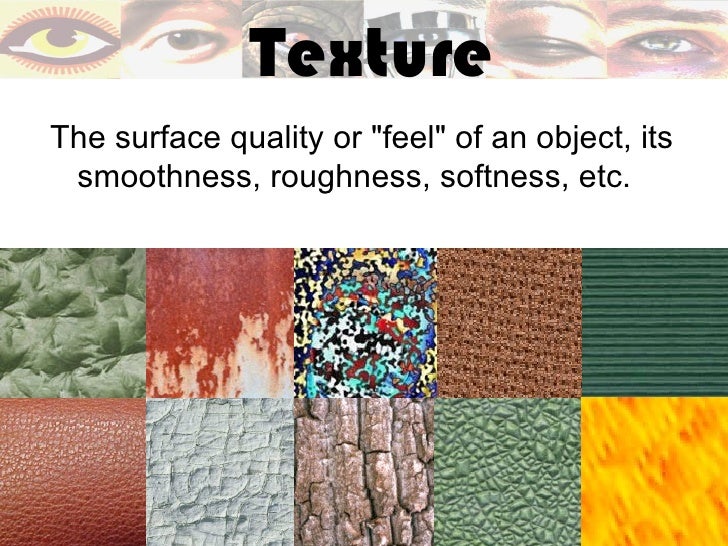

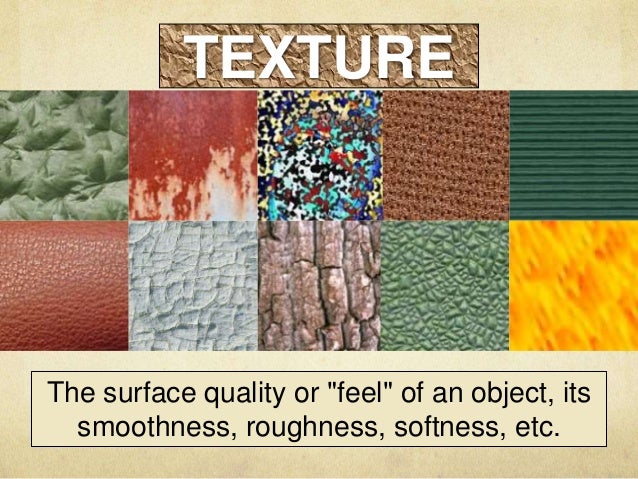

What Refers To The Quality Of A Form's Surface

In manufacturing, design, and art, the tactile and visual characteristics of a surface are paramount. Often referred to as surface texture, these attributes determine not only the aesthetic appeal but also the functional performance of an object.

This article delves into the multifaceted concept of surface texture, exploring its various measures, its significance across different industries, and the methods employed to assess and manipulate it. Understanding surface texture is crucial for engineers, designers, and anyone involved in creating or evaluating physical forms.

