Standard Copper Tube Sizes In Mm

Imagine stepping into a bustling workshop, the air thick with the scent of solder and metal. Copper tubing gleams under the bright lights, meticulously organized in neat stacks. Each tube, a precisely engineered piece, ready to carry water, gas, or refrigerant through homes and buildings. But behind this orderly scene lies a world of standardization, a silent language of millimeters ensuring compatibility and efficiency across countless projects.

This article delves into the world of standard copper tube sizes in millimeters, exploring the significance of these measurements, their applications, and the underlying reasons for their standardization. Understanding these seemingly simple numbers is crucial for anyone involved in plumbing, HVAC, or construction, ensuring projects are completed safely, efficiently, and according to industry best practices.

A Brief History of Copper Tubing

Copper has been used for plumbing for centuries, dating back to ancient civilizations. Its resistance to corrosion, durability, and malleability made it an ideal material for transporting water. However, the standardization of copper tube sizes is a relatively recent development, driven by the need for interoperability and efficient manufacturing.

In the past, variations in tube dimensions could lead to compatibility issues, requiring custom fittings and increasing the risk of leaks. The development of standard sizes, expressed primarily in inches in some regions and millimeters in others, streamlined the industry, reducing waste and ensuring consistent performance.

Understanding the Millimeter Standard

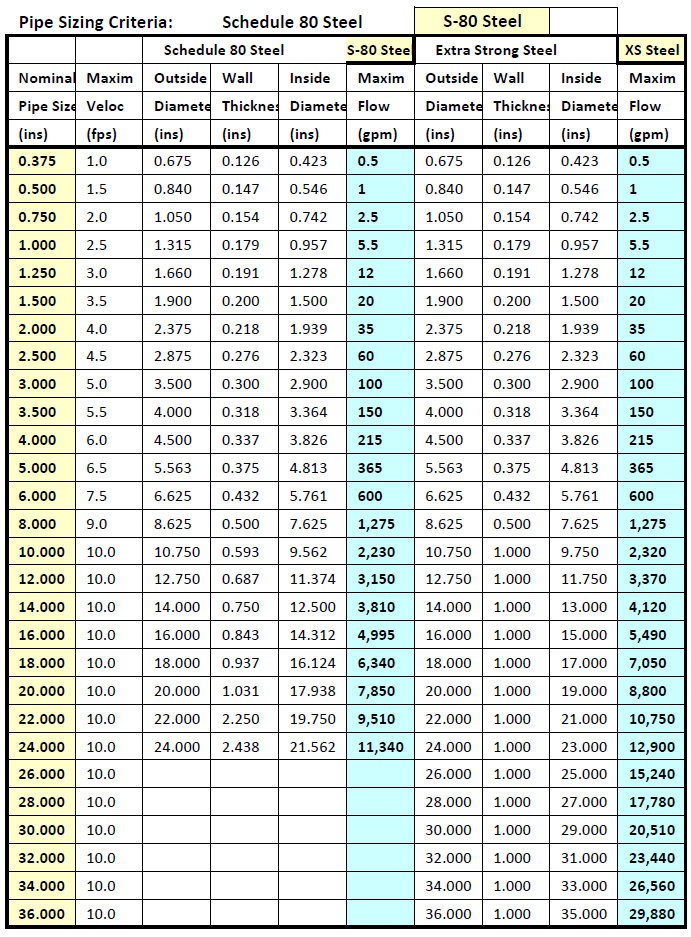

While inches are common in some parts of the world, the metric system, and specifically millimeters, is the standard in many countries for specifying copper tube sizes. This shift reflects a global trend toward metrication and the benefits of using a decimal-based system for engineering and manufacturing.

