The Quality Control Manager Of A Large Factory

The hum of machinery and the constant whir of conveyor belts are the daily soundtrack for Maria Rodriguez, Quality Control Manager at the sprawling GlobalTech Manufacturing plant on the outskirts of Anytown, USA. Her role is a critical, often unseen, cog in the machine that produces thousands of electronic components each day, destined for devices around the world.

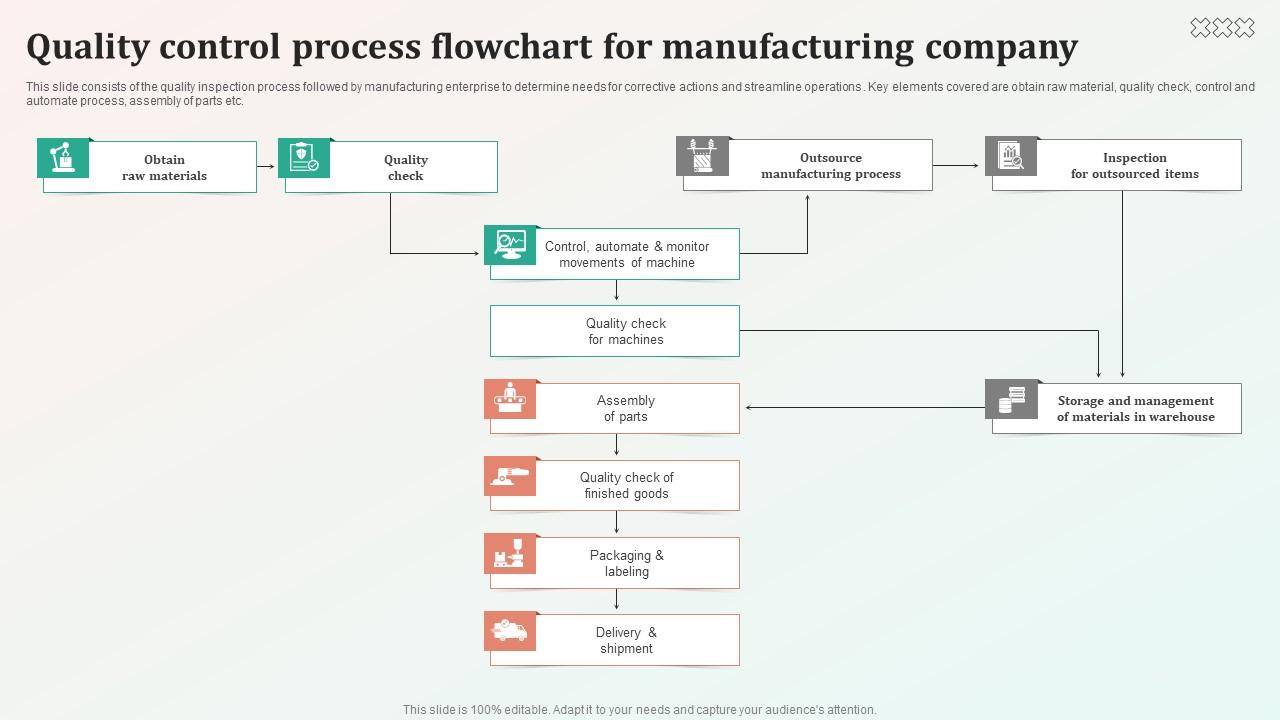

Rodriguez's responsibilities extend far beyond simply spotting defective parts. She oversees a team of inspectors, analyzes data, implements preventative measures, and ensures that every product leaving the GlobalTech factory meets stringent international standards. The quality control process she manages directly impacts product safety, customer satisfaction, and the company's bottom line.

The Gatekeeper of Quality: Maria Rodriguez's Day-to-Day

Rodriguez's day begins before the first shift even clocks in. She reviews overnight reports, analyzing production statistics to identify any emerging trends or potential issues. "Early detection is key," Rodriguez explains, "Addressing a small problem at the source is much more efficient than dealing with a massive recall later on."