Understanding Surface Texture

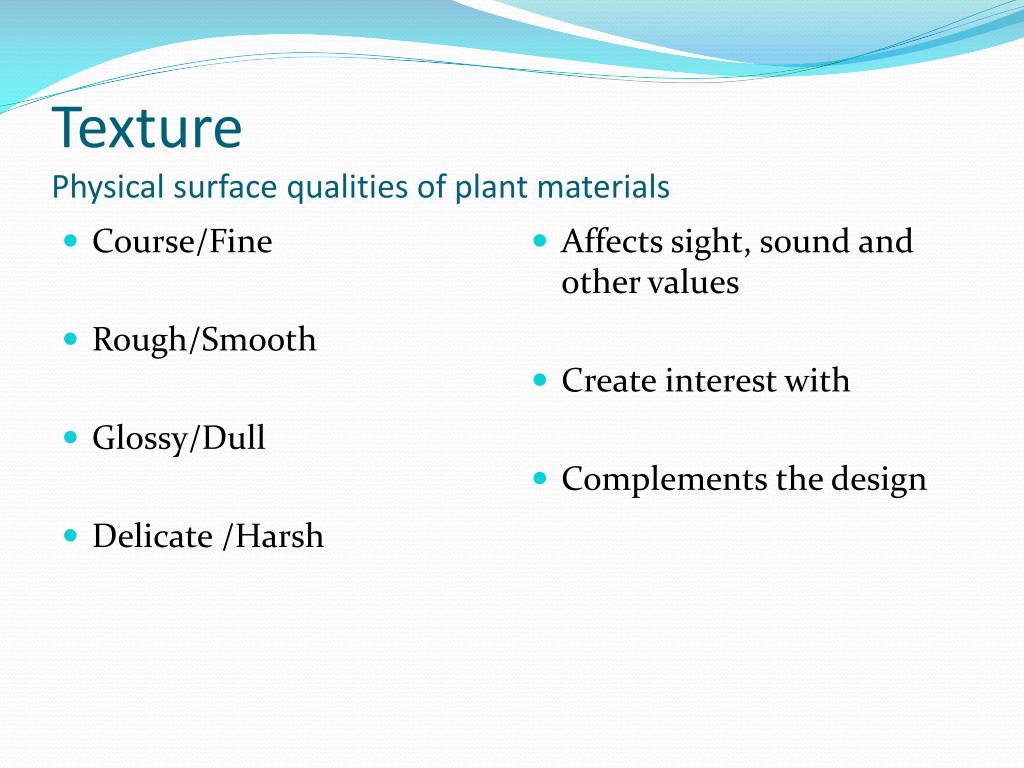

Surface texture, also known as surface finish or surface roughness, encompasses the microscopic deviations from a perfectly smooth or ideal surface. These deviations include irregularities such as roughness, waviness, lay, and flaws.

Roughness refers to the fine, closely spaced irregularities that are inherent in the manufacturing process. Waviness describes the more widely spaced irregularities that can result from machine vibrations, material deformation, or heat treatment. Lay indicates the predominant direction of surface patterns, while flaws are unintentional imperfections like scratches, cracks, or inclusions.

These elements collectively contribute to the overall perception and performance of a surface.