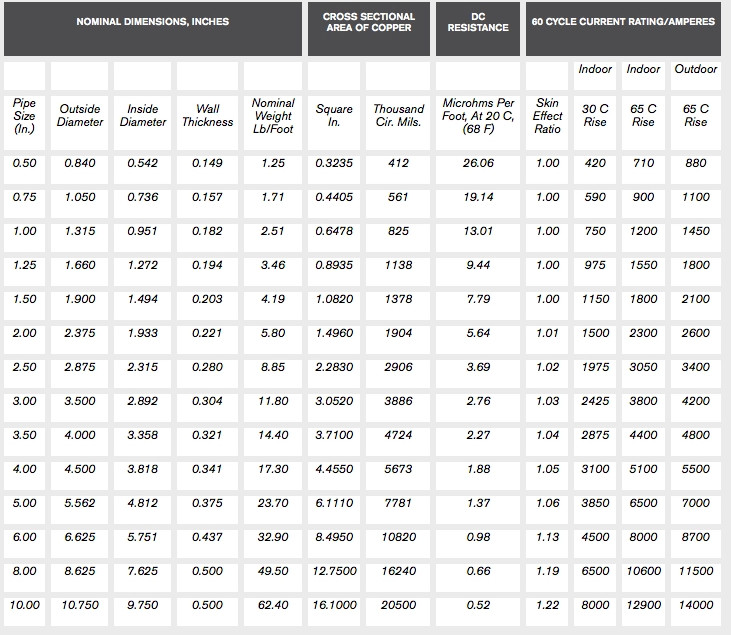

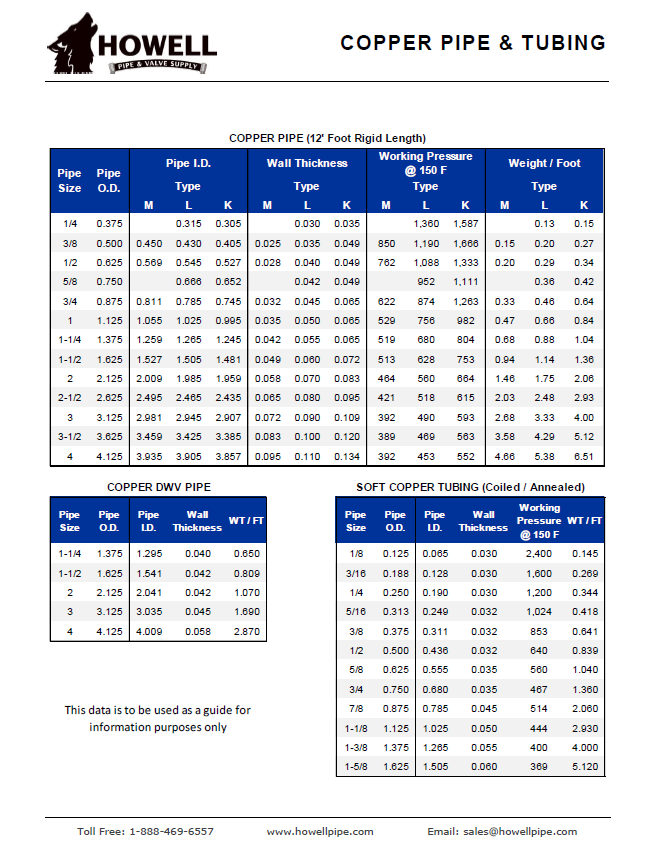

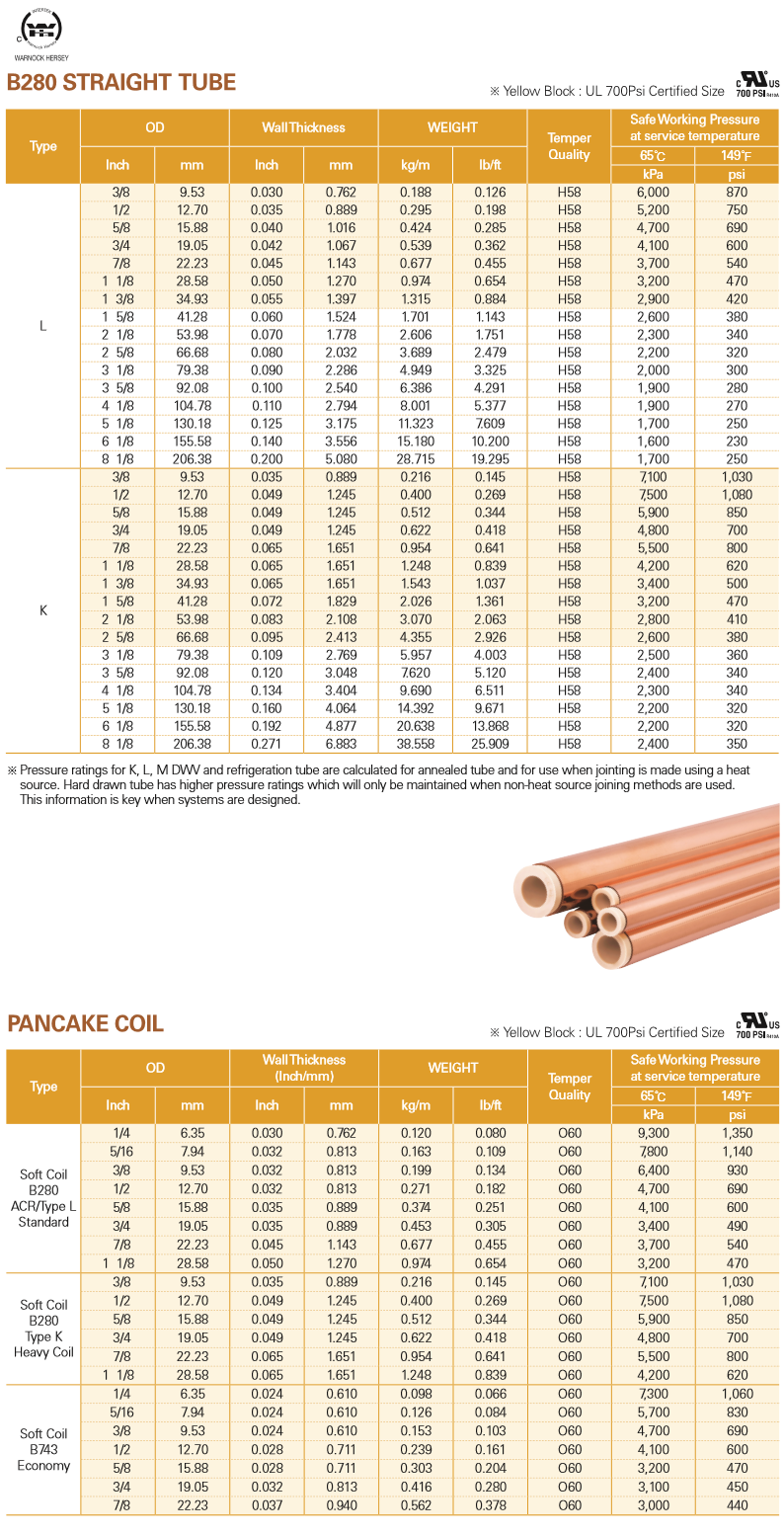

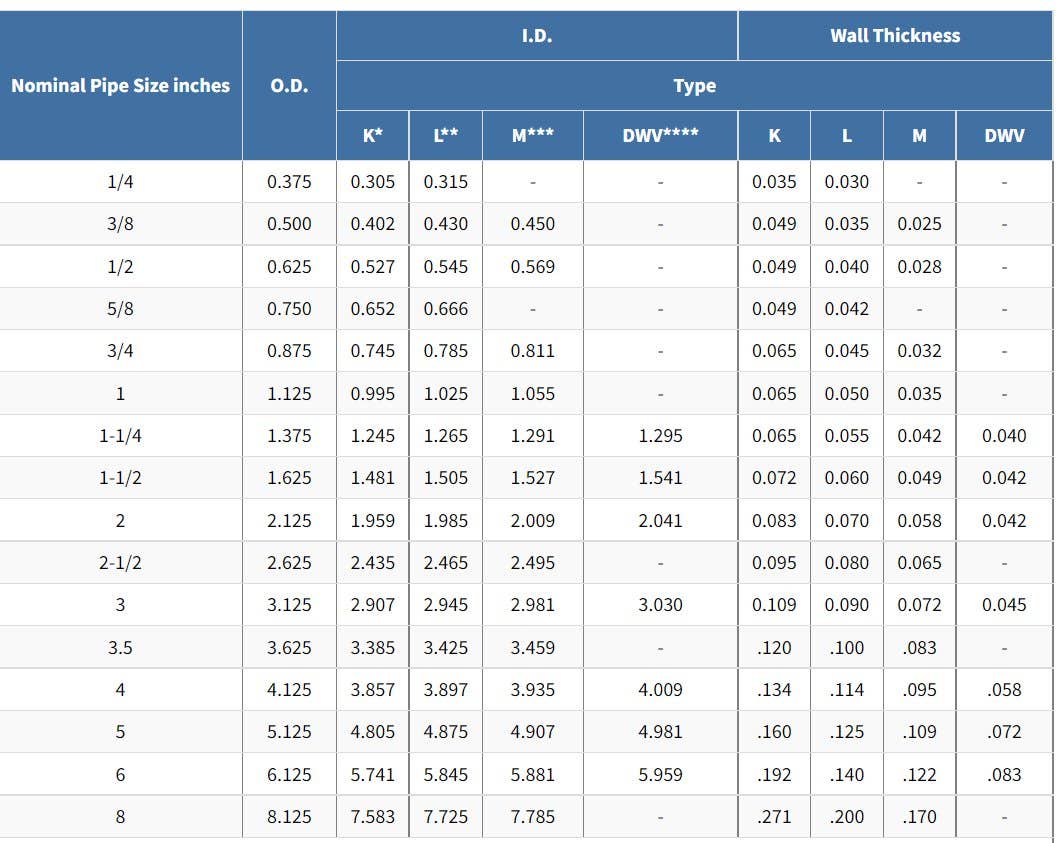

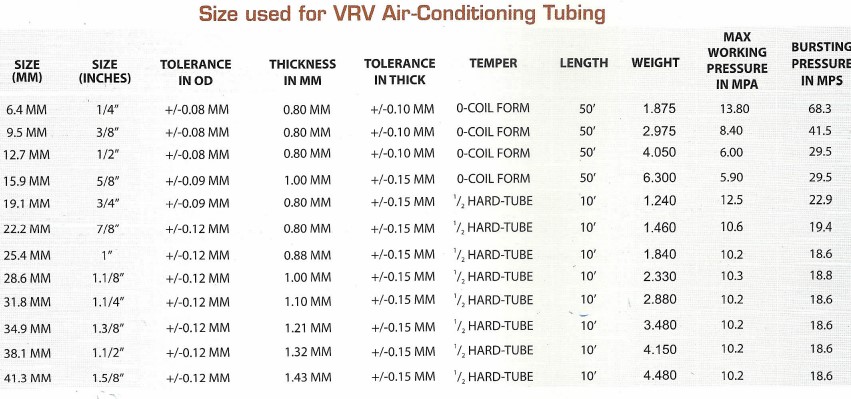

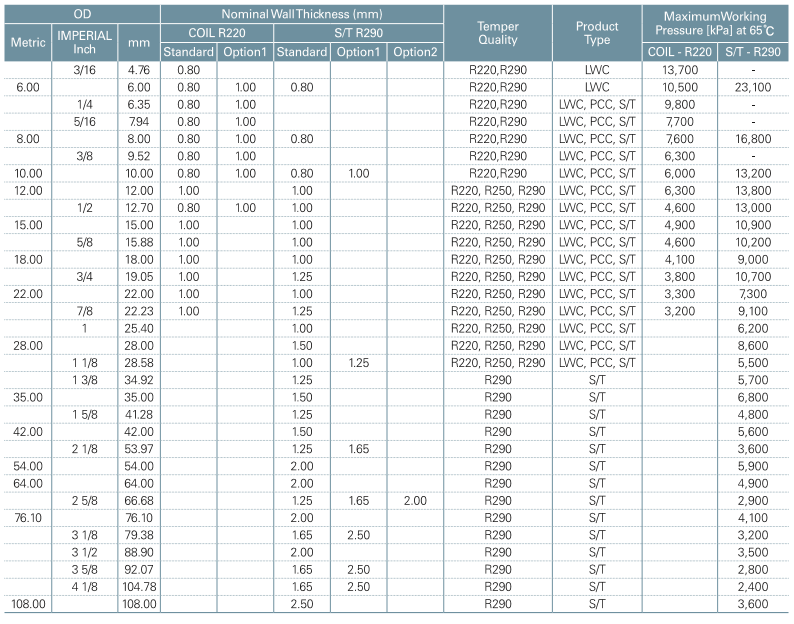

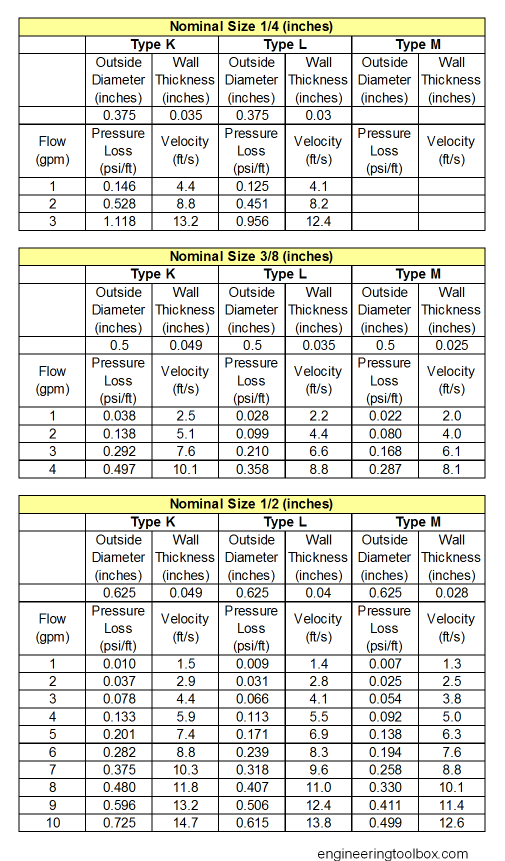

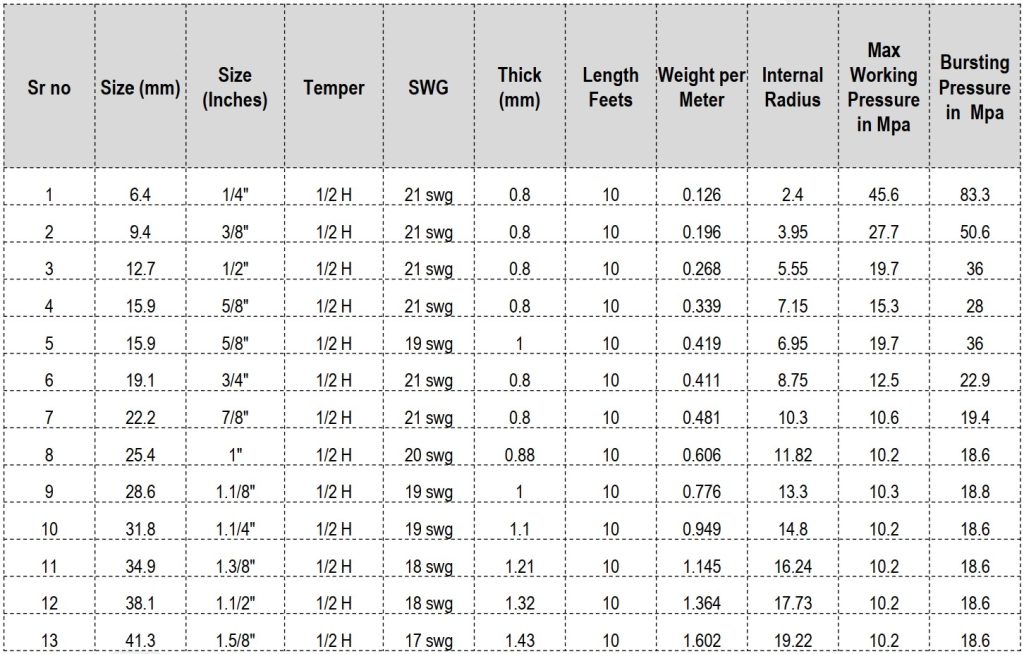

