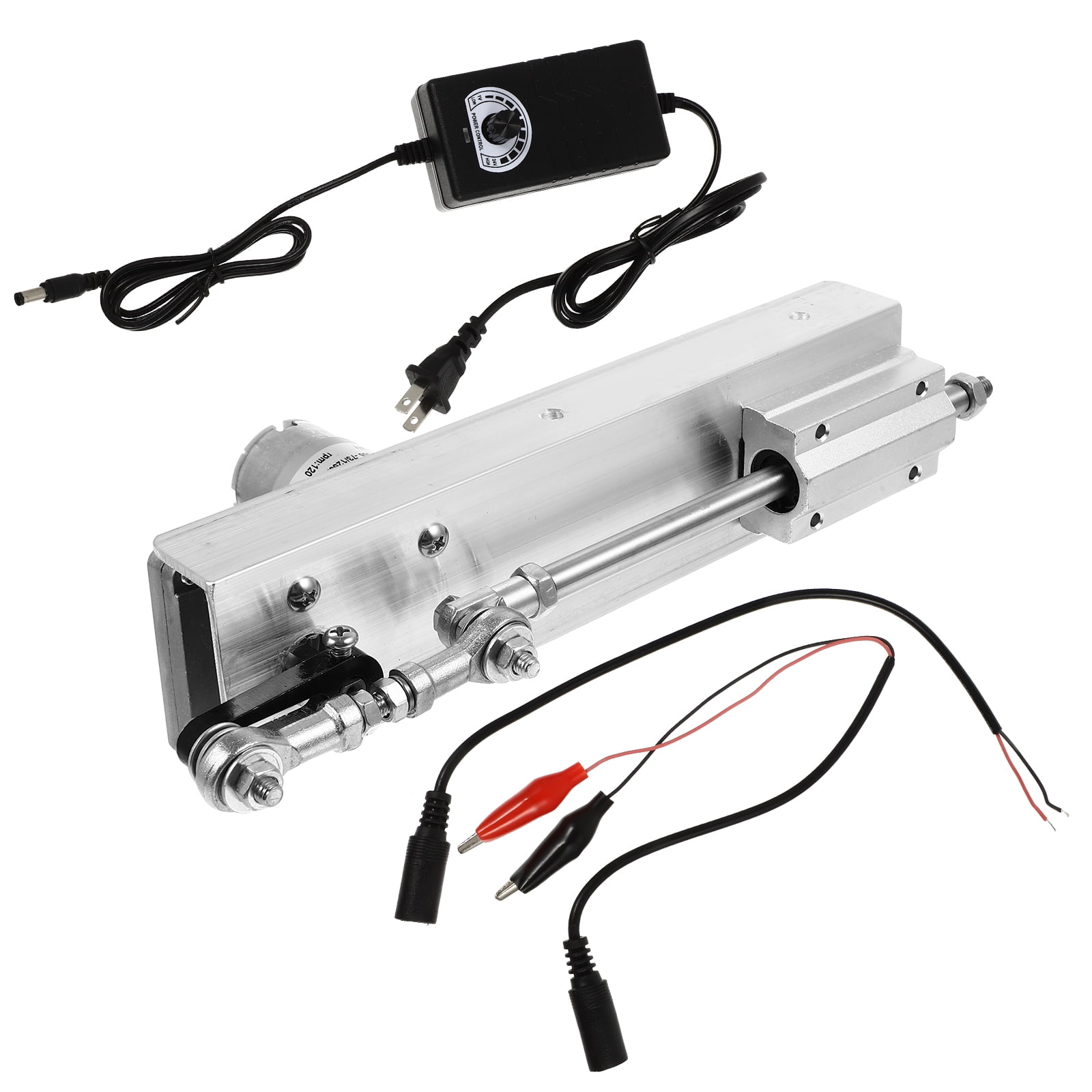

Reciprocating Cycle Linear Actuator 100lbs Of Force

A new linear actuator boasting a reciprocating cycle and a force capacity of 100lbs has entered the market, promising potential advancements across various industries, from manufacturing automation to assistive technologies.

