What Is The Fulcrum Of A Forklift

Imagine the bustling warehouse floor: the rhythmic hum of machinery, the scent of cardboard and oil, and the ballet of forklifts gracefully navigating pallets stacked high. A forklift, a marvel of engineering, effortlessly lifts and moves tons of material. But what’s the secret to its strength, that invisible pivot point that allows it to defy gravity and make light work of heavy loads?

At the heart of every forklift's lifting capability lies a simple yet powerful principle: the lever. The fulcrum, the pivot point of that lever, is the key to understanding how these machines operate. It's the silent partner, the unseen hero responsible for multiplying the force applied by the forklift's engine and hydraulics. Understanding the fulcrum is understanding the very essence of forklift physics.

The Lever Principle: A Foundation of Physics

The concept of the lever, and with it the fulcrum, dates back to ancient times. Archimedes, the famed Greek mathematician and inventor, famously said, "Give me a lever long enough and a fulcrum on which to place it, and I shall move the world." This simple statement encapsulates the immense power of leverage.

A lever is essentially a rigid bar that pivots around a fixed point – the fulcrum. When force is applied to one end of the lever (the effort), it is multiplied to lift or move a load placed on the other end. The closer the fulcrum is to the load, the less effort is required to lift it.

Locating the Fulcrum on a Forklift

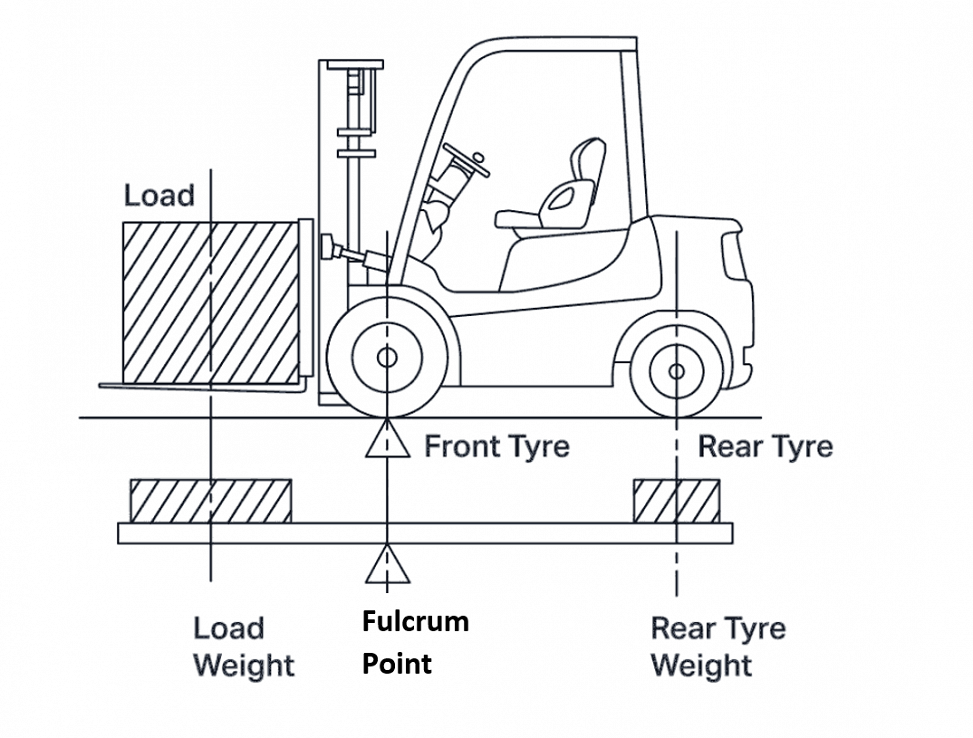

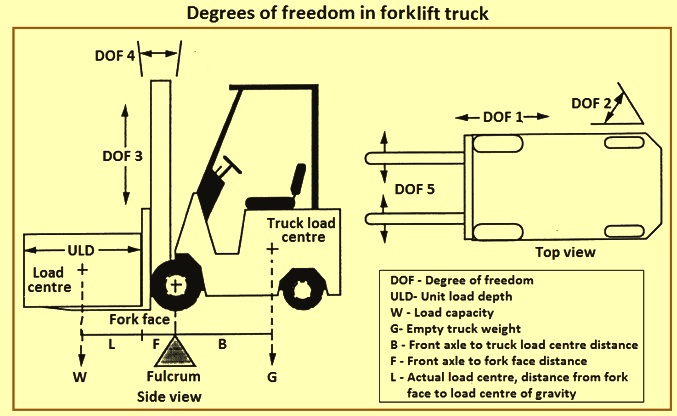

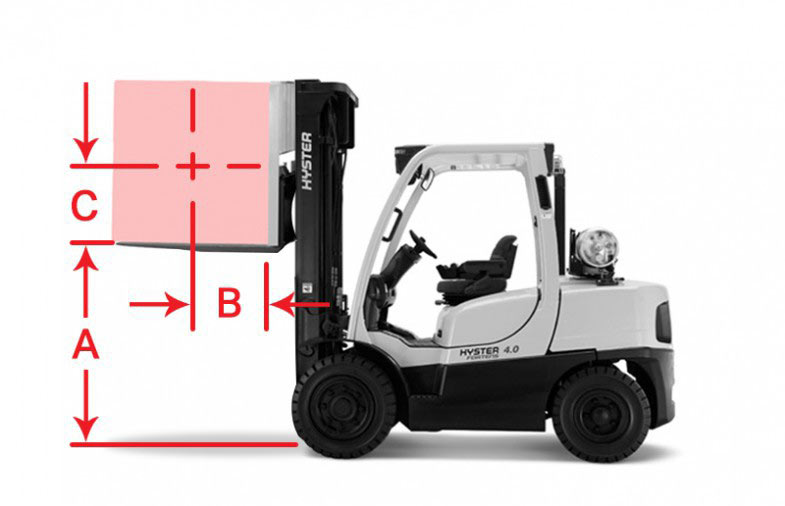

On a forklift, the fulcrum isn't a single, easily identifiable point. Instead, it's an axis of rotation, primarily located along the front axle of the vehicle. The front tires act as the main support, allowing the forklift to tilt and lift loads effectively.

This design is crucial for stability. By positioning the fulcrum (front axle) close to the load being lifted, the forklift minimizes the amount of counterweight needed at the rear to prevent tipping.

The Role of Counterweight

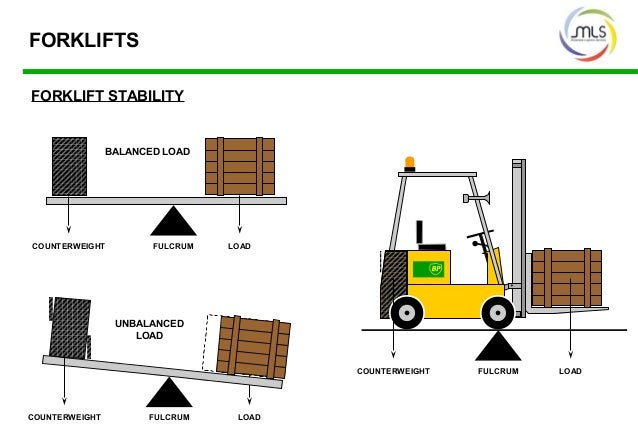

Forklifts rely on a substantial counterweight located at the rear of the vehicle to balance the load being lifted. This counterweight works in conjunction with the fulcrum to maintain stability.

Think of a seesaw. The front axle is the fulcrum, the load on the forks is one child, and the counterweight is the other. The heavier the load on the forks, the heavier the counterweight needs to be to keep the seesaw balanced.