Key Metrics for Evaluating Surface Texture

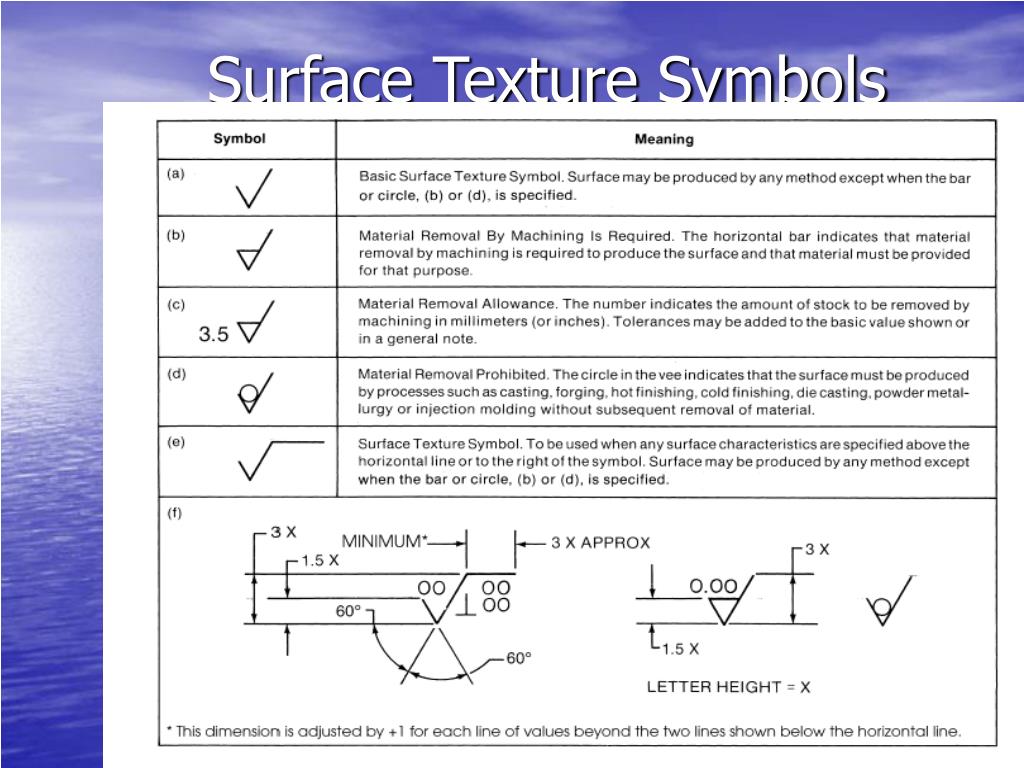

Several metrics are used to quantify surface texture, enabling objective assessment and comparison. One of the most common is Ra, the average roughness, which represents the arithmetic average of the absolute values of the height deviations from the mean line.

Another important parameter is Rq, the root mean square roughness, which is the standard deviation of the height deviations. Rq is more sensitive to large peaks and valleys than Ra.

Other parameters include Rmax (maximum peak-to-valley height) and Rz (average maximum height of the profile), providing further insights into the surface's characteristics. Choosing the appropriate parameter depends on the specific application and the critical aspects of the surface being evaluated.

Significance Across Industries

The quality of a form's surface texture holds immense significance across a wide array of industries. In the automotive industry, for instance, surface finish affects the performance and durability of engine components, impacting friction, wear, and lubrication.

In the medical device sector, surface texture plays a crucial role in biocompatibility, influencing cell adhesion and tissue integration. A rougher surface may promote cell adhesion for implants, while a smoother surface might be preferred for devices in contact with blood to minimize clotting.

In the aerospace industry, surface texture affects aerodynamic performance and drag. A smooth surface reduces air resistance, improving fuel efficiency. Furthermore, in the manufacturing of semiconductors and optical components, precise surface control is essential for achieving desired functionality and performance.

Methods for Assessing and Manipulating Surface Texture

Various methods are available for assessing and manipulating surface texture, catering to different needs and applications. Contact profilometers, such as stylus instruments, measure the surface profile by physically tracing it with a sharp tip.

Optical methods, like interferometry and confocal microscopy, use light to create three-dimensional surface maps, providing non-contact and high-resolution measurements. Atomic force microscopy (AFM) offers even higher resolution, enabling the analysis of surface texture at the nanometer scale.

To manipulate surface texture, various manufacturing processes can be employed. Machining operations, such as turning, milling, and grinding, can create specific surface finishes. Surface treatments, like polishing, etching, and coating, further modify the surface characteristics. Additive manufacturing techniques, such as 3D printing, offer the potential to create complex geometries and controlled surface textures.

"Surface texture is no longer just a cosmetic concern; it is a critical design parameter that impacts performance, reliability, and functionality," Dr. Emily Carter, a materials scientist at MIT, emphasized in a recent interview.

Impact and Future Trends

The growing emphasis on precision engineering and advanced materials is driving increased focus on surface texture control. Improved measurement techniques and manufacturing processes are enabling the creation of surfaces with tailored properties.

For instance, self-cleaning surfaces with nanoscale textures that repel water and dirt are becoming increasingly prevalent. Also, the development of bio-inspired surfaces with optimized textures for specific applications, such as adhesion and friction reduction, is a promising area of research.

As technology advances, our understanding of surface texture and its impact on various phenomena will continue to deepen, leading to novel applications and improved performance in diverse fields.

Ultimately, the ability to define, measure, and control the quality of a form's surface is essential for innovation and progress across numerous industries, impacting everything from the efficiency of engines to the effectiveness of medical implants.