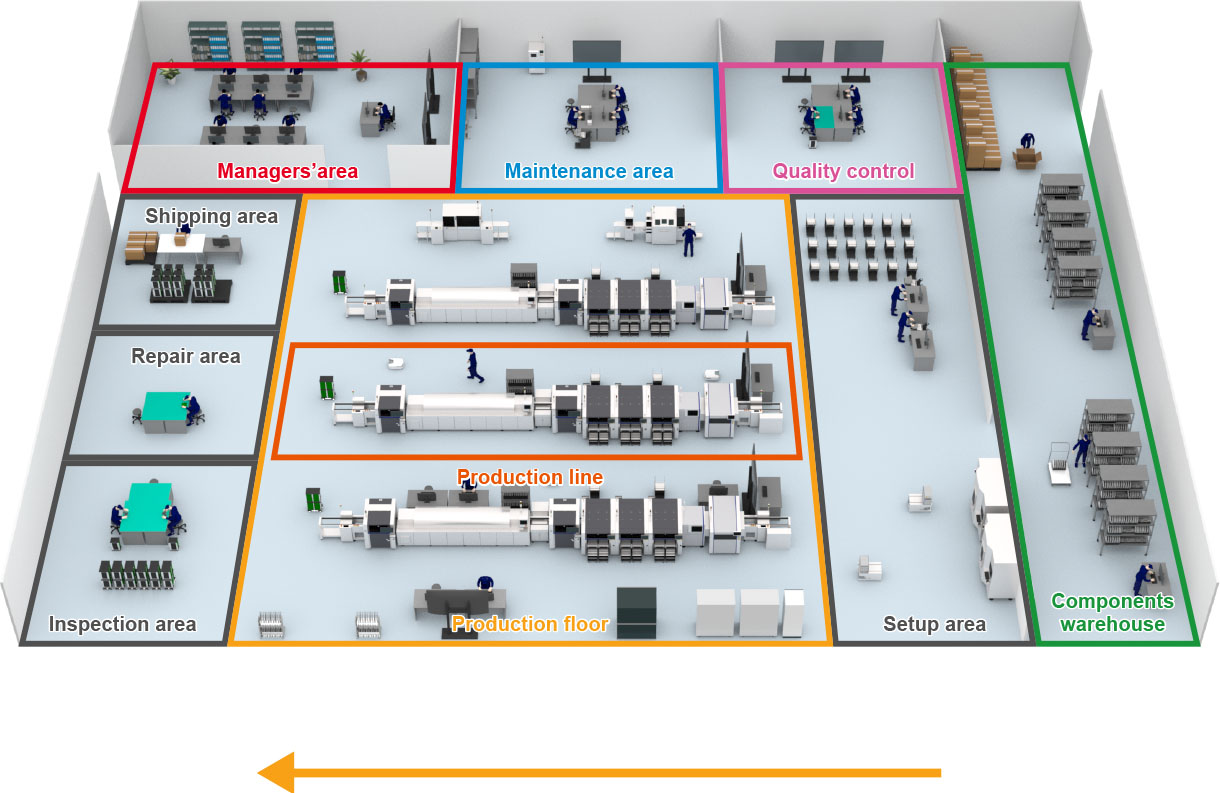

The core of her day is spent on the factory floor, working directly with her team. They perform a series of rigorous tests, using calibrated instruments and visual inspections to catch any deviations from the set specifications. Samples are pulled from various production lines, and subjected to stress tests, endurance tests, and functional evaluations.

Data analysis plays a crucial role. Sophisticated software tracks every stage of the production process, generating real-time reports on defect rates, potential bottlenecks, and overall efficiency. Rodriguez uses this data to pinpoint areas where improvements can be made, proactively addressing potential problems before they escalate. This data-driven approach allows the team to operate efficiently and meet global standards.

