustainability, reaffirming its commitment to innovation and leadership in the automotive industry.

Next Steps and Ongoing Developments

GM will continue to roll out its AI-powered manufacturing systems and advanced materials technologies across all of its global plants over the next three years.

The company is actively seeking partnerships with other technology companies and research institutions to further accelerate innovation. A company-wide meeting is scheduled next month to discuss the phased implementation strategy at the Spring Hill, Tennessee plant.

Regular progress reports will be issued to investors and stakeholders, detailing the impact of these initiatives on GM’s financial performance and operational efficiency.