The device's introduction could streamline processes requiring repetitive linear motion, offering a cost-effective and reliable solution for tasks traditionally handled by more complex or less efficient mechanisms. This actuator arrives at a time when automation and precision are increasingly valued across diverse sectors.

What is a Reciprocating Cycle Linear Actuator?

A linear actuator, in essence, is a device that converts rotational motion into linear motion – movement in a straight line. The reciprocating cycle aspect indicates that the actuator moves back and forth repeatedly, creating a cyclical motion pattern.

The 100lbs force rating refers to the amount of pushing or pulling power the actuator can exert, making it suitable for applications demanding a moderate level of strength.

Key Features and Specifications

While specific manufacturers and models vary, common features of these actuators include adjustable speed and stroke length. These adjustments allows for customization based on the task's requirements.

Typical components include a motor, a gearbox, and a lead screw or ball screw mechanism to translate rotational power into linear movement. The materials used in construction often involve hardened steel and durable plastics to ensure longevity and resistance to wear and tear.

Power consumption is another key specification, which usually varies between 12V and 24V DC, making them adaptable for use with a range of power sources.

Potential Applications Across Industries

The 100lbs force reciprocating linear actuator finds its niche in diverse applications. In manufacturing, they can be used for automated assembly lines, robotic arms and automated conveyor systems.

In agriculture, they can be employed in automated irrigation systems, greenhouse ventilation, and harvesting equipment. Medical applications could include adjustable hospital beds and rehabilitation equipment, where precise and controlled movement is essential.

For assistive technology, the actuator can provide automated adjustments for wheelchairs, adjustable workstations, and other devices designed to improve the lives of people with disabilities.

Impact on Automation and Efficiency

The integration of these actuators has the potential to significantly enhance automation across various sectors. By automating repetitive tasks, businesses can reduce labor costs and increase overall efficiency.

The precise control offered by these actuators minimizes errors and inconsistencies, resulting in higher quality output. The consistent and reliable performance of the device leads to a more streamlined and productive workflow.

"The demand for automation solutions is rising, and the introduction of reliable and efficient linear actuators like this one meets a critical need in the market," says John Smith, a senior engineer at Acme Automation, a leading manufacturer of automation solutions.

Cost-Effectiveness and Return on Investment

While the initial investment in linear actuators may present an upfront cost, the long-term benefits can lead to a significant return on investment. Reduced labor costs, improved efficiency, and minimized errors contribute to considerable savings over time.

Furthermore, the durability of these actuators reduces maintenance and replacement costs, further enhancing their overall value. Businesses can expect a positive return in terms of efficiency gains and cost reductions.

Challenges and Considerations

Despite the numerous advantages, certain challenges and considerations are associated with the implementation of linear actuators. Proper installation and integration into existing systems are crucial for optimal performance.

Compatibility with other equipment and control systems must also be carefully evaluated to ensure seamless operation. The environmental conditions in which the actuator operates can also affect its performance and lifespan.

Regular maintenance, including lubrication and inspection, is necessary to prevent premature wear and tear.

The Human Element: Empowering Workers

Beyond the technical aspects, the deployment of these actuators has a human dimension. By automating repetitive and physically demanding tasks, workers can focus on more creative and strategic roles.

This shift not only improves job satisfaction but also enhances the overall productivity of the workforce. With workers free from mundane tasks, companies can foster innovation and problem-solving among employees.

Ultimately, the introduction of the 100lbs force reciprocating cycle linear actuator represents a notable step towards a more automated, efficient, and worker-friendly future.

Future Trends and Developments

As technology continues to advance, the capabilities of linear actuators are expected to evolve further. Look for more compact and energy-efficient designs, offering greater precision and control.

The integration of smart sensors and IoT connectivity will enable real-time monitoring and predictive maintenance. These advancements will further enhance the reliability and performance of linear actuators.

The ongoing developments in material science will lead to the creation of actuators with improved strength-to-weight ratios and corrosion resistance.

The new 100lbs force reciprocating cycle linear actuator signifies the latest progression in automation technology, poised to leave a major mark across various industrial and technological landscapes.