Once Acid Is Created Within The Refrigeration System

Imagine a sweltering summer day. The aroma of freshly cut grass hangs heavy in the air, and all you crave is the icy blast from your refrigerator. But what if, instead of cool refreshment, your fridge harbored a silent, corrosive enemy? An enemy that could slowly eat away at its vital components, leaving you with a costly repair bill and a fridge full of spoiled food.

This invisible threat is acid, and its presence within a refrigeration system signals a serious problem. It's not just about a broken appliance; it's about understanding the delicate chemical balance within these systems and the potential for widespread damage when that balance is disrupted. Understanding the causes, consequences, and preventive measures associated with acid formation is crucial for anyone involved in refrigeration, from homeowners to seasoned technicians.

The Silent Destroyer: Acid Formation in Refrigeration Systems

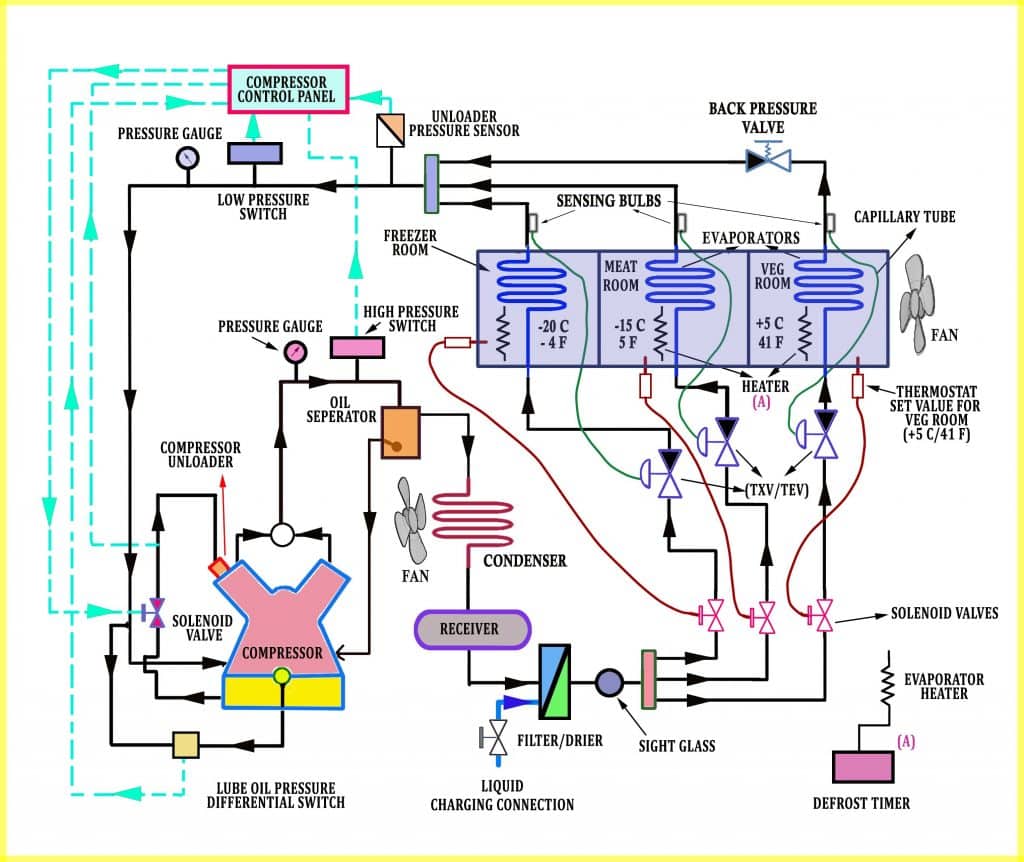

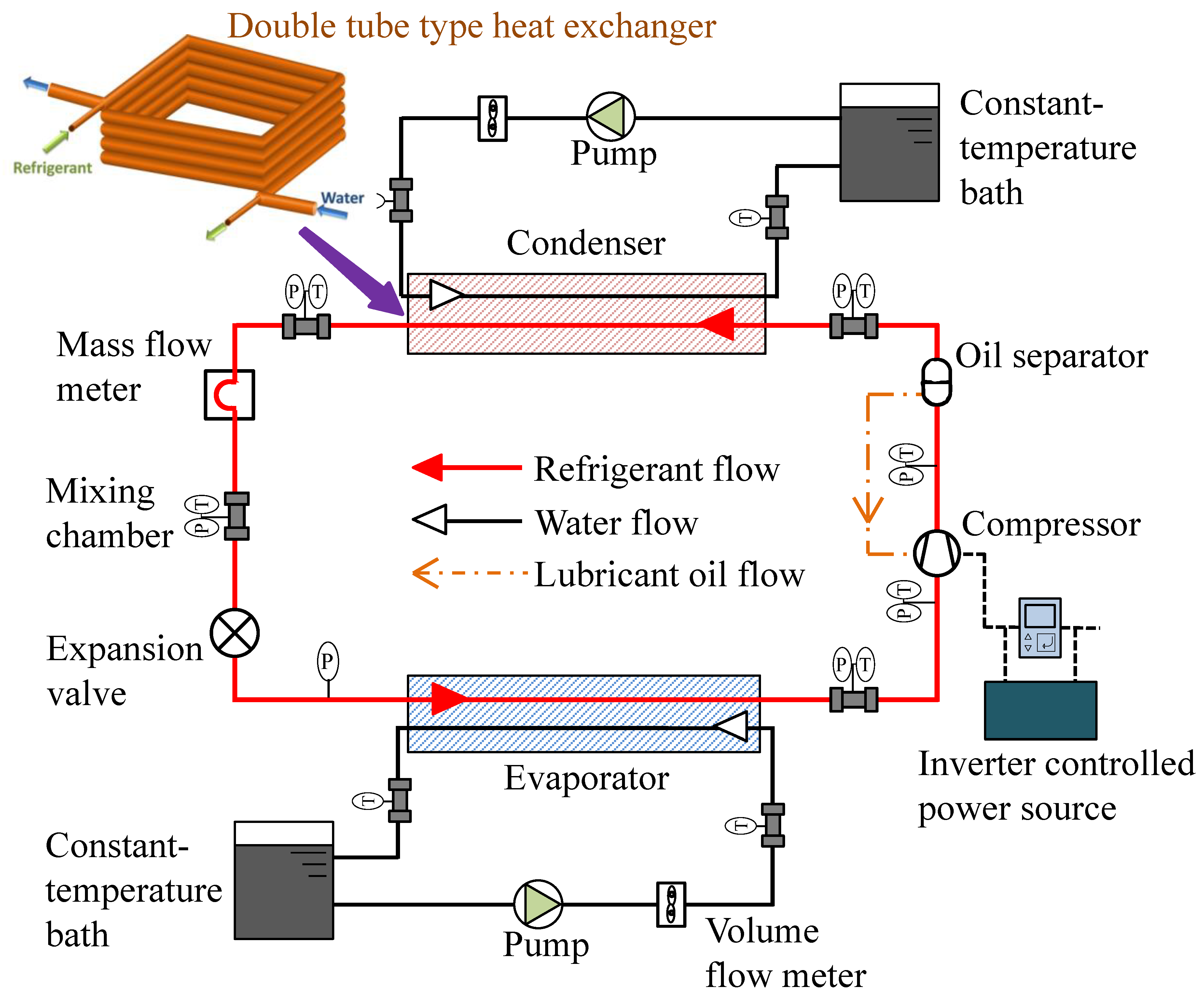

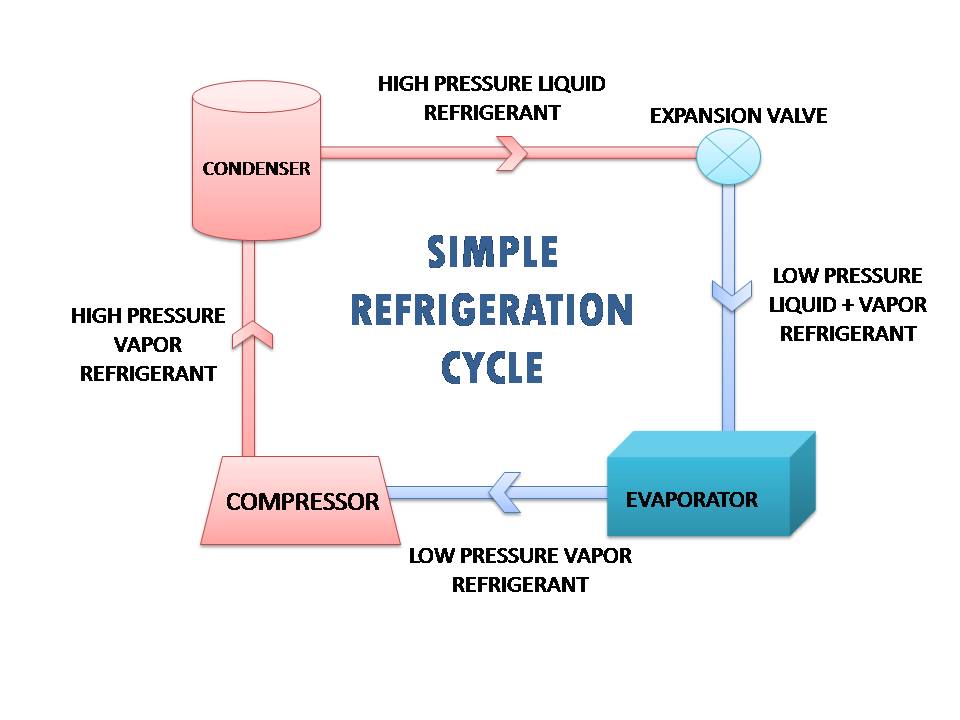

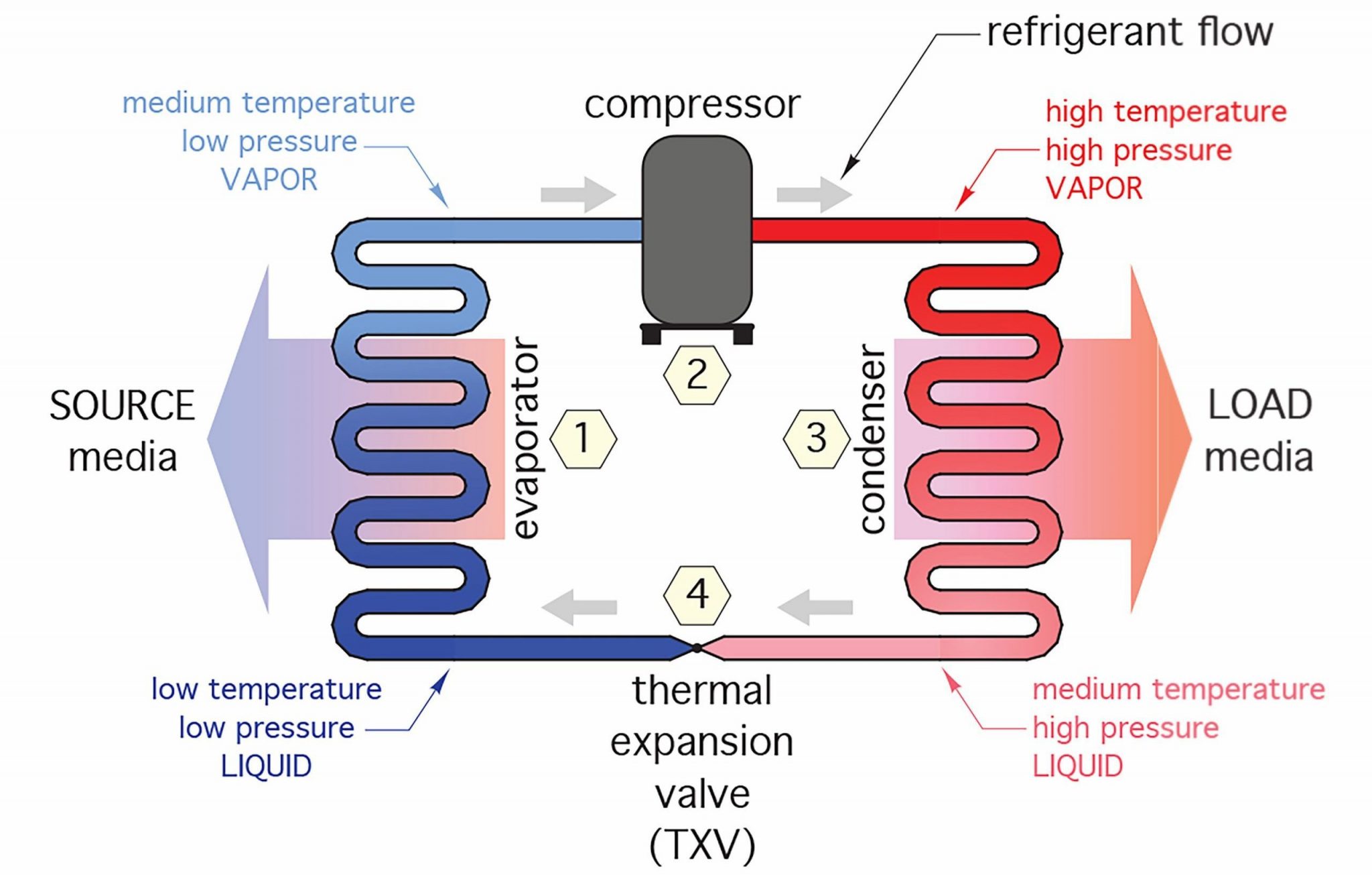

