Service Contract Semiconductor Vacuum And Abatement

The global semiconductor industry is increasingly reliant on specialized service contracts to maintain the complex vacuum and abatement systems essential for chip manufacturing. These contracts, encompassing everything from preventative maintenance to emergency repairs, are critical for ensuring production uptime and environmental compliance. The rising demand reflects the growing complexity of semiconductor fabrication and the stringent regulations surrounding emissions.

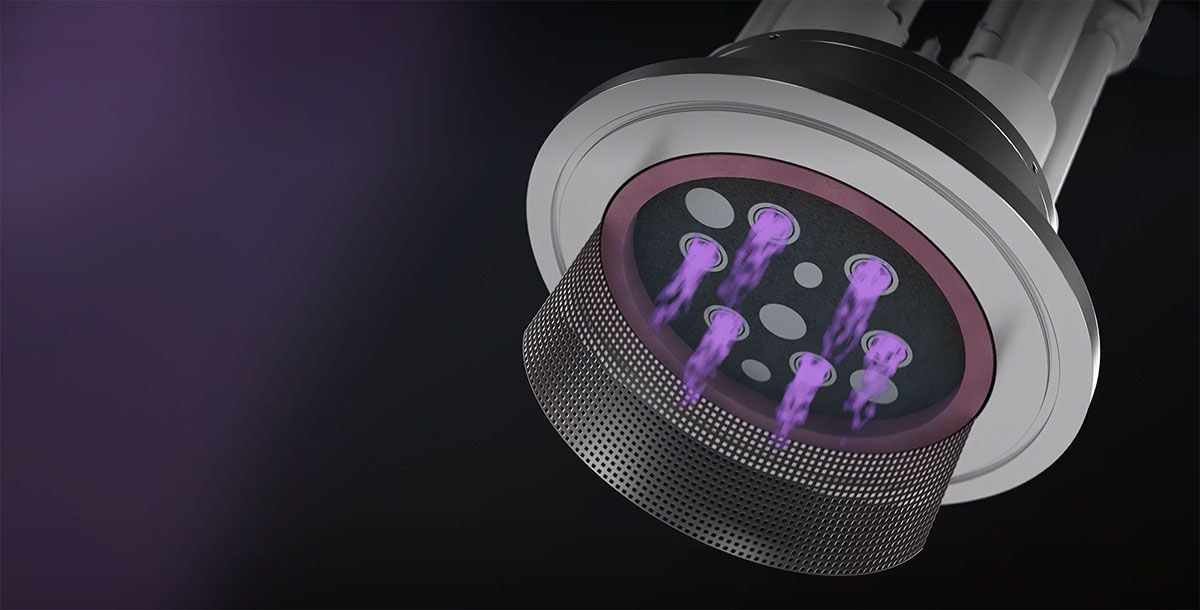

The intricate nature of semiconductor manufacturing processes necessitates sophisticated vacuum and abatement equipment. These systems play a crucial role in creating the ultra-clean environments required for chip fabrication and in neutralizing harmful byproducts generated during the manufacturing process. Service contracts are becoming indispensable tools for chipmakers seeking to optimize equipment performance and minimize disruptions.

The Nuts and Bolts of Service Contracts

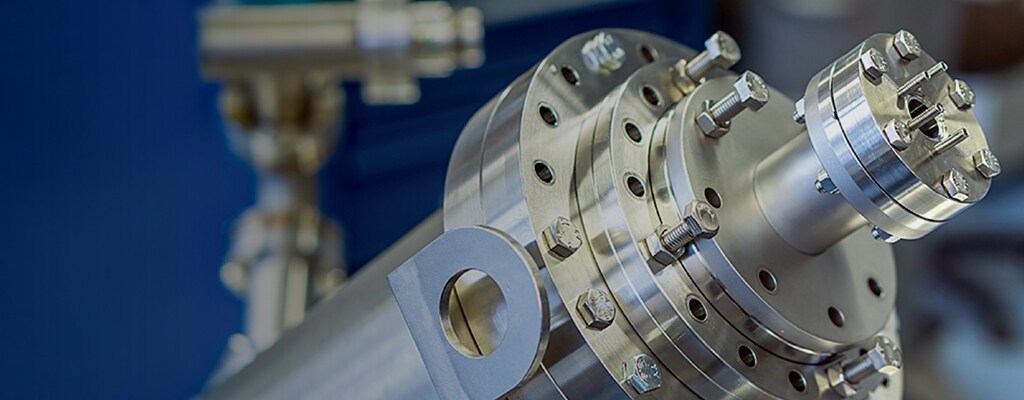

At its core, a service contract for semiconductor vacuum and abatement equipment is an agreement between a chip manufacturer and a specialized service provider. These contracts typically cover a range of services including scheduled maintenance, emergency repair, parts replacement, and system optimization. The specific terms and conditions of each contract vary depending on the equipment type, the manufacturer's needs, and the service provider's capabilities.