Understanding Load Capacity and Stability

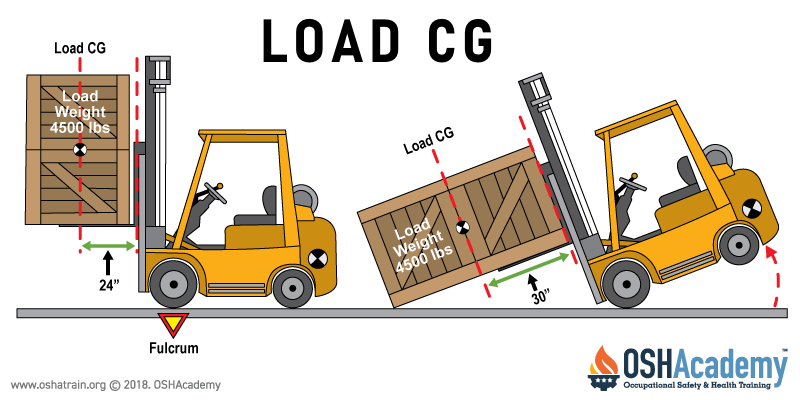

The placement of the fulcrum and the amount of counterweight directly impact a forklift's load capacity. Every forklift has a clearly marked load capacity, which specifies the maximum weight it can safely lift at a specific load center.

The load center refers to the distance from the front of the forks to the center of gravity of the load. A load placed further out on the forks creates more leverage, requiring more counterweight and potentially exceeding the forklift's capacity.

Exceeding the load capacity or misjudging the load center can lead to dangerous situations, including tipping. According to the Occupational Safety and Health Administration (OSHA), forklift accidents are a significant cause of workplace injuries.

"Forklift overturns are the leading cause of fatalities involving forklifts. They are often caused by improper load handling, traveling at excessive speeds, and turning on ramps." - OSHA

Types of Forklift Fulcrum Designs

While the basic principle of the fulcrum remains the same, different types of forklifts may have variations in their design. For example, reach trucks, designed for narrow aisles, often use a different type of fulcrum system.

Reach trucks have extending forks, allowing them to reach into racking systems without needing to turn the entire truck. This design requires a more complex fulcrum system to maintain stability during extension and retraction.

Similarly, rough terrain forklifts, used in outdoor environments, have a wider wheelbase and a higher center of gravity to provide better stability on uneven surfaces. Their fulcrum point is designed to accommodate these factors.

The Impact of Tire Condition

The condition of the forklift's tires also plays a crucial role in the effectiveness of the fulcrum. Worn or damaged tires can affect the stability of the forklift and alter the effective fulcrum point.

Proper tire inflation and maintenance are essential for ensuring that the forklift operates within its designed parameters. Uneven tire wear can lead to instability and increase the risk of accidents.

Beyond the Physics: Operator Skill and Training

While understanding the physics of the fulcrum is important, it's equally crucial for forklift operators to receive proper training. Operator skill and awareness are key to safe and efficient operation.

Training programs emphasize the importance of load assessment, proper load handling techniques, and safe operating procedures. Operators must be able to accurately estimate the weight and center of gravity of loads to avoid overloading the forklift.

Furthermore, operators must be aware of their surroundings and potential hazards. Operating a forklift requires constant vigilance and a commitment to safety.

The Future of Forklift Design

As technology advances, forklift designs are becoming more sophisticated. Manufacturers are exploring new ways to improve stability, increase load capacity, and enhance operator safety.

Some newer forklifts incorporate electronic stability control systems that automatically adjust the counterweight and wheel position to prevent tipping. These systems rely on sensors and algorithms to constantly monitor the forklift's stability and make adjustments in real-time.

The focus remains on optimizing the relationship between the fulcrum, the load, and the counterweight to create safer and more efficient machines. Innovation continues to drive improvements in forklift technology.

A Foundation for Safety and Efficiency

The seemingly simple concept of the fulcrum is fundamental to understanding how forklifts operate. It's the unseen force that enables these machines to lift heavy loads and move materials efficiently.

By understanding the principles of leverage and the importance of load capacity, operators can ensure safe and productive work environments. The fulcrum, a silent partner in the warehouse ballet, reminds us that even the most complex machines rely on simple, elegant physics.

So, the next time you see a forklift effortlessly lifting a pallet of goods, remember the fulcrum – the invisible pivot point that makes it all possible. It's a testament to the power of simple physics and the ingenuity of engineering, working in harmony to keep our world moving.