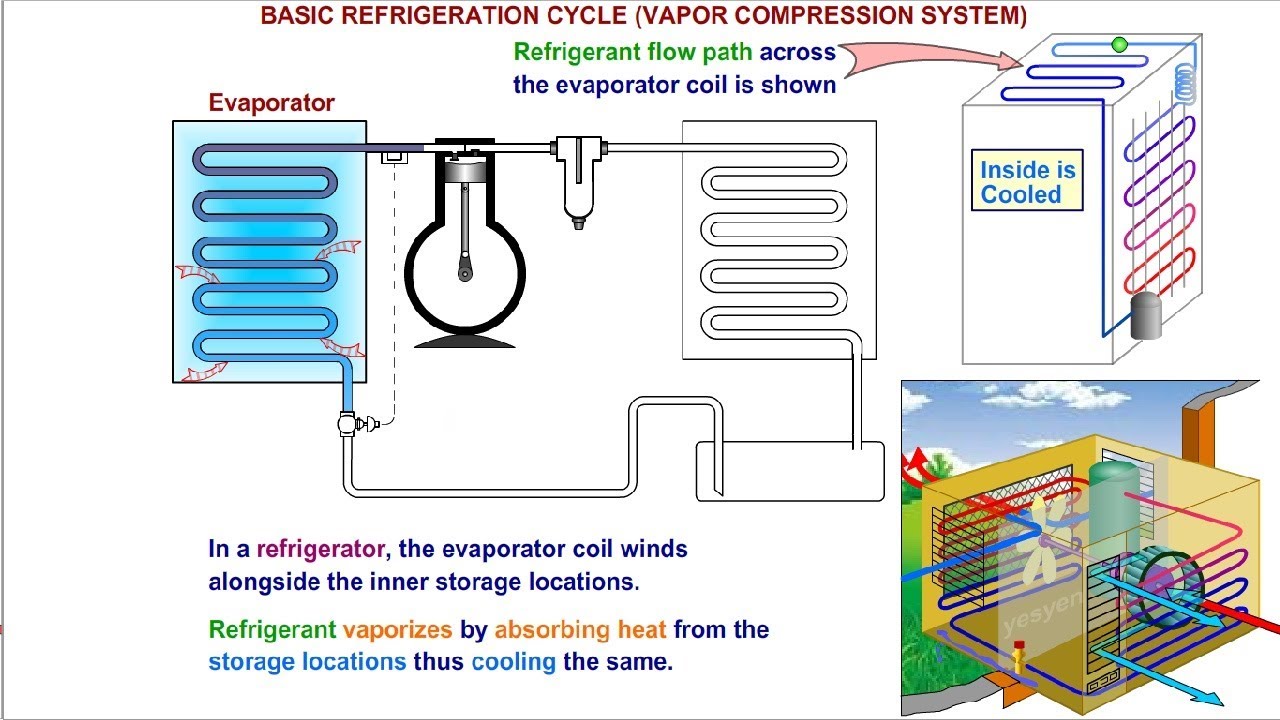

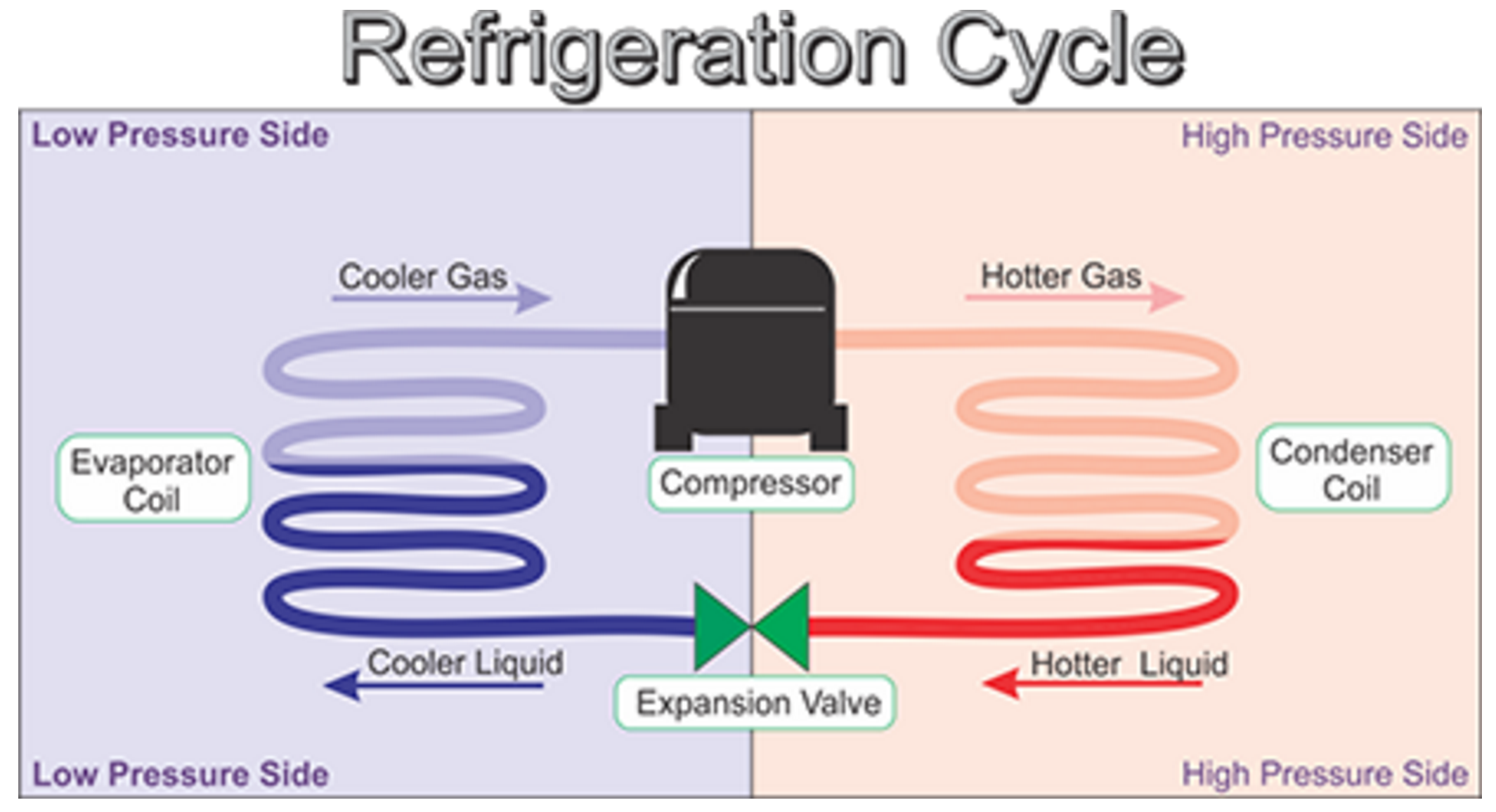

The heart of any refrigeration system is the refrigerant, a substance that cycles through the system, absorbing heat and releasing it elsewhere. However, this cycle isn't always smooth. The interaction of refrigerant, lubricant, and contaminants like moisture and air can lead to a chemical reaction – the formation of acid.

But how exactly does this happen? Primarily, it’s about unwanted elements sneaking into the hermetically sealed system. Moisture is the biggest culprit. It enters the system via leaks or when components are open to the atmosphere during servicing.

Once inside, the moisture reacts with the refrigerant and lubricant, particularly at high temperatures, to form hydrochloric and hydrofluoric acids. These acids are highly corrosive and can wreak havoc on the internal components of the system.

Understanding the Key Players

Several factors contribute to acid formation. Let's break down the roles of the key players:

Refrigerant: While designed for heat transfer, refrigerants can become unstable in the presence of contaminants. Older refrigerants like CFCs and HCFCs were particularly susceptible, but even modern HFCs and HFOs are not immune.

Lubricant: The lubricant’s primary purpose is to minimize friction between moving parts, but it also plays a role in the chemical reaction. Certain lubricants are more reactive with contaminants than others.

Moisture: As mentioned earlier, this is the primary catalyst. Even trace amounts of moisture can trigger acid formation. According to the Air-Conditioning, Heating, and Refrigeration Institute (AHRI), maintaining a system free of moisture is paramount for longevity.