Edwards Vacuum, Pfeiffer Vacuum, and Atlas Copco are among the leading providers of these specialized services. These companies boast extensive experience in maintaining and servicing vacuum pumps, abatement systems, and related equipment used in semiconductor fabs worldwide. Their service contracts offer chipmakers access to specialized expertise and resources that can be difficult or expensive to maintain in-house.

Key Benefits for Chipmakers

The adoption of service contracts brings numerous advantages for semiconductor manufacturers. Enhanced equipment uptime is a primary benefit, reducing costly production stoppages. Preventative maintenance helps identify and address potential issues before they escalate into major breakdowns.

Cost predictability is another significant factor. Service contracts often include fixed fees for specific services, enabling chipmakers to accurately budget for maintenance and repair expenses. Moreover, access to specialized expertise ensures equipment operates at peak efficiency, reducing energy consumption and optimizing resource utilization.

Perhaps most critically, service contracts facilitate environmental compliance. Abatement systems are designed to neutralize harmful gases and byproducts generated during chip manufacturing. Regular maintenance and optimization ensure these systems function effectively, minimizing environmental impact and adhering to increasingly stringent regulations.

The Growing Demand and Market Dynamics

The demand for service contracts in the semiconductor vacuum and abatement sector is on the rise, driven by several key factors. The increasing complexity of chip manufacturing processes requires more sophisticated and specialized equipment. Maintaining this equipment demands a high level of expertise, which is often best obtained through specialized service providers.

Furthermore, the growing emphasis on environmental sustainability is fueling demand for comprehensive abatement services. Chipmakers are under increasing pressure to minimize their environmental footprint and comply with stringent regulations on emissions. Service contracts provide a mechanism for ensuring abatement systems operate effectively and meet these requirements.

According to a recent report by Global Industry Analysts Inc., the global market for semiconductor manufacturing equipment services is projected to reach $14.8 billion by 2027. This growth is largely attributed to the increasing demand for sophisticated vacuum and abatement systems and the associated service contracts needed to maintain them.

The Human Element: Training and Expertise

Beyond the technology and equipment, the success of these service contracts hinges on the expertise of the service technicians. These individuals are responsible for performing maintenance, troubleshooting issues, and optimizing equipment performance. Investing in training and development is crucial for ensuring technicians possess the necessary skills and knowledge.

"Our service engineers undergo rigorous training programs to ensure they are equipped to handle the most complex vacuum and abatement systems," said a spokesperson for Edwards Vacuum in a recent statement. "We understand that their expertise is critical to our customers' success."

The demand for skilled technicians in this field is expected to grow in the coming years. As the semiconductor industry continues to expand, so too will the need for qualified professionals to maintain and service the critical equipment used in chip manufacturing.

Challenges and Future Trends

Despite the numerous benefits, there are challenges associated with implementing service contracts. Selecting the right service provider is crucial. Chipmakers must carefully evaluate the provider's experience, expertise, and track record.

Managing the relationship between the chipmaker and the service provider also requires careful attention. Clear communication, well-defined service level agreements, and a collaborative approach are essential for ensuring a successful partnership. The industry is increasingly adopting predictive maintenance strategies, leveraging data analytics to anticipate potential equipment failures and proactively schedule maintenance.

The integration of artificial intelligence and machine learning into service contracts is also gaining traction. These technologies can analyze equipment data in real-time, identify patterns, and predict potential issues, enabling more proactive and efficient maintenance.

Conclusion

Service contracts for semiconductor vacuum and abatement equipment are becoming increasingly vital for ensuring production uptime, cost predictability, and environmental compliance. As the semiconductor industry continues to evolve, the reliance on these specialized services will only grow. By partnering with reputable service providers and embracing new technologies, chipmakers can optimize equipment performance, minimize disruptions, and maintain a competitive edge in the global market.