Which Application Is Most Likely To Use Dynamic Braking

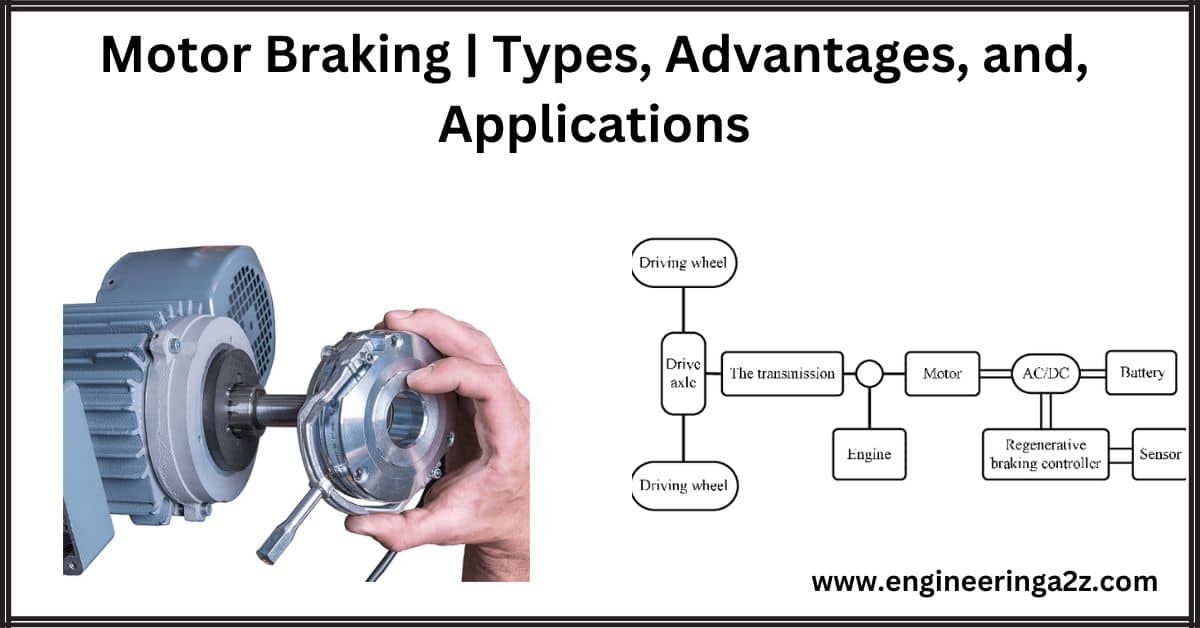

The debate is over: Electric vehicles (EVs), particularly trains and heavy-duty trucks, stand out as the most significant beneficiaries and users of dynamic braking technology. This braking system, which leverages the electric motor as a generator to slow the vehicle, offers unparalleled efficiency and reduces wear on traditional friction brakes.

Dynamic braking isn't merely a feature; it's a game-changer, substantially improving energy efficiency and lowering maintenance costs in applications demanding frequent deceleration. The technology allows these EVs to recover kinetic energy during braking, converting it back into electricity to recharge the battery, a process known as regenerative braking, which is a subset of dynamic braking.

The Rise of Dynamic Braking in Transportation

Electric trains, especially in mountainous regions, have long employed dynamic braking. The primary reason is safety and energy conservation. Consider locomotives traversing steep gradients: relying solely on friction brakes would lead to rapid wear and potential brake failure.

Dynamic braking addresses this by using the traction motors to generate electricity as the train descends. This generated electricity can then be fed back into the power grid or used to power other onboard systems, significantly reducing energy consumption.

Heavy-Duty Electric Trucks Leading the Charge

The burgeoning electric truck market represents another crucial area where dynamic braking is poised for widespread adoption. As reported by BloombergNEF, electric trucks are expected to constitute a significant portion of new truck sales by 2040, and their energy efficiency will largely depend on effective regenerative braking systems.