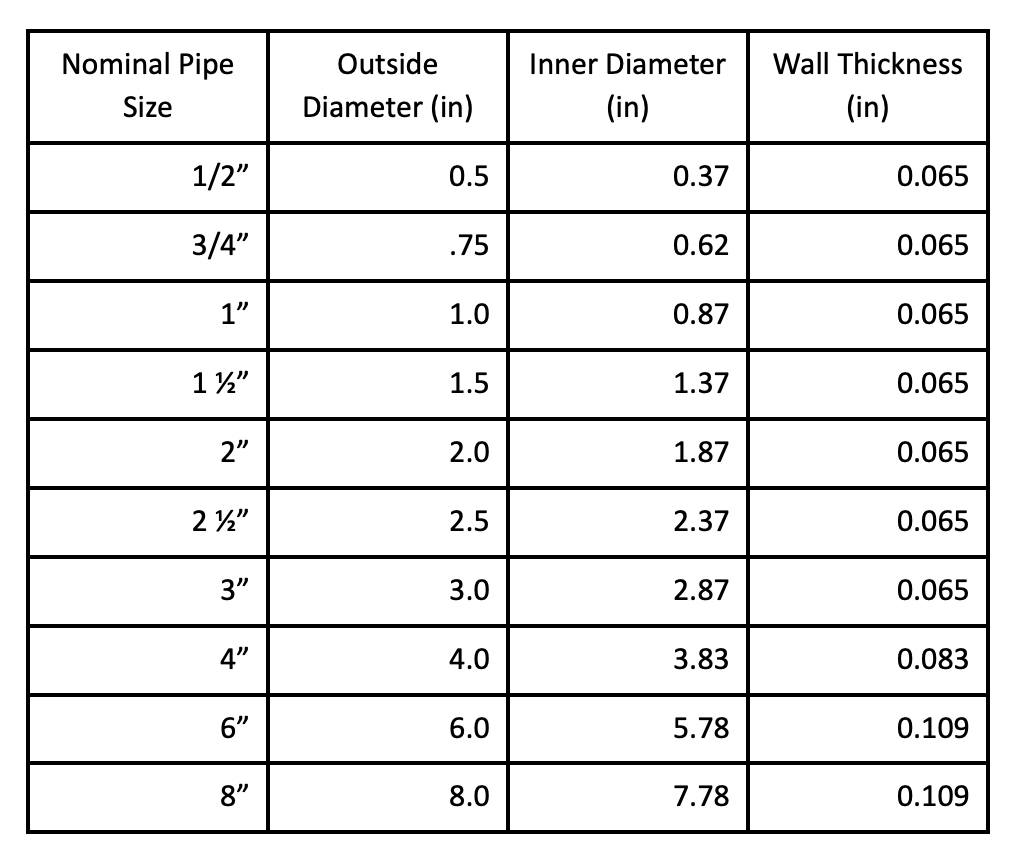

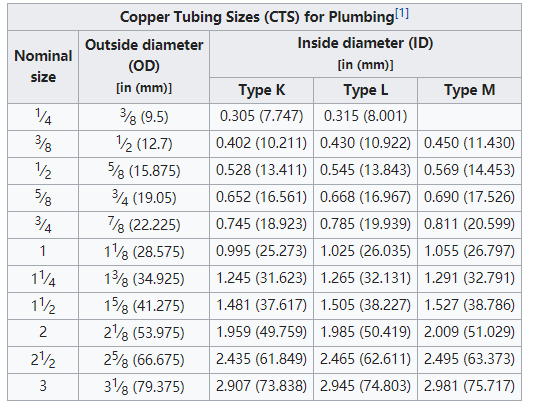

The key measurement to understand is the outside diameter (OD) of the tube, typically expressed in millimeters. This dimension is critical for selecting the correct fittings and ensuring a secure, leak-proof connection. Wall thickness also plays a significant role, influencing the tube's pressure rating and overall strength.

Common Copper Tube Sizes in Millimeters

Several standard copper tube sizes are widely used in various applications. These sizes are carefully selected to balance flow rate, pressure resistance, and cost-effectiveness. Here are some of the most common examples:

- 6 mm: Often used for small refrigerant lines or instrumentation.

- 8 mm: Similar applications to 6 mm, sometimes found in air conditioning systems.

- 10 mm: Commonly used for potable water supply lines in residential plumbing.

- 12 mm: Another standard size for water supply, often used for branch lines.

- 15 mm: A very common size for domestic water plumbing, particularly in Europe and other regions that have adopted the metric system.

- 18 mm: Used for larger water supply lines or specialized applications.

- 22 mm: Frequently used for central heating systems and larger plumbing installations.

- 28 mm: Often used for main water supply lines or in commercial plumbing systems.

- 35 mm: Common for larger commercial plumbing and heating applications.

- 42 mm: Used for larger systems, such as those found in apartment buildings or industrial facilities.

It's important to note that these are just a few examples, and the specific sizes used will vary depending on the application and regional standards. Consulting local building codes and regulations is crucial to ensure compliance and safety.

