Which Of The Following Is Not An Energy-isolating Device

Workplace safety took center stage recently as a series of training sessions and safety audits highlighted potential confusion surrounding energy-isolating devices, crucial components in preventing accidents during machinery maintenance and repair. A recurring question emerged: Which devices do *not* qualify as reliable energy isolation methods?

The debate centers on ensuring that all employees, particularly those working with heavy machinery, understand the distinction between adequate and inadequate isolation techniques. This misunderstanding can lead to serious injuries or even fatalities, underscoring the critical importance of proper training and readily available resources.

The issue gained prominence following a series of internal safety reviews conducted by several manufacturing companies across the Midwest. These reviews, prompted by a recent increase in near-miss incidents, revealed inconsistencies in how lockout/tagout (LOTO) procedures were being implemented.

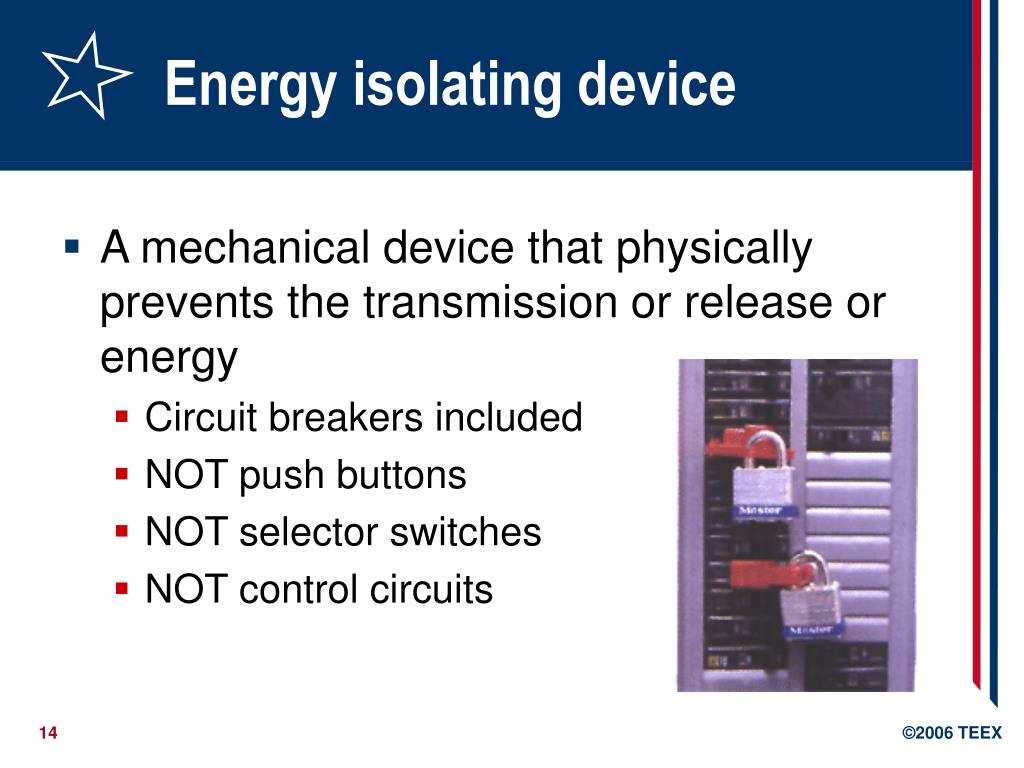

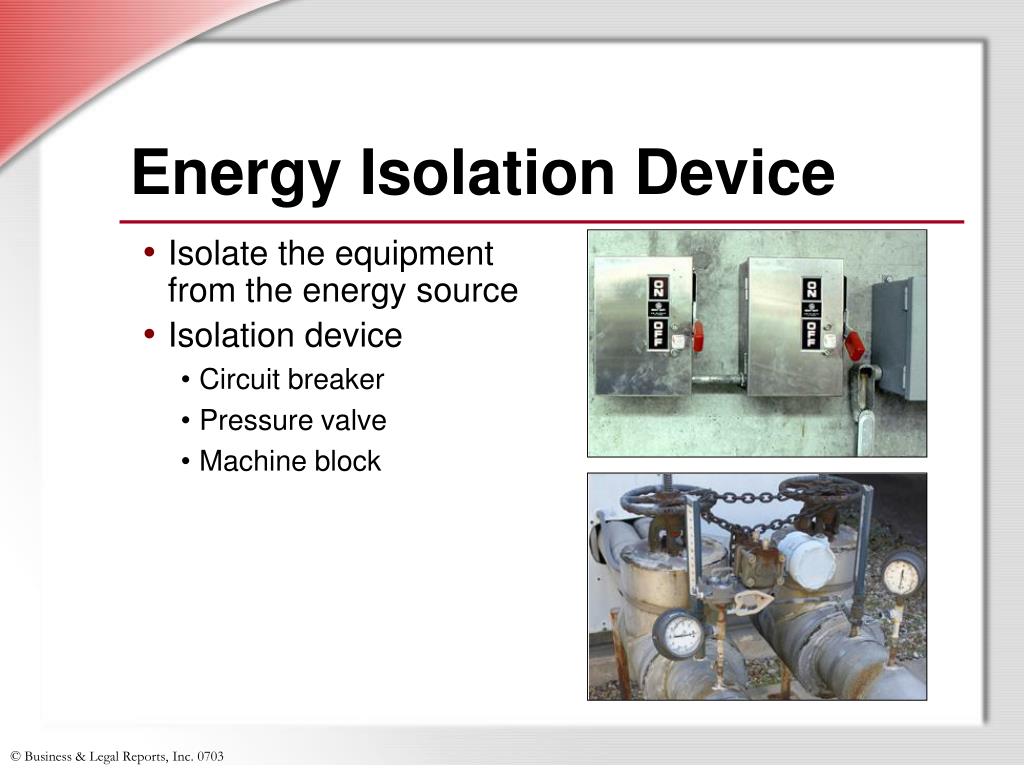

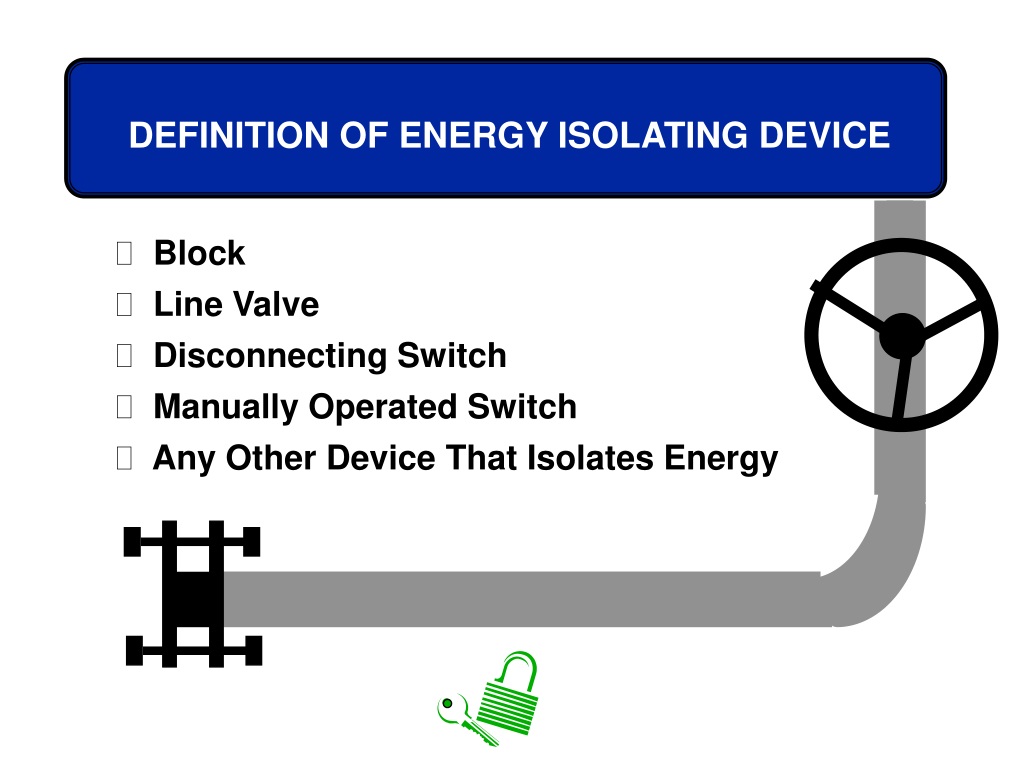

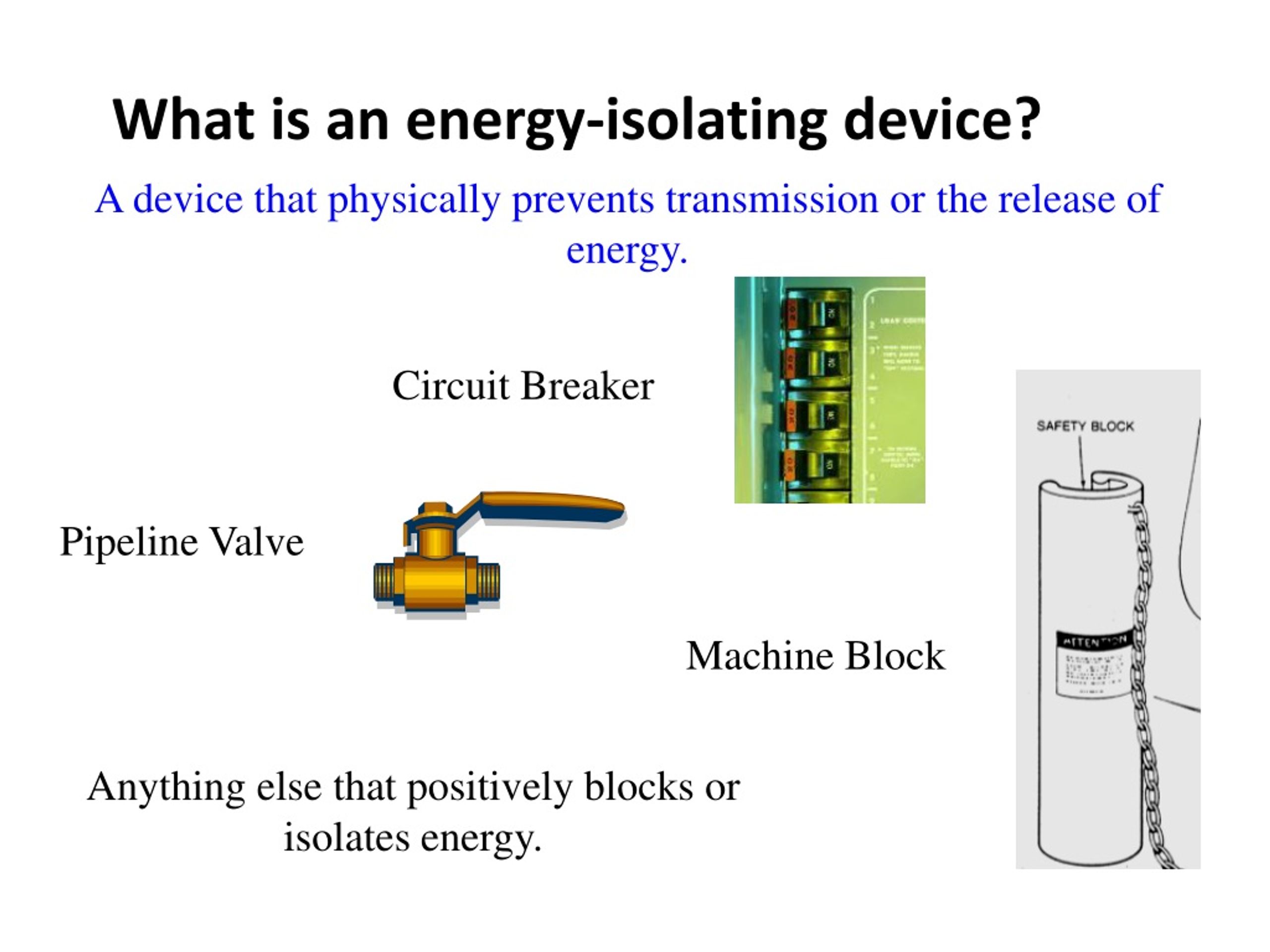

Central to the discussion is the definition of an energy-isolating device. According to the Occupational Safety and Health Administration (OSHA), an energy-isolating device is a mechanical device that physically prevents the transmission or release of energy. Examples include manually operated electrical circuit breakers, disconnect switches, line valves, and blocks.

However, certain devices often mistakenly considered as adequate for energy isolation, do not meet the required safety standards. These include, but are not limited to, push buttons, selector switches, and certain types of interlock systems that rely solely on control circuits.

