What Is One Drawback Of Outsourcing

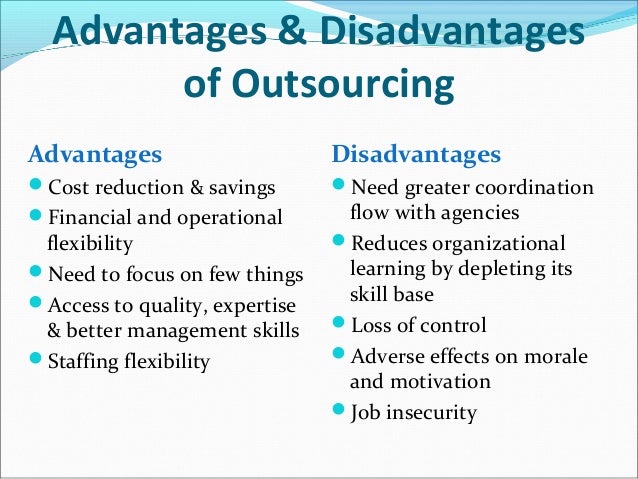

In an era defined by globalization and interconnected economies, outsourcing has become a ubiquitous strategy for businesses seeking to optimize costs and enhance efficiency. While the benefits of outsourcing, such as access to specialized skills and reduced labor expenses, are widely touted, a critical drawback often lurks beneath the surface: a potential decline in quality control.

This article delves into the complexities of quality control in outsourcing arrangements, exploring how distance, communication barriers, and differing operational standards can compromise product or service quality. We examine the implications of diminished quality, including damage to brand reputation, increased customer dissatisfaction, and potential financial losses. Further, we consider strategies businesses can employ to mitigate these risks and ensure outsourcing partnerships yield the desired outcomes without sacrificing quality.

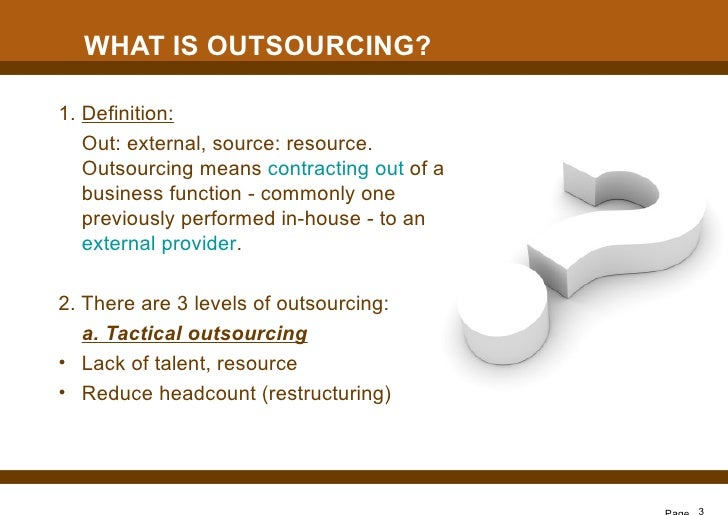

The Erosion of Direct Oversight

One of the most significant challenges in maintaining quality control when outsourcing is the physical separation between the company and the outsourced provider. This distance hinders direct oversight and immediate intervention when issues arise, leading to delayed responses and potentially compounding errors.

Consider a software development company outsourcing its testing phase to a team in another country. Without real-time communication and close collaboration, bugs might go undetected for longer, resulting in a substandard product launch and negative user reviews. This lack of direct control can prove detrimental.

