The System Of Mass Production In Manufacturing Developed Rapidly

The landscape of manufacturing has undergone a dramatic transformation in recent years, with the system of mass production experiencing an unprecedented period of accelerated development. This rapid evolution is reshaping industries globally, impacting everything from consumer goods to complex industrial components.

This article examines the factors driving this accelerated development, explores the key innovations fueling the changes, and analyzes the potential impacts on businesses, workers, and consumers alike. Understanding this evolution is crucial for navigating the complexities of the modern economy.

The Rise of Automation and Robotics

One of the primary drivers of the rapid development in mass production is the increasing integration of automation and robotics.

Advanced robotics systems, capable of performing complex tasks with speed and precision, are becoming increasingly prevalent on assembly lines. This transition reduces reliance on manual labor and dramatically increases output.

According to a recent report by the International Federation of Robotics (IFR), the number of industrial robots operating worldwide reached a record high in 2023, signaling a widespread adoption of these technologies.

The Role of Data and Analytics

Data and analytics are playing an equally significant role in optimizing mass production processes.

Manufacturers are now collecting vast amounts of data from various stages of the production line, using sensors and IoT devices to monitor performance and identify potential bottlenecks.

This data is then analyzed using sophisticated algorithms to optimize processes, predict equipment failures, and improve product quality. This data-driven approach leads to increased efficiency and reduced waste.

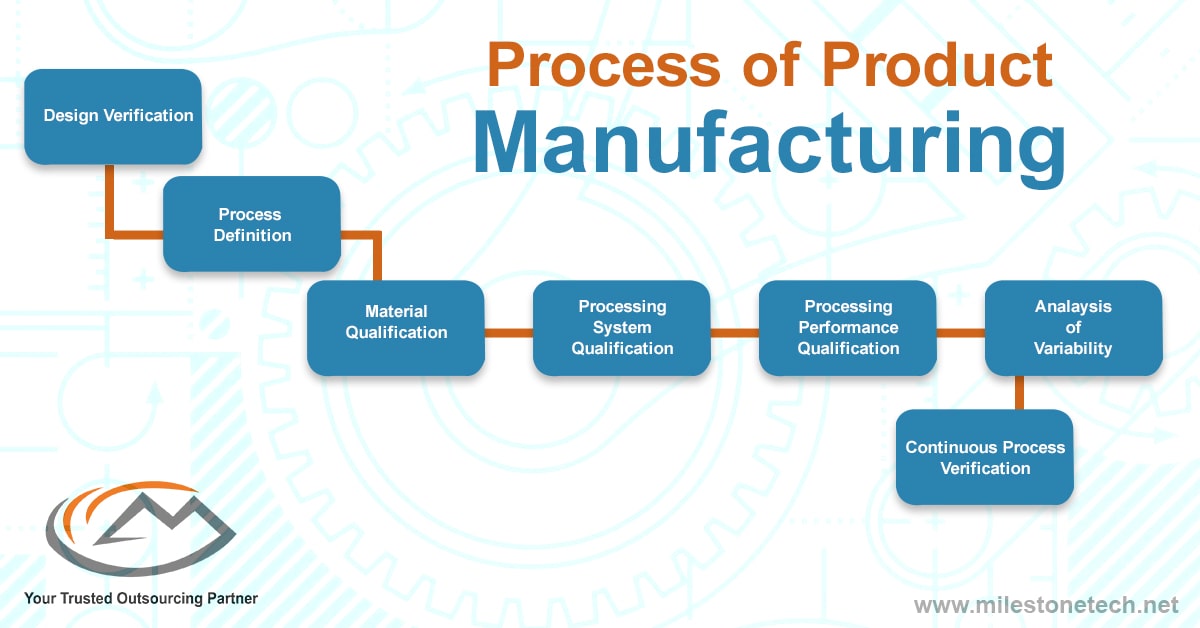

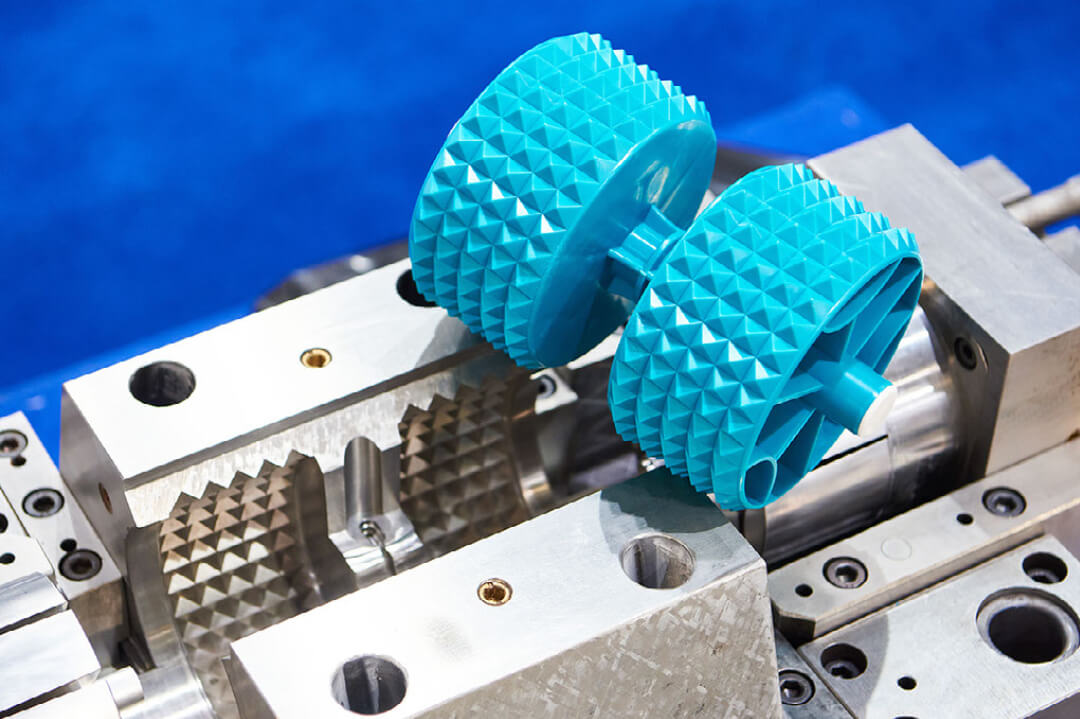

Additive Manufacturing (3D Printing)