Air: Air introduces oxygen and nitrogen into the system. Oxygen accelerates the oxidation process, while nitrogen can react with refrigerants at high temperatures.

The Devastating Consequences of Acid Buildup

The presence of acid in a refrigeration system can lead to a cascade of problems. These issues range from reduced efficiency to catastrophic component failure.

One of the first signs is often a decrease in cooling performance. The acid corrodes the internal surfaces of the compressor, condenser, and evaporator, reducing their ability to transfer heat effectively.

Over time, the acid can attack the compressor windings, leading to short circuits and eventually compressor failure. Compressor burnout is a common and costly consequence of acid contamination.

Furthermore, the acid can react with the lubricant, causing it to break down and lose its lubricating properties. This accelerates wear and tear on the compressor, further shortening its lifespan.

The acid can also damage the system's seals and O-rings, leading to refrigerant leaks. This not only reduces cooling performance but also contributes to environmental damage.

According to studies by the Environmental Protection Agency (EPA), refrigerant leaks are a significant contributor to greenhouse gas emissions. Addressing acid buildup can indirectly help reduce environmental impact.

Detecting and Neutralizing the Threat

Fortunately, acid formation isn't an insurmountable problem. With proper maintenance and diagnostic techniques, it can be detected and neutralized.

The most common method of detection is an acid test kit. This kit involves taking a sample of the refrigerant oil and testing it for acidity using a color-changing indicator. A change in color indicates the presence of acid.

Another diagnostic tool is refrigerant analysis. This involves sending a sample of the refrigerant to a laboratory for detailed analysis. The lab can identify the presence of acid and other contaminants, providing a more comprehensive picture of the system's health.

Once acid is detected, it's crucial to neutralize it and remove the contaminants. This is typically done using acid neutralizers, which are added to the system to counteract the acidity.

After neutralization, it's essential to flush the system thoroughly to remove any remaining acid and contaminants. This often involves using a specialized flushing agent and replacing the filter drier.

The filter drier plays a crucial role in removing moisture and other contaminants from the system. It should be replaced regularly as part of routine maintenance.

Preventive Measures: A Proactive Approach

The best way to deal with acid formation is to prevent it in the first place. Here are some key preventive measures:

Proper Evacuation: Before charging a system with refrigerant, it's essential to evacuate it thoroughly to remove moisture and air. This involves using a vacuum pump to pull a deep vacuum on the system.

Using High-Quality Refrigerant and Lubricant: Always use high-quality refrigerant and lubricant that are compatible with the system. Avoid using generic or substandard products.

Proper Installation and Servicing: Ensure that the system is installed and serviced by qualified technicians. Proper installation and servicing can prevent leaks and contamination.

Regular Maintenance: Schedule regular maintenance checks to identify and address potential problems early. This includes checking for leaks, testing the refrigerant oil, and replacing the filter drier.

Looking Ahead: Innovations in Refrigeration Technology

The refrigeration industry is constantly evolving, with new technologies and refrigerants being developed to improve efficiency and reduce environmental impact.

One area of innovation is the development of more stable refrigerants that are less susceptible to acid formation. These new refrigerants offer improved performance and reduced risk of contamination.

Another area of focus is the development of advanced diagnostic tools that can detect acid formation earlier and more accurately. These tools can help technicians identify and address problems before they become serious.

Furthermore, there's increasing emphasis on sustainable refrigeration practices. This includes using environmentally friendly refrigerants, reducing refrigerant leaks, and improving energy efficiency.

Ultimately, the key to combating acid formation in refrigeration systems lies in understanding the underlying causes, implementing preventive measures, and staying informed about the latest technologies and best practices.

By taking a proactive approach, we can ensure the longevity and efficiency of our refrigeration systems, while also protecting the environment.

So, the next time you reach for that refreshing drink from your refrigerator, remember the silent battle being waged within its coils. A battle against acid, a battle for efficiency, and a battle for a cooler, greener future.

![Once Acid Is Created Within The Refrigeration System [DIAGRAM] Diagram Refrigeration Cycle - MYDIAGRAM.ONLINE](https://insulation.org/io/wp-content/uploads/sites/3/2016/10/IO150704_01.jpg)

![Once Acid Is Created Within The Refrigeration System [DIAGRAM] Ph Diagram Refrigeration Cycle - MYDIAGRAM.ONLINE](https://i.ytimg.com/vi/XscHn6GPWO0/maxresdefault.jpg)