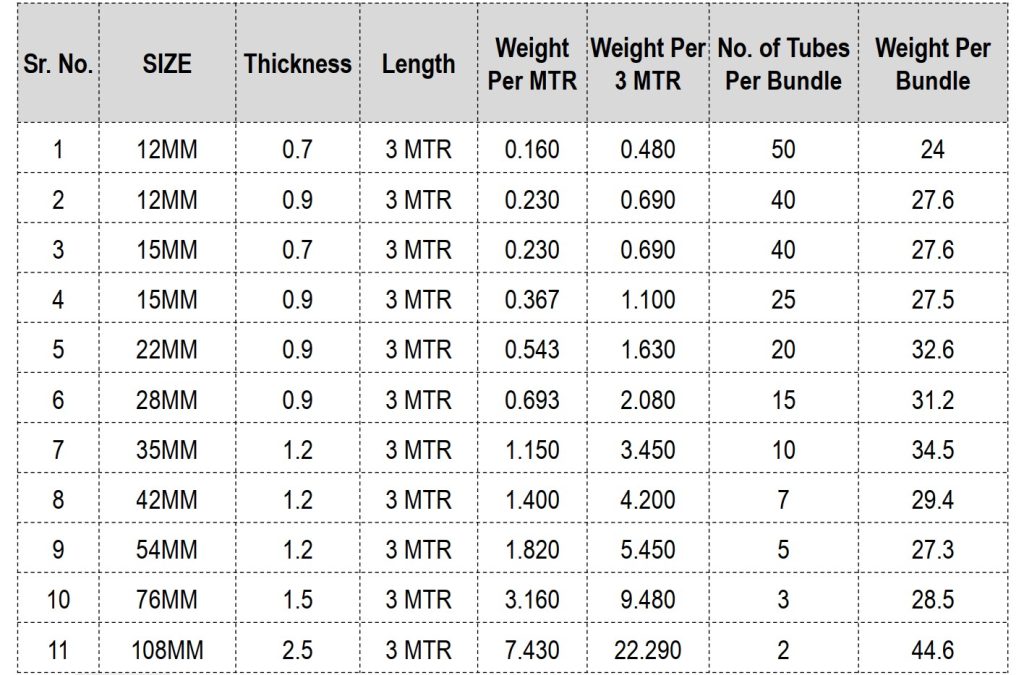

Equivalents between Metric and Imperial

While millimeters are the standard in many regions, some areas still rely on inches for specifying copper tube sizes. Understanding the approximate conversions between these units is essential for working on projects that involve both systems.

For example, a 1/2 inch copper tube has an approximate OD of 12.7 mm. A 3/4 inch tube is roughly equivalent to 19.05 mm. While these conversions provide a general idea, it's crucial to use precise measurements when selecting fittings to avoid leaks or compatibility issues.

Types of Copper Tubing

Beyond the size, the type of copper tubing also matters. Different types are designed for specific applications, with varying wall thicknesses and pressure ratings. The most common types include:

- Type K: The thickest and strongest type, suitable for underground water mains and high-pressure applications.

- Type L: A medium-thickness type, commonly used for interior plumbing and water distribution.

- Type M: The thinnest and most cost-effective type, generally used for drain, waste, and vent (DWV) systems.

Each type is clearly marked with color-coded lettering (usually green for K, blue for L, and red for M) for easy identification. Always choose the appropriate type of tubing based on the specific requirements of the project.

The Importance of Standardization

The standardization of copper tube sizes, whether in millimeters or inches, offers numerous benefits to the plumbing and construction industries. These standards ensure:

- Interoperability: Fittings and tubing from different manufacturers are compatible, simplifying installation and reducing the risk of leaks.

- Efficiency: Consistent dimensions allow for automated manufacturing processes, lowering production costs and improving quality control.

- Safety: Standardized pressure ratings and material specifications ensure that systems are designed to withstand the intended operating conditions.

- Ease of Maintenance: Repair and replacement are simplified when standard sizes are used, making it easier to find compatible components.

These benefits contribute to a more efficient, reliable, and safer plumbing and HVAC infrastructure. Without standardization, the industry would be plagued by compatibility issues and increased risks.

Challenges and Future Trends

While the standardization of copper tube sizes has brought numerous advantages, challenges still exist. Variations in manufacturing tolerances and regional differences in standards can sometimes lead to compatibility issues. Continuous efforts are underway to refine these standards and promote greater uniformity across the industry.

Furthermore, alternative materials, such as PEX (cross-linked polyethylene), are gaining popularity in certain applications. However, copper remains a widely used and trusted material, particularly for high-pressure and high-temperature systems.

"The future of copper tubing likely involves a combination of continued standardization, improved manufacturing techniques, and integration with smart building technologies," says John Smith, a leading plumbing engineer.

Conclusion

The seemingly simple act of specifying a copper tube size in millimeters represents a complex web of engineering, manufacturing, and standardization. These numbers are not just arbitrary measurements; they are the foundation upon which safe, efficient, and reliable plumbing and HVAC systems are built.

Understanding the significance of these standards is crucial for anyone involved in the construction industry. By adhering to these established guidelines, professionals can ensure that their projects are completed to the highest standards of quality and safety, contributing to a more sustainable and efficient built environment. The next time you see a copper tube, remember the silent language of millimeters that ensures its seamless integration into the systems that keep our buildings running smoothly.

.jpg)