Teck Mining Builds Biologic Treatment For Selenium

The Elk Valley, a region nestled in the southeastern corner of British Columbia, Canada, is renowned for its rich coal deposits. This abundance, however, comes with a significant environmental challenge: selenium contamination. For decades, mining activities, particularly those of Teck Resources, have released selenium into local waterways, impacting aquatic ecosystems and raising concerns about long-term ecological health. Now, a new initiative promises a potential turning point in the battle against this persistent pollutant.

At the heart of this development is a pioneering biological treatment facility constructed by Teck. This facility, leveraging naturally occurring microbial processes, aims to remove selenium from mine-affected water, offering a sustainable and environmentally conscious solution to a decades-old problem. The success of this project could not only transform water management practices in the Elk Valley but also set a new standard for mining operations globally. It could demonstrate how industries can proactively mitigate their environmental footprint.

The Selenium Challenge: A Lingering Legacy

Selenium, a naturally occurring element, is essential in trace amounts for human and animal health. However, elevated concentrations can be toxic, especially to aquatic life. In the Elk Valley, selenium leaches from coal mine waste rock into waterways, affecting fish populations and disrupting delicate ecosystem balances.

The primary concern revolves around the bioaccumulation of selenium in fish. Elevated selenium levels can lead to reproductive impairment and deformities, threatening the long-term viability of fish populations. These effects have triggered regulatory scrutiny and sparked concern from environmental groups and local communities. Addressing this issue is crucial for preserving the ecological integrity of the Elk Valley’s watersheds.

Teck's Biologic Treatment Solution: Harnessing Nature's Power

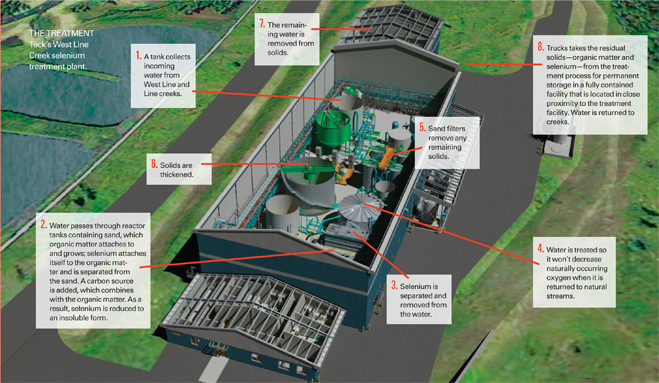

Teck's new treatment facility employs a biological process called bioremediation. This process utilizes microorganisms to transform selenium into less harmful forms. Specialized bacteria convert selenium into elemental selenium, a less bioavailable and less toxic form, which can then be safely removed from the water.