Communication Barriers and Cultural Differences

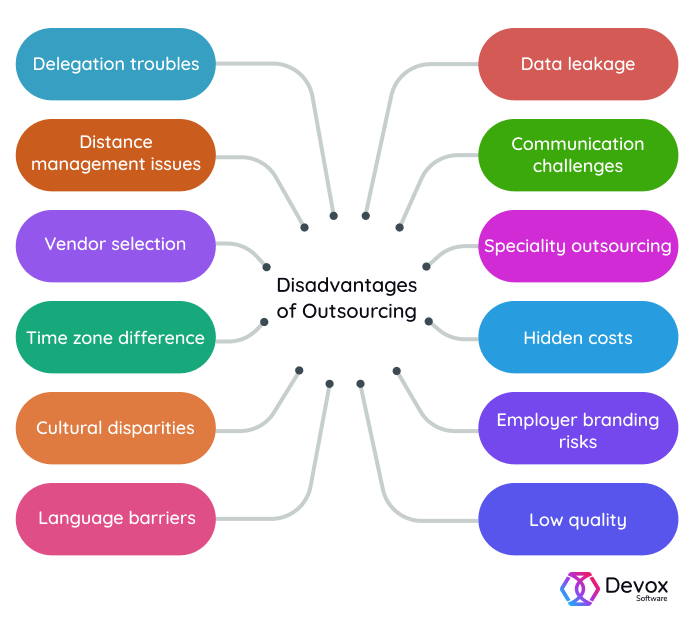

Effective communication is crucial for maintaining quality standards, but outsourcing often introduces communication barriers. These barriers may stem from language differences, varying time zones, and dissimilar cultural norms. These challenges can lead to misunderstandings, misinterpretations of requirements, and ultimately, compromised quality.

For example, a manufacturing company outsourcing production to a facility overseas might struggle to convey precise specifications due to language barriers. This can result in products that do not meet the required standards, leading to costly rework or even product recalls. Clear and consistent communication protocols are therefore essential.

Divergent Operational Standards and Ethical Considerations

Companies that outsource often face the challenge of ensuring their partners adhere to the same operational standards and ethical guidelines. A discrepancy in these areas can directly impact the quality of goods and services produced. Different labor practices, environmental regulations, and quality control processes can contribute to lower quality outcomes.

According to a report by the International Labour Organization (ILO), variations in labor standards can lead to compromised worker safety and product quality. Businesses outsourcing manufacturing should ensure their partners maintain acceptable working conditions and adhere to rigorous quality control processes. This helps to reduce ethical risks.

Impact on Brand Reputation and Customer Satisfaction

Reduced quality due to outsourcing can have a significant impact on a company's brand reputation and customer satisfaction. When customers receive substandard products or services, their trust in the brand erodes. Negative reviews and word-of-mouth can quickly damage a brand's image and lead to a loss of customers.

A study by PwC found that 71% of consumers lose trust in a brand after a single negative experience. Therefore, maintaining quality is crucial for safeguarding a company’s reputation and ensuring customer loyalty. The long-term costs of poor quality can far outweigh any short-term cost savings from outsourcing.

Mitigating the Risks

Despite the potential drawbacks, outsourcing remains a valuable strategy for many businesses. By implementing robust quality control measures, companies can mitigate the risks associated with outsourcing and ensure that quality remains a priority.

One key strategy is to establish clear and measurable quality standards in outsourcing contracts. Regular audits, performance monitoring, and open communication channels are also essential for maintaining quality. Building strong, collaborative relationships with outsourcing partners can also help to ensure alignment on quality goals. Additionally, consider investing in training programs for both the company and the outsourcing partner's employees.

Looking Ahead

As outsourcing continues to evolve, businesses must prioritize quality control to reap the benefits of this strategy. Embracing new technologies, such as AI-powered quality monitoring systems, can further enhance quality assurance in outsourcing arrangements. Businesses should also consider a more strategic approach to outsourcing, carefully selecting partners who share their commitment to quality and ethical practices.

The future of outsourcing hinges on the ability of companies to balance cost savings with quality control. By proactively addressing the potential drawbacks of outsourcing, businesses can ensure that these partnerships contribute to their long-term success and sustainability. The key is to prioritize quality.

:max_bytes(150000):strip_icc()/what-is-outsourcing-2533662-FINAL-5bad44ae46e0fb00261e05c6.png)

![What Is One Drawback Of Outsourcing IT Outsourcing: 8 Pros and Cons [2023]](https://global-uploads.webflow.com/622fa4d65a5fab0c3465af07/627938b52256a99d70dfe882_pros-cons-it-outsourcing-lists.png)