Types Of Decompounding In The Paper Industry

The paper industry faces intensifying pressure from environmental regulations and economic volatility, forcing a radical rethinking of traditional pulping and manufacturing processes. Decompounding, the process of breaking down complex paper structures back into their constituent components, is emerging as a critical area of innovation, with various methods showing promise but also presenting significant challenges.

This article examines the primary types of decompounding techniques currently being explored and implemented within the paper industry, highlighting their potential benefits and drawbacks in addressing sustainability and efficiency concerns.

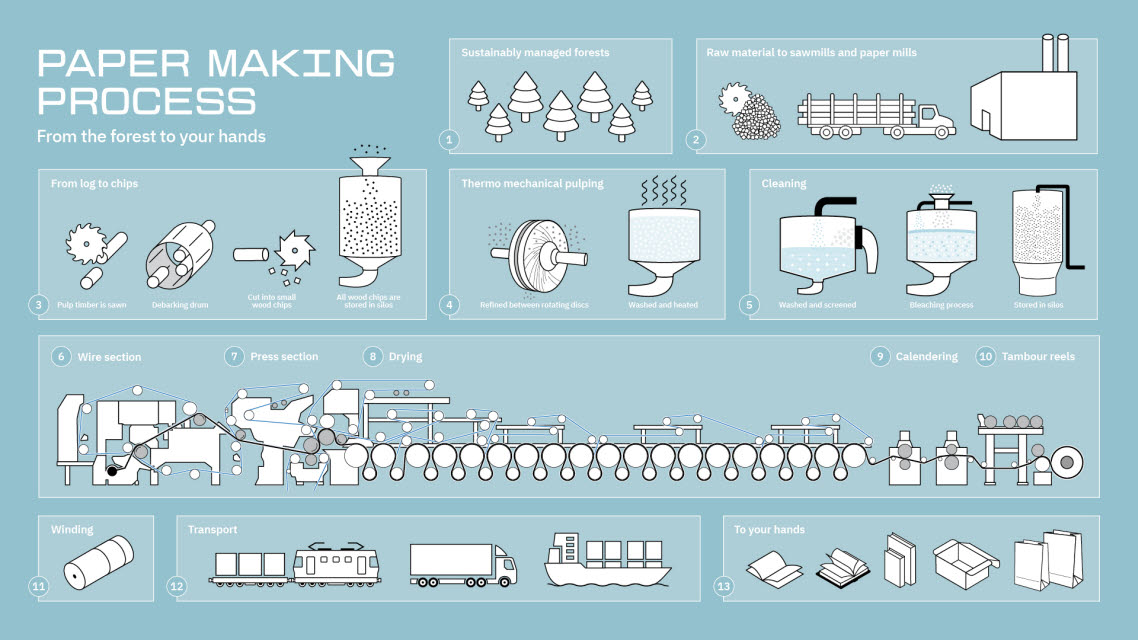

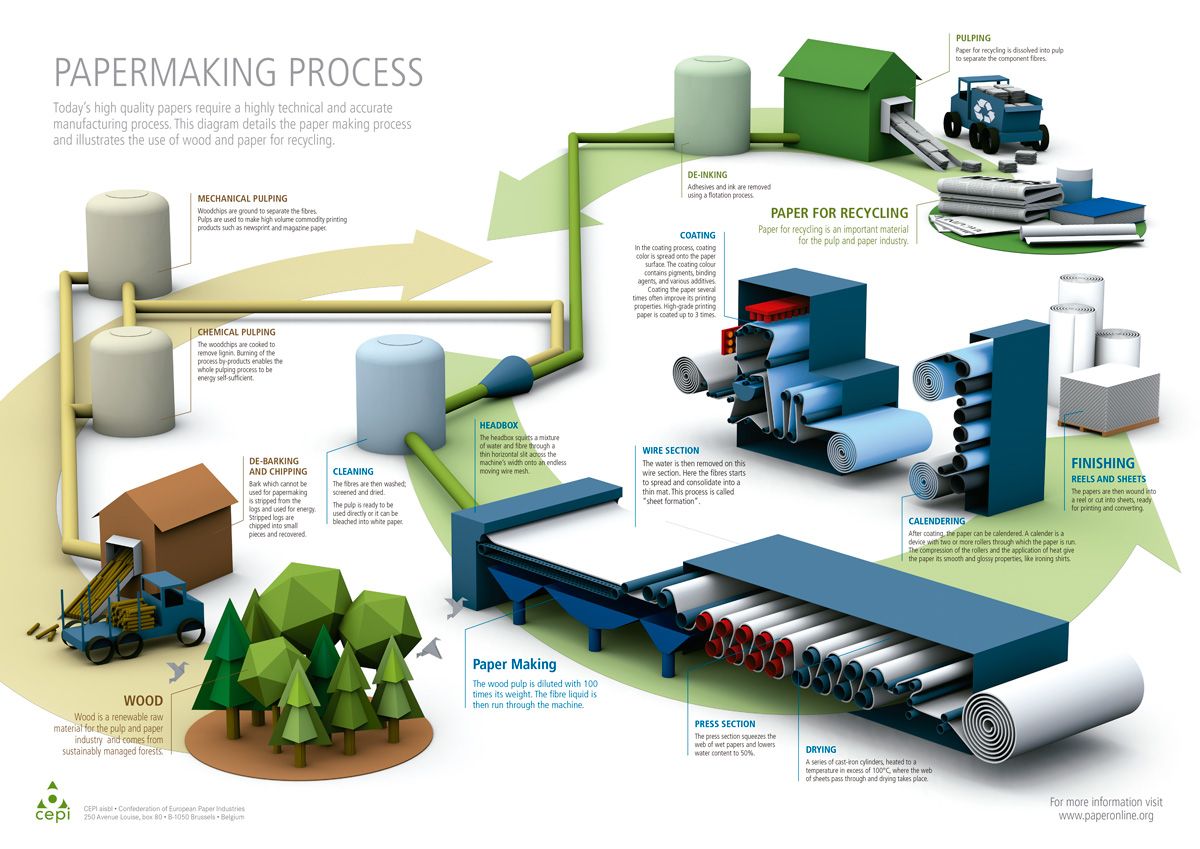

Mechanical Decompounding: The Forceful Approach

Mechanical decompounding relies on physical force to break down paper fibers. This usually involves shredding, grinding, or pulverizing paper into smaller particles, effectively separating the interwoven fibers.

While relatively simple and cost-effective compared to other methods, mechanical decompounding often results in significant fiber damage, reducing the quality of the recovered material for reuse in high-grade paper products.

Hydro-Mechanical Decompounding

A variation of mechanical decompounding, the hydro-mechanical approach utilizes water to aid the fiber separation process. This combines mechanical forces with the hydrating and swelling effects of water, leading to a more efficient separation with less fiber damage compared to dry mechanical methods.

However, hydro-mechanical decompounding generates significant wastewater that requires treatment before discharge, posing an additional environmental challenge.