“The key differentiator is physical blockage,” explained Sarah Chen, a certified safety professional with the National Safety Council. “A device must physically prevent the flow of energy, not just rely on electrical signals or software controls. Push buttons, for instance, can fail, leaving workers vulnerable."

The confusion often stems from a lack of comprehensive training and easily accessible information. Many employees may not fully grasp the complexities of different machinery and the specific energy sources they control. This knowledge gap can lead to the incorrect application of isolation procedures.

Key Differences in Energy Isolation

The distinction between suitable and unsuitable energy-isolating devices is crucial for preventing unexpected energization or startup of equipment during maintenance. Understanding these differences is essential for safeguarding workers and ensuring compliance with OSHA regulations.

Unacceptable Devices: Reliance on Control Circuits

Devices that rely solely on control circuits are generally considered inadequate for energy isolation. Push buttons, selector switches, and certain light curtains fall into this category. These devices can be bypassed or malfunction, leading to a hazardous situation.

According to a recent OSHA safety bulletin, relying on control circuits alone is akin to "hoping" the machine stays off, rather than ensuring it remains off through a physical barrier.

Acceptable Devices: Physical Barriers

Acceptable energy-isolating devices provide a physical barrier to prevent the release of energy. This includes manually operated circuit breakers, disconnect switches with lockout capabilities, and line valves that can be physically blocked.

These devices must be designed to withstand the potential energy they are isolating and must be lockable in the safe or "off" position.

The Impact on Workplace Safety

The misidentification of energy-isolating devices has a direct and significant impact on workplace safety. Improper isolation procedures can lead to accidental startups, electrical shocks, and other serious injuries. These incidents not only harm workers but also disrupt operations and increase costs.

Mark Johnson, a plant manager at a manufacturing facility in Ohio, shared a personal account: "We had a near-miss incident where a worker narrowly avoided injury because a push button failed to prevent a machine from starting up during maintenance. It was a wake-up call that highlighted the need for better training and stricter adherence to LOTO procedures."

This incident prompted the company to invest in additional training and equipment upgrades. These changes resulted in a significant reduction in near-miss incidents and improved overall workplace safety.

Moving Forward: Enhancing Training and Awareness

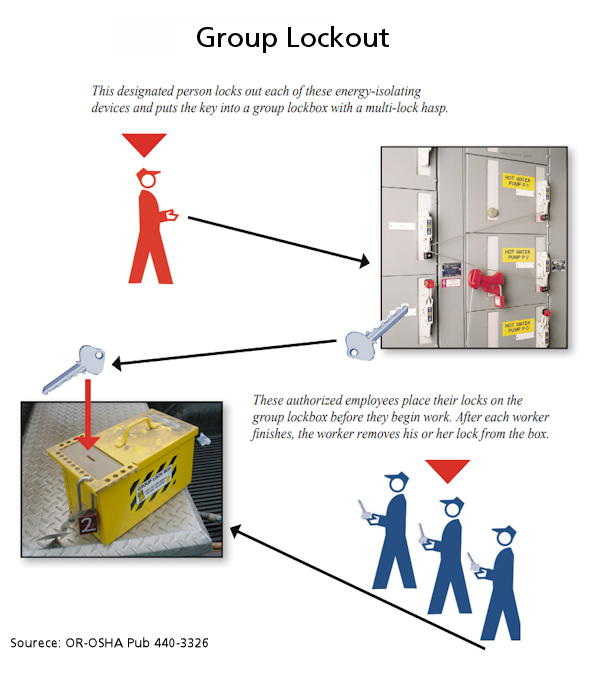

To address the issue of misidentified energy-isolating devices, companies must prioritize comprehensive training and awareness programs. These programs should clearly define what constitutes an acceptable energy-isolating device and provide hands-on training on proper LOTO procedures.

OSHA offers a variety of resources and training materials to assist employers in developing and implementing effective LOTO programs. Utilizing these resources can help ensure that employees are properly trained and equipped to safely perform maintenance and repair tasks.

Furthermore, regular safety audits and inspections are essential for identifying and correcting any deficiencies in energy isolation procedures. By proactively addressing potential hazards, companies can create a safer work environment and prevent accidents.

Ultimately, ensuring workplace safety requires a commitment from both employers and employees. By working together to promote a culture of safety and adhering to proper LOTO procedures, companies can minimize the risk of accidents and protect their workers from harm. A clear understanding of what *is* and *is not* an acceptable energy-isolating device is a fundamental step in achieving this goal.