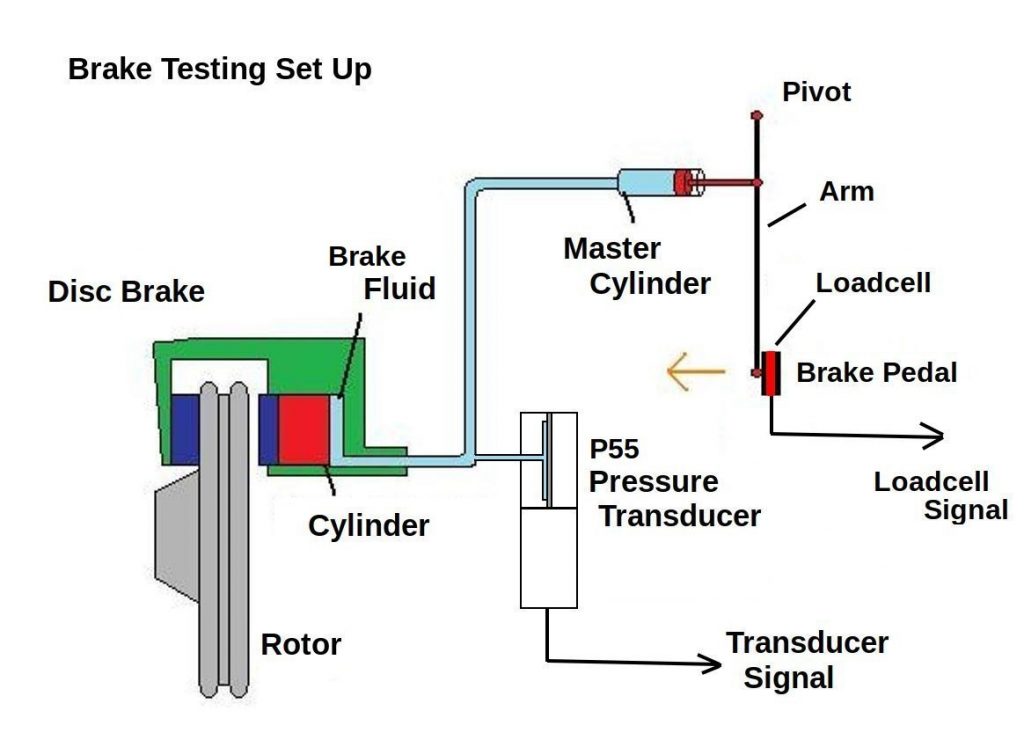

These trucks, often tasked with hauling heavy loads over long distances, undergo considerable brake usage. Dynamic braking helps manage this strain, extending the lifespan of brake pads and rotors, thereby reducing operational costs for fleet owners.

Furthermore, dynamic braking contributes to safer driving by providing enhanced control during downhill driving. This feature is especially important for heavy vehicles, where uncontrolled speed can lead to dangerous situations.