Additive manufacturing, commonly known as 3D printing, represents a significant paradigm shift in mass production.

While traditionally used for prototyping and small-scale production, 3D printing is increasingly being used for mass producing customized products. This offers unprecedented flexibility and allows manufacturers to cater to individual customer needs.

The ability to create complex geometries and use a wide range of materials makes 3D printing a powerful tool for innovation.

The Impact on Labor Markets

The rapid development of mass production has significant implications for labor markets.

While automation and robotics can lead to job displacement in some sectors, they also create new opportunities in areas such as robotics maintenance, data analysis, and software development. The key is adapting to these changes through education and re-training programs.

The World Economic Forum estimates that automation will create more jobs than it displaces in the long run, but the transition will require careful management and investment in human capital.

Supply Chain Resilience

The recent global disruptions have highlighted the importance of supply chain resilience.

Manufacturers are investing in technologies and strategies to diversify their supply chains, improve inventory management, and enhance their ability to respond to unexpected events. This includes leveraging digital platforms for better visibility and collaboration across the entire supply chain.

"Building resilient supply chains is no longer just a competitive advantage, it's a necessity," stated John Smith, CEO of Global Manufacturing Solutions, at a recent industry conference.

Sustainability and Green Manufacturing

Sustainability is becoming an increasingly important consideration in mass production.

Consumers are demanding more environmentally friendly products and production processes. Manufacturers are responding by adopting sustainable practices, such as reducing energy consumption, minimizing waste, and using recycled materials. They are also exploring new manufacturing processes that are less harmful to the environment.

Government regulations and incentives are also playing a role in driving the adoption of green manufacturing practices.

The Future of Mass Production

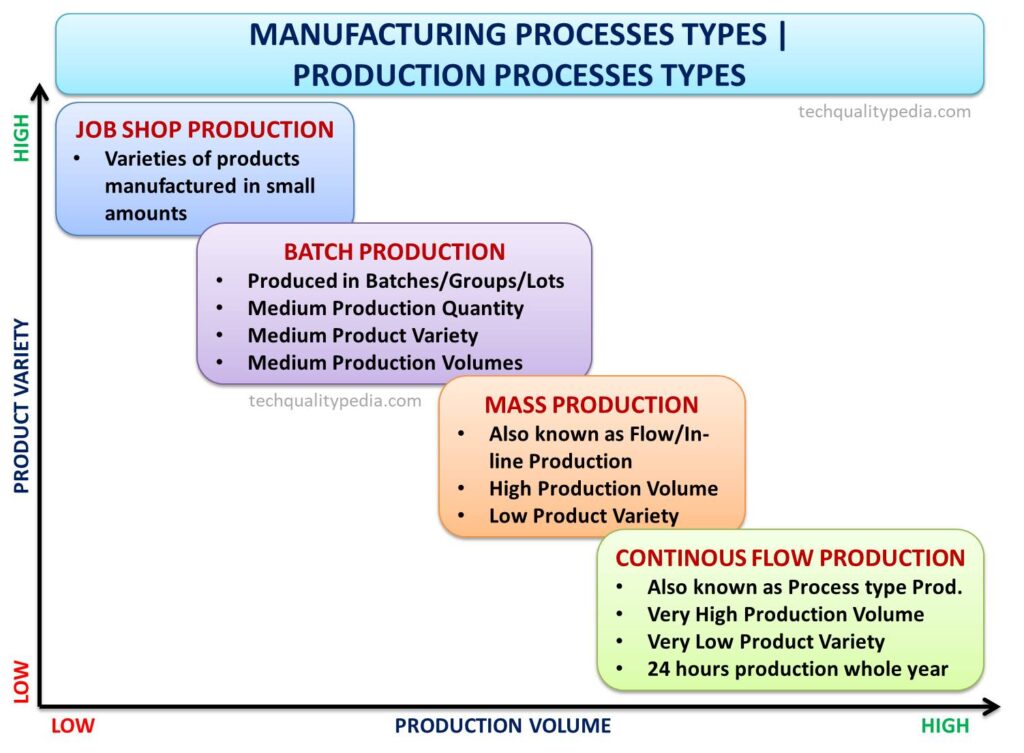

The system of mass production is expected to continue its rapid development in the coming years.

We can expect to see even greater integration of artificial intelligence, machine learning, and advanced materials. This will lead to more efficient, flexible, and sustainable manufacturing processes. The successful manufacturers will be those who can adapt to these changes and embrace new technologies.

The rise of personalized manufacturing and on-demand production is also likely to transform the way goods are made and distributed. This will require a shift from mass production to mass customization, where products are tailored to individual customer needs.

The ongoing transformation of mass production presents both challenges and opportunities. Businesses that embrace innovation, invest in their workforce, and prioritize sustainability will be best positioned to succeed in the future.