A Focus on Prevention

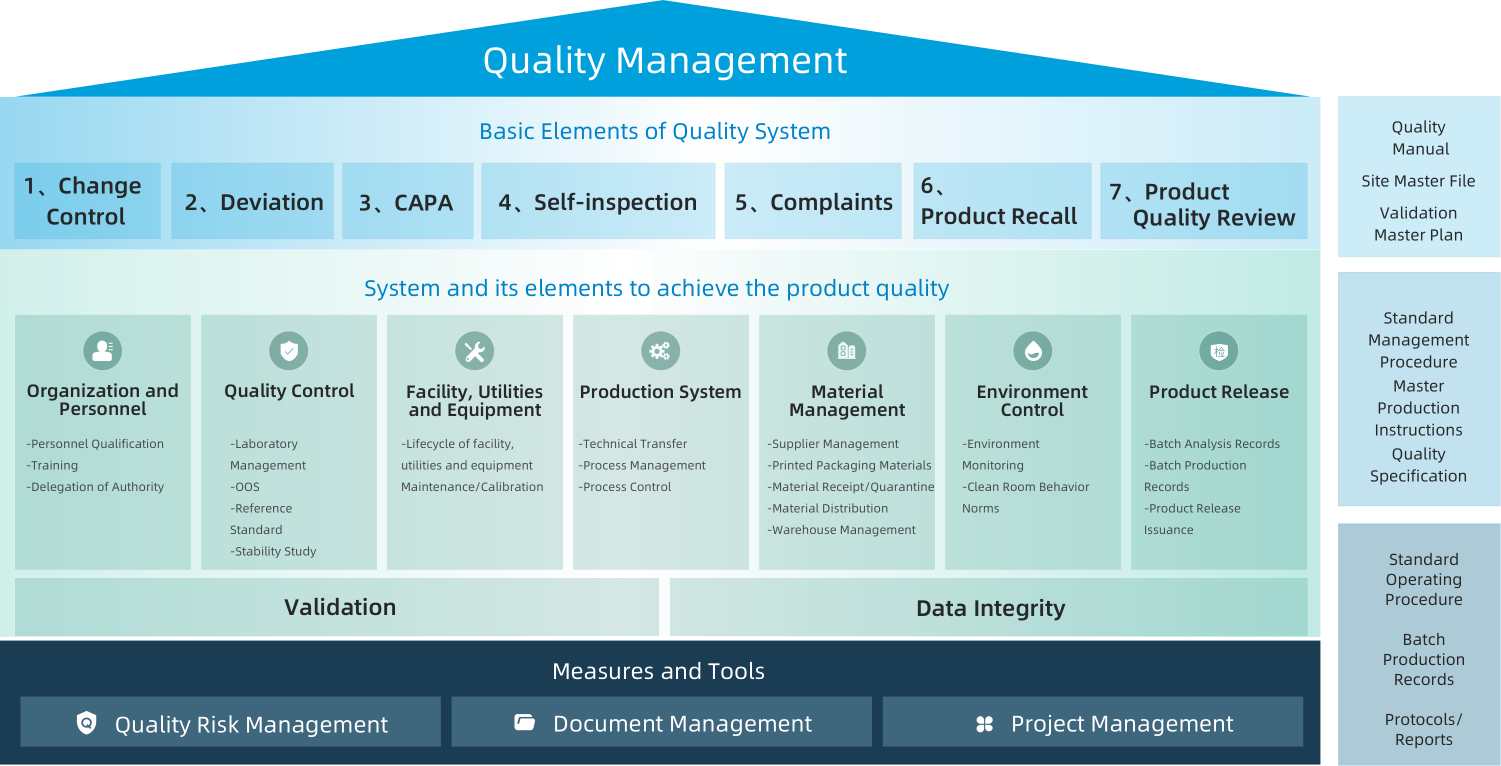

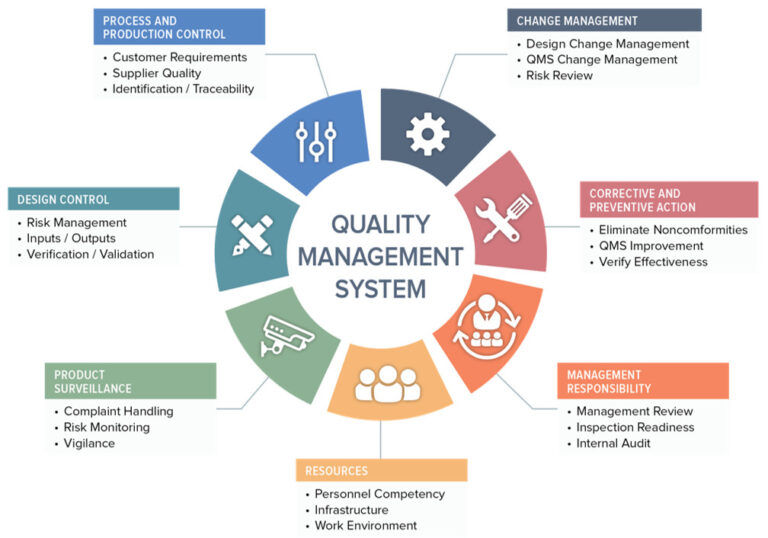

Rodriguez emphasizes that quality control is not just about catching mistakes, but about preventing them from happening in the first place. A significant portion of her job involves working with engineering and production teams to refine manufacturing processes and implement preventative measures.

“We use a variety of strategies," states Rodriguez, "from implementing statistical process control to training employees on best practices. The goal is to build quality into every stage of production, not just inspect it at the end." This proactive approach is not only designed to improve product quality but also to reduce waste, lower production costs, and increase overall efficiency.

GlobalTech has implemented several new employee training programs as a result of quality control analysis, including advanced soldering techniques and precision assembly. These programs are directly credited with a 15% reduction in component defects, according to internal company reports.

The Importance of Global Standards

GlobalTech, like many manufacturers, adheres to international quality standards such as ISO 9001. Maintaining compliance requires meticulous record-keeping, regular audits, and a commitment to continuous improvement. Rodriguez is responsible for ensuring that the plant meets all necessary requirements.

Meeting these standards is crucial for maintaining GlobalTech’s reputation and ensuring that its products can be sold in markets around the world. Failure to comply can result in hefty fines, loss of certifications, and damage to the company’s brand.

Rodriguez regularly participates in industry conferences and seminars, staying up-to-date on the latest developments in quality control methodologies and regulatory requirements. She also works closely with external auditors, providing them with the information and access they need to assess the plant's compliance.

Challenges and Future Trends

The manufacturing industry is constantly evolving, with new technologies and materials emerging all the time. This presents a significant challenge for quality control managers like Rodriguez, who must stay ahead of the curve and adapt their processes accordingly.