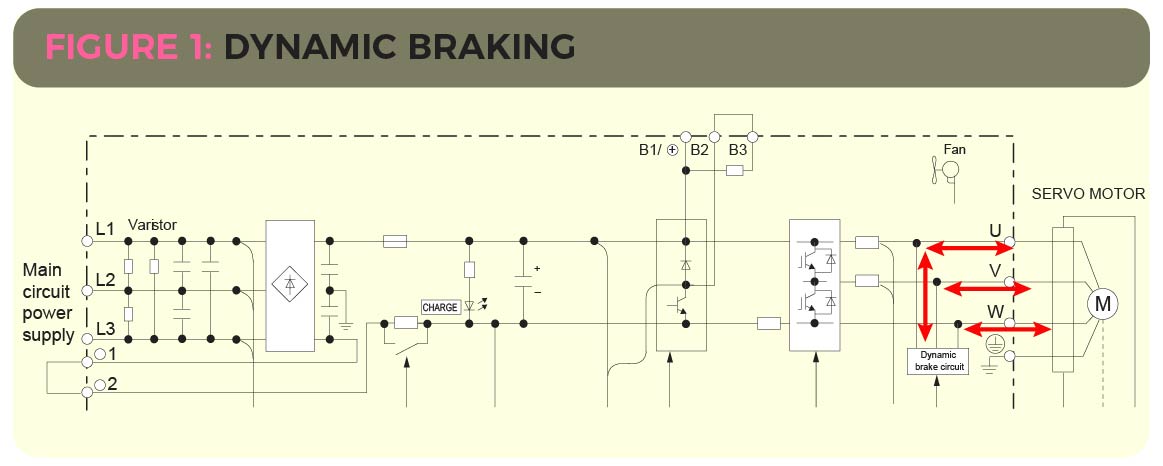

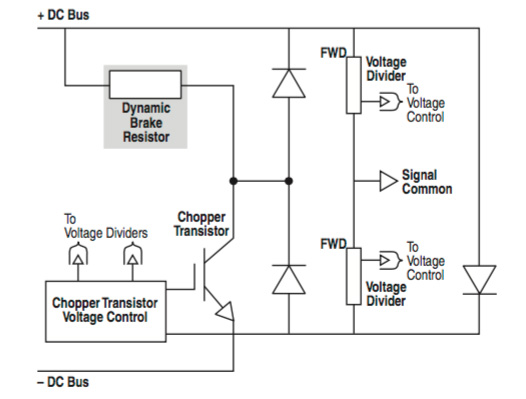

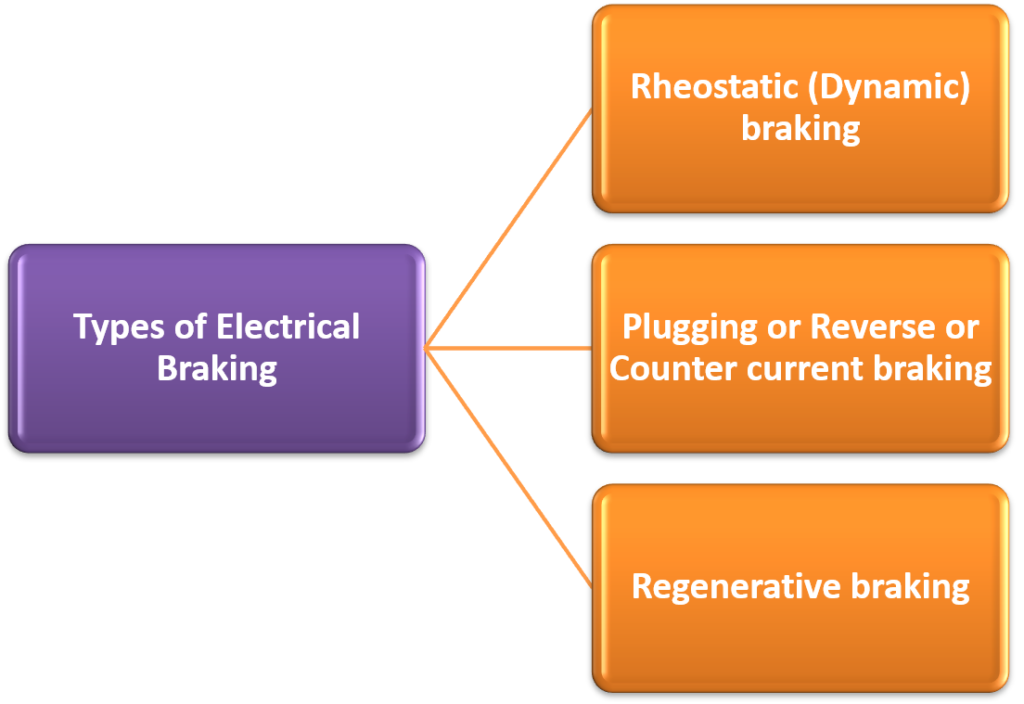

How Dynamic Braking Works

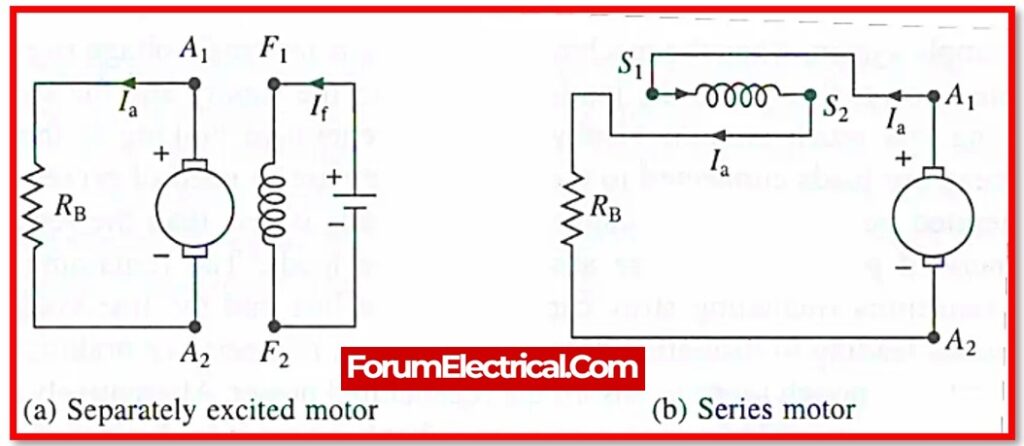

At its core, dynamic braking turns the electric motor into a generator. When the driver initiates braking, the motor's circuitry is altered to oppose the vehicle's rotation. This opposition generates electricity, slowing the vehicle down.

The generated electricity is then routed back to the battery pack, replenishing its charge. This process is meticulously managed by the vehicle's control system to ensure efficient energy recovery and prevent overcharging of the battery.

Modern dynamic braking systems often incorporate sophisticated algorithms that blend dynamic and friction braking seamlessly. This ensures optimal braking performance under various conditions, from gentle deceleration to emergency stops.

The Impact on Battery Technology

The efficiency of dynamic braking is inextricably linked to the battery technology used in EVs. Batteries with higher charge acceptance rates can recover more energy during braking, maximizing the benefits of the system.

Lithium-ion batteries, currently the dominant battery technology in EVs, offer excellent charge acceptance and energy density, making them well-suited for dynamic braking applications. However, ongoing research into solid-state batteries and other advanced chemistries promises even greater performance in the future.

Data from a Tesla Model 3, analyzed by Consumer Reports, indicates that regenerative braking can extend the vehicle's range by up to 15% in city driving conditions. This highlights the significant impact of dynamic braking on overall energy efficiency.

Challenges and Future Directions