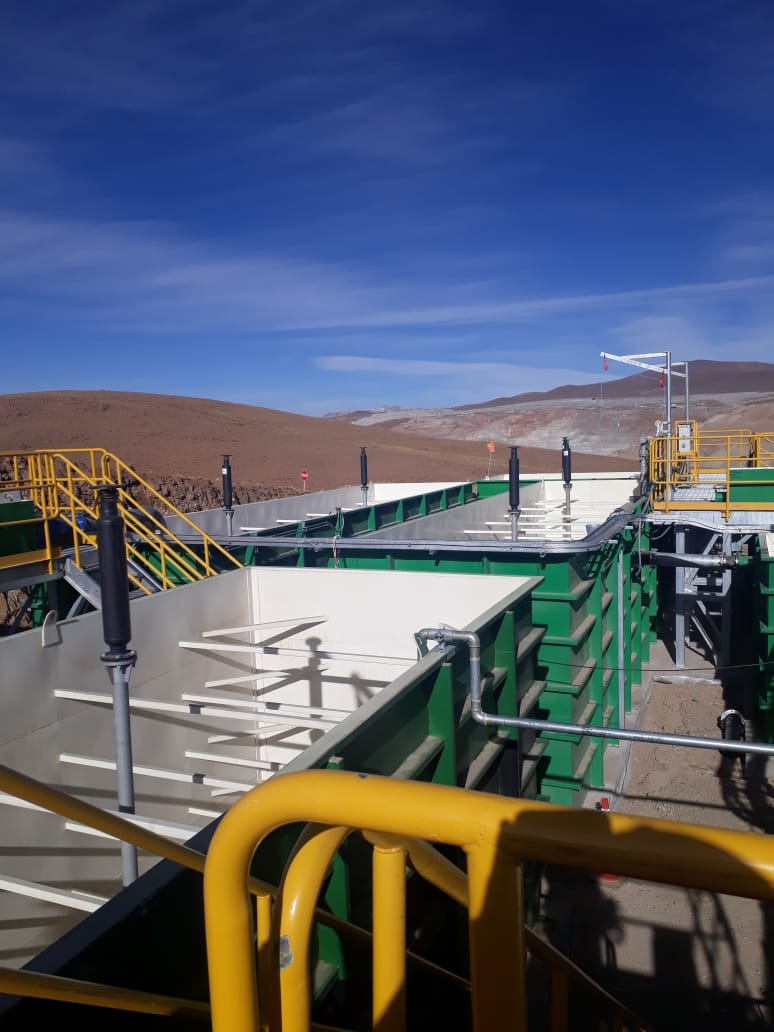

The facility is designed to treat a substantial volume of water, significantly reducing selenium concentrations before it enters the receiving environment. This approach represents a shift from traditional chemical treatment methods, which can be energy-intensive and generate their own waste streams. The new facility promises a more sustainable and environmentally friendly alternative.

How the Facility Works

The treatment process begins with the collection of mine-affected water. This water is then channeled into a series of bioreactors, where the specialized bacteria thrive. These bacteria, carefully cultivated and maintained, consume the selenium and convert it into elemental selenium.

The elemental selenium is then separated from the water through a settling process. Cleaned water is discharged back into the environment, meeting stringent water quality standards. The captured elemental selenium is managed and disposed of responsibly, preventing it from re-entering the ecosystem.

Environmental Benefits and Monitoring

The primary environmental benefit of this biologic treatment is the reduction of selenium concentrations in the Elk Valley's waterways. This, in turn, is expected to improve the health and reproductive success of fish populations. It also aims to restore the overall ecological integrity of the affected areas.

Teck has committed to rigorous monitoring programs to assess the effectiveness of the treatment facility. These programs involve regular water quality testing, fish population surveys, and ecosystem health assessments. This ongoing monitoring is essential for ensuring the facility meets its objectives and that any unforeseen impacts are promptly addressed.

Stakeholder Perspectives and Community Engagement

The selenium issue in the Elk Valley has drawn attention from various stakeholders, including environmental groups, government agencies, and local communities. Teck has engaged in extensive consultations with these groups to address their concerns and incorporate their feedback into its water management plans.

Environmental organizations, while cautiously optimistic about the new treatment facility, emphasize the need for long-term monitoring and adaptive management. They advocate for a comprehensive approach that includes source control measures to minimize selenium release at the mine site. Local communities, dependent on the health of the Elk Valley's ecosystem, seek reassurance that the treatment facility will effectively protect water quality and fish populations.

Challenges and Future Directions

While the biologic treatment facility represents a significant step forward, challenges remain. One key challenge is the long-term operational performance of the facility and its ability to consistently meet water quality standards. Another is the management of the captured elemental selenium, ensuring its safe and permanent disposal.

Teck is also exploring innovative technologies to further enhance selenium removal and reduce its environmental footprint. These include advanced filtration systems and novel bioreactor designs. Continuous research and development are crucial for optimizing treatment processes and adapting to changing environmental conditions.

A Path Towards Sustainable Mining

Teck's investment in biologic treatment technology underscores a growing recognition within the mining industry of the importance of sustainable practices. By proactively addressing environmental challenges, mining companies can minimize their impacts and contribute to the long-term health of the communities and ecosystems in which they operate.

The success of the Elk Valley project could serve as a model for other mining operations facing similar selenium contamination issues. It demonstrates that innovative technologies and collaborative partnerships can lead to effective solutions. It also confirms that mining can be conducted in a responsible manner that protects the environment and supports sustainable development.