One of the biggest trends is the increasing use of automation and artificial intelligence in manufacturing. While these technologies offer many benefits, they also require careful monitoring and oversight to ensure that they are performing as expected. "We're always looking for ways to incorporate new technologies into our quality control processes," Rodriguez says, "but we need to do it in a way that enhances, rather than replaces, human expertise."

Another challenge is the growing complexity of supply chains. With companies sourcing components from all over the world, it can be difficult to ensure that all suppliers are meeting the same quality standards. To combat this, GlobalTech has implemented a rigorous supplier vetting process, including on-site audits and regular performance reviews.

The Human Element

While data and technology play a crucial role in quality control, Rodriguez emphasizes the importance of the human element. "Ultimately, it's the people on the factory floor who are responsible for making sure that our products meet our standards," she says.

She believes that effective communication, teamwork, and a commitment to quality are essential for creating a culture of excellence. She encourages her team to speak up if they see something that doesn't look right, and she empowers them to take ownership of their work. Her approach to management is one of support and guidance to empower the team.

Rodriguez's dedication to quality has not gone unnoticed. She has received numerous awards and accolades throughout her career, and she is widely respected within the industry. More importantly, she takes pride in knowing that her work is helping to ensure that consumers are getting safe, reliable products.

The success of GlobalTech Manufacturing, in many ways, hinges on the quiet, persistent efforts of Maria Rodriguez and her team. They are the unsung heroes of the production line, ensuring that quality remains at the forefront. They are the guardians of customer satisfaction and the backbone of a thriving manufacturing operation.

.jpg)