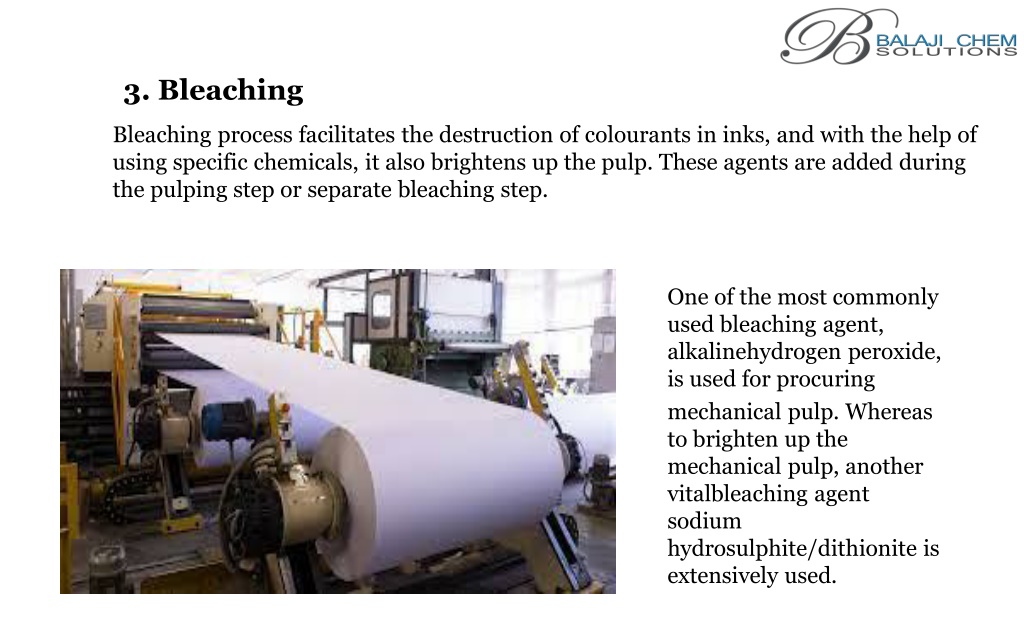

Chemical Decompounding: Breaking Bonds with Chemistry

Chemical decompounding involves using chemical agents to dissolve or break down the bonds holding paper fibers together. This approach offers the potential to recover high-quality fibers with minimal damage, but also poses significant environmental and economic hurdles.

The chemicals used can be corrosive, toxic, and require careful handling and disposal, making this a more complex and costly decompounding method.

Alkaline Decompounding

Alkaline decompounding uses alkaline solutions, such as sodium hydroxide, to dissolve lignin and other binding agents in the paper. This releases individual fibers and enables their recovery.

The process is effective for certain types of paper, but can generate significant amounts of alkaline wastewater and require careful pH control to prevent fiber degradation.

Enzymatic Decompounding

Enzymatic decompounding utilizes enzymes to selectively degrade specific components of paper, such as lignin and hemicellulose. This is considered a more environmentally friendly approach compared to traditional chemical methods.

Enzymes are highly specific, reducing the risk of damage to cellulose fibers. However, enzymatic processes can be slower and more expensive than chemical methods, and require precise control of temperature and pH for optimal performance.

Thermal Decompounding: Heat-Driven Separation

Thermal decompounding involves using heat to break down paper fibers. This can be achieved through various methods, including pyrolysis and gasification.

While thermal decompounding can effectively convert paper waste into energy or valuable chemical products, it also requires high energy inputs and can generate air pollutants if not properly controlled.

Pyrolysis

Pyrolysis involves heating paper waste in the absence of oxygen, causing it to decompose into gases, liquids (bio-oil), and solid residue (biochar). The resulting products can be used as fuel or as raw materials for chemical production.

Pyrolysis requires careful temperature control and gas management to maximize the yield of valuable products and minimize the formation of unwanted byproducts.

Biological Decompounding: Nature's Way

Biological decompounding uses microorganisms to break down the organic components of paper waste. This method is generally considered environmentally friendly, but can be slow and require careful monitoring.

Composting and anaerobic digestion are examples of biological decompounding methods used for paper waste treatment.

Anaerobic Digestion

Anaerobic digestion involves the breakdown of organic matter by microorganisms in the absence of oxygen. This process produces biogas, which can be used as a renewable energy source.

Anaerobic digestion can be used to treat paper sludge and other paper mill wastes, reducing their volume and generating energy.

The Future of Decompounding

The paper industry is actively researching and developing new and improved decompounding technologies. Hybrid approaches combining multiple methods are also gaining traction.

Ongoing research focuses on optimizing process parameters, reducing energy consumption, and minimizing environmental impacts to make decompounding more economically viable and sustainable.

Stakeholders are closely monitoring pilot projects and data from implemented processes to determine the most effective solutions for different types of paper waste and regional contexts.