While dynamic braking offers numerous advantages, challenges remain. One key issue is managing the heat generated during braking. Excessive heat can reduce braking efficiency and potentially damage electrical components.

Another challenge is optimizing the braking system for various driving conditions and vehicle loads. Sophisticated control algorithms are needed to ensure consistent and predictable braking performance across the board.

Future research will focus on improving the efficiency of energy recovery, developing more robust heat management systems, and integrating dynamic braking with advanced driver-assistance systems (ADAS) to enhance safety and automation.

The Verdict is In: EVs Reign Supreme in Dynamic Braking

Electric vehicles, especially trains and heavy-duty trucks, are currently the applications most likely to leverage dynamic braking. Their inherent electric drivetrains make them uniquely suited for this energy-efficient braking system.

As the electrification of transportation continues, dynamic braking will play an increasingly important role in improving energy efficiency, reducing maintenance costs, and enhancing the overall driving experience.

Ongoing developments include further refinement of control algorithms and exploration of advanced materials to enhance heat dissipation, setting the stage for even more widespread adoption of dynamic braking in the future. The U.S. Department of Transportation is actively researching and promoting these technologies through grants and research initiatives.

![Which Application Is Most Likely To Use Dynamic Braking Hydraulic Braking System: Diagram, Parts & Working [PDF]](https://www.theengineerspost.com/wp-content/uploads/2022/09/Hydraulic-Braking-System.jpg)